Sea-Bird Electronics SBE 37-SMP MicroCAT User manual

SBE 37-SMP MicroCAT

Conductivity, Temperature, and (optional) Pressure Recorder

with RS-232 Interface and Integral Pump

Shown with optional ShallowCAT plastic housing;

standard titanium housing available

User’s Manual

Sea-Bird Electronics, Inc.

13431 NE 20th Street

Bellevue, Washington 98005 USA

Telephone: +1 425-643-9866 Manual version #019, 09/19/13

Fax: +1 425-643-9954 Firmware version 4.1 and later

E-mail: [email protected] SeatermV2 version 2.3.0 and later

Website: www.seabird.com SBE Data Processing version 7.23.1 and later

For most

applications,

deploy in

orientation

shown

(connector

end down) for

proper

operation

2

Limited Liability Statement

Extreme care should be exercised when using or servicing this equipment. It should be used or serviced

only by personnel with knowledge of and training in the use and maintenance of oceanographic

electronic equipment.

SEA-BIRD ELECTRONICS, INC. disclaims all product liability risks arising from the use or servicing

of this system. SEA-BIRD ELECTRONICS, INC. has no way of controlling the use of this equipment

or of choosing the personnel to operate it, and therefore cannot take steps to comply with laws

pertaining to product liability, including laws which impose a duty to warn the user of any dangers

involved in operating this equipment. Therefore, acceptance of this system by the customer shall be

conclusively deemed to include a covenant by the customer to defend, indemnify, and hold SEA-BIRD

ELECTRONICS, INC. harmless from all product liability claims arising from the use or servicing of

this system.

Manual revision 019 Declaration of Conformity SBE 37-SMP RS-232

3

Declaration of Conformity

Manual revision 019 Table of Contents SBE 37-SMP RS-232

4

Table of Contents

Limited Liability Statement ................................................................ 2

Declaration of Conformity .................................................................. 3

Table of Contents ................................................................................. 4

Section 1: Introduction ........................................................................ 6

About this Manual .............................................................................................6

Quick Start .........................................................................................................6

Unpacking MicroCAT .......................................................................................7

Shipping Precautions .........................................................................................8

Section 2: Description of MicroCAT.................................................. 9

System Description ............................................................................................9

Specifications...................................................................................................11

Dimensions and End Cap Connector ...............................................................12

Cables and Wiring ...........................................................................................13

Sample Timing.................................................................................................14

Battery Endurance............................................................................................14

External Power.................................................................................................15

Cable Length and External Power ............................................................15

Section 3: Preparing MicroCAT for Deployment........................... 17

Battery Installation...........................................................................................17

Software Installation ........................................................................................19

Power and Communications Test ....................................................................19

Test Setup .................................................................................................19

Test ...........................................................................................................20

Section 4: Deploying and Operating MicroCAT............................. 25

Sampling Modes ..............................................................................................25

Polled Sampling........................................................................................26

Autonomous Sampling (Logging commands) ..........................................27

Serial Line Synchronization (Serial Line Sync) .......................................28

Real-Time Data Acquisition ............................................................................29

Timeout Description ........................................................................................29

Command Descriptions....................................................................................30

Data Formats....................................................................................................45

Optimizing Data Quality / Deployment Orientation ........................................47

Setup for Deployment ......................................................................................48

Deployment......................................................................................................49

Recovery ..........................................................................................................50

Uploading and Processing Data .......................................................................51

Editing Raw Data File......................................................................................58

Section 5: Routine Maintenance and Calibration........................... 59

Corrosion Precautions......................................................................................59

Connector Mating and Maintenance ................................................................59

Conductivity Cell Maintenance .......................................................................60

Plumbing Maintenance ....................................................................................60

Handling Instructions for Plastic ShallowCAT Option ....................................61

Replacing Batteries ..........................................................................................62

Pressure Sensor (optional) Maintenance..........................................................62

Replacing Anti-Foulant Devices – Mechanical Design Change ......................63

Replacing Anti-Foulant Devices (SBE 37-SI, SM, IM)...................................64

Sensor Calibration............................................................................................65

Manual revision 019 Table of Contents SBE 37-SMP RS-232

5

Section 6: Troubleshooting................................................................ 67

Problem 1: Unable to Communicate with MicroCAT .....................................67

Problem 2: No Data Recorded .........................................................................67

Problem 3: Unreasonable T, C, or P Data........................................................67

Problem 4: Salinity Spikes...............................................................................68

Glossary .............................................................................................. 69

Appendix I: Functional Description................................................. 71

Sensors .............................................................................................................71

Sensor Interface ...............................................................................................71

Real-Time Clock..............................................................................................71

Appendix II: Electronics Disassembly/Reassembly ........................ 72

Appendix III: Command Summary ................................................. 74

Appendix IV: AF24173 Anti-Foulant Device .................................. 76

Appendix V: Replacement Parts ...................................................... 80

Appendix VI: Manual Revision History .......................................... 82

Index.................................................................................................... 84

Manual revision 019 Section 1: Introduction SBE 37-SMP RS-232

6

Section 1: Introduction

This section includes a Quick Start procedure, photos of a standard MicroCAT

shipment, and battery shipping precautions.

About this Manual

This manual is to be used with the SBE 37-SMP MicroCAT Conductivity and

Temperature Recorder (pressure optional) with RS-232 Serial interface,

internal Memory, and integral Pump. It is organized to guide the user from

installation through operation and data collection. We’ve included detailed

specifications, command descriptions, maintenance and calibration

information, and helpful notes throughout the manual.

Sea-Bird welcomes suggestions for new features and enhancements of our

products and/or documentation. Please contact us with any comments or

suggestions (seabird@seabird.com or 425-643-9866). Our business hours are

Monday through Friday, 0800 to 1700 Pacific Standard Time (1600 to 0100

Universal Time) in winter and 0800 to 1700 Pacific Daylight Time (1500 to

0000 Universal Time) the rest of the year.

Quick Start

Follow these steps to get a Quick Start using the MicroCAT.

The manual provides step-by-step details for performing each task:

1. Install batteries and test power and communications (Section 3: Preparing

MicroCAT for Deployment).

2. Deploy the MicroCAT (Section 4: Deploying and Operating MicroCAT):

A. Install new batteries if necessary.

B. Ensure all data has been uploaded, and then send InitLogging to

make entire memory available for recording if desired.

C. Set date and time, and establish setup and logging parameters.

D. Check status (DS) and calibration coefficients (DC) to verify setup.

E. Set MicroCAT to start logging now or in the future.

F. Remove yellow protective label from plumbing intake and exhaust.

Remove conductivity cell guard, and verify AF24173 Anti-Foulant

Devices are installed. Replace conductivity cell guard. Leave label off

for deployment.

G. Install dummy plug or cable connector, and locking sleeve.

H. Deploy MicroCAT, using Sea-Bird or customer-supplied hardware.

For most applications, mount the MicroCAT with the connector at

the bottom for proper operation.

I. Upload data from memory.

Manual revision 019 Section 1: Introduction SBE 37-SMP RS-232

7

Unpacking MicroCAT

Shown below is a typical MicroCAT shipment.

Spare hardware

and o-ring kit Conductivity cell cleaning

solution (Triton-X)

Software, and Electronic Copies of

Software Manuals and User Manual

Batteries

I/O cable

SBE 37-SMP MicroCAT

Manual revision 019 Section 1: Introduction SBE 37-SMP RS-232

8

Shipping Precautions

For its main power supply, the MicroCAT uses twelve 3.6-volt AA lithium

batteries (Saft LS14500). The MicroCAT was shipped from the factory with

the batteries packaged separately within the shipping box (not inside

MicroCAT).

If the shipment is not packaged as described above, or does not meet the requirements below, the

shipment is considered Dangerous/Hazardous Goods, and must be shipped according to those rules.

1-5 MicroCATs

and associated

batteries,

but no spares

1-5 MicroCATs and

associated batteries,

plus up to 2 spare

battery sets/MicroCAT

Spares

(without MicroCATs) –

Note new rules as of

January 1, 2013

UN #

UN3091

UN3091

Must be shipped as

Class 9 Dangerous Goods.

If re-shipping spares, you must have your

own Dangerous Goods program.

Packing Instruction (PI) #

969

969

Passenger Aircraft

Yes

No

Cargo Aircraft

Yes

Yes

Labeling Requirement

1 **

1, 2 **

Airway Bill (AWB)

Requirement

Yes * Yes *

* AWB must contain following information in Nature and Quantity of Goods Box: “Lithium Metal Batteries”, “Not Restricted”, “PI #”

** Labels are defined below:

Install batteries in the MicroCAT for testing (see Battery Installation in

Section 3). If you will re-ship the MicroCAT after testing:

1. Remove the battery pack assembly from the MicroCAT.

2. Remove the batteries from the battery pack assembly.

3. Pack the batteries properly for shipment, apply appropriate labels, and

prepare appropriate shipping documentation.

BATTERY PACKAGING

Batteries are packed in heat-sealed plastic,

and then placed in bubble-wrap outer

sleeve and strong packaging for shipment.

DISCLAIMER / WARNING:

The shipping information provided in is a general overview of lithium battery shipping requirements; it does not provide

complete shipping information. The information is provided as a courtesy, to be used as a guideline to assist properly trained

shippers. These materials do not alter, satisfy, or influence any federal or state requirements. These materials are subject to

change due to changes in government regulations. Sea-Bird accepts no liability for loss or damage resulting from changes,

errors, omissions, or misinterpretations of these materials. See the current edition of the IATA Dangerous Good

Regulations for complete information on packaging, labeling, and shipping document requirements.

Note:

Remove the batteries before returning

the MicroCAT to Sea-Bird. Do not

return used batteries when shipping

the MicroCAT for calibration or repair.

All setup information is preserved

when the batteries are removed.

2

1

– Shipper must provide an

emergency phone number

xxx.xxxx.xxxx

WARNING!

Do not ship

assembled

battery pack.

Assembled

battery

pack

Manual revision 019 Section 2: Description of MicroCAT SBE 37-SMP RS-232

9

Section 2: Description of MicroCAT

This section describes the functions and features of the SBE 37-SMP

MicroCAT, including specifications, dimensions, end cap connectors, sample

timing, battery endurance, and external power.

System Description

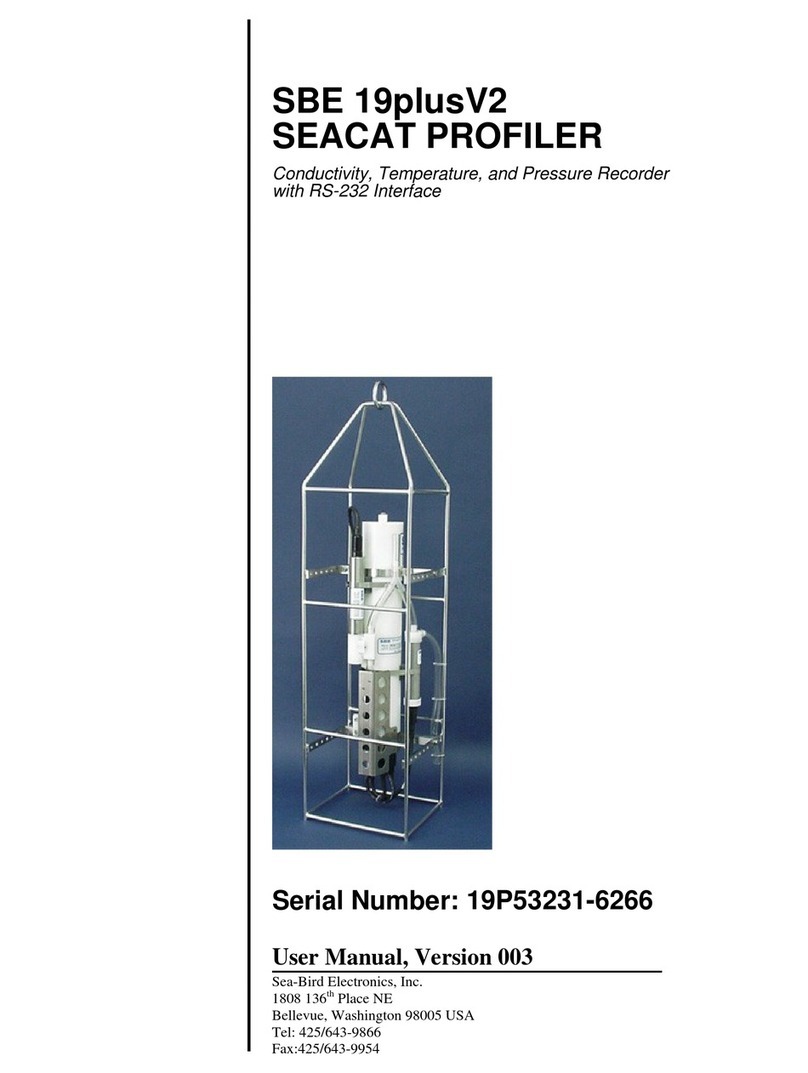

The SBE 37-SMP MicroCAT is a high-accuracy conductivity and temperature

recorder (pressure optional) with internal battery and non-volatile memory, an

integral pump, and a standard RS-232 serial interface. Designed for moorings

and other long-duration, fixed-site deployments, MicroCATs have non-

corroding titanium housings rated for operation to 7000 meters (23,000 feet)

or pressure sensor full-scale range. An optional plastic ShallowCAT housing

rated for 350 meters (1150 feet) is also available.

Communication with the MicroCAT is over an internal, 3-wire, RS-232C

link. Over 50 different commands can be sent to the MicroCAT to provide

status display, data acquisition setup, data retrieval, and diagnostic tests.

User-selectable operating modes include:

•Autonomous sampling – At pre-programmed intervals, the MicroCAT

wakes up, runs the pump, samples, stores the data in its FLASH memory,

and goes to sleep. If desired, real-time data can also be transmitted.

•Polled sampling – On command, the MicroCAT runs the pump, takes one

sample, and transmits the data. Polled sampling is useful for integrating

the MicroCAT with satellite, radio, or wire telemetry equipment.

•Serial line sync – In response to a pulse on the serial line, the MicroCAT

wakes up, runs the pump, samples, stores the data in its FLASH memory,

and goes to sleep. If desired, real-time data can also be transmitted. Serial

line sync provides an easy method for synchronizing MicroCAT sampling

with other instruments such as Acoustic Doppler Current Profilers

(ADCPs) or current meters, without drawing on their battery or memory

resources.

The MicroCAT can be deployed in two ways:

•Cable installed – The MicroCAT can be remotely controlled, allowing for

polled sampling or serial line sync, or for periodic requests of data from

the MicroCAT memory. If desired, data can be periodically uploaded

while the MicroCAT remains deployed. Additionally, the MicroCAT can

be externally powered.

•Dummy plug installed – The MicroCAT cannot be remotely controlled.

Autonomous sampling is programmed before deployment, and data is

uploaded after recovery.

Calibration coefficients stored in EEPROM allow the MicroCAT to transmit

data in engineering units. The MicroCAT retains the temperature and

conductivity sensors used in the Seacat and Seacat plus family. The

MicroCAT’s aged and pressure-protected thermistor has a long history of

exceptional accuracy and stability (typical drift is less than 0.002 °C per year).

Electrical isolation of the conductivity electronics eliminates any possibility of

ground-loop noise.

For most applications, deploy in orientation

shown (connector end down) for proper

operation – see Optimizing Data Quality /

Deployment Orientation in Section4:

Deploying and Operating MicroCAT

Optional plastic

ShallowCAT housing

Manual revision 019 Section 2: Description of MicroCAT SBE 37-SMP RS-232

10

The MicroCAT’s internal-field conductivity cell is immune to proximity errors

and unaffected by external fouling. The conductivity cell guard retains the

expendable AF24173 Anti-Foulant Devices at the conductivity cell intake and

pump exhaust.

The MicroCAT’s integral pump runs for 1.0 second each time the

MicroCAT takes a sample, providing the following advantages over a

non-pumped system:

•Improved conductivity response – The pump flushes the previously

sampled water from the conductivity cell and brings a new water sample

quickly into the cell.

•Reduced fouling – Water does not freely flow through the conductivity

cell between samples, minimizing fouling.

Note that the MicroCAT was designed to be deployed as shown, with the

sensor end up, providing an inverted U-shape for the flow. This orientation

prevents sediment from being trapped in the pump impeller housing. An air

bleed hole in the top of the duct allows air to escape from the plumbing, so the

pump will prime. See Optimizing Data Quality / Deployment Orientation in

Section 4: Deploying and Operating MicroCAT.

The MicroCAT’s optional strain-gauge pressure sensor is available in the

following pressure ranges: 20, 100, 350, 600, 1000, 2000, 3500, and

7000 meters. Compensation of the temperature influence on pressure offset

and scale is performed by the MicroCAT’s CPU.

Future upgrades and enhancements to the MicroCAT firmware can be easily

installed in the field through a computer serial port and the bulkhead connector

on the MicroCAT, without the need to return the MicroCAT to Sea-Bird.

The MicroCAT is supplied with a powerful software package, Seasoft©V2,

which includes:

•Deployment Endurance Calculator– program for determining

deployment length based on user-input deployment scheme, instrument

power requirements, and battery capacity.

•SeatermV2 – terminal program for easy communication and data

retrieval. SeatermV2 is a launcher, and launches the appropriate terminal

program for the selected instrument (Seaterm232 for RS-232 instruments

such as this MicroCAT).

•SBE Data Processing - program for calculation and plotting of

conductivity, temperature, pressure (optional), and derived variables such

as salinity and sound velocity.

Notes:

•Help files provide detailed

information on the software.

•A separate software manual on

CD-ROM contains detailed

information on the setup and

use of SBE Data Processing.

•Sea-Bird supplies the current

version of our software when you

purchase an instrument. As software

revisions occur, we post the revised

software on our FTP site. See our

website (www.seabird.com) for the

latest software version number, a

description of the software changes,

and instructions for downloading the

software from the FTP site.

Intake

Exhaust

Air bleed

hole in top

Anti-Foulant

Devices

Conductivity

cell

Thermistor

Shown with conductivity

cell guard removed

Manual revision 019 Section 2: Description of MicroCAT SBE 37-SMP RS-232

11

Specifications

Temperature

(°C)

Conductivity

(S/m)

Optional

Pressure

Measurement

Range -5 to +35 0 to 7

(0 to 70 mS/cm)

0 to full scale range:

20 / 100 / 350 / 600 /

1000 / 2000 / 3500 /

7000 meters

Initial

Accuracy ± 0.002 ± 0.0003

(0.003 mS/cm)

± 0.1% of

full scale range

Typical

Stability

0.0002

per month

0.0003

(0.003 mS/cm)

per month

0.05% of

full scale range

per year

Resolution 0.0001 0.00001

(0.0001 mS/cm)

0.002% of

full scale range

Sensor

Calibration +1 to +32

0 to 6; physical calibration

over range 2.6 to 6 S/m,

plus zero conductivity (air)

Ambient pressure to

full scale range in

5 steps

Memory 8 Mbyte non-volatile FLASH memory

Data

Storage

Conductivity & temperature: 6 bytes per sample (3 bytes each)

Time: 4 bytes per sample.

Pressure (optional): 5 bytes per sample.

Recorded Parameters Memory Space (number of samples)

C, T, and time 800,000

C, T, P, and time 533,000

Real-Time

Clock 32,768 Hz TCXO accurate to ±1 minute/year.

Internal

Batteries

Nominal 7.8 Amp-hour pack consisting of 12 AA Saft LS 14500 lithium

batteries (3.6 V and 2.6 Amp-hours each), with 3 strings of 4 batteries.

Capacity for more than 380,000 samples for a typical sampling scheme

(see Battery Endurance for example calculation). See Shipping

Precautions in Section 1: Introduction.

Note: Saft batteries can be purchased from Sea-Bird or other sources.

See Saft’s website for suppliers (www.saftbatteries.com).

Alternatively, substitute either of the following:

- Tadiran TL-4903, AA (3.6 V and 2.4 Amp-hours each)

(www.tadiran.com)

- Electrochem 3B0064/BCX85, AA (3.9 V and 2.0 Amp-hours each)

(www.electrochemsolutions.com)

External

Power

0.25 Amps at 9 - 24 VDC. To avoid draining internal batteries,

use an external voltage greater than 10 VDC. See External Power.

Power

Requirements

•Quiescent current: 30 microAmps.

•Communication current: 4.3 milliAmps.

•Acquisition current (excluding pump):

- 9.1 milliAmps if transmitting real-time data.

- 7.9 milliAmps if not transmitting real-time data.

•Pump current: 25.3 milliAmps

(0.025 Amp-second per 1.0 second pulse)

Acquisition time: 1.9 – 2.9 seconds per sample (depending on

sampling mode and inclusion of pressure sensor, see Sample Timing).

Housing and

Depth Rating

Standard: Titanium housing rated at 7000 m (23,000 ft)

Optional: Plastic housing rated at 350 m (1150 ft)

Weight

(with clamps)

Standard titanium housing: 3.7 kg (8.3 lbs) in air, 2.2 kg (4.8 lbs) in water

Optional plastic housing: 3.4 kg (7.5 lbs) in air, 1.6 kg (3.5 lbs) in water

Note:

Pressure ranges are expressed

in meters of deployment

depth capability.

CAUTION:

See Section 5: Routine

Maintenance and Calibration for

handling instructions for the

plastic ShallowCAT housing.

Manual revision 019 Section 2: Description of MicroCAT SBE 37-SMP RS-232

12

Dimensions and End Cap Connector

Note:

For most applications, deploy in

the orientation shown (connector

end down) for proper operation.

Manual revision 019 Section 2: Description of MicroCAT SBE 37-SMP RS-232

13

Cables and Wiring

Manual revision 019 Section 2: Description of MicroCAT SBE 37-SMP RS-232

14

Sample Timing

Sample timing is dependent on several factors, including sampling mode and

whether the MicroCAT has an optional pressure sensor. The pump runs for

1.0 second while the Wein bridge is stabilizing before each measurement.

Autonomous Sampling (time between samples = SampleInterval) or

Serial Line Sync Sampling

Power on time for each sample while logging, if not transmitting real-time data:

•Without pressure: power-on time = 1.9 seconds to run pump and sample

•With pressure: power-on time = 2.6 seconds to run pump and sample

Power on time for each sample while logging, if transmitting real-time data:

•Without pressure: power-on time = 2.2 seconds to run pump and sample

•With pressure: power-on time = 2.9 seconds to run pump and sample

Polled Sampling

Time from receipt of take sample command to beginning of reply:

•Without pressure: power-on time = 1.9 seconds to run pump and sample

•With pressure: power-on time = 2.6 seconds to run pump and sample

Battery Endurance

The battery pack (4 batteries in series, 3 parallel strings) has a nominal

capacity of 7.8 Amp-hours (2.6 Amp-hours * 3). For planning purposes, to

account for the MicroCAT’s current consumption patterns and for

environmental conditions affecting battery performance, Sea-Bird

recommends using a conservative value of 6.0 Amp-hours.

Acquisition current varies, depending on whether the MicroCAT is

transmitting real-time data: 9.1 mA if transmitting real-time data, 7.9 mA if

not. Pump current is 0.025 Amp-seconds per pulse (1.0 second pulse).

Quiescent current is 30 microAmps (0.26 Amp-hours per year).

Acquisition time is shown above in Sample Timing. The time required for each

sample is dependent on the user-programmed sampling mode, and inclusion of

a pressure sensor in the MicroCAT. So, battery endurance is highly dependent

on the application. An example is shown below. You can use the Deployment

Endurance Calculator to determine the maximum deployment length, instead

of performing the calculations by hand.

Notes:

•If the MicroCAT is logging data and

the battery voltage is less than

7.1 volts for five consecutive scans,

the MicroCAT halts logging.

•Sea-Bird recommends using the

capacity value of 6.0 Amp-hours

for the Saft batteries as well as for

the alternate battery types

(Tadiran TL-4903 and

Electrochem 3B0064/BCX85 AA).

•This MicroCAT uses a battery pack

with a yellow cover plate. Older

MicroCATs used a battery pack with

a red cover plate; the wiring of the

red battery pack is different from this

one, and cannot be used with this

MicroCAT.

•See Specifications above for data

storage limitations.

Example: A MicroCAT with pressure sensor is set up to sample autonomously every 5 minutes (12 samples/hour), and

is not transmitting real-time data. How long can it be deployed?

Samplingtime (autonomous sampling, with pressure sensor) = 2.6 seconds

Sampling current consumption = 0.0079 Amps * 2.6 seconds = 0.021 Amp-seconds/sample

In 1 hour, sampling current consumption = 12 * 0.021 Amp-seconds/sample = 0.25 Amp-seconds/hour

Pump current consumption = 0.025 Amp-seconds/pulse

In 1 hour, pump current consumption = 12 * 0.025 Amp-seconds/pulse = 0.3 Amp-seconds/hour

Quiescent current = 30 microAmps = 0.03 mA

In 1 hour, quiescent current consumption ≈ 0.03 mA * 3600 seconds/hour = 0.11 Amp-seconds/hour

Total current consumption / hour = 0.25 + 0.3 + 0.11 = 0.66 Amp-seconds/hour

Capacity = (6.0 Amp-hours * 3600 seconds/hr) / (0.66 Amp-seconds/hour) = 32727 hours = 1363 days = 3.7 years

However, Sea-Bird recommends that batteries should not be expected to last longer than 2 years in the field.

Number of samples = 32,000 hours * 12 samples/hour = 380,000 samples

Notes:

•Acquisition time shown does not

include time to transmit real-time

data, which is dependent on

baud rate (BaudRate=) and number

of characters being transmitted

(defined by OutputFormat=,

OutputSal=, and OutputSV=).

•Time stored and output with the data

is the time at the start of the

sample, after a small amount of time

for the MicroCAT to wake up, run

the pump, and prepare to sample.

For example, if the MicroCAT is

programmed to wake up and sample

at 12:00:00, the stored time will

indicate 12:00:01 or 12:00:02.

Manual revision 019 Section 2: Description of MicroCAT SBE 37-SMP RS-232

15

External Power

The MicroCAT can be powered from an external source that supplies

0.25 Amps at 9-24 VDC. The internal lithium pack is diode-OR’d with the

external source, so power is drawn from whichever voltage source is higher.

The MicroCAT can also be operated from the external supply without having

the lithium batteries installed. Electrical isolation of conductivity prevents

ground loop noise contamination in the conductivity measurement.

Cable Length and External Power

There are two issues to consider if powering the MicroCAT externally:

•Limiting the communication IR loss to 1 volt if transmitting real-time

data; higher IR loss will cause the instrument to transmit data that does

not meet the RS-232 communication standard.

•Supplying enough power at the power source so that sufficient power is

available at the instrument after considering IR loss.

Each issue is discussed below.

Limiting Communication IR Loss to 1 Volt if Transmitting Real-Time Data

The limit to cable length is typically reached when the maximum

communication current times the power common wire resistance is more than

1 volt.

Vlimit = 1 volt = IR limit

Maximum cable length = R limit / wire resistance per foot

where I = communication current required by MicroCAT (4.3 milliAmps;

see Specifications).

Note:

Common wire resistances:

Gauge Resistance (ohms/foot)

12 0.0016

14 0.0025

16 0.0040

18 0.0064

19 0.0081

20 0.0107

22 0.0162

24 0.0257

26 0.0410

28 0.0653

Note:

See Real-Time Data Acquisition

in Section 4: Deploying and

Operating MicroCAT for baud rate

limitations on cable length if

transmitting real-time data.

Example 1 – For 20 gauge wire, what is maximum distance to transmit power to MicroCAT if transmitting real-time data?

For 4.3 milliAmp communications current, R limit = V limit / I = 1 volt / 0.0043 Amps = 232 ohms

For 20 gauge wire, resistance is 0.0107 ohms/foot.

Maximum cable length = 232 ohms / 0.0107 ohms/foot = 21734 feet = 6626 meters

Example 2 – Same as above, but there are 4 MicroCATs powered from the same power supply.

For 4.3 milliAmp communications current, R limit = V limit / I = 1 volt / (0.0043 Amps * 4 MicroCATs) = 58 ohms

Maximum cable length = 58 ohms / 0.0107 ohms/foot = 5433 feet = 1656 meters (to MicroCAT furthest from power source)

Manual revision 019 Section 2: Description of MicroCAT SBE 37-SMP RS-232

16

Supplying Enough Power to MicroCAT

Another consideration in determining maximum cable length is supplying

enough power at the power source so that sufficient voltage is available, after

IR loss in the cable (from the 0.25 Amp turn-on transient, two-way

resistance), to power the MicroCAT. The power requirement varies,

depending on whether any power is drawn from the batteries:

•Provide at least 10 volts, after IR loss, to prevent the MicroCAT from

drawing any power from the batteries (if you do not want to draw down

the batteries): V - IR > 10 volts

•Provide at least 9 volts, after IR loss, if allowing the MicroCAT to draw

down the batteries or if no batteries are installed: V - IR > 9 volts

where I = MicroCAT turn-on transient (0.25 Amps; see Specifications).

Example 1 – For 20 gauge wire, what is maximum distance to transmit power to MicroCAT if using 12 volt power source

and deploying MicroCAT with no batteries?

V - IR > 9 volts 12 volts - (0.25 Amps) * (0.0107 ohms/foot * 2 * cable length) > 9 volts

3 volts > (0.25 Amps) * (0.0107 ohms/foot * 2 * cable length) Cable length < 560 ft = 170 meters

Note that 170 m << 6626 m (maximum distance if MicroCAT is transmitting real-time data), so IR drop in power is

controlling factor for this example. Using a higher voltage power supply or a different wire gauge would increase

allowable cable length.

Example 2 – Same as above, but there are 4 MicroCATs powered from same power supply.

V - IR > 9 volts 12 volts - (0.25 Amps * 4 MicroCATs) * (0.0107 ohms/foot * 2 * cable length) > 9 volts

3 volts > (0.25 Amps * 4 MicroCATs) *(0.0107 ohms/foot * 2 * cable length)

Cable length < 140 ft = 42 meters (to MicroCAT furthest from power source)

Manual revision 019 Section 3: Preparing MicroCAT for Deployment SBE 37-SMP RS-232

17

Section 3:

Preparing MicroCAT for Deployment

This section describes the pre-check procedure for preparing the MicroCAT

for deployment. Installation of the battery pack, installation of Sea-Bird

software, and testing power and communications are discussed.

Battery Installation

Description of Batteries and Battery Pack

Sea-Bird supplies twelve 3.6-volt AA lithium batteries, shipped with the

MicroCAT in a heat-sealed plastic bag placed in bubble wrap and a cardboard

box. The empty battery holder is installed inside the MicroCAT for shipment.

No soldering is required when assembling the battery pack.

Installing Batteries

1. Remove the I/O connector end cap:

A. Wipe the outside of the I/O end cap and housing dry, being careful to

remove any water at the seam between them.

B. Remove the 2 cap screws on the sides of the housing. Do not remove

any other screws.

Note: Sea-Bird ships the MicroCAT with a 9/64-inch Allen wrench

for these screws.

C. Remove the I/O end cap by twisting the end cap counter clockwise;

the end cap will release from the housing. Pull the end cap out.

D. The end cap is electrically connected to the electronics with a Molex

connector. Holding the wire cluster near the connector, pull gently to

detach the female end of the connector from the pins.

E. Remove any water from the O-ring mating surfaces inside the

housing with a lint-free cloth or tissue.

F. Put the end cap aside, being careful to protect the O-rings from

damage or contamination.

WARNING!

Do not ship the MicroCAT with

batteries installed.

See Shipping Precautions in

Section 1: Introduction.

CAUTION:

See Section 5: Routine Maintenance

and Calibration for handling

instructions for the plastic ShallowCAT

housing.

Batteries in heat-sealed plastic, bubble-

wrap outer sleeve, and strong packaging.

2 screws

securing

connector

end cap

(screws

shown

partially

removed)

Cable

mounting

guide

Molex connector

O-rings

Twist end cap

counter clockwise,

twisting cap screw

out of machined slot;

end cap releases

from housing.

Manual revision 019 Section 3: Preparing MicroCAT for Deployment SBE 37-SMP RS-232

18

2. Remove the battery pack assembly from the housing:

A. Loosen the captured screw from the battery cover plate, using the

7/64-inch Allen wrench included with the shipment.

B. Lift the battery pack assembly straight out of the housing, using

the handle.

3. Keep the handle in an upright position. Holding the edge of the yellow

cover plate, unscrew the cover plate from the battery pack assembly.

Note: Older MicroCATs used a battery pack with a red cover plate; the

wiring of that pack is different from this one, and cannot be used with

this MicroCAT.

4. Roll the 2 O-rings on the outside of the battery pack out of their grooves.

5. Insert each battery into the pack, alternating positive (+) end first and

negative (-) end first to match the labels on the pack.

6. Roll the 2 O-rings on the outside of the battery pack into place in the

grooves. The O-rings compress the side of the battery pack and hold the

batteries tightly in place in the pack.

7. Reinstall the battery pack cover plate:

A. Align the pin on the battery cover plate PCB with the post hole in the

battery pack housing.

B. Place the handle in an upright position. Screw the yellow cover plate

onto the battery pack assembly. Ensure the cover is tightly screwed

on to provide a reliable electrical contact.

8. Replace the battery pack assembly in the housing:

A. Align the D-shaped opening in the cover plate with the pins on the

shaft. Lower the assembly slowly into the housing, and once aligned,

push gently to mate the banana plugs on the battery compartment

bulkhead with the lower PCB. A post at the bottom of the battery

compartment mates with a hole in the battery pack’s lower PCB to

prevent improper alignment.

B. Secure the assembly to the shaft with the captured screw, using the

7/64-inch Allen wrench. Ensure the screw is tight to provide a

reliable electrical contact.

9. Reinstall the I/O connector end cap:

A. Remove any water from the O-rings and mating surfaces in the

housing with a lint-free cloth or tissue. Inspect the O-rings and

mating surfaces for dirt, nicks, and cuts. Clean as necessary. Apply a

light coat of O-ring lubricant (Parker Super O Lube) to the O-rings

and mating surfaces.

B. Plug the female end of the Molex connector onto the pins.

C. Carefully fit the end cap into the housing until the O-rings are

fully seated.

D. Reinstall the cap screws to secure the end cap.

Handle

Loosen

captured

screw

Roll 2

O-rings

out of

grooves

Roll

2 O-rings

into

grooves

after

inserting

batteries

Align pin in cover

plate with post hole

in battery pack

Pins on

shaft

Manual revision 019 Section 3: Preparing MicroCAT for Deployment SBE 37-SMP RS-232

19

Software Installation

Seasoft V2 was designed to work with a PC running Windows XP service

pack 2 or later, Windows Vista, or Windows 7.

If not already installed, install Sea-Bird software programs on your computer

using the supplied software CD:

1. Insert the CD in your CD drive.

2. Install software: Double click on SeasoftV2.exe. Follow the dialog box

directions to install the software. The installation program allows you to

install the desired components. Install all the components, or just install

Deployment Endurance Calculator (battery endurance calculator),

SeatermV2 (terminal program launcher for the MicroCAT), and

SBE Data Processing (data processing).

The default location for the software is c:\Program Files\Sea-Bird. Within that

folder is a sub-directory for each program.

Power and Communications Test

The power and communications test will verify that the system works,

prior to deployment.

Test Setup

1. Remove dummy plug (if applicable):

A. By hand, unscrew the locking sleeve from the MicroCAT’s bulkhead

connector. If you must use a wrench or pliers, be careful not to loosen

the bulkhead connector instead of the locking sleeve.

B. Remove the dummy plug from the MicroCAT’s I/O bulkhead

connector by pulling the plug firmly away from the connector.

2. Standard Connector - Install the I/O cable connector, aligning the raised

bump on the side of the connector with the large pin (pin 1 - ground) on

the MicroCAT. OR

MCBH Connector – Install the I/O cable connector, aligning the pins.

3. Connect the I/O cable connector to your computer’s serial port.

Notes:

•Help files provide detailed

information on the software.

A separate software manual

on the CD-ROM contains

detailed information on

SBE Data Processing.

•It is possible to use the MicroCAT

without the SeatermV2 terminal

program by sending direct

commands from a dumb terminal or

terminal emulator, such as Windows

HyperTerminal.

•Sea-Bird supplies the current

version of our software when you

purchase an instrument. As software

revisions occur, we post the revised

software on our FTP site. See our

website (www.seabird.com) for the

latest software version number, a

description of the software changes,

and instructions for downloading the

software from the FTP site.

Locking sleeve

I/O cable

Manual revision 019 Section 3: Preparing MicroCAT for Deployment SBE 37-SMP RS-232

20

Test

1. Double click on SeatermV2.exe. The main screen looks like this:

SeatermV2 is a launcher, and launches the appropriate terminal program

for the selected instrument.

2. In the Instruments menu, select SBE 37 RS232.

Seaterm232 opens; the main screen looks like this:

•Menus – For tasks and frequently executed instrument commands.

•Send Commands window – Contains commands applicable to your

MicroCAT. The list appears after you connect to the MicroCAT.

•Command/Data Echo Area – Title bar of this window shows

Seaterm232’s current comm port and baud rate. Commands and the

MicroCAT responses are echoed here. Additionally, a command can

be manually typed or pasted (ctrl + V) here. Note that the MicroCAT

must be connected and awake for it to respond to a command.

•Status bar – Provides connection, upload, script, and capture status

information.

Note:

See SeatermV2’s Help files.

If uploading

- upload file name.

If sending XML script

– script file name

Capture

status

Progress bar for

uploading data

Status –

Ready,

Uploading,

Finished

Upload, etc.

Status Bar

Command/Data Echo Area

Send Commands

Window

Menus

Note:

See Seaterm232’s Help files.

Table of contents

Other Sea-Bird Electronics Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Omega

Omega PX2088 user guide

Emerson

Emerson DIXELL XWEB1000D PRO Installing and operating instructions

Endress+Hauser

Endress+Hauser Cubemass DCI technical information

Teledyne Lecroy

Teledyne Lecroy HVD3000 Series Operator's manual

Decagon Devices

Decagon Devices SC-1 quick start guide

General

General CT6235B user manual