Sea-Bird Scientific SBE 37 MicroCAT User manual

User manual

SBE 37 MicroCAT

RS485 Conductivity and temperature sensor (optional

pressure and optical dissolved oxygen)

Document No. 37 RS485 SM,

SMP, SMP-ODO

Release Date: 2023-01-05

Version: A

Software: Seasoft V2

425-643-9866

seabird.com

Table of Contents

Section 1 Safety information............................................................................................................ 3

1.1 Hazard information....................................................................................................................... 3

1.2 Equipment labels.......................................................................................................................... 4

Section 2 MicroCAT quick start guide........................................................................................... 5

Section 3 Specifications.................................................................................................................... 7

3.1 Feature summary......................................................................................................................... 7

3.2 Mechanical................................................................................................................................... 7

3.2.1 Bulkhead connector.............................................................................................................7

3.2.2 Dimensions..........................................................................................................................8

3.3 Electrical....................................................................................................................................... 9

3.4 Communications.......................................................................................................................... 9

3.5 Analytical.................................................................................................................................... 10

Section 4 Overview........................................................................................................................... 11

4.1 Operation................................................................................................................................... 11

4.2 Sample times............................................................................................................................. 11

4.3 Battery life.................................................................................................................................. 12

4.4 Cable length and external power............................................................................................... 13

Section 5 Set up sensor and verify operation............................................................................ 15

5.1 Verify anti-fouling devices.......................................................................................................... 15

5.2 Install batteries........................................................................................................................... 16

5.3 Install software and test sensor.................................................................................................. 18

5.3.1 Software menu items.........................................................................................................19

5.3.2 Communication troubleshooting........................................................................................ 19

5.4 Set up pump............................................................................................................................... 20

5.4.1 Set up pump for ODO accuracy........................................................................................ 20

Section 6 Deployment and recovery.............................................................................................23

6.1 Data collection modes................................................................................................................ 25

6.1.1 Polled (controlled) mode................................................................................................... 25

6.1.2 Autonomous mode............................................................................................................ 26

6.2 Default output format ................................................................................................................. 27

6.2.1 Other data formats............................................................................................................ 28

6.2.1.1 XML data format....................................................................................................... 28

6.2.1.2 Alternate output format ............................................................................................ 29

6.2.1.3 Diagnostic data format............................................................................................. 29

6.3 Transmit real-time data.............................................................................................................. 30

6.4 Recover sensor from deployment.............................................................................................. 31

Section 7 Transmit and convert data........................................................................................... 33

7.1 Transmit data to PC................................................................................................................... 33

7.2 Convert data............................................................................................................................... 34

Section 8 Maintenance..................................................................................................................... 37

8.1 Plastic sensor maintenance....................................................................................................... 37

8.2 Remove or replace anti-fouling devices..................................................................................... 37

8.3 Clean flow path.......................................................................................................................... 38

8.4 Maintain pump............................................................................................................................ 39

8.5 Clean pressure sensor............................................................................................................... 39

8.6 Examine O-rings........................................................................................................................ 40

8.7 Clean bulkhead connectors........................................................................................................ 40

8.8 CTD storage............................................................................................................................... 41

8.8.1 Mechanical specs.............................................................................................................. 42

1

8.9 Calibration.................................................................................................................................. 46

8.9.1 Conductivity....................................................................................................................... 46

8.9.2 Temperature...................................................................................................................... 46

8.9.3 Pressure............................................................................................................................ 47

8.9.4 Optical Dissolved Oxygen................................................................................................. 47

8.10 Spare parts and accessories.................................................................................................... 47

8.10.1 SBE 37 spare hardware and O-ring kit............................................................................48

Section 9 Reference: command descriptions............................................................................ 49

9.1 Sensor ID................................................................................................................................... 49

9.2 Global......................................................................................................................................... 49

9.3 Get data..................................................................................................................................... 50

9.4 Status......................................................................................................................................... 50

9.5 General setup............................................................................................................................. 53

9.6 Pump setup................................................................................................................................ 53

9.7 Memory setup............................................................................................................................ 54

9.8 Output format setup................................................................................................................... 54

9.9 Autonomous operation with data storage................................................................................... 55

9.10 Polled data collection............................................................................................................... 56

9.11 Data upload.............................................................................................................................. 56

9.12 Coefficients.............................................................................................................................. 56

9.13 Optical Dissolved Oxygen sensor............................................................................................ 57

9.13.1 ODO setup...................................................................................................................... 57

9.13.2 Dissolved oxygen coefficients......................................................................................... 58

Section 10 Troubleshooting........................................................................................................... 59

10.1 No communications with sensor.............................................................................................. 59

10.2 No data recorded..................................................................................................................... 59

10.3 Data looks incorrect................................................................................................................. 59

10.4 Salinity spikes.......................................................................................................................... 59

Section 11 General information..................................................................................................... 61

11.1 Warranty................................................................................................................................... 61

11.2 Service and support................................................................................................................. 61

11.3 AF24173 anti-foulant device.................................................................................................... 61

11.4 Lithium battery shipment.......................................................................................................... 63

11.5 China RoHS disclosure table................................................................................................... 64

Table of Contents

2

Section 1 Safety information

Please read this entire manual before this equipment is unpacked, set up, or operated.

Pay attention to all danger, warning, and caution statements. Failure to do so could result

in serious injury to the operator or damage to the equipment.

DANGER

Indicates a potentially or imminently hazardous situation which, if not avoided, will result in death

or serious injury.

WARNING

Indicates a potentially or imminently hazardous situation which, if not avoided, could result in

death or serious injury.

CAUTION

Indicates a potentially hazardous situation that may result in minor or moderate injury.

NOTICE

Indicates a situation which, if not avoided, may cause damage to equipment. Information that

requires special emphasis.

1.1 Hazard information

WARNING

If the user thinks that the lithium batteries have leaks, pressure may have built up inside

of the pressure housing. Follow ESD protocols to release internal pressure. Put on

safety glasses and protective gloves and make sure that the sensor is pointed away

from the body and other people. In a well ventilated very SLOWLY loosen the bulkhead

connector to release the pressure. Keep away from heat, sparks, flame, and other

sources of ignition. Do not smoke.

CAUTION

The pressure housing contains Electrostatic Discharge (ESD) sensitive parts and

assemblies that are susceptible to damage from ESD. Follow ESD protocols:

• Put on protective eye wear before you open the pressure housing.

• Any electrostatic charge on the body of the human operator must be released

before the pressure housing is opened: put a hand on a grounded surface, or

better, wear a grounded antistatic wrist strap.

• At a minimum, wear short-sleeved antistatic clothing, such as cotton, or better,

wear an antistatic smock for this service activity. Do not wear a sweater, fleece or

polyester-based clothing.

• At a minimum, use a workstation with a wood or metal tabletop, or better, a

tabletop that dissipates static. Do not use a workstation with a synthetic or

polymeric-based tabletop.

CAUTION

AF24173 anti-fouling devices contain bis(tributyltin) oxide. Wear rubber or latex gloves and eye

protection to replace these devices on the sensor if it is so equipped. Wash hands with soap and

water when finished.

Read the precautions on the product label.

It is a violation of US federal law to use this product in a manner that is inconsistent with its label.

3

NOTICE

The manufacturer is not responsible for any damages due to misapplication of misuse of this

product including, without limitation, direct, incidental and consequential damages, and disclaims

such damages to the full extent permitted under applicable law. The user is solely responsible to

identify critical application risks and install appropriate mechanisms to protect process during a

possible equipment malfunction.

1.2 Equipment labels

Read all labels and tags attached to the equipment. Personal injury or damage to the

equipment could occur if not observed. A symbol on the equipment is referenced in the

manual with a precautionary statement.

Electrical equipment marked with this symbol may not be disposed of in European domestic or public disposal

systems. Return old or end-of-life equipment to the manufacturer at no charge to the user.

ATTENTION!

Remove sticker before deployment!

This sticker protects your instrument during shipping. REMOVE BEFORE DEPLOYMENT;if it is not removed,

your instrument will not operate properly and you may cause severe damage to the conductivity cell. The

conductivity cell is made of glass and will break if mishandled or frozen while filled with water. Apply new sticker

to protect instrument when not in use (see spares kit).

NOTICE: Sticker may have come in contact with the AF24173 Anti-foulant device, which contains TBTO.

Dispose of the removed sticker' see MSDS for handling precautions.

Safety information

4

Section 2 MicroCAT quick start guide

This quick start guide gives the steps necessary to make sure that the SBE 37 MicroCat

sensor operates correctly and collects data before it is deployed.

This quick start guide and user manual applies to SBE 37-SM (RS485), SBE 37-SMP

(RS485), and SBE 37-SMP-ODO (RS485) models. Refer to the Feature summary

on page 7 for more details about each model.

What's in the box:

• CD or USB drive—has software, calibration files, documentation

• Dummy plug and lock collar

• Data I/O cable to connect the sensor to a PC

• Plumbing kit and non-ionic surfactant to clean sensor flow path

• Spare hardware and O-ring kit.

1. Install the manufacturer-supplied batteries. Refer to Install batteries on page 16 for

details.

a. Remove the end flange of the sensor

b. Disconnect the battery holder and remove it from the sensor.

c. Install new batteries.

d. Connect the battery pack to the sensor again and install the end flange again.

2. Install the manufacturer-supplied software on a PC. Refer to Install software and test

sensor on page 18 for details.

3. Connect the data I/O cable to the sensor and the PC and double-click on

SeaTermV2.exe to start the software.

4. Set up the sensor for deployment. Refer to Set up sensor and verify operation

on page 15 for details.

a. If necessary, make sure that all data stored in the sensor is transmitted to a PC.

b. Set the date and time and configure the data collection settings.

c. Send the #iiDS and #iiDC commands to verify setup.

d. Use #iiStartNow to start data collection every #iiSampleInterval= x seconds.

e. Use #iiStartDateTime= and #iiStartLater to start data collection at a specified date

and time, every #iiSampleInterval=seconds.

5. Remove the yellow protective label from the plumbing intake and exhaust.

6. Verify the antifouling devices are installed. Refer to Remove or replace anti-fouling

devices on page 37 for details.

7. Deploy the sensor. For most applications, make sure the connector is at the bottom

(lowest point).

8. Immediately after the sensor is recovered from a deployment:

a. Transmit data from the sensor to a PC.

b. Use the software to turn off the sensor.

c. Flush the sensor with fresh water.

d. Keep the sensor out of direct sunlight between deployments

9. Refer to CTD storage on page 41 for details to prepare the sensor for short- or long-

term storage.

5

MicroCAT quick start guide

6

Section 3 Specifications

3.1 Feature summary

Model Hardware options Communication options

(RS232 is standard)

Pressure Internal

batteries

Pump Optical

Dissolved

Oxygen

RS485 SDI-12 Integrated

Inductive

Modem

37-SM X X X

37-SMP X X X X or X

37-SMP-ODO X X X X X or X

37-SI X X

37-SIP X X X

37-IM X X X

37-IMP X X X X

37-IMP-ODO X X X X X

Abbreviation key:

• S = serial communication

• I = internal memory

• M = memory

• P = pump

• IM = inductive modem

• ODO = optical dissolved oxygen

3.2 Mechanical

Weight in air, water, 350 m, plastic Weight in air, water, 7000 m,

titanium

Length

37-SM 2.7, 1.2 kg 3.8, 2.3 kg 56.39 cm

37-SMP 3.5, 1.5 kg 5.0, 3.0 kg 65.61 cm

37-SMP-ODO 3.4, 1.5 kg 4.2, 2.3 kg 53.52 cm

3.2.1 Bulkhead connector

Contact Function MCBH-4-MP

1 Ground

2 RS232 RX

3 RS232 TX

4 Voltage in

7

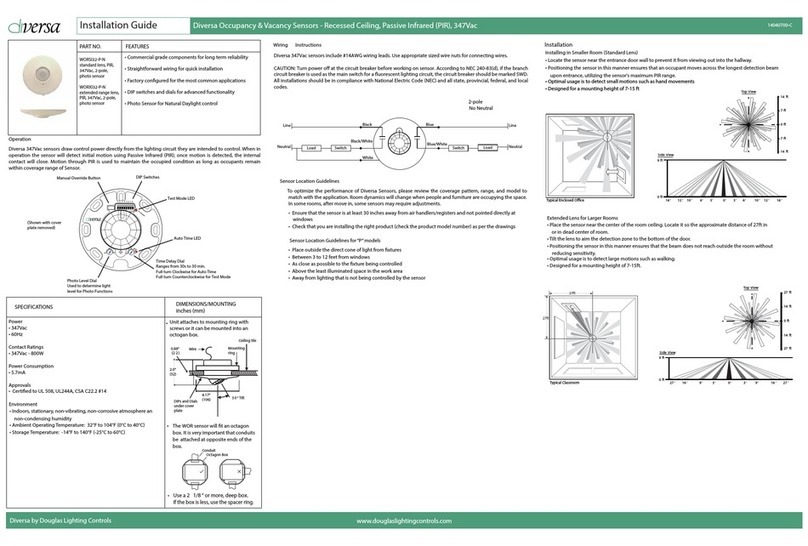

3.2.2 Dimensions

37 SM (RS485)

SMP (RS485)

Specifications

8

SMP-ODO (RS485)

3.3 Electrical

Table 1 Power requirements

SM SMP SMP-ODO

Low power 30 µA

Communication current draw 15 mA 0.065 watts

Data collection current draw, real-time

data transmitted 15 mA

Data collection current draw, no real-time

data transmitted 13 mA

Pump — 260 mA 0.12 watts

Table 2 External power

SM

0.5 A at 9–24 VDC

SMP

SMP-ODO 0.25 A at 9–24 VDC

Table 3 Battery pack

SM

Nominal 10.6 Ah (12 AA size cells, 3.6 V, 2.45 amp-hours each)

SMP

SMP-ODO Nominal 7.8 Ah (12 AA size cells, 3.6 V, 2.6 Ah each)

3.4 Communications

Memory 8 Mb

Communication interface RS485

RS485 output rate user-selectable, 600–115200 baud (default 19200)

Specifications

9

Data collection rate 1 Hz

37-SM data storage

533000 samples

37-SMP data storage

37-SMP-ODO data storage 381000 samples

3.5 Analytical

Parameter Range Accuracy Stability Resolution

Conductivity 0–70 mS/cm ±0.003 mS/cm 0.003 mS/cm/mo 0.0001 mS/cm

Temperature -5–45 °C ±0.002 °C (-5–35 °C) 0.0002 °C/mo 0.0001 °C

Pressure not more than the SBE

37 rated depth

±0.1% full scale range 0.05% full scale range/yr 0.002% full scale range

Specifications

10

Section 4 Overview

4.1 Operation

The SBE 37 MicroCAT measures conductivity (C) and temperature (T).

Optional equipment includes:

• Pressure (depth)

• Internal pump

• Optical Dissolved Oxygen (ODO)

The sensor can operate as a stand-alone or is easily integrated with other platforms.

If so equipped, the internal pump operates for one second each time the sensor collects a

sample. The internal pump has several advantages over sensors without pumps:

• The pump flushes the water from the flow path after each sample and quickly moves

a new sample into the flow path so that conductivity and oxygen measurements are

more accurate.

• Water does not flow freely through the flow path so it stays saturated with the anti-

fouling chemicals.

• The ODO sensor (SMP-ODO only) is integrated in the flow path to better align with

the CTD measurement.

The user can operate the sensor in one of several modes:

Autonomous

• Operates at user-selected intervals (10–21600 seconds).

• Transmits data real-time if #iiTxRealTime=Y.

• Operation sequence:

1. The pump operates for one second (uses #iiMinCondFreq=)

2. The sensor makes one measurement

3. The data is stored internally

4. The sensor goes into a low power mode until the next sample is collected.

Polled operation

• Polled data collection is useful when the sensor is integrated with satellite, radio, or

wire telemetry equipment.

• Operation sequence:

1. The pump operates on command for one second

2. The sensor makes one measurement

3. The sensor sends the data to the controller

4. The sensor goes into a low power mode until the next command to operate.

There are two ways to deploy the sensor.

1. Cable installed—the sensor is controlled remotely and transmits data on command.

The sensor can also operate autonomously and transmit data at a user-set interval.

Data can be transmitted while the sensor is deployed.

2. Dummy plug installed—the interval at which data is collected is set by the user before

deployment. Data is transmitted to a PC after deployment.

4.2 Sample times

The time it takes for the MicroCAT to collect a sample depends on several factors, such

as the data collection mode, and whether the optional pressure sensor is installed.

11

The time that shows with the data is the time at the start of the sample. For example, if

the sensor is set to sample at 12:00:00, the stored time shown in the data will be

12:00:01 or 12:00:02.

Sample times to operate the pump and take a sample

Table 4 Autonomous mode

Condition SM SMP SMP-ODO

No pressure sensor 1.8 sec 1.8 sec 2.4 sec

Pressure sensor — 2.4 sec 2.8 sec

Table 5 Polled or GData modes

Condition SM SMP SMP-ODO

No pressure sensor 2.0 sec 2.0 sec 2.7 sec

Pressure sensor — 2.6 sec 3.1 sec

Communications time, the time it takes to request and transmit data with the Dataii

command: 0.5 seconds.

4.3 Battery life

The battery pack is 4 cells in series of 3 parallel strings. The battery holder has a yellow

cover plate. It is NOT compatible with the older battery holder that has a red cover plate.

The manufacturer recommends the user uses a conservative capacity value:

• SM, SMP—8.8 amp-hours, even though the nominal capacity is calculated at 10.6 A-

hours.

• SMP-ODO—6.0 amp-hours, even though the nominal capacity is calculated at 7.8 A-

hours.

The current draw varies if the sensor is set to transmit data in real-time (15 mA) or not

(13 mA). The current draw of the pump is 0.026 µA-seconds per pulse (1.0 second

pulse). Low power current draw is 30 µA (0.26 amp-hours/year).

The time required for each sample depends on the user-set data collection mode, and

whether the MicroCAT has a pressure sensor. The MicroCAT is shipped with Deployment

Endurance Calculator software to calculate the maximum deployment time. An example

of a manual calculation is shown below.

Example: 10 SBE 37 SMPs with pressure sensors are set up to take a sample every 10 minutes, or 6 samples/hour. Real-

time data is requested once every hour. How long can it be deployed?

Autonomous sample time = 2.4 seconds

Current draw for data collection = 0.013 A × 2.4 seconds = 0.031 A-seconds/sample

6 × 0.031 = 0.19 A-seconds/hour

Polled sample time (with pressure sensor) = 2.6 seconds

In one hour, 1 sample with GData = 0.015 A × 2.6 seconds = 0.04 A-seconds/hour

Pump operation current draw = 0.026 A-seconds/pulse

In one hour, pump current = (6 autonomous + 1 GData sample) × 0.26 A-seconds/sample = 1.82 A-seconds/hour

Communication current draw/query = 0.15 mA × 0.5 seconds/MicroCat queried × 10 MicroCATs on line = 0.001 A-

seconds/hour

Low power current draw = 30 µA, or 0.03 mA

In 1 hour, 0.03 mA × 3600 seconds/hour = 0.11 A-seconds/hour

Total current draw/hour = 0.19 + 1.82 + 0.0011 + 0.11 = 2.12 A-seconds/hour

Capacity = (8.8 A-hours × 3600 seconds/hour) ÷ 2.12 A-seconds/hour = 14900 hours = 622 days = 1.7 years

Number of samples = 14900 hours × 6 samples/hour = 89400 samples

Overview

12

Example: 10 SBE 37 SMP-ODOs with pressure sensors are set up to sample autonomously and take a sample every

10 minutes, or 6 samples/hour (GData and Dataii). Real-time data is requested once every hour. Adaptive Pump Control is

enabled. Deployment is at approximately 500db, at a temperature of approximately 10 °C. OxTau20 is manufacturer-set at

5.5. OxNTau is 7.0. How long can they be deployed?

CTD-DO operation 0.155 watts × 2.8 second sample time = 0.434 Joules/hour

In one hour, operation power draw = 6 samples/hour × 0.434 Joules/sample = 2.60 Joules/hour

Pump

ft = A + (B × T) + (C × T2) = 2.549 + (-1.106 × 10-1 × 10) + (1.571 × 10-3 × 10 ×10) = 1.600

fp = e(pcor × P) = e(1.45e-4 × 500) = 1.075

tau = OxTau20 × ft × fp = 5.5 × 1.600 × 1.075 = 9.46

Pump time = OxNTau × tau = 7.0 × 9.46 = 66.2 seconds (> minimum pump time of 3 seconds)

In one hour, pump current = (6 autonomous + 1 GData sample) × 0.26 A-seconds/sample = 1.82 A-seconds/hour

Pump operates for an additional 2.8 seconds during data collection.

Pump operation, 0.12 watts × (66.2 + 2.8 seconds) = 8.28 Joules/sample = 49.68 Joules/hour

CTD-DO in standby, pump operates = 0.016 watts × 66.2 seconds = 1.06 Joules/sample

ln one hour, power draw = 6 samples/hour × 0.16 Joules/sample = 6.36 Joules/hour

CTD-DO in standby, between samples = 0.0004 watts × (600 - [66.2 + 2.8]) seconds = 0.21 Joules/sample

In one hour, power draw = 6 samples/hour × 0.21 Joules/sample = 1.26 Joules/hour

Additional sample taken one per hour with Gdata approximately 0.434 Joules/sample + 8.28 Joules/sample =

8.72 Joules/hour

Communications = 0.065 watts × 0.5 seconds/MicroCAT × 10 MicroCATs on line =0.32 Joules/hour

Total power draw/hour = 2.60 + 49.68 + 6.36 + 1.26 + 8.72 + 0.32 = 68.94 Joules/hour

Battery pack capacity

Nominal voltage of 14 V and 85% DC-DC converter efficiency

14 V × 6 amp-hours × 3600 seconds/hour × 0.85 = 257040 Joules

Capacity = 257040 Joules ÷ 68.94 Joules/hour = 3728 hours = 155 days = 0.42 years

Number of samples = 3728 hours × 6 samples/hour = 22368 samples

4.4 Cable length and external power

The sensor can use an external power source that supplies 9–24 VDC in addition to or

instead of the internal batteries. The MicroCAT uses power from the source that supplies

the highest voltage.

Calculate the maximum cable length after IR loss to make sure that an external power

source supplies enough voltage to the MicroCAT.

For 37 SM and 37 SMP:

• Supply a minimum of 10 V, after IR loss, so the MicroCAT does not get any power

from the internal batteries. V - IR > 10 V.

• Supply a minimum of 9 V, after IR loss, so the MicroCAT uses the internal batteries,

or if no batteries are installed. V - IR > 9 V.

• I = required communication current = 0.5 amps

What is the maximum cable length needed to supply 12 volts of power from an external power source to the SM or SMP with

20 gauge wire?

12 V - 0.5 amps × (0.0107 ohms/ft × 2 × cable length) > 9 V

3 V > 0.5 amps × (0.0107 ohms/ft × 2 × cable length) = cable length 280 ft (85 m)

For 37 SMP-ODO:

• Supply a minimum of 16 V, after IR loss, so the MicroCAT does not get any power

from the internal batteries. V - IR > 16 V.

Overview

13

• Supply a minimum of 9 V, after IR loss, so the MicroCAT uses the internal batteries,

or if no batteries are installed. V - IR > 9 V.

• I = required communication current = 0.25 amps

What is the maximum cable length needed to supply 12 volts of power from an external power source to the 37 SMP-ODO

with 20 gauge wire?

12 V - 0.25 amps × (0.0107 ohms/ft × 2 × cable length) > 9 V

3 V > 0.25 amps × (0.0107 ohms/ft × 2 × cable length) = cable length 560 ft (170 m)

Table 6 Common wire resistance

Gauge Ohms/ft.

12 0.0016

14 0.0025

16 0.0040

18 0.0064

20 0.0081

22 0.0107

24 0.0162

26 0.0410

28 0.0653

Overview

14

Section 5 Set up sensor and verify operation

CAUTION

AF24173 anti-fouling devices contain bis(tributyltin) oxide. Wear rubber or latex gloves and eye

protection to replace these devices on the sensor if it is so equipped. Wash hands with soap and

water when finished.

Read the precautions on the product label.

It is a violation of US federal law to use this product in a manner that is inconsistent with its label.

Set up the hardware and install the software for the sensor to make sure that it functions

correctly before deployment.

• If so equipped, install the internal batteries.

• If so equipped, set up the pump.

• Install the manufacturer-supplied software.

• Verify operation.

5.1 Verify anti-fouling devices

New sensors have two anti-fouling devices and a yellow protective label installed by the

manufacturer.

NOTICE

Make sure to remove the label before the sensor is deployed or pressurized or the conductivity

cell can be damaged.

1. Remove the yellow label.

• The user can make sure the anti-fouling devices are installed. Refer to "Remove

or replace AF24173 devices" below for details.

2. Keep the label to attach again to protect the intake and exhaust ports when the

sensor is not deployed.

15

5.2 Install batteries

WARNING

Explosion hazard. If the batteries are not installed correctly, explosive gases can be

released. Make sure that the batteries are of the same approved chemical type and are

inserted in the correct orientation.

WARNING

If the user thinks that a sensor has water in the pressure housing: Disconnect the

sensor from any power supply. Put on safety glasses and make sure that the sensor is

pointed away from the body and other people. In a well ventilated area, use the purge

port (if the sensor is so equipped), or very SLOWLY loosen the bulkhead connector to

let the pressure release.

WARNING

If the user thinks that the lithium batteries have leaks, pressure may have built up inside

of the pressure housing. Follow ESD protocols to release internal pressure. Put on

safety glasses and protective gloves and make sure that the sensor is pointed away

from the body and other people. In a well ventilated very SLOWLY loosen the bulkhead

connector to release the pressure. Keep away from heat, sparks, flame, and other

sources of ignition. Do not smoke.

CAUTION

The pressure housing contains Electrostatic Discharge (ESD) sensitive parts and

assemblies that are susceptible to damage from ESD. Follow ESD protocols:

• Put on protective eye wear before you open the pressure housing.

• Any electrostatic charge on the body of the human operator must be released

before the pressure housing is opened: put a hand on a grounded surface, or

better, wear a grounded antistatic wrist strap.

• At a minimum, wear short-sleeved antistatic clothing, such as cotton, or better,

wear an antistatic smock for this service activity. Do not wear a sweater, fleece or

polyester-based clothing.

• At a minimum, use a workstation with a wood or metal tabletop, or better, a

tabletop that dissipates static. Do not use a workstation with a synthetic or

polymeric-based tabletop.

The manufacturer ships the twelve lithium batteries for the sensor separately. Do the

steps below to install or replace the batteries. See also the "how to" video on the

manufacturer's website to do this procedure.

Do not ship assembled battery packs Lithium batteries are packaged in heat-sealed plastic and bubble-wrap.

Set up sensor and verify operation

16

Table 7 Recommended lithium battery brands

SAFT LS-14500 (included) 3.6 V, 2.6 Ah

Tadiran TL-4903 3.6 V, 2.4 Ah

Electrochem BCX85 series 3.9 V, 2.0 Ah

1. Make sure that the end flange and pressure housing are dry.

2. Use a 9/64" hex key to remove the two screws on the sides of the pressure housing.

3. Install these two screws into the sides of the end flange to start to loosen the end

flange.

4. If necessary, hold the bulkhead connector with a crescent wrench to make it easier to

turn the end flange.

5. Turn the end flange counter-clockwise to loosen it from the pressure housing.

6. Pull gently to disconnect the battery wires in the end flange from the battery pack.

7. Use a lint-free tissue to remove any water from the O-ring surfaces inside the

pressure housing and end flange.

8. Use a 7/64" hex key to loosen the captured screw in the battery cover plate.

9. Remove the battery pack from the pressure housing.

10. Turn the yellow cover plate counterclockwise to remove it from the battery pack body.

11. Move each of the two O-rings on the outside of the battery holder from the grooves.

It makes it easier to remove or insert batteries.

12. Examine the O-rings and surfaces for dirt, cuts, or other damage.

Clean or replace as necessary.

13. If necessary, remove the size AA batteries in the pack.

14. Insert new batteries.

Make sure to alternate the positive (+) and the negative (-) ends on the size AA

batteries to agree with the labels on the pack as they are installed.

15. Move the O-rings back into the grooves.

16. Align the pin on the yellow battery cover with the post hole in the battery pack

assembly.

Set up sensor and verify operation

17

17. Align the "D"-shaped part of the battery pack with the pins on the shaft.

18. Slowly move the assembly onto the housing. Push gently to connect the battery

assembly with the circuit board in the pressure housing.

19. Use a 7/64" hex key to tighten the captured screw on the yellow battery cover onto

the shaft in the pressure housing.

20. Attach the Molex connector on the end flange to the connector in the pressure

housing.

21. Examine the O-rings on the end flange. They must be pristine, with no lint or

scratches or chips.

• Apply a small quantity of Parker Super O Lube® to any new O-rings.

22. Align the end flange holes with the holes in the pressure housing.

23. Carefully push the end flange into the pressure housing.

It may help to rotate the end flange so that the wires do not bend too much.

24. If necessary, use a 9/64" hex key to remove the two screws from the end flange.

25. Use a 9/64" hex key to install the two screws into the pressure housing of the sensor

again.

5.3 Install software and test sensor

Make sure that the sensor is connected to a power supply and PC through the serial

connector on the supplied cable. Most PCs no longer have serial ports, and a serial-to-

USB adapter is necessary. Make sure that the USB driver software is installed on the PC

so that there is communication between the sensor and the PC.

1. Install the Seasoft V2 software from the manufacturer-supplied CD.

2. Remove the dummy plug from the sensor.

3. Connect the I/O cable to the sensor and to the PC and a power supply (9–24 VDC).

4. Supply power to the sensor.

Set up sensor and verify operation

18

Other manuals for SBE 37 MicroCAT

2

Table of contents

Other Sea-Bird Scientific Accessories manuals