Sea-Bird Scientific SBE 19plus V2 SeaCAT Quick manual

19plus V2 BUM

SBE 19plus V2 SeaCAT

09/2022, Edition A

Basic user manual

Basic user manual

Basic user manual

Table of Contents

English..............................................................................................................................3

Deutsch.......................................................................................................................... 15

Español.......................................................................................................................... 28

2

Table of Contents

1 SBE 19plus V2 quick start guide on page 3

2 Specifications on page 4

3 Replace alkaline batteries on page 7

4 Charge NiMH batteries on page 8

5 Antifouling devices on page 10

6 General information on page 12

Section 1 SBE 19plus V2 quick start guide

This quick start guide and user manual applies to the SBE 19plus V2 SeaCAT. The full user manual,

with details about setup, operation, and maintenance can be found on the manufacturer's website.

Refer to the full user manual for details about topics shown in italics.

What's in the box:

• CD or USB drive with software, calibration files, documentation

• Dummy plugs and lock collars for each bulkhead connector

• Data I/O cable to connect the sensor to a PC

• Non-ionic surfactant to clean sensor flow path

• Conductivity cell tubing and storage kit

• Spare hardware and O-ring kit.

1. Install the manufacturer-supplied software on a PC. Refer to Install software for details.

2. Connect the data I/O cable to the sensor and the PC and double-click on SeaTermV2.exe to start

the software.

3. If necessary, install new batteries. Refer to Replace alkaline batteries or Recharge NiMH

batteries for details.

4. Make sure that all data stored in the sensor is transmitted to a PC.

5. Set the date and time and configure the data collection settings.

6. Install dummy plugs and lock collars on bulkhead connectors that are not used.

7. If necessary, remove the end-to-end loop of Tygon® tubing from around the conductivity cell. It is

used when the SeaCAT is in storage.

8. Connect the tubing from the pump to the conductivity cell.

9. Send the DS and DCal commands to verify status and calibration coefficients.

10. Moored Mode (MM): use StartNow to start data collection every SampleInterval= x seconds.

11. Moored Mode (MM): use StartDateTime= and StartLater to start data collection at a specified

date and time, every SampleInterval=seconds.

12. Profile Mode (MP), as necessary:

• Put the magnetic switch in the On position, or

• If IgnoreSwitch=Y, send commands to start data collection now, with StartNow, or in the future,

with StartDateTime= and StartLater to start data collection at a specified date and time, or

• If AutoRun=Y, apply external power.

13. Deploy the sensor. For most applications, make sure the connector is at the bottom (lowest

point).

14. Immediately after the sensor is recovered from a deployment:

a. Transmit data from the sensor to a PC. Refer to Transmit data for details.

b. Turn off the sensor.

c. Flush the sensor with fresh water.

d. Keep the SeaCAT out of direct sunlight between deployments.

15. Refer to Prepare sensor for storage for details to prepare the sensor for short- or long-term

storage.

English 3

Section 2 Specifications

2.1 Mechanical

Weight, 600 m, plastic, no pump, in air, water 7.3, 2.3 kg

Weight, 10500 m, titanium, no pump, in air, water 13.7, 8.6 kg

Weight, 5M, plastic 0.3, 0.1 kg

Weight, 5M, titanium 0.3, 0.4 kg

Weight, 5T, P, plastic 0.5, 0.1 kg

Weight, 5T, P, titanium 0.7, 0.3 kg

Depth rating, acetal plastic 600 m

Depth rating, 3AL–2.5V titanium 7000 m

Depth rating, 6AL–4V titanium 10500 m

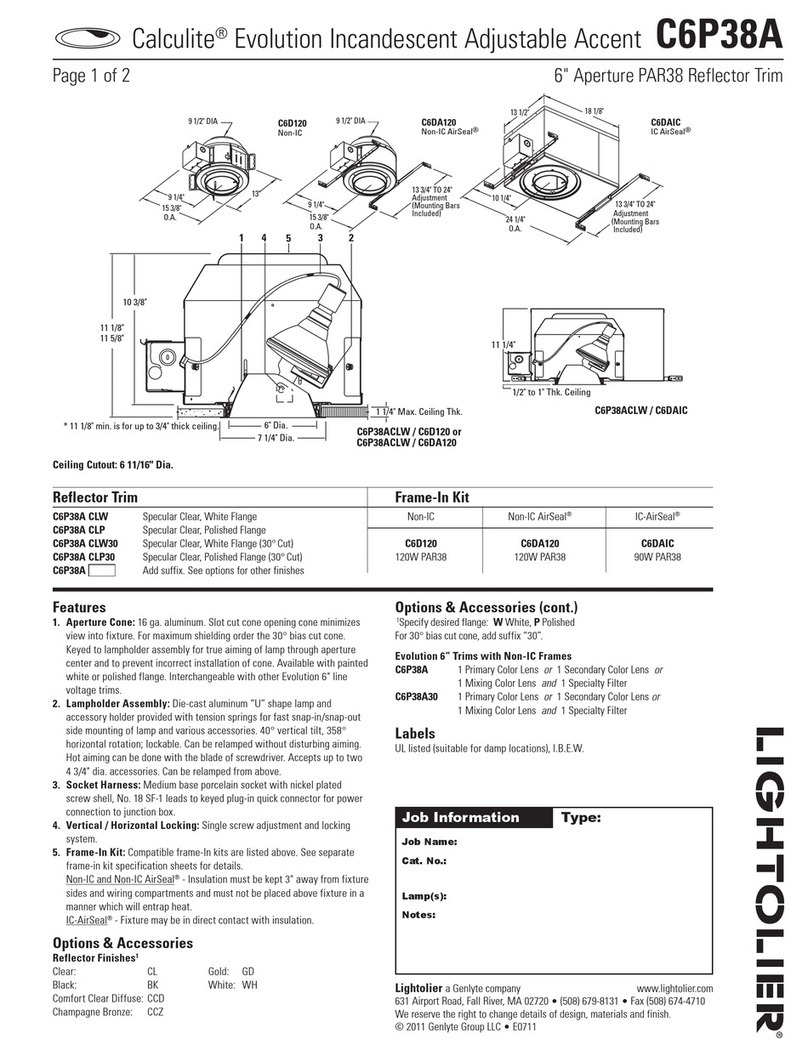

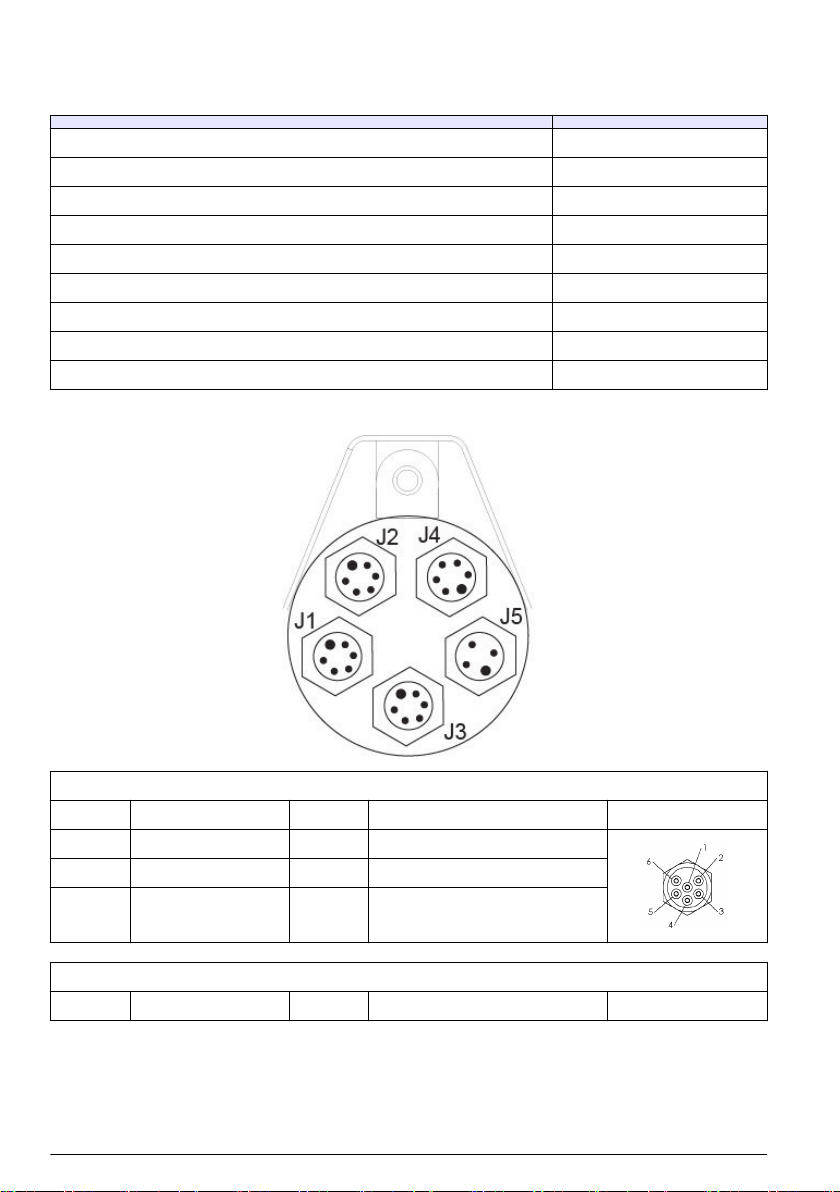

2.1.1 Connectors and cables

J1 auxiliary differential input 0,1

Contact Function Contact Function MCBH6MP

1 Common 4 Voltage 1 signal

2 Voltage 0 signal 5 Voltage 1 common

3 Voltage 0 common 6 Auxiliary power out

J2 auxiliary differential input 2, 3

Contact Function Contact Function MCBH6MP

4 English

1 Common 4 Voltage 3 signal

2 Voltage 2 signal 5 Voltage 3 common

3 Voltage 2 common 6 Auxiliary power out

J3 data I/O, pump, external power

Contact Function Contact Function MCBH6MP

1 Common 4 Pump power common

2 RS232 data RX 5 Pump power

3 RS232 data TX 6 Auxiliary power in, 9–28 VDC

J4 auxiliary differential input 4, 5

Contact Function Contact Function MCBH6MP

1 Common 4 Voltage 5 signal

2 Voltage 4 signal 5 Voltage 5 common

3 Voltage 4 common 6 Auxiliary power out

J5 auxiliary serial input

sensor and 19plus must be set to the same baud rate

Contact Function MCBH4MP

1 Common

2 RS232 data transmit to RS232 sensor

3 RS232 data receive from RS232 sensor

4 Power to RS232 sensor

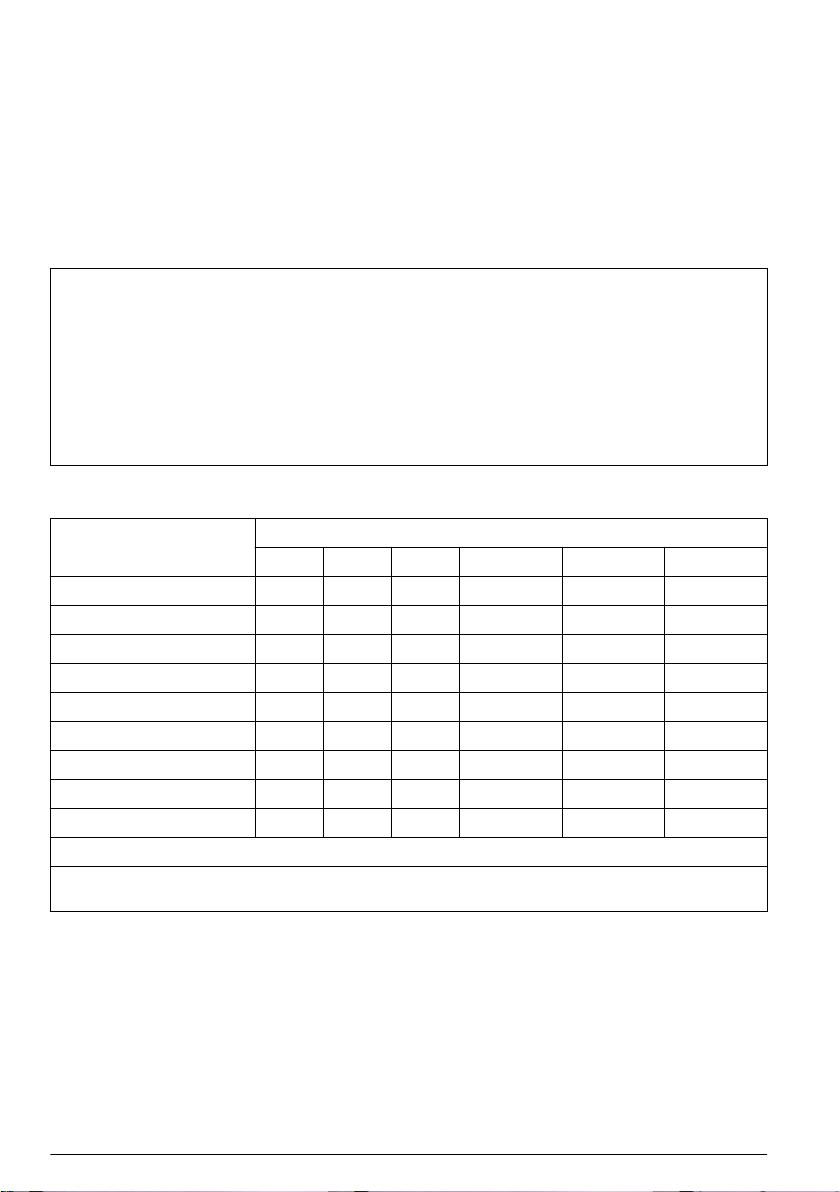

Figure 1 Y cable

English 5

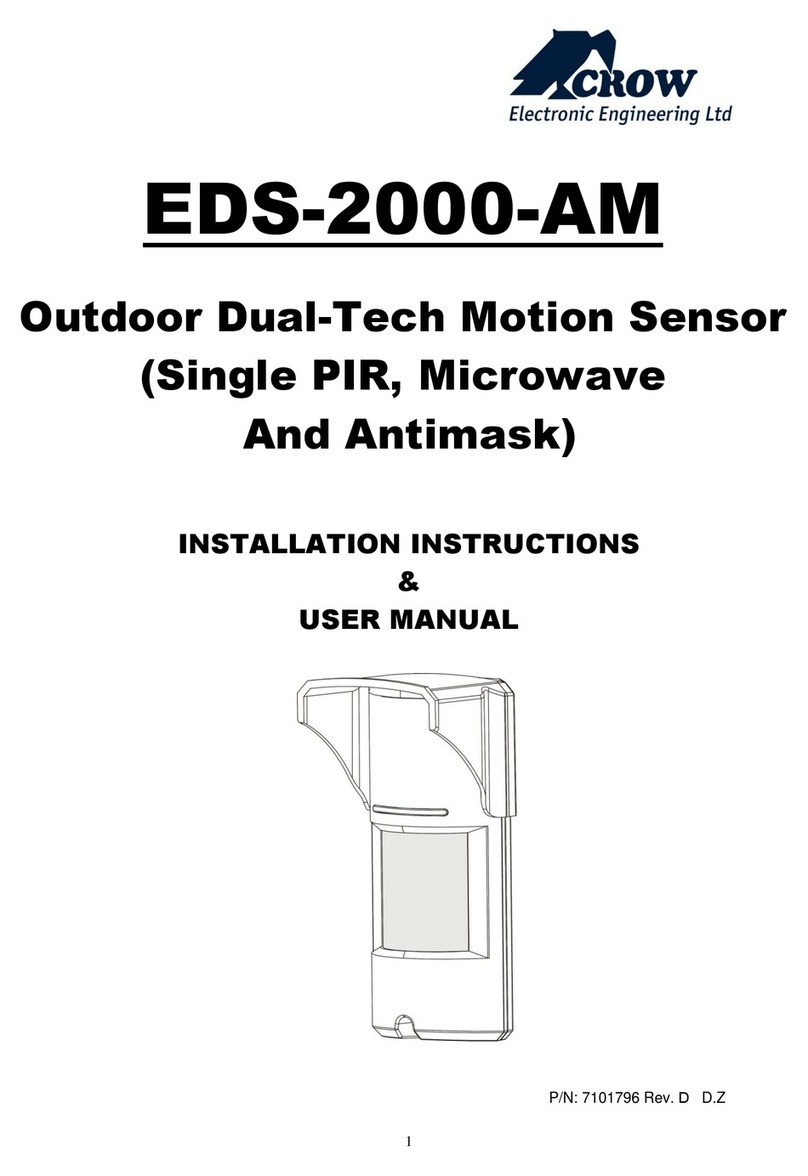

Figure 2 Data I/O cable

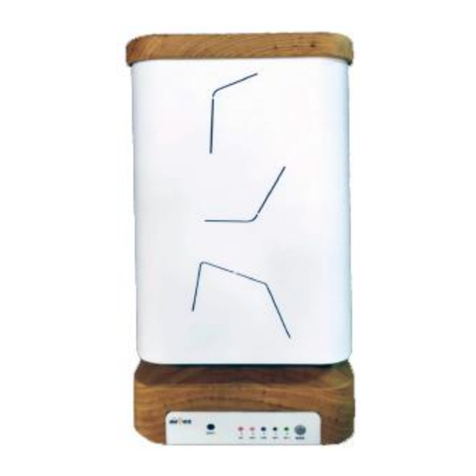

Figure 3 SBE 5 to CTD cable

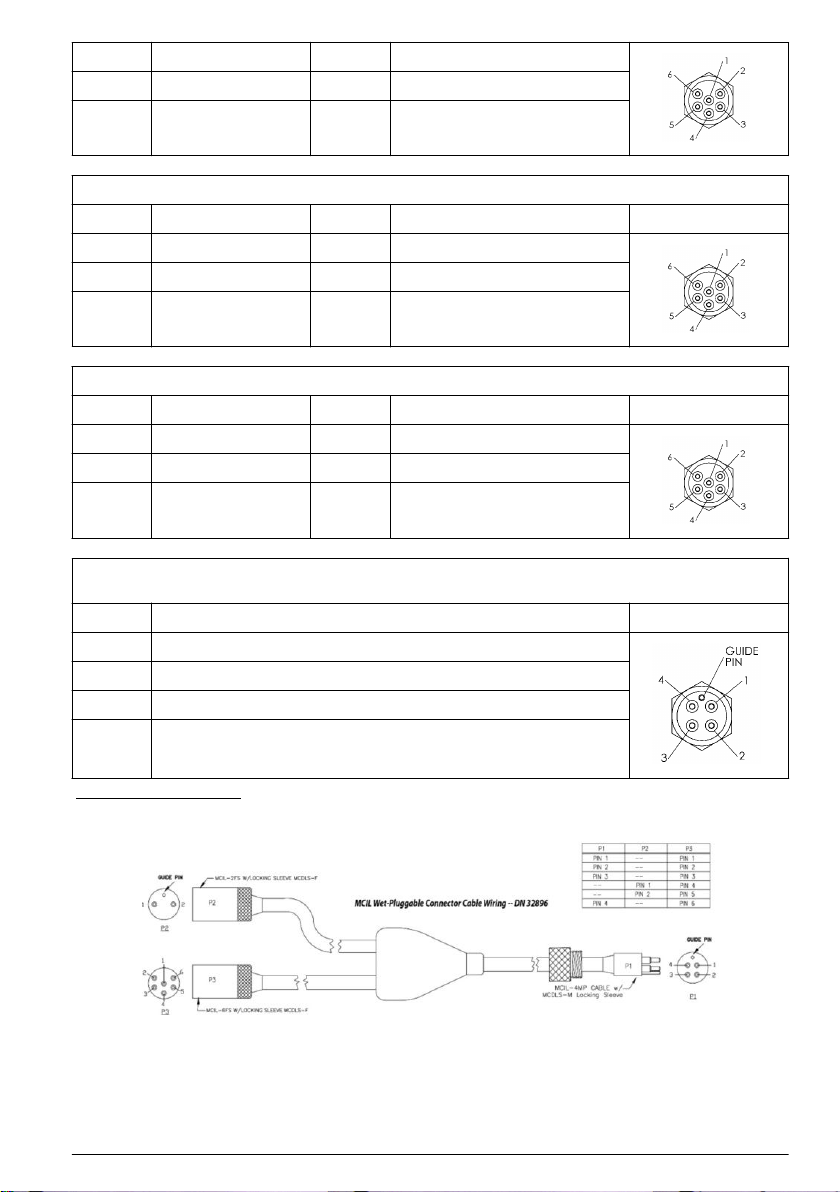

2.1.2 Dimensions

2.2 Electrical and communications

Input from external power supply 9–28 VDC

Current draw from external power supply, 5M 3 A at 9V, 0.5 A at 12V and 19V

Current draw from external power supply, 5T, 5P 3 A at 12V, 1.5 A at 19V

Current draw, data collection 70 mA

Current draw, 5M pump 100 mA

Current draw, 5T, 5P 150 mA

Current draw, communications 65 mA

Current draw, low power (powered by internal batteries) 20 µA

Internal battery capacity, 9 alkaline D-cells 14 Ah

Internal battery capacity, NiMH pack 8 Ah

Auxiliary power out at 10.5–11 VDC to 500 mA

Voltage A/D resolution 14 bits

Voltage sensor input range 0–5 VDC

Memory 64 MB Flash

6 English

Communication interface RS232

Data collection rate 4 Hz

2.3 Analytical

Parameter Range Accuracy Stability Resolution

Conductivity 0–9 ±±0.005 V 0.0003 S/m per month 0.00007 S/m

Temperature -5–35 °C ±0.005 V 0.0002 °C/mo 0.0001 °C

Pressure,

strain gauge

various to 10,500 m ±0.1% full scale

range

±0.1% full scale range 0.002% full scale

range

Pressure,

quartz

various to 10,500 m ± 0.02% ± 0.02% 0.0025% of full scale

range

Section 3 Replace alkaline batteries

WARNING

If the user thinks that a sensor has water in the pressure housing: Disconnect the sensor from any

power supply. Put on safety glasses and make sure that the sensor is pointed away from the body

and other people. In a well ventilated area, use the purge port (if the sensor is so equipped), or very

SLOWLY loosen the bulkhead connector to let the pressure release.

WARNING

If the user thinks that the alkaline batteries have leaks, pressure may have built up inside of the

pressure housing. Follow ESD protocols to release internal pressure. Put on safety glasses and

protective gloves and make sure that the sensor is pointed away from the body and other people. In

a well ventilated very SLOWLY loosen the bulkhead connector to release the pressure. Keep away

from heat, sparks, flame, and other sources of ignition. Do not smoke.

CAUTION

The pressure housing contains Electrostatic Discharge (ESD) sensitive parts and assemblies that

are susceptible to damage from ESD. Follow ESD protocols:

• Put on protective eye wear before you open the pressure housing.

• Any electrostatic charge on the body of the human operator must be released before the

pressure housing is opened: put a hand on a grounded surface, or better, wear a grounded

antistatic wrist strap.

• At a minimum, wear short-sleeved antistatic clothing, such as cotton, or better, wear an antistatic

smock for this service activity. Do not wear a sweater, fleece or polyester-based clothing.

• At a minimum, use a workstation with a wood or metal tabletop, or better, a tabletop that

dissipates static. Do not use a workstation with a synthetic or polymeric-based tabletop.

1. Use a clean cloth to dry the outside of the battery end flange. Make sure to remove any water at

the interface between the pressure housing and the end flange.

2. Use a wrench on the white plastic bar to turn the end flange counterclockwise to loosen.

English 7

3. Remove any water on all of the O-ring surfaces with a lint-free cloth or tissue.

4. Keep the end flange and make sure to protect the O-ring from contamination or other damage.

5. Remove the three Phillips-head screws and washers from the battery cover plate.

The battery cover plate will pop out.

6. Remove the batteries.

7. Install new batteries. Make sure the + terminal is on the flat battery contacts and the - terminal is

on the spring contacts.

8. Align the battery cover with the housing. The posts inside the housing are asymmetrical, to the

cover fits into the housing only one way.

One screw hole is closer to the edge than the others and aligns with the post that is closest to the

housing.

9. Install the three Phillips-head screws and washers again: push firmly on the cover to make sure

that the spring is fully in contact with the batteries.

Make sure the screws are fully tightened or battery power will be intermittent.

10. Verify that the battery voltage at BAT + and BAT - on the battery cover is approximately 18 V.

11. Make sure all O-ring surfaces are clean and dry. Replace O-rings as necessary.

12. Apply a light coat of silicone-based Parker Super O Lube to the O-ring mating surfaces.

13. Carefully put the end flange onto the housing and screw the end flange into place. Use a wrench

to make sure the cap is tightly installed.

14. Verify that the switch plunger is pulled out so that the Searam is in a low-power mode.

Section 4 Charge NiMH batteries

WARNING

If the user thinks that a sensor has water in the pressure housing: Disconnect the sensor from any

power supply. Put on safety glasses and make sure that the sensor is pointed away from the body

and other people. In a well ventilated area, use the purge port (if the sensor is so equipped), or very

SLOWLY loosen the bulkhead connector to let the pressure release.

8 English

WARNING

If the user thinks that the NiMH batteries have leaks, pressure may have built up inside of the

pressure housing. Follow ESD protocols to release internal pressure. Put on safety glasses and

protective gloves and make sure that the sensor is pointed away from the body and other people. In

a well ventilated very SLOWLY loosen the bulkhead connector to release the pressure. Keep away

from heat, sparks, flame, and other sources of ignition. Do not smoke.

CAUTION

The pressure housing contains Electrostatic Discharge (ESD) sensitive parts and assemblies that

are susceptible to damage from ESD. Follow ESD protocols:

• Put on protective eye wear before you open the pressure housing.

• Any electrostatic charge on the body of the human operator must be released before the

pressure housing is opened: put a hand on a grounded surface, or better, wear a grounded

antistatic wrist strap.

• At a minimum, wear short-sleeved antistatic clothing, such as cotton, or better, wear an antistatic

smock for this service activity. Do not wear a sweater, fleece or polyester-based clothing.

• At a minimum, use a workstation with a wood or metal tabletop, or better, a tabletop that

dissipates static. Do not use a workstation with a synthetic or polymeric-based tabletop.

It is not necessary to remove the battery pack from the housing to charge the NiMH batteries (steps

5 and 12).

1. Use a clean cloth to dry the outside of the battery end flange. Make sure to remove any water at

the interface between the pressure housing and the end flange.

2. Use a wrench on the white plastic bar to turn the end flange counterclockwise to loosen.

3. Remove any water on all of the O-ring surfaces with a lint-free cloth or tissue.

4. Keep the end flange and make sure to protect the O-ring from contamination or other damage.

5. Remove the battery pack from the housing:

a. Unscrew each of the three cap screws just until they reach the bottom of the protective

plastic plate.The battery pack will come out of the housing approximately 6 mm because of

the spring contacts at the bottom of the battery compartment.

b. Unscrew the cap screws again. The battery pack will come further out of the housing and

should now be disconnected from the battery posts.

c. Pull on the cord to remove the battery pack from the housing.

6. Connect the battery charger to a power source and turn on power to the charger.

7. Connect the charger cable to the battery pack and charger.

The LED shows READY, and the display shows the battery type and voltage.

English 9

8. Push the DISCHARGE button on the charger.

This starts the discharge cycle, so that any voltage in the batteries is discharged. This increases

the life of the batteries. Discharge takes approximately 75 minutes. When complete, the LED

shows EMPTY.

9. Push the CHARGE button.

The LED shows FAST CHARGE (or WARM-UP CHARGE, or REFILL CHARGE, or TOP-OFF.)

The FAST CHARGE cycle takes approximately 2 hours. The REFILL CHARGE takes

approximately 15 hours. When the batteries are charged, the LED shows BATTERY FULL.

10. Turn off power to the charger.

11. Disconnect the charger cable from the battery pack and the power supply.

12. Install the battery pack into the housing again:

a. The battery pack fits tightly in the housing. Align it carefully and slowly insert it straight into the

housing. Be careful not to tear the shrink wrap on the battery pack.

b. Install the three cap screws into the top plate.

c. Push firmly on the protective plastic plate to make sure that the spring is fully in contact with

the batteries.

d. Make sure that the screws are fully tightened or the battery power will be intermittent.

13. Carefully put the end flange onto the housing and screw the end flange into place. use a wrench

to make sure the cap is tightly installed.

14. Verify that the switch plunger is pulled out so that the Searam is in a low power mode.

Section 5 Antifouling devices

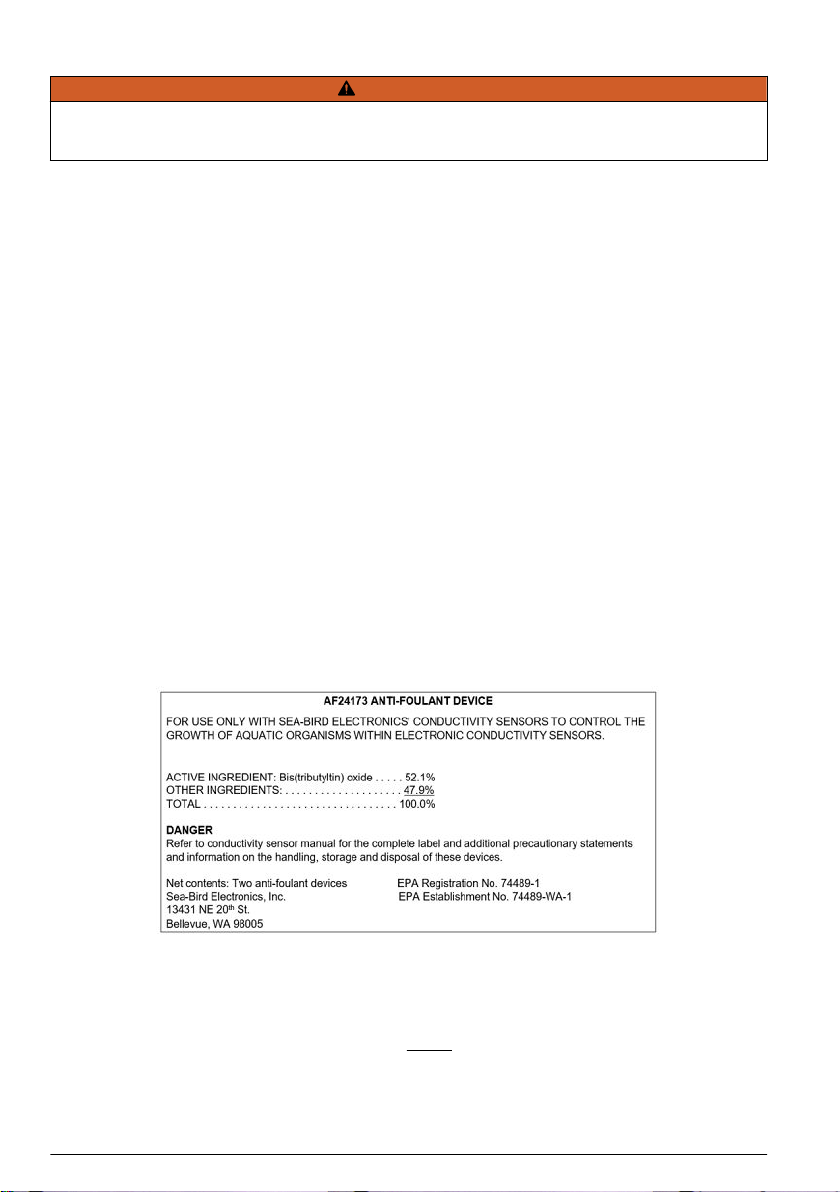

CAUTION

AF24173 anti-fouling devices contain bis(tributyltin) oxide. Wear rubber or latex gloves and eye protection to

replace these devices on the sensor if it is so equipped. Wash hands with soap and water when finished.

Read the precautions on the product label.

It is a violation of US federal law to use this product in a manner that is inconsistent with its label.

5.1 Verify anti-fouling devices

New sensors have two anti-fouling devices and a yellow protective label installed by the

manufacturer.

10 English

N O T I C E

Make sure to remove the label before the sensor is deployed or pressurized or the conductivity cell can be

damaged.

1. Remove the yellow label.

• The user can make sure the anti-fouling devices are installed: refer to "Remove or replace anti-

fouling devices" for details.

2. Keep the label to attach again to protect the intake and exhaust ports when the sensor is not

deployed.

5.2 Remove or replace anti-fouling devices

Remove the anti-fouling devices as a first maintenance task to save the anti-fouling material for

deployments.

1. Use a 5/32 inch hex wrench to loosen the two captured cap screws that attach the copper anti-

fouling assembly to the plastic assembly on the pressure housing. Carefully remove the copper

anti-fouling assembly from the housing.

2. Remove the three Phillips-head screws from the copper anti-fouling assembly, and pull the

copper guard off of the plastic anti-fouling holder.

3. Remove the protective plug from the anti-fouling device cup.

4. Use a toothpick to lift each of the anti-fouling devices out of the holder. If necessary, use needle-

nose pliers to carefully break up the device.

Option Procedure

To deploy sensor Insert new anti-fouling devices into the cup, then install the cap onto the cup. Do not

tighten too tight.

Attach the copper assembly to the sensor again.

To clean or store

sensor

Do not insert new anti-fouling devices. Install the protective plug. Make sure to remove

the plug before the next deployment or pressurization of the sensor. Damage to the

conductivity cells can be caused if the plugs are not removed.

English 11

Section 6 General information

WARNING

This product can expose the user to chemicals with silica, crystalline (airborne particles of respirable size), which

is known to the State of California to cause cancer and birth defects or other reproductive harm. For more

information, go to www.P65Warnings.ca.gov.

6.1 Warranty

Refer to the manufacturer's website for warranty information (seabird.com/warranty).

6.2 Service and support

The manufacturer recommends that sensors be sent back to the manufacturer annually to be

cleaned, calibrated, and for standard maintenance.

Refer to the website for FAQs and technical notes, or contact the manufacturer for support at

[email protected]. Do the steps below to send a sensor back to the manufacturer.

1. Complete the online Return Merchandise Authorization (RMA) form or contact the manufacturer.

Note: The manufacturer is not responsible for damage to the sensor during return shipment.

2. Remove all batteries from the sensor, if so equipped.

3. Remove all anti-fouling treatments and devices.

Note: The manufacturer will not accept sensors that have been treated with anti-fouling compounds for service

or repair. This includes AF 24173 devices, tri-butyl tin, marine anti-fouling paint, ablative coatings, etc.

4. Use the sensor's original ruggedized shipping case to send the sensor back to the manufacturer.

5. Write the RMA number on the outside of the shipping case and on the packing list.

6. Use 3rd-day air to ship the sensor back to the manufacturer. Do not use ground shipping.

7. The manufacturer will supply all replacement parts and labor and pay to send the sensor back to

the user via 3rd-day air shipping.

6.3 AF24173 anti-foulant device

AF24173 Anti-Foulant Devices supplied for user replacement are supplied in polyethylene bags

displaying the following label:

AF24173 ANTI-FOULANT DEVICE

FOR USE ONLY WITH SEA-BIRD ELECTRONICS' CONDUCTIVITY SENSORS TO CONTROL

THE GROWTH OF AQUATIC ORGANISMS WITHIN ELECTRONIC CONDUCTIVITY SENSORS.

ACTIVE INGREDIENT: Bis(tributyltin) oxide . . . . . 52.1%

OTHER INGREDIENTS: . . . . . . . . . . . . . . . . . . . . 47.9%

TOTAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100.0%

DANGER

See Precautionary Statements for additional information.

12 English

FIRST AID

If in eyes • Hold the eye open and rinse slowly and gently with water for 15–20 minutes.

• Remove contact lenses, if present, after the first 5 minutes, then continue rinsing

eye.

• Call a poison control center or doctor for treatment advice.

If on skin or clothing • Take off contaminated clothing.

• Rinse skin immediately with plenty of water for 15–20 minutes.

• Call a poison control center or doctor for treatment advice.

If swallowed • Call poison control center or doctor immediately for treatment advice.

• Have person drink several glasses of water.

• Do not induce vomiting.

• Do not give anything by mouth to an unconscious person.

HOT LINE NUMBER

Note to Physician Probable mucosal damage may contraindicate the use of gastric lavage.

Have the product container or label with you when calling a poison control center or doctor, or going for

treatment. For further information, call National Pesticide Telecommunications Network (NPTN) at

1-800-858-7378.

Net contents: Two anti-foulant devices

Sea-Bird Electronics, Inc.

13431 NE 20th St.

Bellevue, WA 98005

EPA Registration No. 74489-1

EPA Establishment No. 74489-WA-1

PRECAUTIONARY STATEMENTS

HAZARD TO HUMANS AND DOMESTIC ANIMALS

Danger:

Corrosive—Causes irreversible eye damage and skin burns. May be fatal if swallowed or absorbed

through the skin. Do not get in eyes, on skin, or on clothing. Wash thoroughly with soap and water

after handling and before eating, drinking, chewing gum, using tobacco, or using the toilet. Remove

and wash contaminated clothing before reuse.

PERSONAL PROTECTIVE EQUIPMENT

Users must wear: protective gloves (rubber or latex), goggles or other eye protection, long-sleeved

shirt, long pants, and shoes plus socks.

USER SAFETY RECOMMENDATIONS

Users should:

• Remove clothing immediately if pesticide gets inside. Then wash thoroughly and put on clean clothing.

• Follow the manufacturer's instructions for cleaning and maintaining PPE. If no such instructions for washables,

use detergent and hot water. Keep and wash PPE separately from other laundry.

ENVIRONMENTAL HAZARDS

Do not discharge effluent containing this product into lakes, streams, ponds, estuaries, oceans, or

other waters unless in accordance with the requirements of a National Pollutant Discharge

Elimination System (NPDES) permit and the permitting authority has been notified in writing prior to

discharge. Do not discharge effluent containing this product to sewer systems without previously

notifying the local sewage treatment plant authority. For guidance contact your State Water Board or

English 13

Regional Office of EPA. This material is toxic to fish. Do not contaminate water when cleaning

equipment or disposing of equipment washwaters.

PHYSICAL OR CHEMICAL HAZARDS

Do not use or store near heat or open flame. Avoid contact with acids and oxidizers.

DIRECTIONS FOR USE

It is a violation of Federal Law to use this product in a manner inconsistent with its labeling.

For use only in Sea-Bird Electronics' conductivity sensors. Read installation instructions in the

applicable Conductivity Instrument Manual.

Intended for professional use by military, government, academic, commercial, and scientific

personnel.

STORAGE AND DISPOSAL

PESTICIDE STORAGE: Store in original container in a cool, dry place. Prevent exposure to heat or flame. Do not

store near acids or oxidizers. Keep container tightly closed.

PESTICIDE SPILL PROCEDURE: In case of a spill, absorb spills with absorbent material. Put saturated

absorbent material into a labeled container for treatment or disposal.

PESTICIDE DISPOSAL: Pesticide that cannot be used according to label instructions must be disposed of

according to Federal or approved State procedures under Subtitle C of the Resource Conservation and Recovery

Act.

CONTAINER HANDLING: Nonrefillable container. Do not reuse this container for any other purpose. Offer for

recycling, if available.

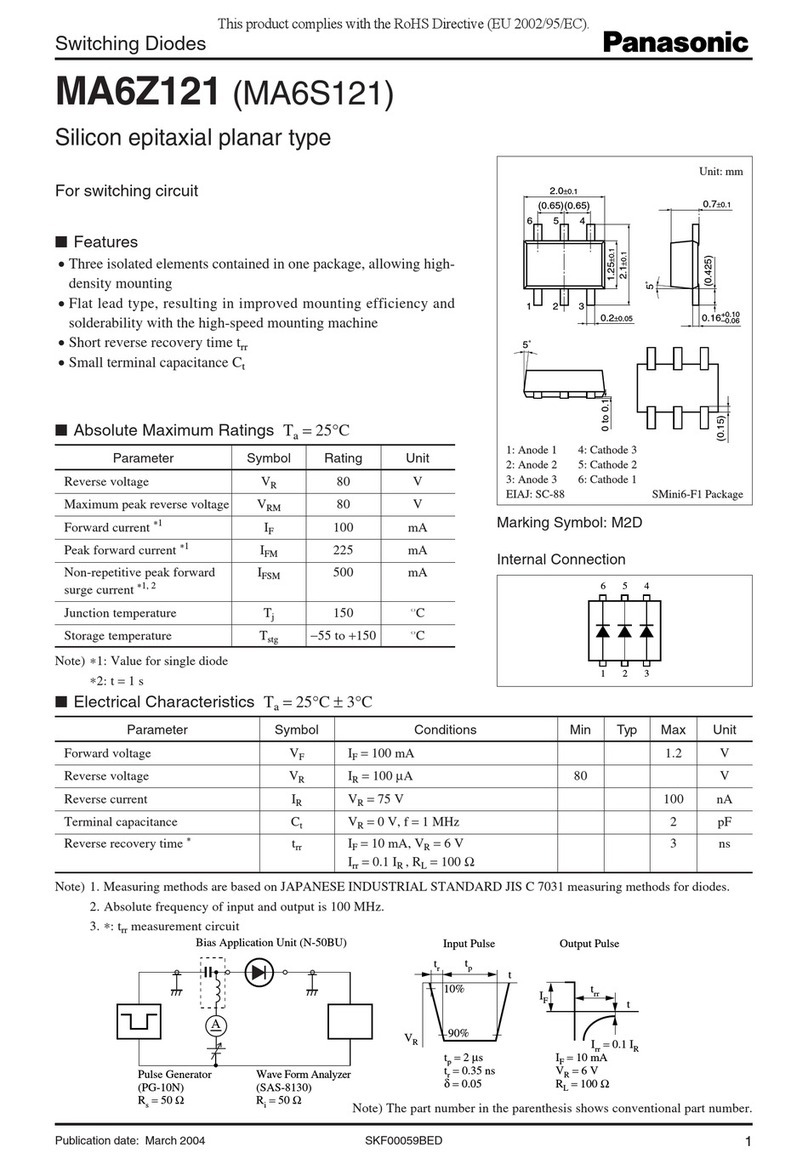

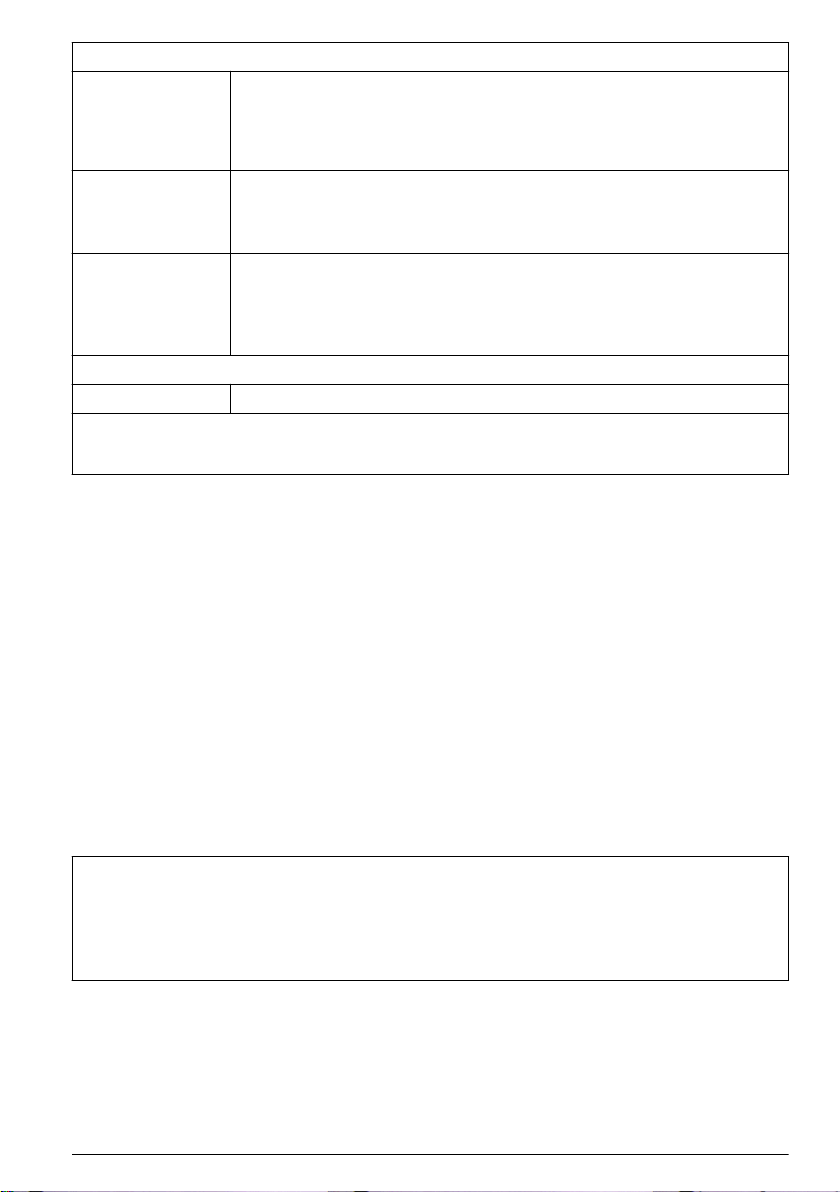

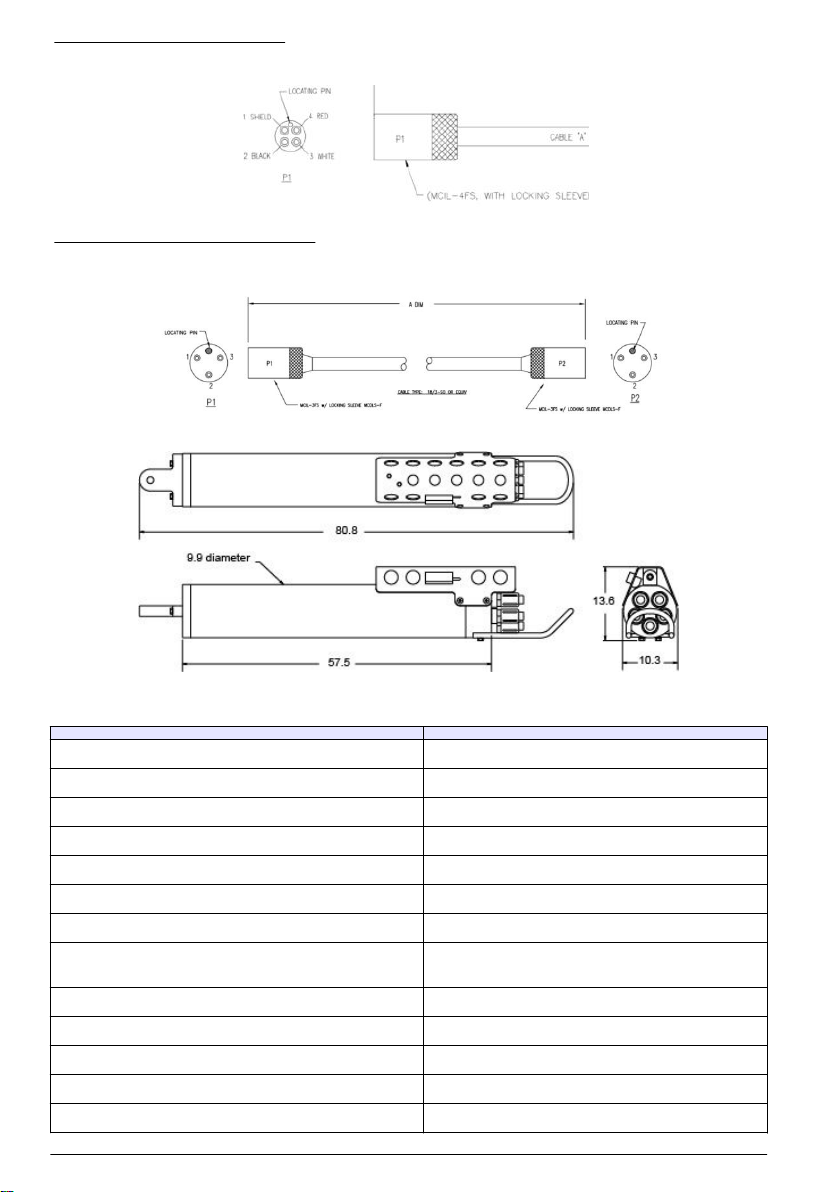

6.4 China RoHS disclosure table

Name of Part Hazardous substance or element in product

Pb Hg Cd Cr(VI)) PBB PBDE

PCBs X O O O O O

Conductivity cell X O O O O O

Battery pack O O O O O O

Cables X O O O O O

Housing O O O O O O

Plumbing O O O O O O

Frame O O O O O O

Mounting hardware O O O O O O

Accessories O O O O O O

This table is compiled to the SJ/T 11364 standard.

O: This hazardous substance is below the specified limits as described in GB/T 26572.

X: This hazardous substance is above the specified limits as described in GB/T 26572.

14 English

Inhaltsverzeichnis

1 SBE 19plus V2 Kurzanleitung auf Seite 15

2 Technische Daten auf Seite 16

3 Alkalibatterien austauschen auf Seite 19

4 NiMH-Akkus aufladen auf Seite 21

5 Antifouling-Vorrichtungen auf Seite 23

6 Allgemeine Informationen auf Seite 24

Kapitel 1 SBE 19plus V2 Kurzanleitung

Diese Kurzanleitung und Bedienungsanleitung gilt für den SBE 19plus V2 SeaCAT. Das vollständige

Benutzerhandbuch mit Einzelheiten zu Einrichtung, Betrieb und Wartung finden Sie auf der Website

des Herstellers. Ausführliche Informationen zu den kursiv dargestellten Themen finden Sie im

vollständigen Benutzerhandbuch.

Im Lieferumfang enthalten:

• CD oder USB-Laufwerk mit Software, Kalibrierungsdateien und Dokumentation

• Blindstopfen und Schließringe für jeden Schottanschluss

• Daten-E/A-Kabel zum Anschließen des Sensors an einen PC

• Nichtionisches Tensid zur Reinigung des Sensor-Durchflusswegs

• Schläuche für Leitfähigkeitszelle und Aufbewahrungskit

• Ersatz-Kleinteile und Satz O-Ringe

1. Installieren Sie die vom Hersteller bereitgestellte Software auf einem PC. Weitere Informationen

finden Sie unter Software installieren.

2. Schließen Sie das Daten-E/A-Kabel an den Sensor und den PC an, und doppelklicken Sie auf

SeaTermV2.exe, um die Software zu starten.

3. Setzen Sie bei Bedarf neue Batterien ein. Einzelheiten dazu finden Sie unter Alkalibatterien

austauschen oder NiMH-Akkus aufladen.

4. Stellen Sie sicher, dass alle im Sensor gespeicherten Daten an einen PC übertragen werden.

5. Stellen Sie Datum und Uhrzeit ein, und konfigurieren Sie die Einstellungen für die

Datenerfassung.

6. Bringen Sie an nicht benutzten Schottanschlüssen Blindstopfen und Schließringe an.

7. Entfernen Sie bei Bedarf den umlaufenden Tygon® Schlauch, der die Leitfähigkeitszelle umgibt.

Dieser wird verwendet, wenn der SeaCAT eingelagert wird.

8. Verbinden Sie die Schläuche von der Pumpe mit der Leitfähigkeitszelle.

9. Senden Sie die DS- und DCal-Befehle, um Status und Kalibrierungskoeffizienten zu verifizieren.

10. Moored Mode (MM, Modus für festen Standort): Verwenden Sie StartNow, um die

Datenerfassung alle SampleInterval= x Sekunden zu starten.

11. Moored Mode (MM, Modus für festen Standort): Verwenden Sie StartDateTime= und StartLater,

um die Datenerfassung zu einem bestimmten Datum und Zeitpunkt alle

SampleInterval=Sekunden zu starten.

12. Profile Mode (MP, Profil-Modus), bei Bedarf:

• Stellen Sie den Magnetschalter in die Position Ein, oder

• Wenn IgnoreSwitch=Y, senden Sie Befehle zum Starten der Datenerfassung jetzt, mit

StartNow, oder in der zukunft, mit StartDateTime= und StartLater, um die Datenerfassung zu

einem bestimmten Datum und einer bestimmten Zeit zu starten, oder

• Wenn AutoRun=Y, schließen Sie eine externe Stromversorgung an.

13. Setzen Sie den Sensor ein. Bei den meisten Anwendungen muss sich der Anschluss unten

befinden (unterster Punkt).

14. Unmittelbar nach Einsatz des Sensors:

a. Übertragen Sie die Daten vom Sensor an einen PC. Weitere Informationen finden Sie unter

Daten übertragen.

b. Schalten Sie den Sensor aus.

Deutsch 15

c. Den Sensor mit frischem Wasser spülen.

d. Den SeaCAT zwischen den Einsätzen vor direktem Sonnenlicht schützen.

15. Weitere Informationen zur Vorbereitung des Sensors auf eine kurz- oder langfristige Lagerung

finden Sie unter Sensor für die Lagerung vorbereiten.

Kapitel 2 Technische Daten

2.1 Mechanische Daten

Gewicht, 600 m, Kunststoff, keine Pumpe, in Luft, Wasser 7,3, 2,3 kg

Gewicht, 10500 m, Titan, keine Pumpe, in Luft, Wasser 13,7, 8,6 kg

Gewicht, 5M, Kunststoff 0,3, 0,1 kg

Gewicht, 5M, Titan 0,3, 0,4 kg

Gewicht, 5T,P, Kunststoff 0,5, 0,1 kg

Gewicht, 5T, P, Titan 0,7, 0,3 kg

Nenntiefe, Acetal-Kunststoff 600 m

Nenntiefe, 3 AL–2,5 V Titan 7000 m

Nenntiefe, 6 AL–4 V 10500 m

2.1.1 Anschlüsse und Kabel

J1 zusätzlicher differentieller Eingang 0,1

Kontakt Funktion Kontakt Funktion MCBH6MP

1 Masse 4 Spannung 1 Signal

2 Spannung 0 Signal 5 Spannung 1 Masse

3 Spannung 0 Masse 6 Zusätzlicher Stromausgang

J2 zusätzlicher differentieller Eingang 2, 3

Kontakt Funktion Kontakt Funktion MCBH6MP

16 Deutsch

1 Masse 4 Spannung 3 Signal

2 Spannung 2 Signal 5 Spannung 3 Masse

3 Spannung 2 Masse 6 Zusätzlicher Stromausgang

J3 Daten E/A, Pumpe, externe Stromversorgung

Kontakt Funktion Kontakt Funktion MCBH6MP

1 Masse 4 Pumpenversorgung Masse

2 RS232 Daten RX 5 Pumpenversorgung

3 RS232 Daten TX 6 Zusätzlicher Stromeingang, 9 - 28 V

DC

J4 zusätzlicher differentieller Eingang 4, 5

Kontakt Funktion Kontakt Funktion MCBH6MP

1 Masse 4 Spannung 5 Signal

2 Spannung 4 Signal 5 Spannung 5 Masse

3 Spannung 4 Masse 6 Zusätzlicher Stromausgang

J5 zusätzlicher serieller Eingang

Sensor und 19plus müssen auf die gleiche Baudrate eingestellt sein

Kontakt Funktion MCBH4MP

1 Masse

2 RS232 Datenübertragung an RS232 Sensor

3 RS232 Datenempfang von RS232 Sensor

4 Stromversorgung für RS232 Sensor

Abbildung 1 Y-Kabel

Deutsch 17

Abbildung 2 Daten-E/A-Kabel

Abbildung 3 SBE 5 an CTD-Kabel

2.1.2 Abmessungen

2.2 Elektrik und Kommunikation

Eingang von externer Stromversorgung 9 - 28 V DC

Stromaufnahme von externer Stromversorgung, 5M 3 A bei 9 V, 0,5 A bei 12 V und 19 V

Stromaufnahme von externer Stromversorgung, 5T, 5P 3 A bei bei 12 V, 1,5 A bei 19 V

Stromaufnahme, Datenerfassung 70 mA

Stromaufnahme, 5M Pumpe 100 mA

Stromaufnahme, 5T, 5P 150 mA

Stromaufnahme, Kommunikation 65 mA

Stromaufnahme, geringe Leistung (betrieben mit internen

Batterien)

20 µA

Interne Batteriekapazität, 9 Alkali-D-Zellen 14 Ah

Interne Batteriekapazität, NiMH-Akkupack 8 Ah

Zusätzlicher Stromausgang bei 10,5 - 11 V DC bis 500 mA

Spannung Auflösung A/D 14 Bit

Spannung Sensor-Eingangsbereich 0 - 5 V DC

18 Deutsch

Speicher 64 MB Flash

Kommunikationsschnittstelle RS232

Datenerfassungsrate 4 Hz

2.3 Analytische Daten

Parameter Messbereich Genauigkeit Stabilität Lösung

Leitfähigkeit 0 - 9 ±±0,005 V 0,0003 S/m pro Monat 0,00007 S/m

Temperatur -5 - 35 °C ±0,005 V 0,0002 °C/Monat 0,0001 °C

Druck-/Dehnun

gsmessgerät

verschieden bis

10.500 m

±0,1 % des

Messbereich-

Endpunkts

±0,1 % des Messbereich-

Endpunkts

0,002 % des

Messbereich-

Endpunkts

Druck, Quarz verschieden bis

10.500 m

±0,02 % ±0,02 % 0,0025 % des

Messbereich-

Endpunkts

Kapitel 3 Alkalibatterien austauschen

WARNUNG

Wenn der Benutzer der Meinung ist, dass sich Wasser im Druckgehäuse des Sensors befindet, den

Sensor von der Stromversorgung trennen. Setzen Sie eine Sicherheitsbrille auf, und stellen Sie

sicher, dass der Sensor von Ihrem Körper und anderen Personen weg zeigt. Verwenden Sie den

Auslass (sofern der Sensor über einen solchen verfügt) in einem gut belüfteten Bereich, oder

lockern Sie den Schottanschluss ganz LANGSAM, damit der Druck entweichen kann.

WARNUNG

Wenn der Benutzer der Meinung ist, dass die Alkali-Batterien undicht sind, hat sich möglicherweise

Druck im Druckgehäuse aufgebaut. Befolgen Sie die ESD-Protokolle, um den Innendruck

abzulassen. Tragen Sie eine Sicherheitsbrille und Schutzhandschuhe, und stellen Sie sicher, dass

der Sensor von Ihrem Körper und anderen Personen weg zeigt. Lockern Sie in einem gut belüfteten

Bereich ganz LANGSAM den Schottanschluss, damit der Druck entweichen kann. Von Wärme,

Funken, Flammen und anderen Zündquellen fernhalten. Nicht rauchen.

VORSICHT

Das Druckgehäuse enthält gegen elektrostatische Entladung (ESD) empfindliche Teile und

Baugruppen, die durch ESD beschädigt werden können. Befolgen Sie die ESD-Protokolle:

• Tragen Sie einen Augenschutz, wenn Sie das Druckgehäuse öffnen.

• Elektrostatische Ladungen am Körper des Bedieners müssen vor dem Öffnen des

Druckgehäuses abgeleitet werden: Legen Sie eine Hand auf eine geerdete Oberfläche, oder

besser: Tragen Sie ein geerdetes Antistatikband.

• Tragen Sie für diese Wartungstätigkeit mindestens kurzärmelige antistatische Kleidung, z.B. aus

Baumwolle, oder besser einen antistatischen Kittel. Tragen Sie keine Pullover, Fleece- oder

Polyesterkleidung.

• Verwenden Sie mindestens eine Arbeitsstation mit einer Tischplatte aus Holz oder Metall oder

besser eine Tischplatte, die statische Elektrizität ableitet. Arbeiten Sie nicht auf einer Tischplatte

aus Synthetik- oder Polymermaterial.

1. Die Außenseite des Batterie-Endflansches mit einem sauberen Tuch abtrocknen. Gegebenenfalls

Wasser zwischen dem Druckgehäuse und dem Endflansch vollständig entfernen.

2. Mithilfe eines Schraubenschlüssels an der weißen Kunststoffschiene den Endflansch gegen den

Uhrzeigersinn drehen, um ihn zu lösen.

Deutsch 19

3. Gegebenenfalls Wasser auf den O-Ring-Oberflächen mit einem fusselfreien Tuch oder

Papiertuch vollständig entfernen.

4. Den Endflansch sauber halten und den O-Ring vor Verschmutzung oder Beschädigung schützen.

5. Die drei Kreuzschlitzschrauben und Unterlegscheiben von der Batterieabdeckung entfernen.

Die Batterieabdeckung löst sich.

6. Nehmen Sie die Batterien aus dem Messgerät.

7. Legen Sie neue Batterien ein. Achten Sie darauf, dass der + Pol sich an der flachen Kontaktseite

und der - Pol sich auf der Kontaktseite mit der Feder befindet.

8. Richten Sie die Batterieabdeckung am Gehäuse aus. Die Bolzen im Gehäuse sind asymmetrisch,

sodass die Abdeckung nur in einer Ausrichtung auf das Gehäuse passt.

Eine Schraubenöffnung befindet sich näher am Rand als die anderen und passt zu dem Bolzen,

der am nächsten zum Gehäuse liegt.

9. Setzen Sie alle drei Kreuzschlitzschrauben und Unterlegscheiben wieder ein: Drücken Sie fest

auf die Abdeckung und achten Sie darauf, dass die Feder richtig an den Batterien anliegt.

Stellen Sie sicher, dass die Schrauben fest angezogen sind, anderenfalls ist die Batterieleistung

nicht zuverlässig.

10. Überprüfen Sie, ob die Batteriespannung an BAT + und BAT - an der Batterieabdeckung etwa

18 V entspricht.

11. Stellen Sie sicher, dass alle O-Ring-Oberflächen sauber und trocken sind. Tauschen Sie die O-

Ringe bei Bedarf aus.

12. Tragen Sie eine dünne Schicht Parker Super O Lube auf Silikonbasis auf die aneinander

liegenden O-Ring-Flächen auf.

13. Setzen Sie den Endflansch vorsichtig auf das Gehäuse und schrauben Sie ihn fest. Stellen Sie

mithilfe eines Schraubenschlüssels sicher, dass die Kappe fest montiert ist.

14. Überprüfen Sie, ob der Schalterstößel herausgezogen ist, sodass sich der Searam in einem

Modus mit geringerer Spannung befindet.

20 Deutsch

Table of contents

Languages:

Other Sea-Bird Scientific Accessories manuals