SE Controls OS2 Manual

OS2 230v AC Controller

Technical Information and Operating Instructions

1

OS2 230v AC Controller

Installation and User Manual

Table of Contents

Section

Reference

Page

1.0

Introduction

2

2.0

Packaging & preparation

3

3.0

Mounting

3

4.0

Installation notes

4

5.0

OS2 AC Controller Connections

5

6.0

Pushbuttons

13

7.0

Indicators

13

8.0

Volt Free Status Connections

13

9.0

Fuse Chart

13

10.0

Disposal

13

11.0

Health and Safety

14

12.0

Contact Details

14

2

1.0 Introduction

The OS2 AC Controller is a 230V AC control unit designed for use with 3-wire 230V AC actuators and

magnets in anatural ventilation system.

Brief device details:

Power

Class 1

Input supply 230V AC 50/60 Hz from a 6A fused un switched spur

Current Rating 6A

Output 230V AC Single Channel

Other Real time clock battery (support life 10 Years)

Environment

IP Rating: IP20

Humidity Range 10 to 90% Non-Condensing

Storage -20 to + 75°C

Operating temp -10 to +50°C

Miscellaneous

Part Number FCS 0021 0001

Dimensions 220x 209x 124mm

Weight 1.2kg (approx)

3

Important Notices

This equipment has no mains on/off switch and is intended for permanent connection.

Do NOT allow:

•

Abuse and mishandling of the device.

•

Connection using a plug to an external mains supply.

•

Adjustments and alterations to the device or it's enclosure including labelling/marking.

•

Installation by persons not qualified electrically.

•

Damage to equipment due to failure to test electrical integrity of external wiring.

•

Failure to install the device in accordance with manufacturer’s instructions.

•

Failure to follow current electrical regulations governing the installation of fixed

equipment.

•

Use or connection of this controller for any other purpose than it is intended by the

manufacturer.

SE Controls accepts no liability for failure to comply with the above statements or the installation and

operation guidance in the following sections of this guide and reserves the right to invalidate the

warranty of the controller.

2.0 Packaging & Preparation

The controller comes in a cardboard box clearly labelled with the S E Controls logo and part number.

After unpacking the controller, use a 3mm hex key to release each quarter turn catch and remove the lid of the

control unit. The following items will now be visible:

•the OS2 AC Controller unit

•a pack of grey Ø20mm cable glands

•the three controller fixing points

•the bonding earth wiring

3.0 Mounting

The controller can either be mounted locally to the device to be operated or as part of a centralised group in a

plant room.

The controller can be mounted on any flat secure surface able to support its weight (typically in a ceiling space,

under a raised floor or on a wall).

Drill appropriate sized pilot/fixing holes and use plastic plugs/cavity fixings where appropriate to fit the base to

the mounting surface. As a minimum, use 40mm No. 8 pan head or countersunk screws to secure firmly into

place.

4

Please note that the controller enclosure is rated at IP20 and so should not be mounted:

•In damp or wet locations

•Where there is likely to be significant amounts of dust.

•In areas classified as having a potentially explosive atmosphere.

At this point it is recommended that the required number of cable entry glands is checked and any additional

knock-outs required to achieve this are removed from the end of the controller. The required number of

Ø20mm end mounted cable glands can then be fitted.

4.0 Installation Notes

It is advisable to strip the outer sheath of signal cables back to the entry point into the enclosure bearing in

mind to leave enough to provide mechanical protection for cable movement over time. Inner cores can be

dressed under the edges of the power and control board providing a neater and more ordered solution. When

stripping inner cores, only strip enough for a good electromechanical contact with terminal blocks.

5

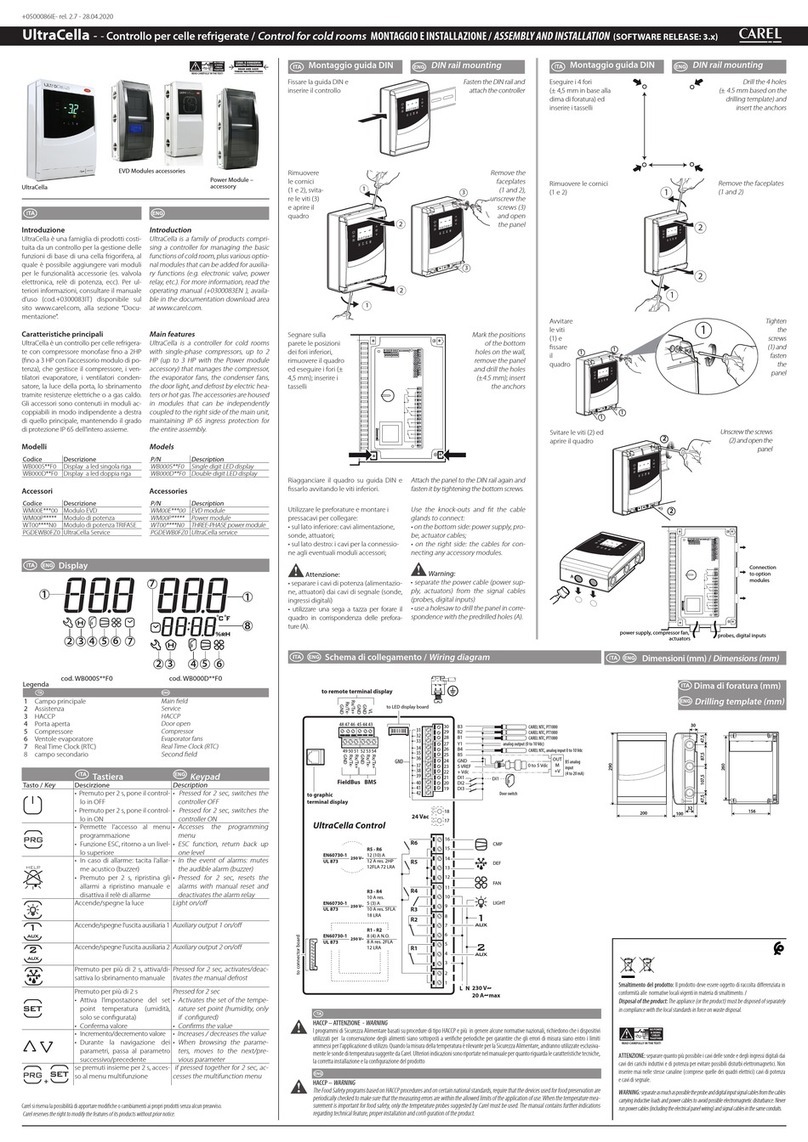

5.0 OS2 AC Controller

Connections

5.1 Introduction

The following is a sketch which highlights the important features of the OS2 AC controller unit which are

covered later inthis document.

All controller cable terminals have a capacity of 2.5mm

2

stranded and 4mm

2

solid core cables.

The installer must not adjust or remove original manufacturers cabling or use terminal outputs or

inputs forpurposes other than their design purposes without the written authorization from S E

Controls.

6

5.2

Mains power connection

Connect the 230V AC supply to the controller using a flexible cable (2 core + earth) of suitable cross

section to the L, Eand N terminals as shown. This cable should be capable of carrying the actuator load

current up to a maximum of 6A @230V AC

5.3 Actuator Connections

Two terminal blocks are supplied for the connection of actuators to the controller. If connecting to more than

two actuators, then external junction boxes will be required.

Connection to the actuators is made using 3 core + earth cable of suitable cross-section to carry the

maximum actuatorcurrent.

In operation, the actuator power is timed off automatically after a period defined for the mode of

operation. For Caretaker,Rain and Thermostat demands this period is 180 seconds (Factory adjustable).

For day to day and 0-10V demands the default period is 18 seconds (Factory adjustable).

The default actuator output mode is for motor open/motor close actuators. Other devices (such as

magnetic catches) canbe selected at the factory by S E Controls.

7

5.4 Control Connections

Each controller can operate either as a stand alone unit or as part of a BMS managed control system. To allow

for this level of control complexity, 7+1 control inputs are provided in the basic controller.

The following list identifies the 7 controls in their priority order;

Caretaker Demand

Slave Demand & Follower Demand

Rain Sensor Demand

Day to Day & Thermostat & 0-10V analogue

In addition to this further manipulation of the inputs is provided by the Auto/Manual selection input.

All control connection devices must be volt-free and capable of switching 24v DC at a nominal current of 10mA.

Cable distance is not of any real concern. However, it is recommended that the maximum control cable distance

be limited to around 500M.

5.5

Caretaker Demand

Connecting CD to 0V will cause the controller to close all attached actuators. The controller will not

respond to any otherinputs until CD is disconnected.

The actuator power is automatically timed off after a period of 180 seconds (factory adjustable). This is

a sufficient length of time to ensure most actuators achieve their fully closed position.

8

5.6 Slave Inputs

The slave inputs are designed to operate at 24VDC voltage levels. Connecting SBL and SBR to the 1BL and 1BR

outputs of an OS2 type 21 controller (see typical arrangement below) will cause the local controller to act as a

slave of the type 21 unit. A 2 core cable is required to make this connection.

In operation, the controller mimics the input demands as output demands but converts them from a

reversing 24VDCsignal to the switching L1 and L2 AC signals required for 230VAC actuators.

5.7

Follower Inputs

The follower inputs are designed to operate at 230VAC voltage levels. Connecting E/N/L1/L2 between

master and slave controllers (see typical arrangement below) will cause the local controller to act as a

slave of the master unit. A 3 core + earth cable is required to make this connection

9

5.8

Rain Sensor

Connecting RNS to 0V will close all attached actuators. By default, the thermostat, Day to Day and 0-10V

inputs are allignored under this condition. The lockout of the Day to Day input and 0-10V inputs can be

modified at the factory by S EControls.

By default, breaking the connection between RNS and 0V will not alter the position of the actuators

(factory adjustable).

In operation, the actuator power is automatically timed off after a period of 180 seconds (factory

adjustable). This is asufficient length of time to ensure most actuators achieve their fully closed position

as required.

To prevent 'machine gun' operation of the actuators, rain sensor movements are also subject to the 180

second (factoryadjustable) lockout period, during which period other rain sensor input changes are

ignored.

5.9

Day to Day Switch

Connecting DO (open) or DC (close) to 0V will open or close all attached actuators. It is recommended that

a retractive 3position switch having 2 normally open contacts is used.

10

In operation, power is applied to the actuator only during the period when one of the contacts is closed. This

mode of operation is factory adjustable by S E Controls.

In the open direction, the actuator power is automatically timed off when a total period of 18 seconds (factory

adjustable) is exceeded.

In the close direction, the actuator power is automatically timed off when the controller believes the

actuator is closed. In practice due to start-up/ stopping delays in the actuators mechanics, this may not

coincide with the physical fully closedposition. If this is the case, closing the DC connection again will

apply power in the close direction to the actuator but willtime off after a period of 180 seconds (factory

adjustable) to guarantee the fully closed position is reached.

5.10Thermostat

For the thermostat input to operate correctly, ensure that the jumper on CN4 is set at 'T'.

Connecting T/A to 0V will open all attached actuators. Breaking the connection between T/A and 0V will

close all attachedactuators.

In operation, the actuator power is automatically timed off after a period of 180 seconds (factory

adjustable). This is asufficient length of time to ensure most actuators achieve their fully open or closed

position as required.

To prevent 'machine gun' operation of the actuators, all thermostat-controlled movements are subject to a

180 second(factory adjustable) lockout period, during which period other thermostat input changes are

ignored.

11

5.11 0-10V analogue input

For the thermostat input to operate correctly, ensure that the jumper on CN4 is set at 'A'.

Applying a voltage in the range 0-10V to the T/A input relative to 0V will cause the controller to move the

actuator to a position which assumes 1V==10% opening.

In operation, the controller calculates the required position using the equation (input voltage)/10*18,

where the 18seconds element can be adjusted at the factory be S E Controls.

The exception to this is if the input voltage is set to 0V. In this case, the controller will apply power in the

close direction tothe actuator but will time off after a period of 180 seconds (factory adjustable) to

guarantee the fully closed position is reached.

By default, the 0-10V input is assumed to be an automatic control but can be adjusted at the factory by

SE controls to bea manual control.

5.12 Auto/Manual input

Connecting AUT to 0V will place the controller in automatic mode. Breaking the connection will place the

controller into manual mode.

12

In manual mode, all input controls will operate (thermostat, Day to Day and 0-10V). In automatic mode

only automatic controls will operate (thermostat and 0-10V). Auto/manual changeover does not effect the

operation of the Caretaker andRain sensor inputs.

To prevent confusion by a user of the Day to Day controls, each time this input is used, a timer with a 1

hour period (factory adjustable) is started. While this timer is running, the auto controls are locked out.

If it is necessary for an automatic control to be used whilst the timer is running, the connecting and

then breaking the connection between AUTand 0V resets the timer allowing automatic controls to

operate once again.

5.13 Network Connection

Connections NA, NB and SCR are used for forming network connections between controllers.

The use of networking requires the installation of suitable network interface plug in boards and reference to

their individual user manuals which are outside the scope of this document.

13

6.0 Pushbuttons

Button

Detail

SVC

Used during the commissioning of the controller into a LONWorks system. Requires

additional hardware to be added to the controller and hence should be considered to

be for factory use only.

LEARN

Reserved for factory use only.

7.0 Indicators

LED

Colour

Detail

LD1 WINK

Red

Used during the commissioning of the controller into a LONWorks system.

Requires

additional hardware to be added to the controller and hence should be

considered to be forfactory use only.

LD2 HLTY

Green

Healthy Lamp - Lit when the controller has not identified any internal faults.

LD3 POW

Green

Lit when Mains supply is connected.

LD4 WDG

Yellow

Watchdog - Flashes to indicate software running in controller ok.

LD5 OPN

Red

Lit when output energized to open

LD6 CLS

Green

Lit when output energized to close

8.0 Volt Free Status connections

CN3 Terminal

Description

COM

Healthy Relay Common

NC

Healthy Relay Normally Closed(open when healthy)

NO

Healthy Relay Normally Open(closed when healthy)

24V

Power supply rail for driving an external indicator or relay

LP

Switch to ground output for driving an external indicator or relay.

9.0 Fusing

Fuse

Function

If open circuit

FH1

ELV Auxiliary supply 200mA

FH2

AC Supply 10A

Note: If a fuse does blow, please check wiring/ external devices for damage and incorrect termination/earth

faults.

10.0 Disposal

For advice on disposal consult the local environmental officer, a recycling or waste management

specialist or SEControls.

14

11.0 Health and Safety

COSHH

; There are no substances or products present or used in the manufacture of this controller that

constitute ahealth risk

12.0 Contact Details

Technical Support.

SE Controls Lancaster House,

Wellington Crescent,

Fradley Park,

Lichfield,

Staffs. WS13 8RZ

Tel 01543 443060

www.secontrols.com

Other manuals for OS2

1

Table of contents

Other SE Controls Controllers manuals

SE Controls

SE Controls OS2 User manual

SE Controls

SE Controls TWIN SECO N 24 25 Manual

SE Controls

SE Controls SECO AKS20000003 Manual

SE Controls

SE Controls SECO Ni AKS20000001 User manual

SE Controls

SE Controls SECO Ni 24 40 Manual

SE Controls

SE Controls SELA U 24 75 Manual

SE Controls

SE Controls Seco Ni 40 Manual

SE Controls

SE Controls SECO Ni Manual