SEA USA VELA INDUSTRIAL User manual

®

International registered trademark n. 2.777.971

web site: www.sea-usa.com

e-mail: [email protected]

SEA USA Inc.

10850 N.W. 21st unit 160 DORAL MIAMI

Florida (FL) 33172

Phone:++1-305.594.1151 Fax: ++1-305.594.7325

Toll Free: 800.689.4716

VELA INDUSTRIAL

Rev. 01 - 11/2010

117 (Vela Ind. Series)

67410268

GENERAL SAFETY REGULATIONS FOR THE INSTALLER

• The installer has to read and understand the functioning of this operator system, its safety features and knowing the manual function in case of emergency.

• Do not modify in any way the automated system’s components. SEA USA Inc. declines all liability concerning the automated system’s security and efficiency if

the used components are not produced by SEAUSAInc. For maintenance, strictly use original SEAUSA Inc. spare parts.

• The installer shall supply the user with all information concerning the proper operation of the product, the system’s manual functioning in case of emergency and

shall hand over to the user the warnings handbook supplied with the product.

• SEA USA Inc. recommends the system to have reversing sensor (encoder) on the drive shaft of the motor. In case of swing/linear/in-ground hydraulic

operators/barriers, SEA USA Inc. recommends to install the SAFETY GATE as an additional reversing sensor. Reversing devices are required to prevent the

system from closing on vehicular traffic and/or help to prevent injuries to pedestrians.

• It is recommended to use indicator-lights as well as warning signs for every system. Both should be visible on each side of the gate and well fixed on the frame

structure.

• Do not leave packing materials (plastic, polystyrene, etc.) within children’s reach, as they are potential sources of danger.

• For products having an emergency release, it is recommended to use it only when the gate/barrier is closed.

• Remove all locks connected to the gates before installing the operator.

• Locate the control button: (a) within sight of door, (b) at minimum height of 5 feet so that small children are not able to reach it, and (c) away from all moving parts

of the door.

• Install entrapment Warning Label next to the control button in a prominent location.Attach marking next to the emegency release.

• Do not employ for any reason automatic closing devices (such as timer, loop sensors, or similar), and do not connect any other activation devices.

GENERAL SAFETY REGULATION FOR THE USER

• Sea strongly recommends to follow these instructions literally to prevent very serious damages to persons. This product was designed and built strictly for the

use indicated in this documentation. Any other use, not expressly indicated here, could compromise the good condition/operation of the product and/or be a

source of danger. SEAUSA Inc. declines all liability caused by improper use or different use in respect to the intended one.

• Only qualified personnel can install, repair and periodically check this equipment.

• The User must not attempt to repair or to take direct action on the system and must solely contact qualified SEA personnel or SEA service centres. User can

apply only the emergency manual function.

• The system has been designed for the control of vehicular traffic only. Pedestrians or bicycles must have a separate access opening.

• Do not allow children or adults to stay near the product while it is operating. The application cannot be used by children, by people with reduced physical, mental

or sensorial capacity, or by people without experience or necessary training. Keep remote controls or other pulse generators away from children to prevent

involuntary activation of the system.

• Transit through the leaves or barrier is allowed only when the gate/barrier is fully open. Operate system only if it is fully visible, and free of obstructions.

• For products having an emergency release use it only when the door/barrier is closed.

ELECTRICAL CONNECTIONS - SAFETY INSTRUCTIONS

• Disconnect the battery back up, if included, before disconnecting main power supply.

•Always disconnect power supply during installation or servicing of the product.

•All electrical connections from the control panel’s to the operator’s must be made in a waterproof junction box.

• The system requires a separate power supply circuit. Check that the main power supply circuit breakers are separated, intended solely for this equipment and

rated for 15AMPS. Visually check that the circuit breakers are in OFF position and mark the circuit breakers USED prior to installation.

• Permanent wiring must be used and installed to the operator as required by local electrical codes and It is recommended to do by a licensed electrician.

It is also recommended to check the local building code requirements before making any type of wiring to be sure that all wirings comply with them. Local building

codes will take precedence. It is recommended to use different colours for all wirings’codes.

• Distance for low voltage control wires, i.e., open input, single leaf, open input and stop input, can run up to 3000 feet with 18AWG wire. Low voltage controls and

communication wirings must all be separated by a minimum of 1 foot from high voltage power wiring and in a separate conduit.

GROUNDING

• Good grounding and proper surge suppression are an integral part of proper installation for all operator systems. One or all of the followings may require surge

suppressors: high voltage power lines, low voltage power lines, telephone lines, data lines, low voltage control lines and loops. Quantity of surge suppression

requires depends on susceptibility of the area to lightning and power surges. Good grounding is essential to realize maximum protection.

• If the circuit breaker box is located close to the gate/barrier operator system, for example, in a guardhouse, then the ground from that circuit can be used to

ground the gate operator system. Eliminate all 90° bends in ground wires and keep a minimum distance of three feet between the surge suppressor and the

equipment to protect.

• If the power source or circuit breaker box is not located close to the operator system, an Isolated Ground Zone (IGZ) must be created. An IGZ is an imaginary

circle drawn around the operator system. An IGZ can also be created, if the circuit breaker box is located close to the operator system. The operator system not

only includes the operator and control panel, but all accessories and devices associated with it at that controlled entry point. This includes loop detectors, card

readers, digital entries, telephone entries, any device that has or requires grounding and all the surge suppressors. The ground bus is a common ground point

called Single Point Ground (SPG). It is used to bond all the equipments and devices grounded in the IGZ together. The SPG is very important because it helps to

eliminate different ground potentials that can be present on the equipment and that could cause damages even with surge suppressors.

• Do not use or connect the ground wire coming from the circuit breaker box. By using an Isolated Ground Zone, you have to separate the operator system from

the house or building ground. This eliminates ground potentials. It is recommended the ground bus to be located in a separate NEMAtype enclosure. All grounds

will be tied to this ground bus.

• Equipment ground wire should be of minimum 12AWG. The main ground wire from the bus bar to the ground rod should be an 8 or 6AWG copper wire.

Ground rod should be minimum 10 feet in length, (length depends on local soil conditions).

• For more information, regarding good grounding practices check: National Electric Code art. 250; IEEE Emerald Book, standard 100; International Association

of Electric Inspectors.

• Where possible, install the opener control 7 feet or more above the floor. For products having an emergency release, mount the emergency release 6 feet above

the floor.

117 (Vela Ind. Series)

International registered trademark n. 2.777.971

SEA USA Inc.

10850 N.W. 21st unit 160 DORAL MIAMI

Florida (FL) 33172

Phone:++1-305.594.1151

Fax: ++1-305.594.7325

Toll Free: 800.689.4716

674102682 Rev. 01 - 11/2010

INSTALLATION WARNINGS

• For gate operators: install only when

A. The operator is appropriate for the gate’s construction and usage Class.

B. All opening spaces on the wall of the horizontal slide gate are guarded or screened from the bottom of the gate to a minimum of 4

feet (1m) above the ground so that it could be possible to keep on the entire surface of the wall a minimum distance of 2-1/4 (57,15mm) inches from the

gate and the wall on which the gate runs.

C.All exposed pinch points are eliminated or guarded

D. Guarding is supplied for exposed rollers.

E. Check if the gate works freely in both directions before installing the gate operator system. Any necessary repair to the gate must be done

before installing the equipment. Swinging gate shall not open into public access areas.

• The operator systems must be installed in a proper place to prevent contacts with adjacent structures in opening and closing. Watch out to install the system so

that users could have full view of the area.

• For operators using non-contact sensors:

A. See instructions on the placement of non-contact sensors for each Type of application.

B. Watch out to reduce the risk of nuisance tripping of the sensor.

C. One or more non-contact sensors shall be located where the risk of entrapment or obstruction exists, such as the perimeter reachable by a moving

gate or barrier.

• For operators utilizing contact sensors:

A. One or more contact sensors must be located where the risk of entrapment or obstruction exists, such as the operators’ edges. They

should be installed both inside and outside the operator’s edge.

B. A hardwired contact sensor must be installed, watching out to arrange its wiring so that the communication between the sensor and the

operator should not be subjected to mechanical damage.

C. A wireless contact sensor such as a radio frequency (RF) signal transmitter must be located where the signal’s transmission cannot be

obstructed by structures or natural landscaping.

• Controls should be far enough from the gate or barrier so that the user is prevented from coming in contact with them while operating the controls. Controls are

intended to be used to reset an operator after 2 sequential activations of the entrapment protection device and must be located in the line-of-sight of the outdoor.

Install a security feature If controls are easily accessible, to prevent unauthorized use.

AFTER INSTALLATION

• Check that: the open and close force are properly adjusted; the piston does not bottom out in either direction, the breather screws have been removed, the

positive stops used are sufficient for stopping the gate properly, all the pinch points and potential entrapment areas are reduced.

• Check and test all reversing devices.

• The installer should instruct user on the operator system’s proper operation. They should together review the basic functions of the reversing devices and how to

periodically test them. Reversing devices include one or more of the followings: reversing loops, photocells, reversing edges, etc. The installer has to instruct

user on how to remove the operator system from service, on shutting power off on the service panel and how to use the operator system manually.

GENERAL ENTRAPMENT PROVISIONS

A vehicular operator must be installed with one independent primary and one independent secondary means at least to protect against entrapment

(see Table A):

Note: The same type of device shall not be utilized for both the primary and secondary entrapment protection means. The use of a single device to cover both

the opening and closing directions is in accordance with the requirements; however, a single device is not required to cover both directions. A combination of

one Type B1 for one direction and one Type B2 for the other direction is the equivalent of one device, for the purpose of complying with the requirements of

either the primary or secondary entrapment protection means.

Entrapment protection types

TypeA: Inherent entrapment sensing system.

Type B1: Provision for connection of a non-contact sensor (photoelectric or equivalent).

Type B2: Provision for connection of a contact sensor (edge device or equivalent).

Type C: Inherent adjustable clutch or pressure relief device.

Type D: Provision for connection of an actuating device requiring continuous pressure to maintain opening or closing motion of the gate.

Type E: An inherent audio alarm.

CLASS OF OPERATORS

RESIDENTIAL VEHICULAR GATE OPERATOR - CLASS I - A vehicular operator (or system) intended for use in a home of one-to four, single-family dwelling, or

a garage or parking area associated therewith.

COMMERCIAL/GENERAL ACCESS VEHICULAR OPERATOR - CLASS II - A vehicular operator (or system) intended for use in a commercial location or

building such as multi-family housing unit (five or more single family units), hotel, garage, retail store, or other building servicing the public.

INDUSTRIAL/LIMITED ACCESS VEHICULAR OPERATOR - CLASS III - A vehicular operator (or system) intended for use in an industrial location or building

such as a factory or loading dock area or other locations not intended to service the public, in which unauthorized access is prevented via supervision by security

personnel.

117 (Vela Ind. Series)

International registered trademark n. 2.777.971

SEA USA Inc.

10850 N.W. 21st unit 160 DORAL MIAMI

Florida (FL) 33172

Phone:++1-305.594.1151

Fax: ++1-305.594.7325

Toll Free: 800.689.4716

67410268 3Rev. 01 - 11/2010

SEA s.r.l. is glad to congratulate and thank you for

choosing our product. Your choice will allow you to

understand how our factory, according to studies, research

and above all the needs of our customers, wants to gather

technology, reliability and safety together keeping in mind

use and installation easiness.

General characteristics

Vela Industrial is an electro-mechanical automation for big carriage entrances (17,

20, 23, 25 feet). The places for fitting are multiple; Vela Industrial is ideal for camp

entrances, hospitals, yards, private roads, port and airport entrances, public parking

with half-intensive working cycles. It is provided with an anti-crush device (230

version) that ensures a strength of max. 33 pound on the beam so to ensure people

and things against accidents. An accurate slowing down system guarantees the total

control of the momentum strength. The manual release makes the beam

independent from the operator so to allow the manual closing and opening.

The automation consists of :

The cataphoresis and epoxy treated dust painted steel sheet casing protects all mechanical and electric devices from

atmospheric agents. On request it is also possible to receive the casing in stainless steel.

The balancing spring is delivered according to the beam length, inside the beam kit (See spring tab.)

Electronic control unit for 230 version, advanced device which allows the programming and control of all working and safety

systems.

Operator with manual release for the manual opening of the beam in case of damages.

Beam in extruded aluminium, available sizes: from 17 to 25 feet.

Mounting plate out of steel sheet coated with zinc.

Balancing wheel in galvanized steel.

1

2

3

4

5

6

7

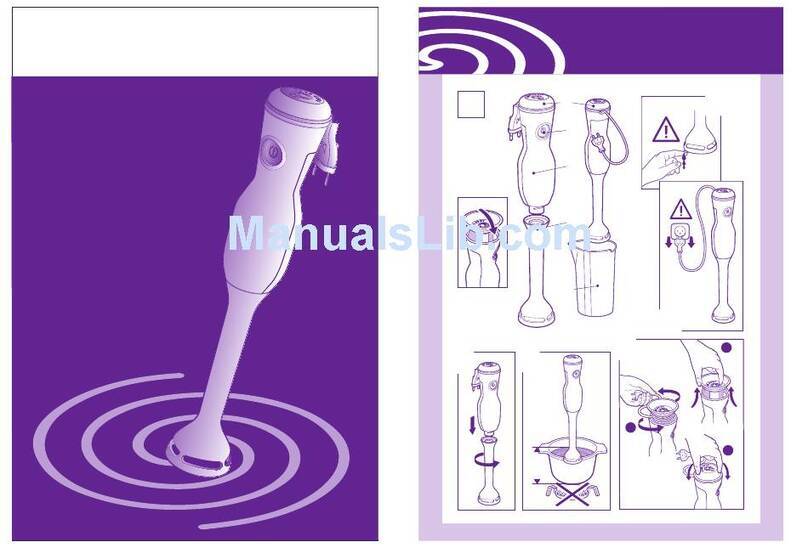

List of the main parts:

1. Vela Industrial Series casing

2.

3. Balancing spring

4. Electronic Control Unit

5. Vela Ind. mounting plate

6.

7. Aluminium beam

8. Balancing lever

Hydraulic pump unit

Piston

88

77

1111

2233

44

4455

4466

2222

117 (Vela Ind. Series)

International registered trademark n. 2.777.971

SEA USA Inc.

10850 N.W. 21st unit 160 DORAL MIAMI

Florida (FL) 33172

Phone:++1-305.594.1151

Fax: ++1-305.594.7325

Toll Free: 800.689.4716

674102684 Rev. 01 - 11/2010

Fig.2

Voltage supply:

Power absorption:

Opening time:

Max. Beam length:

Protection degree:

Motor revolutions:

Operating temperature:

Weight:

Manual release:

Use frequency:

Technical data

Dimensions (inches):

FITTING INSTRUCTIONS

1) Position of spring

Right hand closing barrier Left hand closing barrier

This versatile barrier allows the left or right hand closing according to your

requirements.

If the provided barrier does not close on the desired side it is possible to invert it

following the instructions.

115 V~ 50/60 Hz

22

00 RPM/min.

-4°F ÷ + 131°F

183 pound

Yes

75%

0W

8-12 s

25

Ip55

14

feet with fork / 23 feet side fixation

Note1: The frequency of use is valid only for the first hour at

68°F room temperature.

Nota2: For a frequency of more than 60%, it is recommended to

use the mechanical and electronic limit switch kit for a best

duration in time.

Fig.1

16

8

44

6

3

37

Rectangular beam

Barrier Length

17 feet

20 feet

23 feet

25 feet

D. Spring

0,41 in.

0,43 in.

0,45 in.

0,49 in.

Fexlible support

yes

yes

yes

yes

B-light Beam

Barrier Length

D. Spring Fexlible support

yes

yes

yes

Side beam with skirt

Type of skirt

15 feet

18 feet

21 feet

Barrier Length

D. Spring

117 (Vela Ind. Series)

International registered trademark n. 2.777.971

SEA USA Inc.

10850 N.W. 21st unit 160 DORAL MIAMI

Florida (FL) 33172

Phone:++1-305.594.1151

Fax: ++1-305.594.7325

Toll Free: 800.689.4716

17 feet

20 feet

23 feet

0,41 in.

0,43 in.

0,45 in.

17 feet

20 feet

23 feet

0,43 in.

0,45 in.

0,49 in.

67410268 5Rev. 01 - 11/2010

Example:

Barrier with right hand closing (Fig.1)

Barrier with left hand closing (Fig. 2)

Before installing the spring check the choice of the

barrier, if right or left hand side.

If the barrier is with closing on the left hand side

move the piston from the right to the left hand side

as shown in Fig.4 and 5.

N.B.: Before executing this operation release the

as shown in Fig.18.

operator

Once exchanged the piston tighten its fixation screw and lubricate with grease (Use DIN 51502 KP 2 N-20 - K 2 K-20 grease).

Spring support

Spring

tensioning bolt

N.B.: The operator comes as

shown in Fig.1 (Closing on the

right hand side).

Fig. 3

Fig.4

A

117 (Vela Ind. Series)

International registered trademark n. 2.777.971

SEA USA Inc.

10850 N.W. 21st unit 160 DORAL MIAMI

Florida (FL) 33172

Phone:++1-305.594.1151

Fax: ++1-305.594.7325

Toll Free: 800.689.4716

674102686 Rev. 01 - 11/2010

2) Mounting of the spring

Insert the spring in to the carter as shown in Fig.5.

Lubrication

with grease

during mounting

Fig. 5

3) Mounting plate fixing

- Dig a hole 31,5x24x16 inches

- Widen the foundation plate clamps at 60° (Fig. 6)

- Fill the hole with R425 concrete and place the foundation plate

as in Fig. 6.

- Level the plate with care.

* The plate has got a central hole for electric wiring so before

filling the hole with concrete put an elettric wire sheathing on the

hole.

Concrete

Fondation plate

to be levelled

Wire sheathing

Clamps 60°~

Fig. 6

16

31,5

117 (Vela Ind. Series)

International registered trademark n. 2.777.971

SEA USA Inc.

10850 N.W. 21st unit 160 DORAL MIAMI

Florida (FL) 33172

Phone:++1-305.594.1151

Fax: ++1-305.594.7325

Toll Free: 800.689.4716

67410268 7Rev. 01 - 11/2010

4) Fixing the column on the foundation plate

- Place the column so that the holes at the base correspond to the screws that emerge from the foundation plate.

- Make sure that the wire sheathing is fixed on the big central hole at the base of the column.

- Tighten the column to the foundation plate screwing the provided nuts and bolts with care.

Fixing nuts

& bolts

Hole for wire

sheathing

Fig. 8

5) Mounting of the central beam with fork (Fig. 8)

Beam

Nuts and bolts for

beam fixing

Fig. 7

117 (Vela Ind. Series)

International registered trademark n. 2.777.971

SEA USA Inc.

10850 N.W. 21st unit 160 DORAL MIAMI

Florida (FL) 33172

Phone:++1-305.594.1151

Fax: ++1-305.594.7325

Toll Free: 800.689.4716

674102688 Rev. 01 - 11/2010

6) Mounting of the B Light beam (Fig. 9)

Fig. 9

117 (Vela Ind. Series)

International registered trademark n. 2.777.971

SEA USA Inc.

10850 N.W. 21st unit 160 DORAL MIAMI

Florida (FL) 33172

Phone:++1-305.594.1151

Fax: ++1-305.594.7325

Toll Free: 800.689.4716

67410268 9Rev. 01 - 11/2010

7) Mounting of the skirt on the beam

N.B.: The skirt can be installed only on lateral mounted beams.

Fig. 11

Fig. 10

117 (Vela Ind. Series)

International registered trademark n. 2.777.971

SEA USA Inc.

10850 N.W. 21st unit 160 DORAL MIAMI

Florida (FL) 33172

Phone:++1-305.594.1151

Fax: ++1-305.594.7325

Toll Free: 800.689.4716

6741026810 Rev. 01 - 11/2010

8) Balancing the spring

- Turn the manual release valve anti-clockwise to

release the operator so that the beam can

be opened and closed manually.

-

- Tight or untight the spring adjusting bolt locknut so

that the spring reaches a balance point with the

beam at 45° (Fig.12).

- After balancing fix the spring adjusting bolt

locknut with the bolt and block the operator.

9) Barrier power supply

Now it is possible to power supply the barrier with 115V~

50/60 Hz.

Place the beam at approx. 45° and execute the balancing

with the nuts of Fig.12.

To obtain a correct balancing the beam must be on 45° and

the operator must be unlocked.

NOTE: For the correct balancing of the beam it is

recommended to unhook the piston from the balance

wheel extracting the pivot as in fig.4

Spring bolt

locknut

Spring tension

adjusting bolt

Fig. 13

Unscrew

breather cap

Pressure adjusting

valves

10) Force adjustment

If necessary the piston force can be adjusted by the two adjusting

screws (grey and yellow) placed on the front lower place of the

Hydraulic pump unit (Fig. 13).

*The automation is adjusted at 33 pound force ex works so to guarantee

the anti-crush safety. We recommend to adjust it only in case of

necessity.

Fig. 12

45°45°

117 (Vela Ind. Series)

International registered trademark n. 2.777.971

SEA USA Inc.

10850 N.W. 21st unit 160 DORAL MIAMI

Florida (FL) 33172

Phone:++1-305.594.1151

Fax: ++1-305.594.7325

Toll Free: 800.689.4716

67410268 11Rev. 01 - 11/2010

12) Levelling of the central beam with fork

First extract the screws B, than the screws C (Fig.15).

Continue as described in the preceding paragraph.

Fig. 14

B

Fig. 15

C

Fig. 16

117 (Vela Ind. Series)

International registered trademark n. 2.777.971

SEA USA Inc.

10850 N.W. 21st unit 160 DORAL MIAMI

Florida (FL) 33172

Phone:++1-305.594.1151

Fax: ++1-305.594.7325

Toll Free: 800.689.4716

11) Levelling the beam

Important: This manoeuvre must be executed only if at the

end stroke the beam is not in perfectly horizontal position in

closing or in perfectly vertical position in opening.

- Unlock the actuator through the release screw so that the

beam opens and closes manually.

- Release the end stroke screws unscrewing the lock nuts on

the limit switch (Fig.14).

- Screw or unscrew the end stroke screws so that the beam

stays in perfectly vertical position in opening and in perfectly

horizontal position in closing (Fig.14).

- After levelling, fix the end stroke by tightening the lock nuts

on the limit switch and block the actuator.

6741026812 Rev. 01 - 11/2010

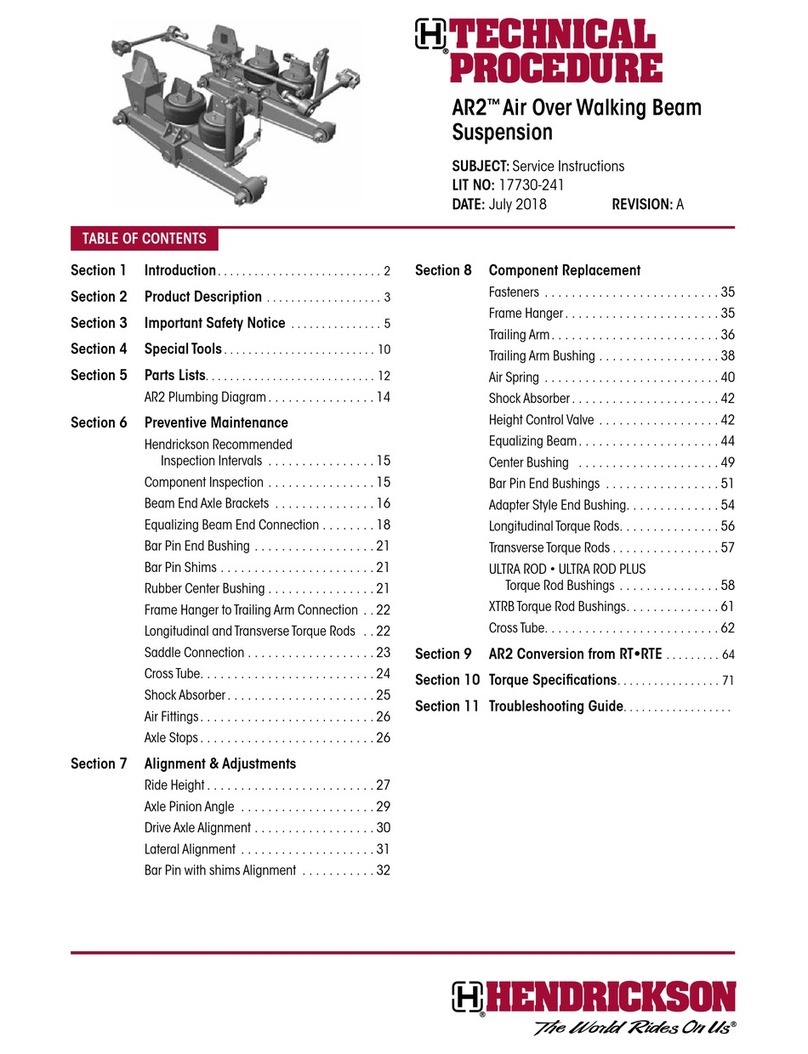

13) Standard installation

In Fig.17 you find the necessary wiring for the barrier installation.

The two numbers placed next to the electric cables show their quantity and section.

Legend:

1) Electronic control unit

2) Photocell (receiver)

3) Photocell (transmitter)

4) Key switch

5) Radio receiver

6) Warning light

7) Push button board

8) Main switch

Fig.17

11

22

33

44

55

66

77

88

2x AWG 16 min

2x AWG 16 min

2x AWG 16 min

4x AWG 16 min

3x AWG 14 min

3x AWG 16 min

14) Accessories for VELA INDUSTRIAL

PHOTOCELLS

KEY SWITCH

WARNING LAMP

SKIRT (ONLY ON SIDE BEAM)

FIXED FORK

SUPPORT

ADJUSTABLE

FORK SUPPORT

FEXLIBLE FORK

SUPPORT

COUNTER PLATE

FOR FORK SUPPORT

LIMIT SWITCH KIT

117 (Vela Ind. Series)

International registered trademark n. 2.777.971

SEA USA Inc.

10850 N.W. 21st unit 160 DORAL MIAMI

Florida (FL) 33172

Phone:++1-305.594.1151

Fax: ++1-305.594.7325

Toll Free: 800.689.4716

67410268 13Rev. 01 - 11/2010

To the attention of users and technicians

PERIODICAL MAINTENANCE

Check the functionality of the release Annually

Lubricate all moving parts Annually

Check the efficiency of the spring (balancing) Annually

Check the beam fixing screws, the balance and the casing Annually

Check the integrity of the connexion cables Annually

All above mentioned operations must be executed exclusively by authorized installers.

15) Release system

To release operate as follows:

- Open the door with the delivered special key

- Turn about 90° into anti-clockwise direction the release srew placed on the hydraulic unit.

- Move the beam with the hand

To re-lock operate as follows:

- Turn about 90° into clockwise direction the release screw placed on the hydraulic unit.

- Close the door

Hydraulic pump

manual release

Release Lock

Verify the efficiency of the limit switches (micro-switch) Annually

Fig. 18

117 (Vela Ind. Series)

International registered trademark n. 2.777.971

SEA USA Inc.

10850 N.W. 21st unit 160 DORAL MIAMI

Florida (FL) 33172

Phone:++1-305.594.1151

Fax: ++1-305.594.7325

Toll Free: 800.689.4716

6741026814 Rev. 01 - 11/2010

GENERAL WARNING: Installation must be realized using parts and accessories approved by SEA. SEA is not

responsible for incorrect installations and/or non-compliance with safety standards according to the law in-force. SEA

is in no way liable for any damages and/or malfunctioning due to using parts and accessories non-compliant with the

UL325 safety standards.

ORDERS: Orders are processed upon approval by SEA. Buyers must confirm orders by sending a written Purchase

Orders to SEA. Purchase Orders are intended as confirmation of orders and binding for the buyer, which accepts SEA

sales condition.

QUOTATION: Quotation and special offers with a non-specified duration expires automatically after 30 days.

PRICES: Prices are based on the Price List in force. Discounts and quotation from Sales Rep. and other selling

branches must be approved by SEA. Prices are F.O.B SEA Warehouse in Miami and do not include shipments costs.

SEAreserves the right to modify the price list at any time and provide notice to its sales network.

PAYMENT: Method of payments and terms are notified by SEA and displayed on the commercial invoice.

DELIVERY: The delivery time on the invoice is not binding and represents an estimated delivery. Shipments costs will

be charged to the buyer and SEA is not responsible for delays and/or damages occurred to the products during

shipment.

COMPLAINS: Complains and/or claims must be notified to SEA within 7 business days after receiving the products.

Claims and complains must be supported by original documents. Customer must contact the factory for instructions

and authorization. Merchandise returned for credit must be current, uninstalled and unused and returned in its original

packaging. Freight must be pre-paid on all authorized returns.

REPAIRS: Repairs and parts are subject to the availability in stock. Shipment of products for repairs must be pre-paid

by the customer. Products shipped without authorization, sender’s details and description of the problems will be

refused. Customers must contact SEAfor instructions.

WARRANTY: for the original buyer only:

Hydraulic and oil-bath motors: 36 months warranty from the date of invoice on manufacturing, assembling and

workmanship defects.

Electro-mechanic motors and electronic control systems: 24 months warranty from the date of invoice on

manufacturing, assembling and workmanship defects.

Lepus and Full Tank Standard model: 60 months warranty from the date of invoice on manufacturing, assembling and

workmanship defects.

No warranty will be recognized for damages due to incorrect installation and/or improper use for which the product was

intended. SEA warranty obligations shall be limited to repair or replace the defective product/parts at SEA option, upon

examination of the products by SEA technical Staff. All replaced parts must remain property of SEA. The warranty

status of the product remains an unquestionable assessment of SEA. Buyer must ship pre-paid defective products.

Products under warranty will be returned pre-paid by SEA. Recognized defects, whatever their nature, will not produce

any responsibility and/or damage claims to SEA USA Inc and SEA s.r.l. Warranty shall not cover any required labor

activities. Warranty will in no case be recognized if alterations and any other changes will be found on products.

Warranty will not cover damages caused by carriers, expendable materials and faults due to improper use with the

products specifications. No indemnities are recognized during repairing and/or replacing of the products under

warranty. SEA USA Inc. and SEA s.r.l. decline any responsibility for damages to person and objects deriving from non-

compliance with safety standards, installation instructions or use of the products sold. It is intended that warranty will be

recognized only on products bought through the SEAauthorized network. Products must be installed by professionals.

No warranty will be recognized if products are installed directly by the final user. Warranty does not apply in case of

unexpected events such as fire, flood, electrical power surge, lightning, vandalism and others.

SEA USA Inc. is not responsible for errors in technical information printed in catalogs and installation

manuals.

SALES CONDITIONS

117 (Vela Ind. Series)

International registered trademark n. 2.777.971

SEA USA Inc.

10850 N.W. 21st unit 160 DORAL MIAMI

Florida (FL) 33172

Phone:++1-305.594.1151

Fax: ++1-305.594.7325

Toll Free: 800.689.4716

To the attention of users and technicians

67410268 15Rev. 01 - 11/2010

web site: www.sea-usa.com

e-mail: [email protected]

SEA USA Inc.

10850 N.W. 21st unit 160 DORAL MIAMI

Florida (FL) 33172

Phone:++1-305.594.1151 Fax: ++1-305.594.7325

Toll Free: 800.689.4716

®

International registered trademark n. 2.777.971

Table of contents