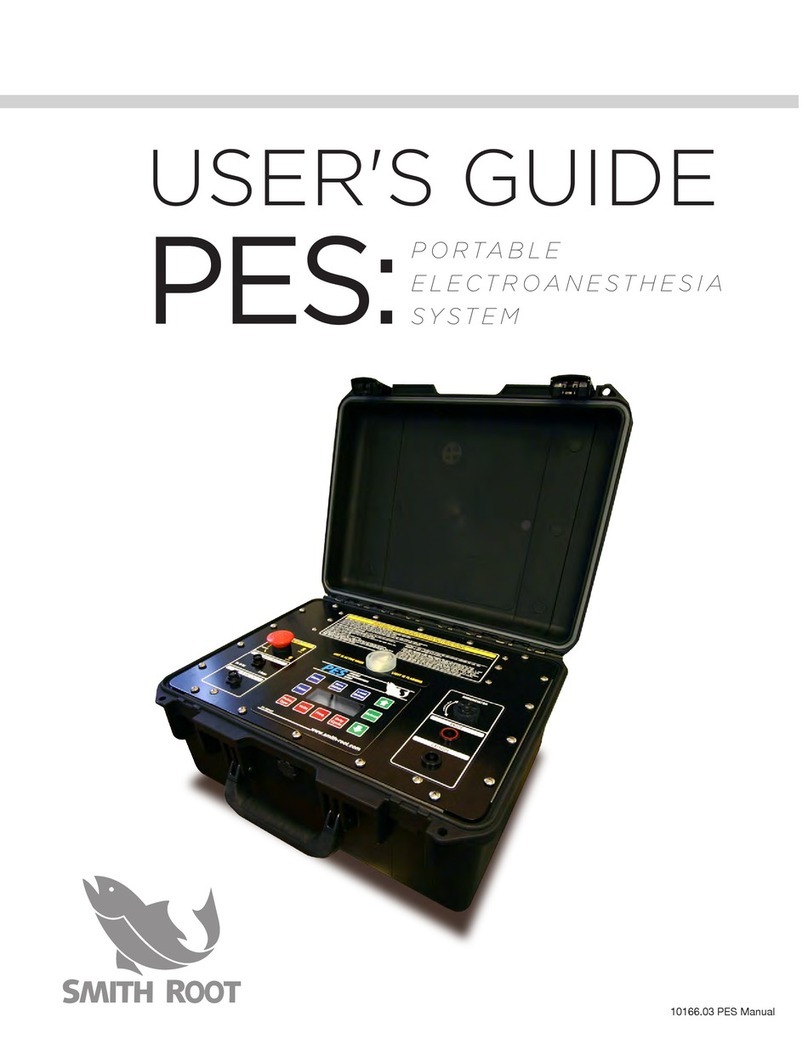

Scotty 1050 User guide

INSTALLATION MAINTENANCE USE & SAFETY

CAUTION! Read through this entire booklet before operating your Scotty Downrigger.

Improper use may damage your Downrigger and void the warranty. You may also expose

yourself to unnecessary danger and physical injury.

downrigger

MANUAL 1050 • 1050MP • 1060

1080 • 1085 • 1091

2

Introduction

Thank you for choosing a Scotty Downrigger. In 1973 Scotty produced its first

downrigger. Our goal was to manufacture a superior downrigger, built to with-

stand the demanding marine environment, and we now produce many manual

and electric models. This instruction book will give you basic instruction on

mounting and using your downrigger. Please read carefully. It will improve your

results and also give you important tips on downrigger safety and care.

Good Fishing!

Features

AUTO BRAKE

Releases automatically when winding up the downrigger and sets automatically

when the handle is released.

CLUTCH BRAKE

The Scotty clutch brake allows descent of the downrigger at any speed you

choose. Most of the time you will want a uniform slow speed to avoid tangles.

However, in instances where you want a lure deep very quickly, the Scotty will

respond, giving you complete control. In addition, the brake is factory set to allow

the line to pay out if you hang up on the bottom. If you do happen to hang up on

the bottom, the clutch brake may allow you time to turn the boat around and lift

the weight free. It is advisable to always carry a good set of wire cutters in case

the downrigger weight cannot be set free.

LIMITED LIFETIME WARRANTY

Scotty is proud to warranty your downrigger for the lifetime of the original owner.

For warranty inquires, please contact Scotty Fishing, Marine and outdoors at

1-800-214-0141, or one of our authorized warranty repair service centers (see

www.scotty.com or call us for the Scotty service center nearest you). We will do

our best to get you back fishing as soon as possible. Please read your warranty

agreement carefully and retain the certification section in a safe place.

HORIZONTAL SPOOL DESIGN

Low profile horizontal spool design for easy winding and compact storage.

Can be wound with either your left or right arm.

POSITIVE DRIVE DEPTH COUNTER

Spray protected positive drive depth counter, reads in feet.

EXTENDABLE HANDLE ARM

Models 1060, 1080, 1085, and 1091 have an extendable handle arm for extra

cranking leverage and a fast retrieve two-foot per turn spool.

3

Fishing with Downriggers

Downrigger fishing is a whole new style of trolling. It may take a little while to get

used to it, but after you begin to catch fish with it, you’ll never go back to using

heavy tackle. Unlike conventional trolling, the first evidence of a strike may show

with just a wiggle of your rod tip or your Downrigger pulley. When a fish strikes,

your rod tip goes up, the line will momentarily go slack and you now have your

fish on the line with no weight at all! Quite often, the fish will rush to the surface

(with no weight to hold him down) and put up a spectacular fight right on top.

After a strike, note the reading on the depth counter so you can get your line

back to the exact same depth after landing the fish. Many suspended fish travel

in schools and returning to the exact same location will increase your chances of

hooking up again.

If the fish is large we suggest you retrieve the Downrigger before you land the

fish. This eliminates the possibility of the fish tangling in the downrigger line or

the weight hitting the bottom if you drift into shallow water while playing the fish.

To avoid tangles you should wind up all downriggers on the boat before you stop

to drift. If fishing alone, you should get your fish under control and then retrieve

the downrigger.

4

Downrigger Safety

The Scotty Models 1085 and 1091 are designed for use

on wide beam boats of 16 ft. long and up. Installation on

smaller boats is not recommended. All sports have some

physical hazards connected with them and fishing with

Downrigger calls for some common sense and precaution.

There are natural physical forces associated with long

armed downriggers. The load of strain at the mounting

point of a downrigger is proportional to the length

of the arm. In the event of a bottom hang-up with a

30”-60” arm and high strength trolling wire, the arm

leverage can exert a tremendous amount of force on

the gunnel of your boat. It is obvious that this force

could overcome a weak mounting point on the boat.

In the case of a small boat, it could cause the boat

to submerge or overturn if the wire is caught on the

bottom in a strong tide or in a heavy wind.

Care must always be exercised to avoid tangling your

downrigger wire in your boat prop. The best way to

avoid this risk is to mount the downrigger near the

stern of the boat so that the wire never gets under

the boat in a turn. Sharp turns should be avoided.

If your model has the tilt-up base and the downrigger

is tilted up, the boom must be tilted back past

vertical, and the red lock lever tucked fully under the

downrigger base.

Keep your fingers away from the underside of the

downrigger base and remove the lead weight when

the downrigger is tilted up or unattended.

Make sure the area where you are mounting your

Downrigger is strong and reinforced. If it is weak,

reinforce it with a backing plate of wood or metal.

Don’t attempt to retrieve a weighted or snagged

downrigger cable by hand. Wave or boat motion

could cause serious injury.

Always try to bring weights, release and tackle

inboard to you. When retrieving or hooking up, do

not lean out, as a sudden roll or a slippery deck could

send you overboard.

5

What happens when you hit bottom?

When your weight touches bottom while trolling, you will see the Downrigger

boom bounce. You should immediately bring your weight up to a safer depth.

WARNING! Be very cautious when fishing in strong tidal currents or on windy

days. If the weight or wire snags on the bottom, the force of the tide or wind on

the boat can put a terrific strain on the Downrigger.

KEEP a pair of wire cutters handy in case you have to cut the wire in an

emergency! Because of the built in tilt-up feature, the Downrigger boom may fly

up quickly when the wire breaks or is cut, so be sure to stand clear, not leaning

over the boom.

We recommend you always have a large scale chart of your fishing area and

know your position at all times when deep trolling. With a relatively smooth

bottom, if your weight hangs up on a small ledge it can often be released by

turning around and pulling from the opposite direction. The wire line can be paid

out if necessary while you turn the boat to the direction of the hang-up. After

a hang-up, the wire should be examined for any broken strands. If strands are

broken, it can be cut and rejoined as a temporary measure but should be replaced

as soon as possible.

6

Mounting Instructions

Our recommendations with regard to mounting locations are:

Downriggers work best if they are mounted near the stern of the boat. They will

work at any location but the risk of tangling wire line in your prop during a turn is

minimized the further back the downrigger is mounted.

The downrigger should be mounted in a location where it is easy to reach and

operate. Remember you will be handling heavy weights on and o and you will

be setting lines and releases. The downrigger needs to be convenient for these

activities. Do not mount it where you have to reach or lean a long way to make

the connections.

FOR MODELS 1050 & 1060

These models mount using the 1010 slide-in mounting bracket supplied with

the downrigger. This bracket should be securely mounted to the boat as shown

below. Slide your downrigger into the mounting bracket and secure the lock bar.

We recommend that a wood or metal backing always be installed on the

underside of the mounting surface. This spreads the load and avoids damage to

the boat, in the event of a bottom hang up.

INBOARD

7

Mounting Instructions

FOR MODELS 1080, 1085 & 1091

These models mount onto a Scotty 1023 tilt-up mounting bracket supplied with

the downrigger. This bracket should be securely mounted to the boat as

shown below. The downrigger can be mounted on the side of the boat, the stern

or o the corner. The mounting bracket must be mounted on a flat surface and

the rear of the bracket must be within ¼” of the edge of the gunnel so that the

downrigger spool has clearance for tilting (see diagram). Because of the heavy

stresses placed on the boat gunnel by the leverage of the long downrigger arm,

we recommend that a wood or metal backing plate always be installed on the

underside of the mounting surface. This spreads the load and avoids damage to

the boat, in the event of a bottom hang up.

Position the downrigger on the tilt bracket. Insert the stainless steel mounting

bolt through the downrigger base and mounting bracket. Hand tighten.

NOTE: If your boat’s gunnel configuration does not allow this standard

mounting, see the optional mounts on page 11

To Rod

Lighter

Release

Harder

Release

To Lure

back-10-30 ft

To Downrigger

weight

Tension Adjuster

8

Rigging your fishing lines

Tighten your downrigger brake by

moving it counter clockwise, and attach

your weight to the downrigger snap

hook. It is best to do this outside the

boat so if you drop the weight it won’t

damage anything.

Clip the snap end of the release clip to

the downrigger weight.

Attach your fishing line to the Power

Grip release by squeezing the jaws

apart and placing your fishing line

between the pads. You can adjust the

release tension by placing the fishing

line further into the jaws. To further

increase the release tension you can

move the tension adjuster slider to the

out position.

With your fishing rod in a rod holder, set

the tension on your reel so that the line

will pay out, but with enough down drag

tension so that it doesn’t free wheel. It is important to have your fishing line

tight to the Downrigger line because you may lose the fish if he has slack line

after releasing o the downrigger.

Moving the brake handle in a clockwise direction lowers the downrigger weight.

You can go as fast or as slow as you wish, but if you are using a flasher or

dodger it is best to descend at a slow, even rate to eliminate fouling the flasher

or dodger with the downrigger cable.

9

Downriggers Do’s & Don’ts

DO Attach your rod and reel line to your downrigger while your boat is in

forward motion. It avoids tangles.

DO Read the depth counter when you catch a fish, then go back to the

same depth.

DO Replace badly worn or kinked wire.

DO Use enough weight (7 to 15 lbs.) on your downrigger to keep your line

at a sharp downward angle, approximately 30 degrees or less when

your trolling speed is correct.

DO Keep a pair of wire cutters handy in the event of a serious bottom

hang-up.

DO Rinse o your downrigger with fresh water after each use, if used in

saltwater.

DON’T Let the downrigger wire go slack. Kinks may form and also the wire

could spill o spool edges.

DON’T Let your fishing reel spin free while you lower your down- rigger. Set a

light drag.

DON’T Use nylon or other monofilament line on your downrigger. Nylon

will stretch in use and shrink back on the spool with enough force to

damage it. Use of nylon line will void the downrigger warranty.

DON’T Spray downrigger or wire with spray lubricants, oils, etc.

DON’T Attempt to retrieve a weighted or snagged downrigger cable by hand.

Wave or boat motion could cause serious injury.

10

Care & Maintenance

Your Scotty downrigger is constructed of corrosion resistant materials. The

following regular maintenance checks should be performed:

1. Rinse with fresh water after every use.

2. Routinely check the stainless steel fastenings with a screwdriver to see that

they are snug and secure.

3. Do not use any lubricants. Lubricants will attack the plastic components.

4. Do not expose the downrigger to ultraviolet light for extended periods of time.

BRAKE ADJUSTMENT

It may be necessary to adjust the brake tension if either the weight does not

descend freely or cannot be held when the brake is in the on position.

1. Lift up (do not twist) to remove the counter cover.

2. Remove the jam nut, which holds down the counter assembly. Lift the counter

assembly o the downrigger. It lifts straight up and sometimes requires some

gentle prying with two screw drivers under the opposite edges.

3. Using two 9/16 wrenches or two small crescent wrenches, hold the bottom

nut with one wrench and loosen the top jam nut with the other wrench. With

the brake in the o or “6 o’ clock” position, either tighten or loosen the

bottom nut as required to obtain the correct brake setting.

4. Tighten down the jam nut and re-assemble the counter assembly. With

a weight on, the brake should engage automatically when the handle is

released, yet slip if constant strain is applied to the wire.

Downrigger Line/Wire Maintenance

We have found that many things can aect the life of your line/wire. Included in

this are such things as an unobserved kink, electrolysis caused by stray electrical

currents emanating from the boat, and certain types of jelly fish and minute sea

creatures which may have corroding eect when left on the line/wire. Frequent

inspection and wiping or washing line/wire with fresh water may help prolong your

line/wires usefulness.

HOW TO REPLACE LINE

If you have occasion to replace the line, proceed as follows:

Mount the downrigger someplace secure (its regular boat mount is good) and

pull o the old line/wire. When you come to the end of the line cut the loop o

the downrigger spool.

Take the free end of the line from the supply spool and thread it through the

pulley and any fairleads. Thread the line/wire through the holes from the inside

of the spool. Tie an overhand knot in the line/wire, pulling it snug against the

spool. Tie a second overhand knot giving you a “square knot” and pull it snug.

The loose end of the line should be pointing back towards the pulley. Secure the

loose end with tape to keep it from fouling the remainder of the line/wire.

Keep tension on the supply spool to wind the new line on as tight as possible.

Avoid twisting or kinking the line/wire, or winding it onto the spool too loosely.

This operation is best carried out with two people. Attach a new Scotty bumper

and snap hook.

NOTE: Winding more than 300’ of 150 lb. test line onto the spool will affect the accuracy of

the depth counter, use of heavier test wire will also affect the counter accuracy.

For more information on these and other Scotty products,

go to our website at www.scotty.com

Downrigger

Pedestal Mount 12"

6" (2106)

2612 Rail

Mount

1027

Right Angle

Side Gunnel Mount

Clamp

Mount

Pedestal

Swivel Mount 1025

1021

1026

Gimbal

Mount - 9"

12" (1029)

1028

Optional Mounts for your Downrigger

11

SCOTTY FISHING & OUTDOOR PRODUCTS

2065 Henry Ave West

Sidney, British Columbia

Canada V8L 5Z6

PHONE 250 656 8102

TOLL FREE 1 800 214 0141

FAX 250 656 8126

EMAIL scotty@scotty.com

www.scotty.com

To obtain parts, information or to locate the warranty service depot nearest

you, check out our website: scotty.com/contact

Although Scotty makes every eort to ensure the accuracy of

specifications at the time of publication, specifications for products

described in this publication are subject to change without notice.

Contact Scotty for the most current information.

In order to maintain your warranty, don’t forget to register your

downrigger.

SERIAL #

This manual suits for next models

5

Table of contents

Other Scotty Fishing Equipment manuals