Table of Contents

Part Number 0200093249 3

Section 1

General Information

Read This Manual ...............................................................................................................5

Unit Inspection ...................................................................................................................5

Serial Number Location .....................................................................................................5

Warranty Information ........................................................................................................5

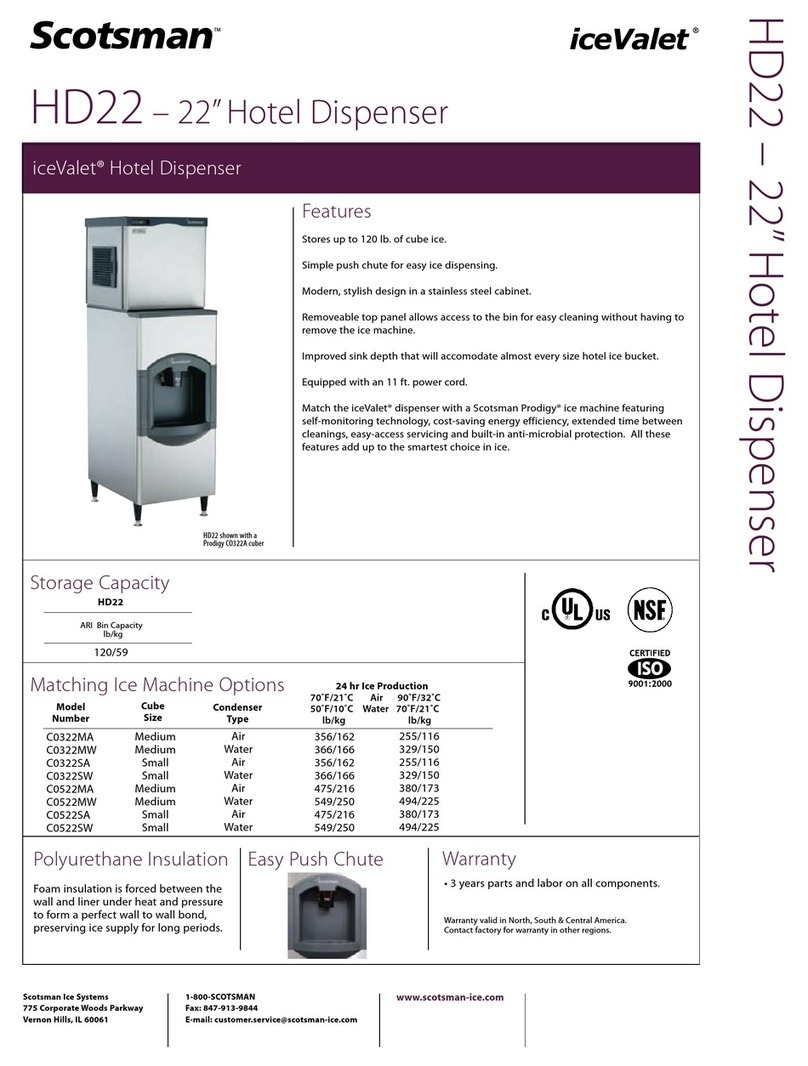

Model Numbers..................................................................................................................5

How to Read a Model Number..........................................................................................................5

Accessories..........................................................................................................................6

Legs .............................................................................................................................................................6

Manual Fill Lid .........................................................................................................................................6

Ice Flow Restrictor..................................................................................................................................6

Section 2

Installation

General................................................................................................................................7

Dimensions .........................................................................................................................7

Max Noise dB(A) .................................................................................................................7

Footprints ...........................................................................................................................8

Location ..............................................................................................................................9

Ways Equipment Should Not be Used ..............................................................................9

Location Requirements for Top Mounted Ice Machine Installations..............................9

Electrical............................................................................................................................10

General.................................................................................................................................................... 10

Minimum Circuit Ampacity.............................................................................................................. 10

Electrical Requirements .................................................................................................................... 10

Voltage .................................................................................................................................................... 10

Minimum Circuit Amperage Chart................................................................................................ 10

Grounding Instructions..................................................................................................................... 10

Pump Deck Wiring .............................................................................................................................. 11

Water Supply ....................................................................................................................12

Recommended Plumbing................................................................................................................ 12

Drains ................................................................................................................................12

Step by Step Installation..................................................................................................13

General.................................................................................................................................................... 13

Specifications Chart............................................................................................................................ 13

Unit Installation.................................................................................................................................... 13

Starting Your WATER/ICE Dispenser.............................................................................................. 14

Section 3

Operation

Component Identification ...............................................................................................15

Sequence of Operation....................................................................................................15

Ice Recommended for Dispensing................................................................................................ 15

Ice Storage and Dispensing............................................................................................................. 15

Rocking Chute Ice Dispensing........................................................................................................ 15

Agitation Timer..................................................................................................................................... 16

Operation Checks and Adjustments...............................................................................16

Rocking Chute Ice Delivery Switch Adjustment....................................................................... 16