TABLE OF CONTENTS – INDICE – TABLE DES MATIERES

ENGLISH

Table of Contents...............................................................................................................................................................................Page 1

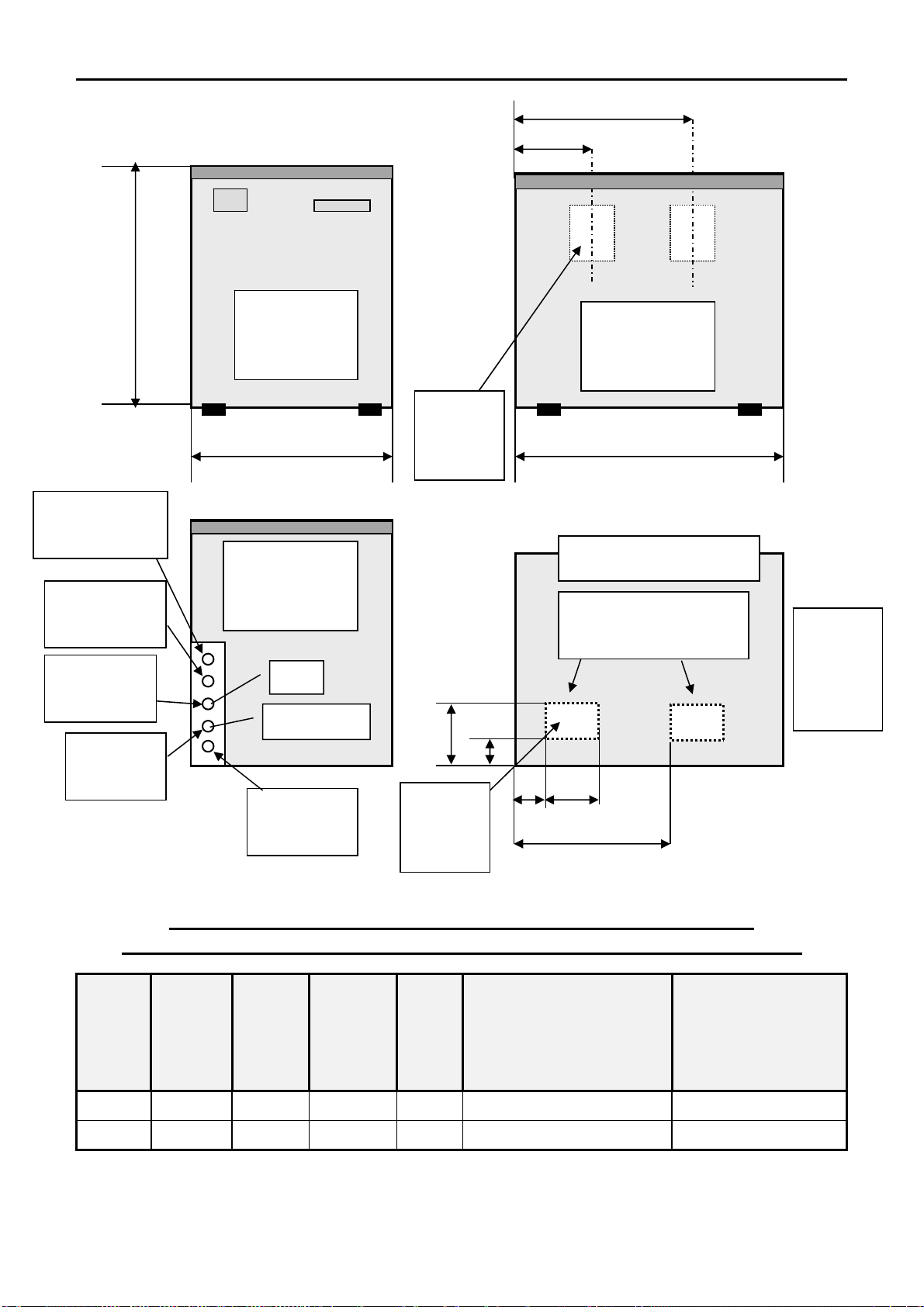

Specifications..............................................................................................................................................................................................2

Technical Specifications..............................................................................................................................................................................2

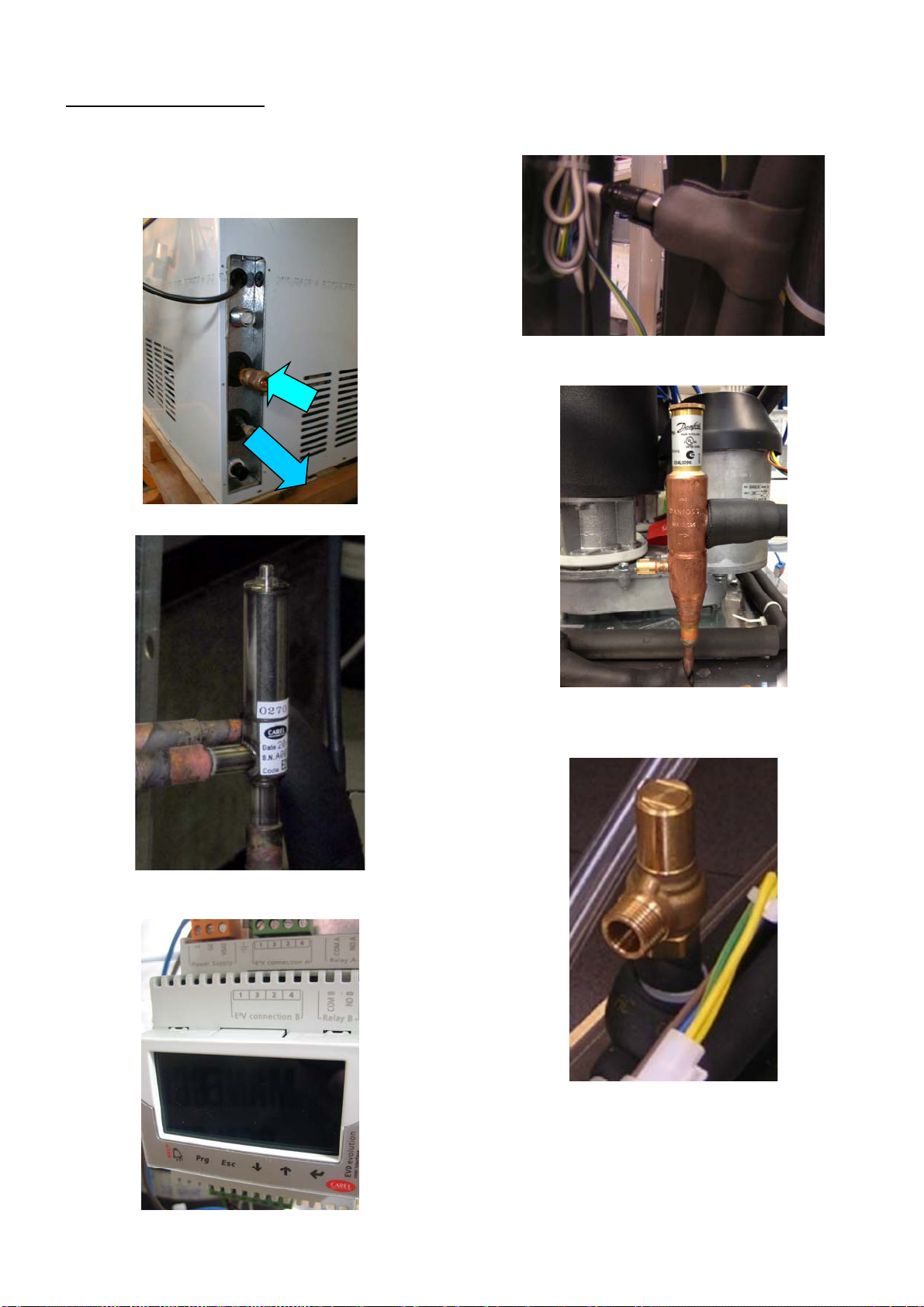

Unpacking and Inspection...........................................................................................................................................................................3

Location and Levelling ................................................................................................................................................................................3

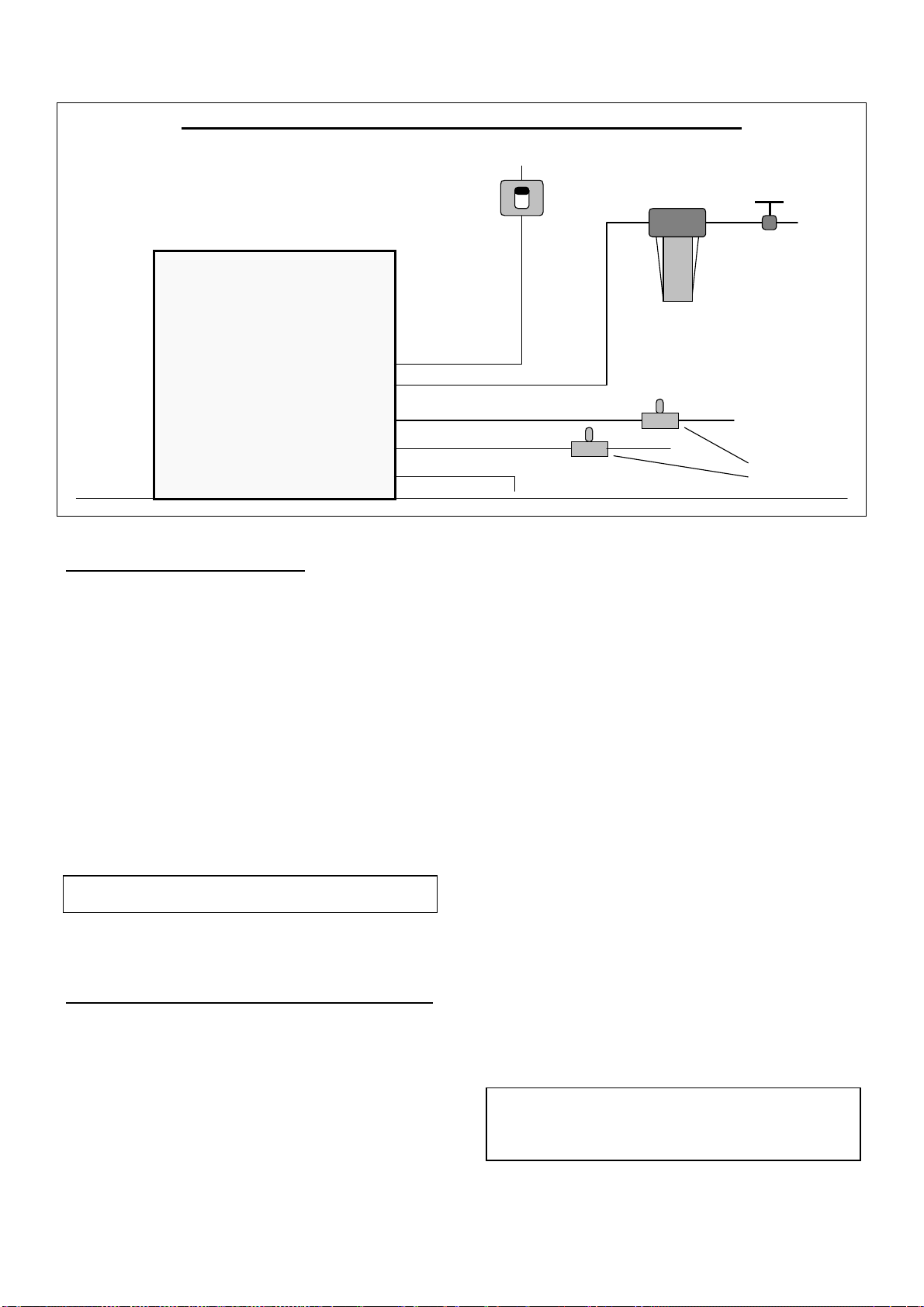

Typical Installation on Refrigerant Plant .....................................................................................................................................................4

Electrical Connections.................................................................................................................................................................................4

Water Supply and Drain Connections.........................................................................................................................................................4

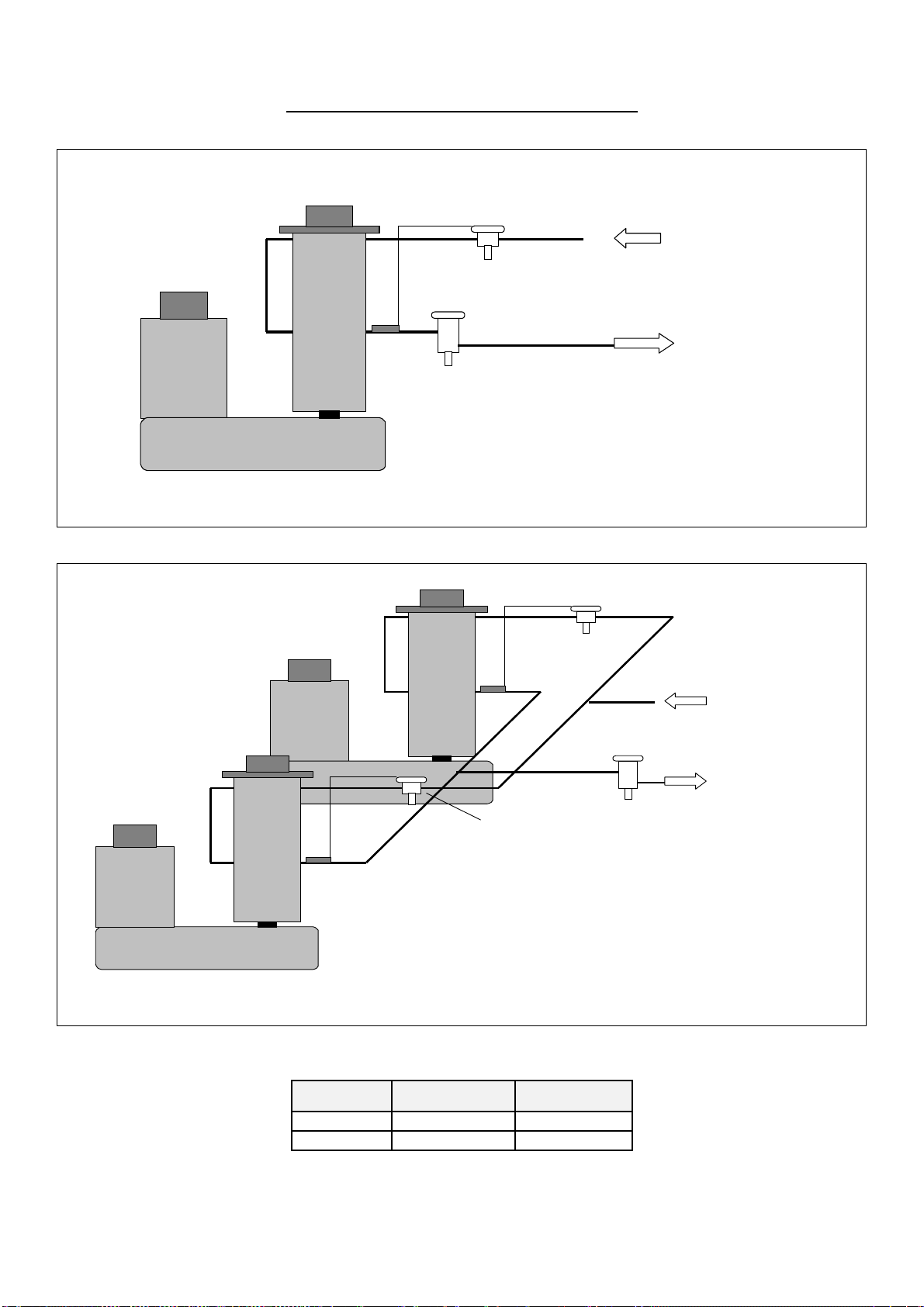

Refrigerant System .....................................................................................................................................................................................5

Refrigerant System Scheme.......................................................................................................................................................................6

Electrical System.........................................................................................................................................................................................7

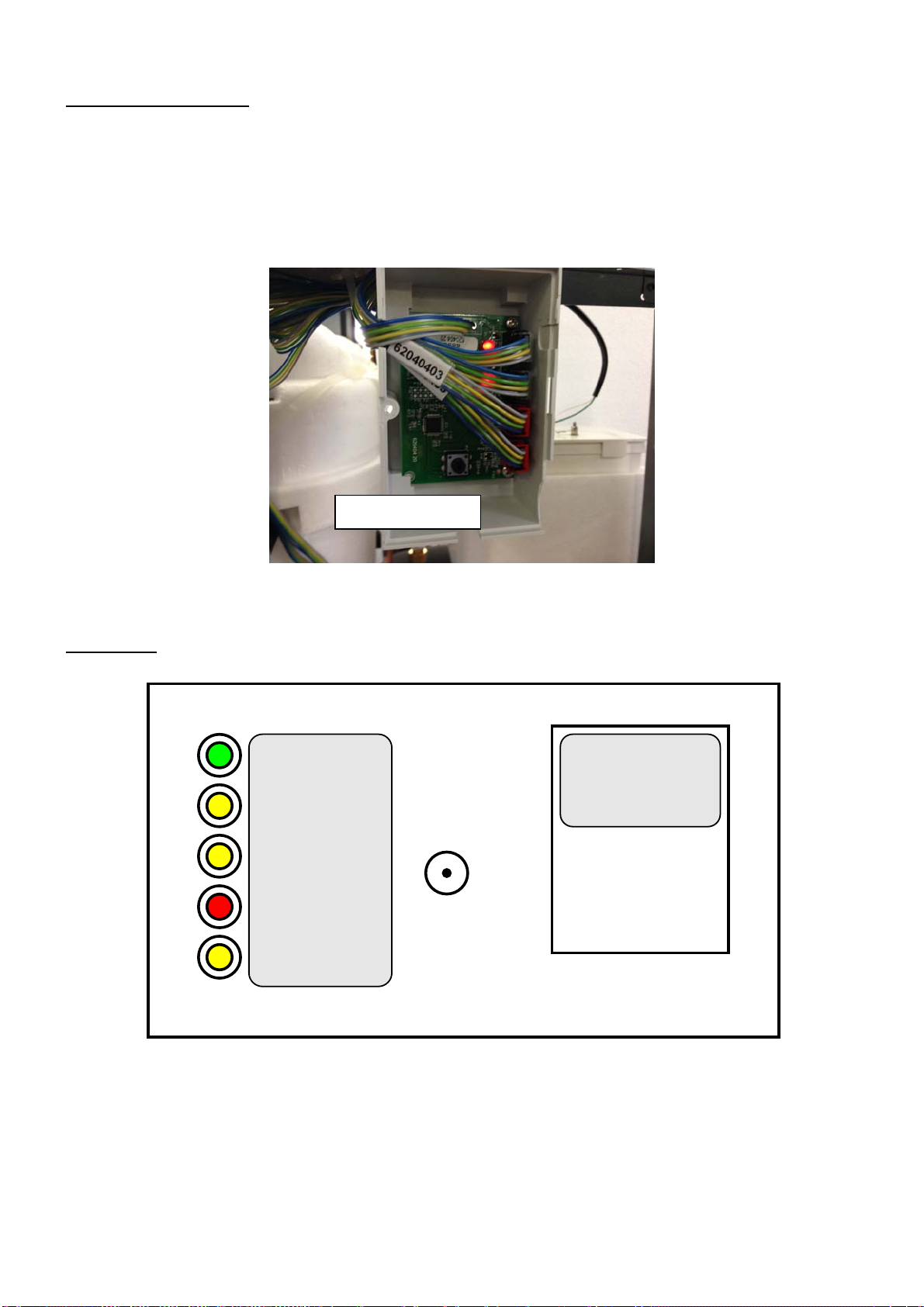

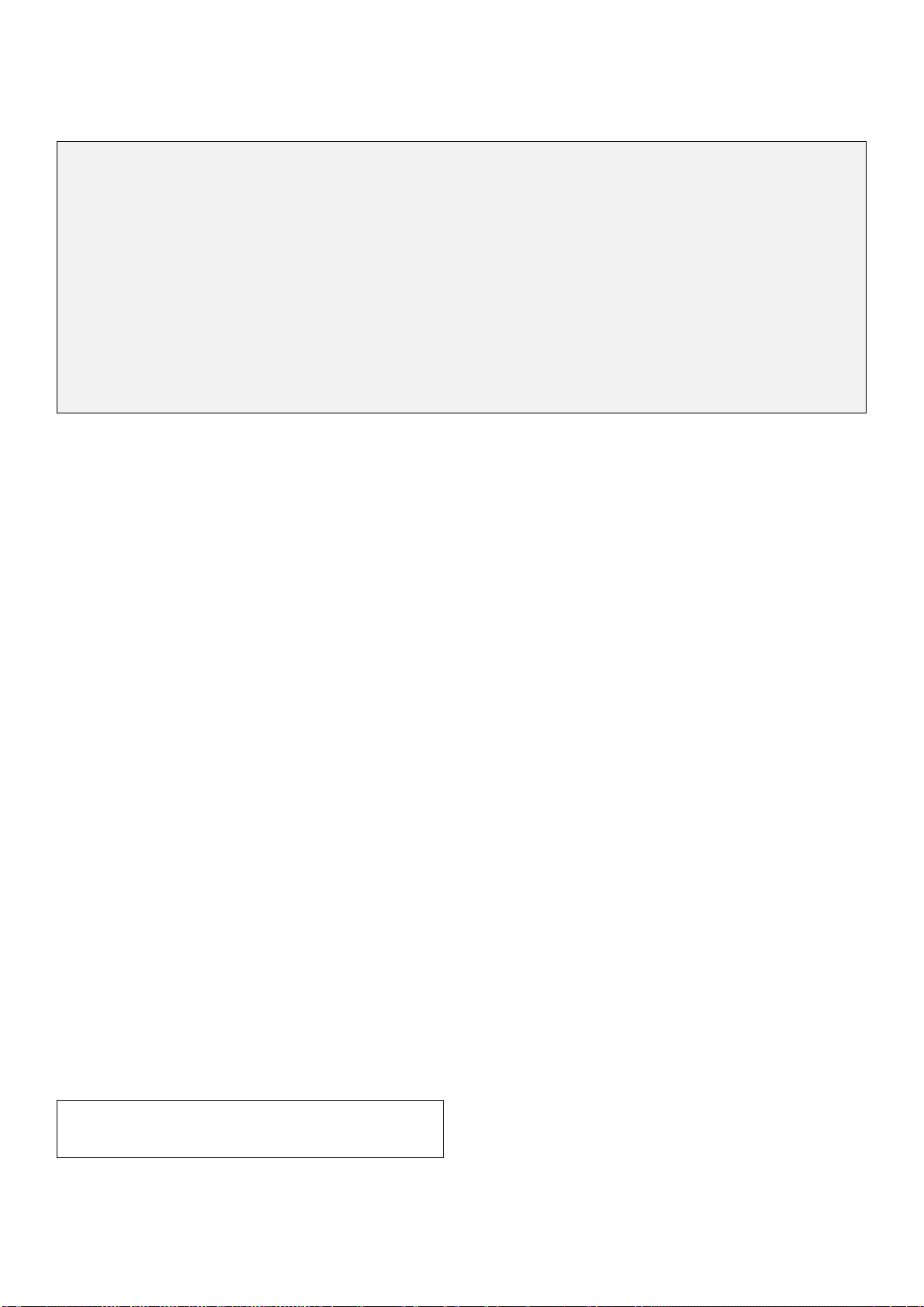

PC Board and sensors................................................................................................................................................................................7

MF 59 - Driver configuration/setting procedure...........................................................................................................................................9

MF 69 – Driver configuration/setting procedure........................................................................................................................................12

Wiring Diagram MF 59..............................................................................................................................................................................46

Wiring Diagram MF 69..............................................................................................................................................................................47

ITALIANO

Indice...............................................................................................................................................................................................Pagina 1

Specifiche....................................................................................................................................................................................................2

Specifiche tecniche.....................................................................................................................................................................................2

Disimballaggio ed Ispezione .....................................................................................................................................................................17

Posizionamento e Livellamento ................................................................................................................................................................17

Istallazione Tipica su un Impianto Frigorifero ...........................................................................................................................................18

Collegamenti Elettrici ................................................................................................................................................................................18

Alimentazione Idrica e Scarico Acqua.......................................................................................................................................................18

Circuito Frigorifero.....................................................................................................................................................................................19

Schema del Circuito Frigorifero.................................................................................................................................................................20

Circuito Elettrico........................................................................................................................................................................................21

Scheda Elettronica e Sensori....................................................................................................................................................................21

MF 59 - Procedura configurazione Driver.................................................................................................................................................23

Mf 69 - Procedura configurazione Driver ..................................................................................................................................................26

Schema Elettrico MF 59............................................................................................................................................................................46

Schema Elettrico MF 69............................................................................................................................................................................47

FRANÇAIS

Table des matières.............................................................................................................................................................................Page 1

Spécifications..............................................................................................................................................................................................2

Caractéristiques techniques........................................................................................................................................................................2

Déballage et inspection.............................................................................................................................................................................32

Emplacement et mise à niveau.................................................................................................................................................................32

Installation frigorifique traditionnelle..........................................................................................................................................................33

Raccordement électrique..........................................................................................................................................................................33

Arrivée d’eau et vidange ...........................................................................................................................................................................33

Système frigorifique ..................................................................................................................................................................................34

Schéma du système frigorifique................................................................................................................................................................35

Circuit électrique .......................................................................................................................................................................................36

Carte de régulation électronique et capteurs............................................................................................................................................36

MF 59 - Procedure configuration Driver....................................................................................................................................................38

MF 69 - Procedure configuration Driver....................................................................................................................................................41

Schéma électrique MF 59.........................................................................................................................................................................46

Schéma électrrique MF 69........................................................................................................................................................................47