Scotsman Ice Systems

InstallationandOperatingInstructions

NW‐307/507/457/608/1008/1408Models

ImportantInformation

Thisequipmentmustbeinstalledinaccordancewithalllocal,state,andnational

regulations.Themachinemustbeinstalledcorrectlyasperinstillationinstructions.

ThismachinemustbeinstalledbyaqualifiedRefrigerationorElectricaltechnician.

Aplumbershouldbeusedtomakethewaterconnectionsonly.

THISMACHINEISNOTDESIGNEDFOROUTDOORUSE

LOCATION‐

Thisicemachinemustbelevelandsituatedinacooldryareawith

sufficientairventilation.TheicemachineisNOTtobeinstalledinacupboardor

withlimitedorrestrictiveairflow.TheequipmentshouldNOTbelocatednextto

equipmentthatdischargesorradiateshotaironorneartheicemachine.NOTE:

HotterworkingenvironmentsORwatertemperatureswillreducetheproduction

capacityofthemachine.OperatingSpecificationsBelow

OperatingairtemperaturesMin10

°

ctoMax40

°

c(24

°

cideal)

OperatingwatertemperaturesMin5

°

ctoMax35

°

c(18

°

cideal)

OperatingwaterpressureMin1bartoMax5bar

MachinesideclearanceMin150mm

MachinerearclearanceMin100mm

MachinetopclearanceMin400mm(NW307/507modelsonly)

Awaterfiltersystemmustbefittedtotheicemachine,thiswillhelptoreduceand

controlthebuildupofsediment,scale,mineralandbacteriafromaccumulatinginside

themachine.

Theicemakerslocationshouldhaveadedicatedpowerpoint,a

dedicatedwatersupplyandawaterdrainagepointwithingonemeterofthe

machine.Fortheicemakertooperateeffectivelyandefficientlythemachine

requiressufficientairventilation.Themachinerequiresaminimumsideclearance

of150mm,aminimumrearclearanceof100mm(NW‐307/507topclearanceminof

400mm)

ContactMoffatServiceSupportOn1300264217ForAssistance

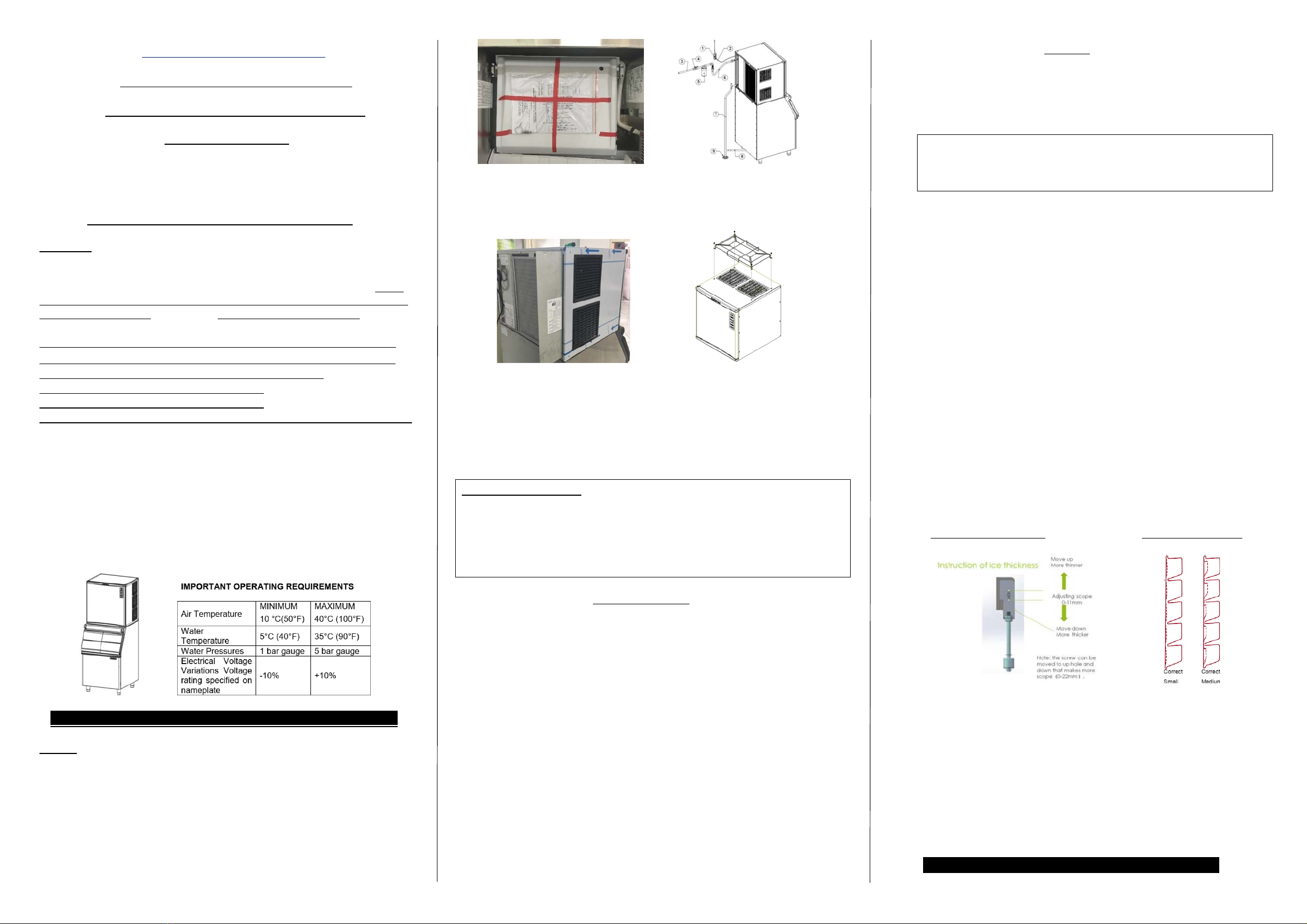

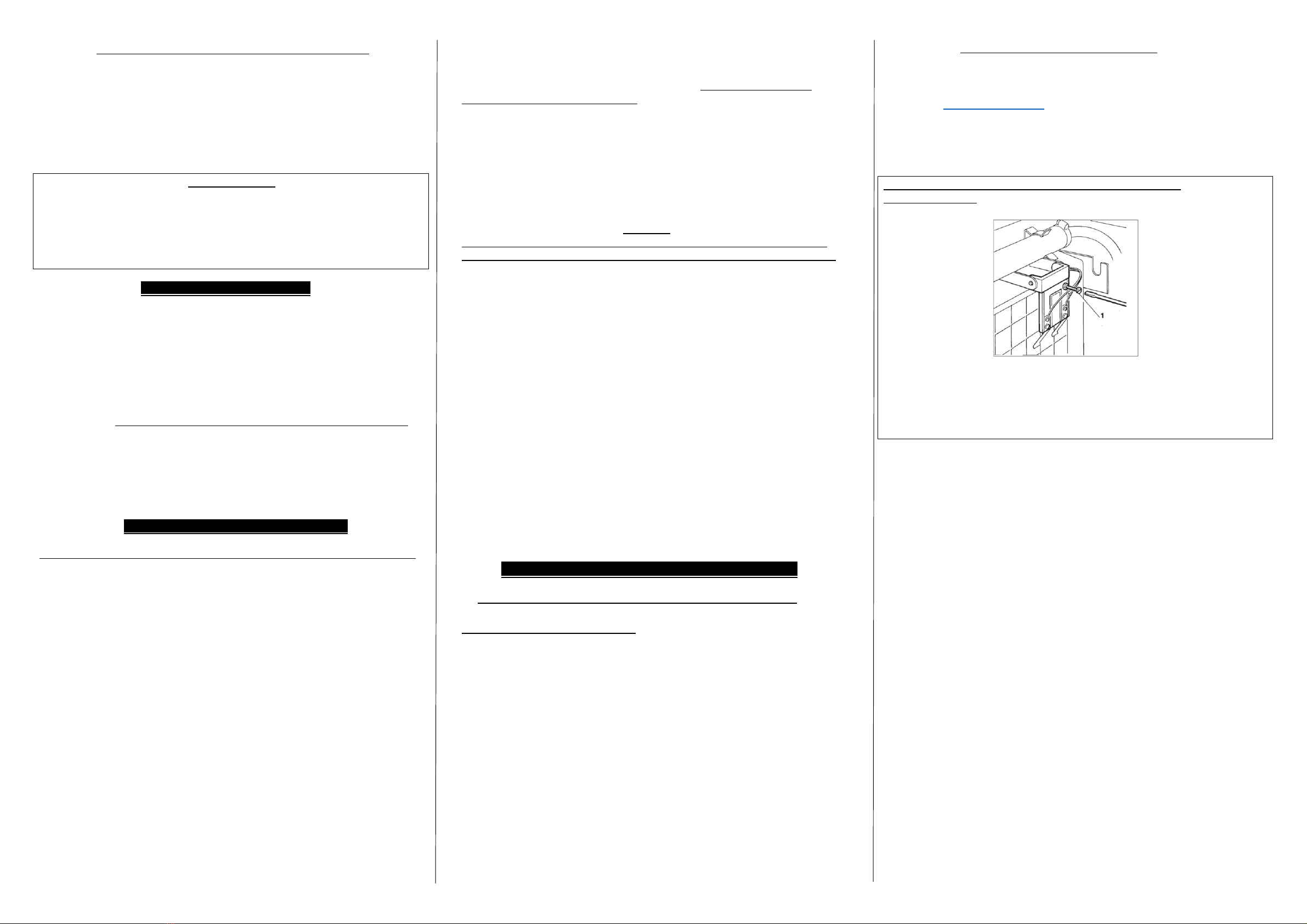

Set‐Up‐

Forinstillationofanicemakertoanicestoragebinortoanicedispenser.

Fitlegstotheicestoragebinoricedispenserandsettominimumheight,fitthe

waterdrainhoseandhosecliptotheundersidewateroutletofthebin/dispenser.

Positiontheicestorageunitnearitsfinallocation.Mounttheicemakerheadtothe

icestorageunit.Openthefrontpaneloftheicemakerandremovethemanuals,

waterhoses,packaging,andredstrappingtape.Removethesidepanelsandsecure

theicemakerheadtotheicebinordispenser.(sidescrewsforicebinandrear

bracketsandscrewsfordispenser)Ensuretheinternalpartsarefittedandsecuredin

theirfinaloperatingpositions(watertrough,waterpump,watercurtain,iceprobeor

float,waterdistributiontube,etc.

)

Fitthewatersupplyhoseandthewaterdrainhosetotheirconnectionpointsatthe

rearoftheicemakerusinghosessupplied.Connectthewatersupplyhosetothe

waterfilteroutlet,attachthewaterdrainhosetothefloordrainortundish.

Fitthesteeldeflectorplateto(backrightside)oftheicemaker.Thisistoprevent

recirculationofhotairbackintotheicemaker.(OntheNW307/507modelsfitthe

wireframetothetopofthemachinetopreventthedischargeventsbeingcovered)

Maneuverthemachineintoitsfinalposition.Ensuretheicemachinehasrequired

side,rear,ortopclearances.Ensurethemachineislevelonceinitsfinalposition.

Removetheprotectiveplasticfromthepanelsofthemachineandicestorageunit.

ElectricalConnections

Theelectricalconnectionsforthismachinemustcomplywithalllocal,state,and

nationalregulations.Theicemakerrequiresadedicatedpowerpoint.Checkthe

serialplatetoensurevoltagerequirementsandplugaresuitableforthewallsocket

andpowersupplyforyourlocalarea.Allelectricalconnectionsandadjustments

mustbeundertakenbyaqualifiedtechnician.

12PointChecklist

1) Istheicemakerlevelandsecuretotheicestorageunit?

2) Istheambientairtemperaturebetween10cand40c?

3) Istheretherequired150mmsideclearance,100mmrearclearanceandtop

ventilationclearances?(NW307/507)Isthereanyotherequipment

discharginghotairnearornexttothemachine?

4) Havethewaterconnectionsbeenmadeandisthewaterpressurebetween1

and5bars?Hasthewaterpressurebeentested?

5) Istheincomingwatertemperaturebetween5Cand35C?

6) Doesthemachinehaveawaterfilterfitted?

7) Dotheelectricalrequirementscomplyandhastheelectricalconnection

beenmade?DONOTTURNONTHEMACHINE.

8) Hasallthepackagingbeenremovedfrominsidetheicemachine?

9) Arealltheinternalcomponentsbeenfittedandsecuredcorrectly?

10) Hastheownerbeeninstructedontheoperationandmaintenanceofthe

machine?Hastheownerbeengiventheinstillationinstructionswhich

includethemaintenancescheduledetails?

11) Hasthemachinebeencleanedandsanitizedbeforestartingup?

12) DoesthecustomerhaveMoffat’sservicecontactdetails?

StartUp

1) Openthewatersupplytotheicemachineandcheckforwaterleaks.

2) Switchthepoweronatthewallsocket.

3) TheNW307/507/457/608modelswillenterthestartupmode.ThePCBoard

willshowthepowerON(greenlighton)andthefreezingandfullbinlights

willflashfor3minuteswhilefilling/purgingwater.

TheNW1008andNW1408machineshavea90‐minutestartdelay.These

modelshaveacrankcaseheaterinthecompressor.Ifthetemperatureis

above25c,thePCBoardwilloverridethetimedelay.Onecanoverridethe

timedelaybypressingthebypassswitchontherearoftheicemachine.

4) Afterstartingupmodethemachinewillenterthefreezingmode.The

refrigerationsystemwillrun,andthecondenserfanwillthermostatonand

offduringthecycle(icemakinggreenlighton)Thewaterpumpwillrunand

circulateswaterovertheevaporator.Thewaterlevelsensorswillmonitor

thewaterlevelandaddwaterwhenrequired.After+‐15to24minutesthe

icethicknessprobe/floatwillputtheicemachineintoaharvestonceit

sensesafullsheetofice.Theharvestmodewillrunfor+‐60secondsand

willheattheevaporatoruntiltheicedropsintotheicebin.

5) Whentheicedropsintotheicebinthewatercurtainopensandthencloses.

ThePCBoardsensestheicedropandputsthemachinebackintoafreeze

cycletomakemoreice.Whentheicebinisfullthewatercurtainisleftin

theopenposition,thePCBoardsensestheopencircuitandshutsthe

machinedown(fullbinorangelighton)untiltheicebinleveldropsenough

forthewatercurtaintoclose.Themachinewillrestartafterathree‐minute

delay.

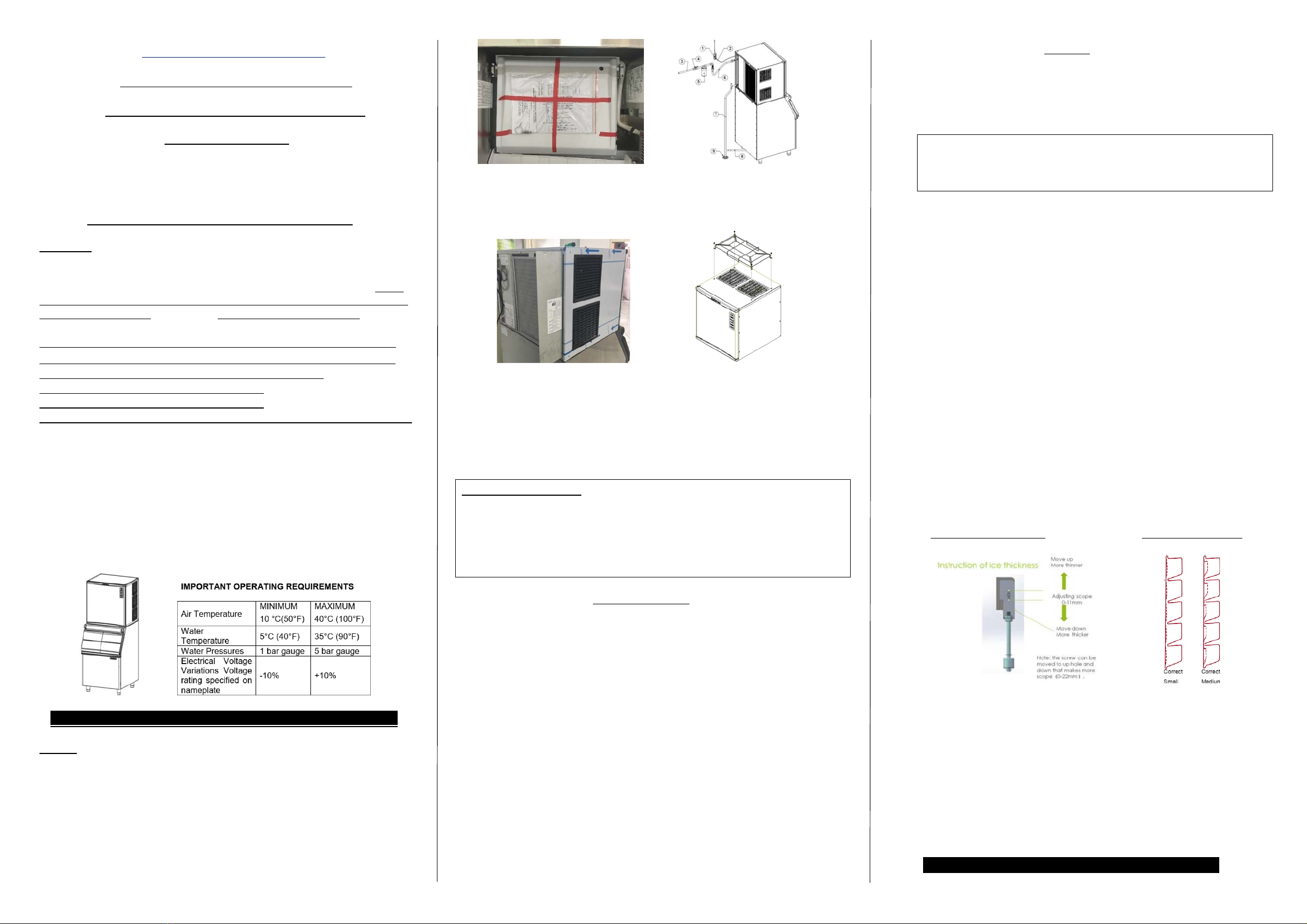

6) Inspecttheiceinthestoragebinaftertheseconddropoficeandif

necessary,adjusttheicethicknessfloatprobeasperbelowdiagram.

NOTE:Theicecubesmusthavea+‐3mmconcavedimpleinthebackof

eachcube.Themachinemakesaslaboficethatbreaksupwhenfalling

intotheicebin,noteveryicecubewillbreakupperfectly.Iftheice

thicknessissettothicktheicewillnotbreakupandiftheiceissettothin,

theicesheetisnotfullyformedandmayshutthemachinedown.The

machinesrequireafullsheetoficetodropofftheevaporator(not

individualpieces)

IceThicknessFloatProbeIceThicknessDiagram

Theicethicknessprobecanbeadjustedforthickerorthinnericecubes.By

carefullylooseningtheicethicknessfloatbracketscrew,movethebracket

upslightly(forthinnerice)ordownslightly(forthickerice)Takeaphotoof

thebracketpositionbeforeyoumaketheadjustment.Onlymovethe

bracket1mmatatime,checktheicethicknessafterthetwodropsofice

aftertheadjustmenthasbeenmade.

NOTE:Theicecubesshouldhavea3mmconcavedimpleonthebackofthe

cube.Theicebridgeconnectingtheicecubesshouldbebetween2mmand

3mmthick.Donotmovetheicethicknessbracketupordownmorethan

1mmatatime.

(Usea6mmdrillbittosetclearancebetweenprobeandevaporator.)

ContactMoffatPtyLtdon1300264217forAssistance