PROGRAMMING A PAIR OF GATES WITHOUT A REBATE/SLAMMING BAR

1

12

ON

Switch-on the mains supply to the control box and check you have 7 Leds lit

1 12

ON

1 12

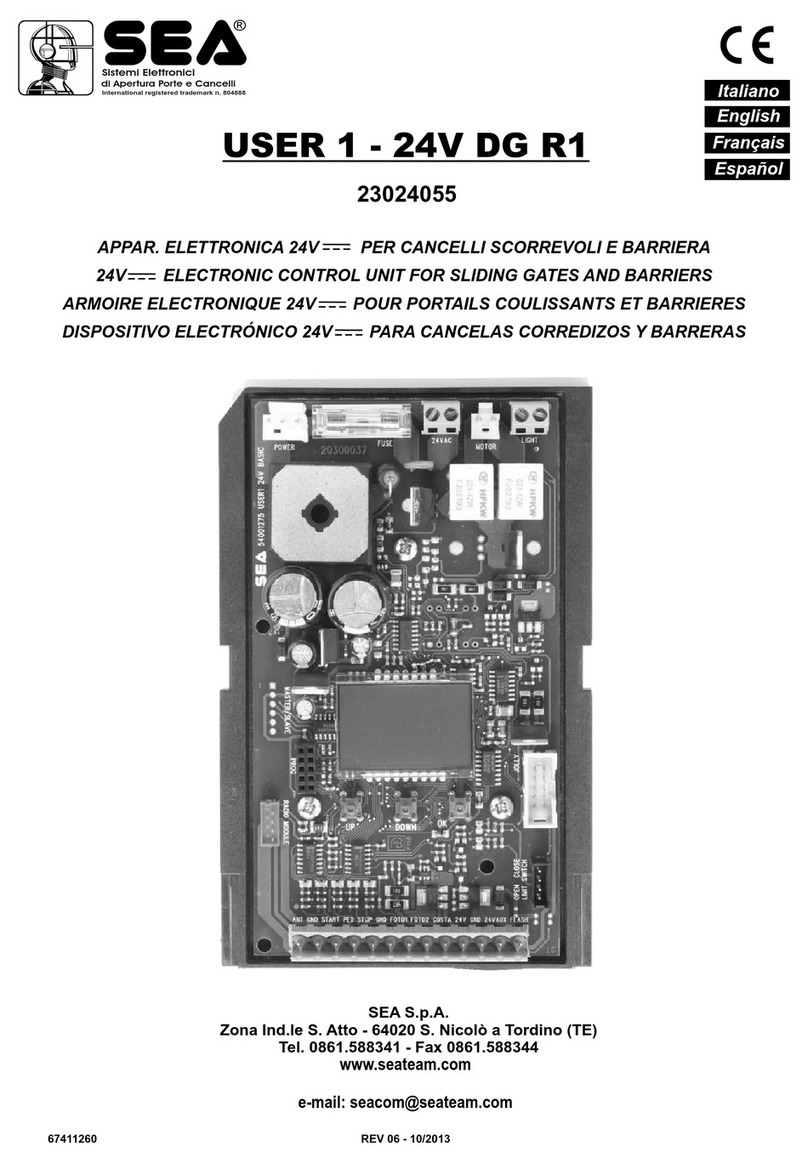

RV3 – O

en Pause

RV2 – Brake Timer

RV1 – Motor Torque

LED 16

P1

P2

Carry out the programming cycle as previously described for gates with rebate

with the exception of the presses shown in red used to set leaf delay times.

It will take a total of 7 presses of the button to complete this programming cycle

PROGRAMMING A SINGLE LEAF GATE

Connect the Gate Motor to the Motor 1 terminals

Do not wire-link out the Limit Switch 2 input (terms. 5 & 6 - CN2)

This programming cycle will only require a total of 4 Presses to complete.

Start with the gate at 45° as previously shown, give Button P a long (10 sec.)

press to enter the programming mode. Then give the button a short press every

time the gate hits a stop.

Fault Indication Chart

If the Gate 2 control unit is not functioning, make the following check:-

Give a ‘Start’ input - If the Programme led (LedP) gives a sequence of flashes,

this may be of assistance in providing an indication of where a fault may be

located. The sequence of Led flashes will last approx. 20 seconds.

Seq. of flashes Fault type Seq. of flashes Fault type

1 Test Photocell 4 Stop

2 Safety Edge 5 Photocell self-test

3 Encoder 6 Triac

More detailed information can be found in the enclosed booklet.

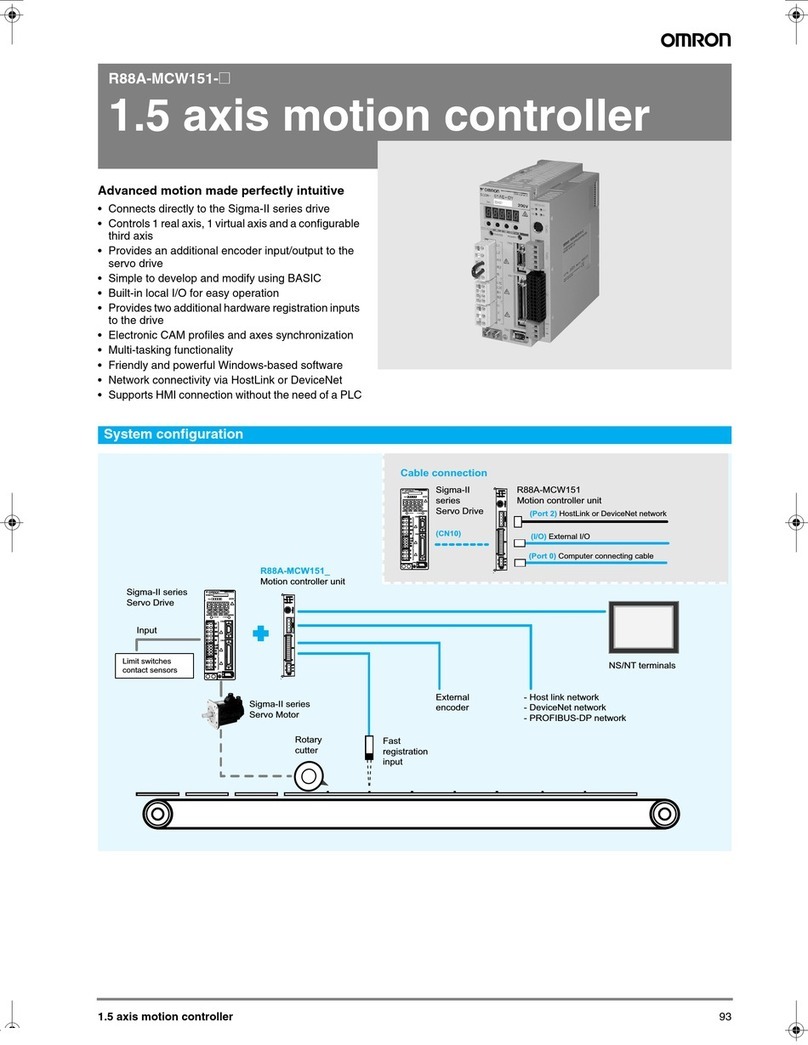

SEA GATE 2 CONTROL BOX

STEP BY STEP PROGRAMMING GUIDE FOR SWING GATES

Before you start the programming phase check all your wiring connections.

Check that all ‘Normally Closed - N.C.’ inputs are either wire-linked out or

connected to a device i.e. Photocells.

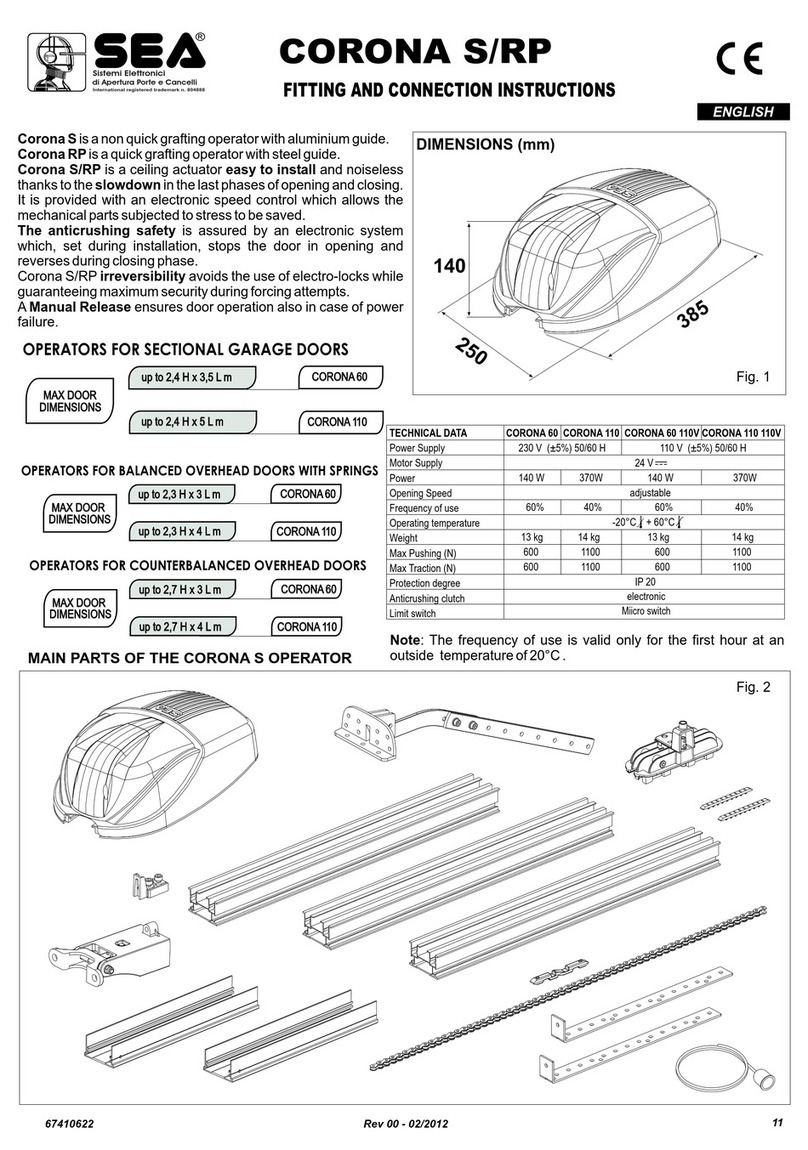

PROGRAMMING A PAIR OF GATES WITH A REBATE OR SLAMMING BAR

Place the gates at 45° and check the emergency releases are reconnected

Set logic DIP switches 1 to 3 ON

If you do not have the correct

number of Leds lit – Switch-off

the mains supply to the control

box and check all ‘normally

closed’ (N.C.) inputs.

Gate 1

Set logic DIP switches 1 to 4 ON

ON

Set logic DIP switches 1 to 3 ON

Gate 2

Contact details:-

SEA

UK

Ltd.

Tel: 0121 706 9629 – Fax: 0121 764 5603 -

email: sales

seaukltd.co.uk

LED P

LED 1

LED 13

TRIMMER DIALS