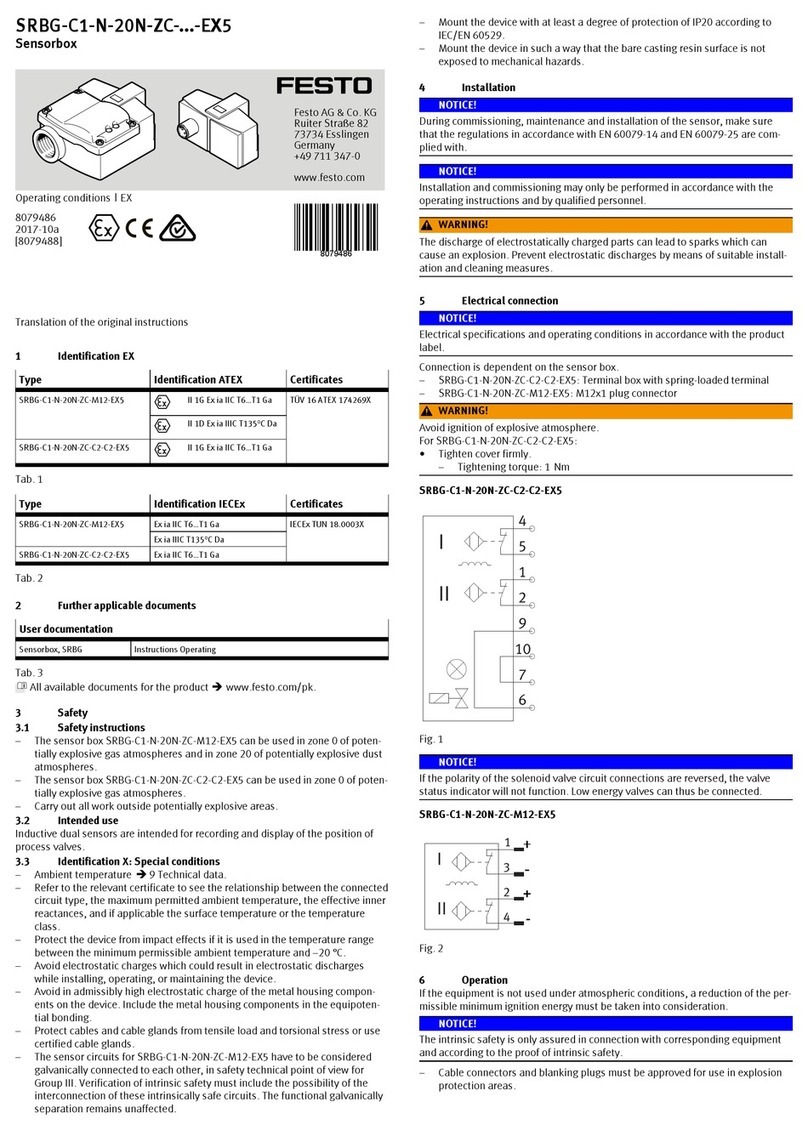

Connection SRBG-…-C2-C2

1. Loosen the housing screws 2on the housing cover. Remove the housing cover.

2. Screw the cable connector into the cable entry. Guide the electric connecting

cable through the cable connector to the terminal block.

– Conductor cross section: 1.5/2.5 mm2(flexible/rigid).

3. Seal unused cable entries with blanking plugs.

4. Wire the connections (èproduct labelling).

5. Place the housing cover in position and tighten the 4 housing screws 2.

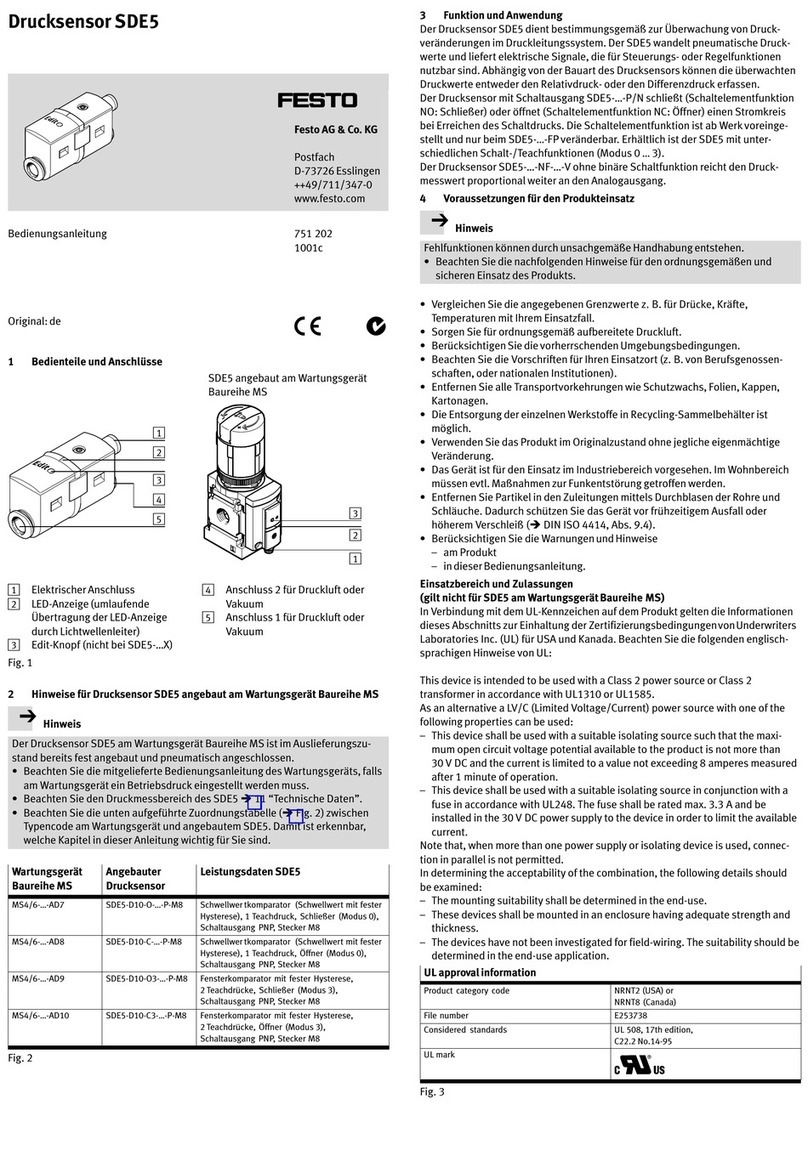

Connection SRBG-C1-N-1-AS-M12-M12 / SRBG-…-M12

12

3

4

5

6

1SRBG-…-M12-M12:

Solenoid valve connection

2SRBG-…-M12-M12:AS-i connection

SRBG-…-M12: sensor connection

3Yellow LED,

witching status indication

4Green LED, power supply indicator

5Switching status indication

6SRBG-…-M12-M12: Switching

status indication for solenoid valve

Programming instructions

Adress 00 preset, can be changed via bus master or programming units

IO code D

Ident. code A

ID1 code 7

ID2 code E

Data bit

Bit Function

D0 Valve status / (0=valve off, 1=valve on)

D1 Valve error1) /(0=wire break/short circuit; 1=no error)

D2 Switching output sensor 12) /(0=attenuated; 1=uncushioned)

D3 Switching output sensor 22) /(0=attenuated; 1=uncushioned)

Parameter bit

Bit Function

P0 Watchdog (0=inactive; 1=active)3)

P1 Switching element function sensor 24) /(0=N/O contact; 1= N/C contact)

P2 Switching element function sensor 14) / (0=N/O contact; 1= N/C contact)

P3 Not used

1) Check only with activated valve (D0=1)

2) Applies to N/C function (P2/P3=1; preset), reversed behaviour with N/O function (P2/P3=0)

3) Watchdog active: Valve voltage drops in the event of AS-Interface communication error

4) Presetting: N/C contact

5 Maintenance and care

If used as intended, the product is maintenance-free.

6 Technical data

Position indicator SASF SASF-S2-B-F-A34 SASF-S2-B-F-A56

Ring diameter [mm] 65 110

Circlip height [mm] 6 7

Ambient temperature [°C] -25 … 80

Mechanical data

Shaft diameter [mm] 58 90

Shaft height [mm] 20/30 30/50

Mounting hole pattern [mm] 30x80 30x130

Material

Housing, Spacer disc, Identification

stopper

PBT

Stopper cap PP

Mounting screw, Actuating lug high-alloy stainless steel

Hinweis

The plastic housings of the position indicator are made of conductive material

and must be integrated into a suitable earthing concept.

Hinweis

The position indicator SASF consists of conductive plastic material.

Use in potentially explosive areas possible, as there is no static charge.

SRBG-…-M12-M12

Switching output AS-Interface

Switching element function Programmable N/O contact/ N/C contact

Max. switching frequency [Hz] 100

Idle current [mA] 35

Operating voltage range DC

AS-Interface

[V] 26.5 … 31.6

Load voltage range DC [V] 21.6 … 26.4

Current consumption with load

voltage from AS-Interface and

load voltage connection

[mA] 100

Protocol AS-Interface specification V3.0 Required master spe

cification ≥ V2.1 Slave type A/B slave

Device-specific diagnostics Wire break/short circuit in valve

Addressing range 1A … 31A (0) / 1B … 31B

Reverse polarity protection for all electrical connections

Sensor connection M12 x 1, plug, 4-pin

Ambient temperature [°C] -25 … 70

Storage temperature [°C] -25 … 70

Degree of protection IP67

Shock resistance Shock test with severity level 2 to FN 942017-5 and

EN 60068-2-27

Vibration resistance Transport application test with severity level 2 to FN

942017-4 and EN 60068-2-6

CE marking in accordance with EU EMC Directive

Approval c UL us (OL) RCM compliance mark

Housing PBT

M12 plug, Screws high-alloy stainless steel

Note on materials RoHS compliant / Contains paint-wetting impairment

substances

Mounting position any

SRBG-…-M12/SRBG-…-C2 -P -ZU -ZC

Switching output PNP non-contacting, 2-wire NAMUR

Switching element function N/O contact N/O contact N/C contact

Max. switching

frequency

[Hz] 500 500 3000

Operating voltage range [V DC] 10 … 30 6 … 60 8.2

Max. output current DC [mA] 100 100 3

Voltage drop [V] 3 6 -

Idle current [mA] 25 - -

Residual current [mA] 0.5 1 -

Minimum load current [mA] - 4 -

Reverse polarity protection for all electrical connections

Switching status indication Yellow LED

Power supply indicator Green LED - -

Sensor connection

SRBG-…-M12

M12 x 1, plug, 4-pin

Electrical connection

SRBG-…-C2

spring-loaded terminal

Ambient temperature [°C] -25 … 70 -25 … 70 -25 … 100

Storage temperature [°C] -25 … 70 -25 … 70 -40 … 100

Degree of protection IP67

Shock resistance Shock test with severity level 2 to FN 942017-5 and

EN 60068-2-27

Vibration resistance Transport application test with severity level 2 to FN

942017-4 and EN 60068-2-6

CE marking in accordance with EU EMC Directive

in accordance

with ATEX

Approval c UL us (OL) RCM compliance mark

Housing PBT

M12 plug, Screws high-alloy stainless steel

Note on materials RoHS compliant / Contains paint-wetting impairment sub

stances

Mounting position any