SeaHawk 10K User manual

Leak Detection

SeaHawk 10K

User Guide

Version 2.0

rletech.com 2 970.484.6510

Copyright and Trademark Notices

© Raymond & Lae Engineering, Inc. 2011. All rights reserved. RLE®is a registered trademark and

SeaHawk™, Falcon™, and Raptor™ are trademarks of Raymond & Lae Engineering, Inc. The

products sold by Raymond & Lae Engineering, Inc. are subject to the limited warranty, limited liability,

and other terms and conditions of sale set forth at http://rletech.com/RLE-Terms-and-Conditions.html.

Revision History

Rev. No. Date

1.0 April 2011

1.1 May 2011

2.0 August 2011

970.484.6510 3 rletech.com

Product Registration

Product registration helps RLE Technologies inform owners of:

• Product upgrades

• New products and technologies

• Special offers available only to registered users

Submit registration information on the Support/Product Registration webpage at www.rletech.com.

Any information provided to RLE Technologies through the registration form will be regarded as

confidential. RLE will not sell or distribute any of the information to third parties. To read our Privacy

Policy, please visit our website: www.rletech.com.

Technical Support

Personal assistance is available Monday through Friday, from 8:00 a.m. to 5:00 p.m. Mountain Time.

A request for assistance may be sent to support@rletech.com.

Otherwise, please call us directly at: (970) 484-6510, and press “2” for technical support.

The following information is located on the bottom of each SeaHawk 10K unit. Please have this

information available whenever a technical support call is placed:

Product Model Number

Product Serial Number

Product Manufacture Date

rletech.com 4 970.484.6510

RLE Product Warranty

Seller warrants to the Ultimate Purchaser (the purchaser who buys for use and not for resale) that all

products furnished under this order and which are manufactured by Seller will conform to final

specifications, drawings, samples and other written descriptions approved in writing by Seller, and will be

free from defects in materials and workmanship. These warranties shall remain in effect for a period of

twelve (12) months after shipment. If the Seller installs the equipment or supplies technical direction of

installation by contract, said one year shall run from the completion of installation, provided installation is not

unreasonably delayed by Ultimate Purchaser. Parts replaced or repaired in the warranty period shall carry

the unexpired portion of the original warranty. A unit placed with the purchaser on consignment and then

later purchased will be warranted for twelve (12) months from the time the Seller receives notification of the

Purchaser's intent to purchase said consigned item. The foregoing is in its entirety is subject to the provision

that in no case will the total warranty period extend beyond 18 months from date Seller ships equipment

from point of manufacture.

Products are NOT life and safety certified. In no event shall the Seller be liable for loss, damage, or expense

directly or indirectly arising from the use of the units, or from any other cause, except as expressly stated in

this warranty. Seller makes no warranties, express or implied, including any warranty as to merchantability

or fitness for a particular purpose or use. Seller is not liable for and Purchaser waives any right of action it

has or may have against Seller for any consequential or special damages arising out of any breach of

warranty, and for any damages Purchaser may claim for damage to any property or injury or death to any

person arising out of its purchase or the use, operation, or maintenance of the product. Seller will not be

liable for any labor subcontracted or performed by Purchaser for preparation of warranted item for return to

Seller's factory or for preparation work for field repair or replacement. Invoicing of Seller for labor either

performed or subcontracted by Purchaser will not be considered as a liability by the Seller.

The liability of Seller hereunder is limited to replacing or repairing at Seller's factory or on the job site at

Seller's option, any part or parts which have been returned to the Seller and which are defective or do not

conform to such specifications, drawings or other written descriptions; provided that such part or parts are

returned by the Ultimate Purchaser within ninety (90) days after such defect is discovered. The Seller shall

have the sole right to determine if the parts are to be repaired at the job site or whether they are to be

returned to the factory for repair or replacement. All items returned to Seller for repair or replacement must

be sent freight, prepaid to its factory. Purchaser must obtain Seller's Return Goods Authorization prior to

returning items. The above conditions must be met if warranty is to be valid. Seller will not be liable for any

damage done by unauthorized repair work, unauthorized replacement parts, from any misapplication of the

item, or for damage due to accident, abuse, or act of God.

This warranty shall be exclusive of any and all other warranties express or implied and may be modified only

by writing signed by any officer of the Seller. This warranty shall extend to the Ultimate Purchaser but to no

one else. Accessories supplied by Seller but manufactured by others carry any warranty the manufacturers

have made to Seller and which can be passed on to the Ultimate Purchaser.

Seller makes no warranty with respect to whether the products sold hereunder infringe any patent, U.S. or

foreign, and Purchaser represents that any specially ordered products do not infringe any patent. Purchaser

agrees to indemnify and hold Seller harmless from any liability by virtue of any patent claims where

Purchaser has ordered a product conforming to Purchaser's specifications, or conforming to Purchaser's

specific design.

Purchaser has not relied and shall not rely on any oral representation regarding the Product sold hereunder

and any oral representation shall not bind Seller and shall not be part of any warranty.

Contents

rletech.com 5 970.484.6510

1 Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2 Installation and Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Prepare for Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Physical Connection Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Mount the SeaHawk 10K . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Establish Physical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

TB1: Summary Relay (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

TB2: Leader Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

TB3 and TB4: Input Power and EIA-485 Modbus Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Select Alarm Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Enable and Disable the Audible Alarm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Set the Re-Alarm Interval. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Connect the SeaHawk Leak Detection Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Connect Lengths of Sensing Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Secure Sensing Cable to the Floor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Apply Power to the SeaHawk 10K . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Test the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Front Panel Controls and Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Manage Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4 Modbus Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Implementation Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Modes of Transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Slave Address Field. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Function Field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Data Field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Error Check (Checksum) Field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5-1.2 Exception Responses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Packet Communications for the SeaHawk 10K . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Function 03: Read Output Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Function 04: Read Input Registers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

RTU Framing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Calibrate Cable Length via Modbus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5 Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

6 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

A Configuration Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

DIP Switch Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

SW1 - Configure the SeaHawk 10K. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Configure the SeaHawk 10K Modbus Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

970.484.6510 6 rletech.com

Figures

rletech.com 7 970.484.6510

1 Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2 Installation and Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

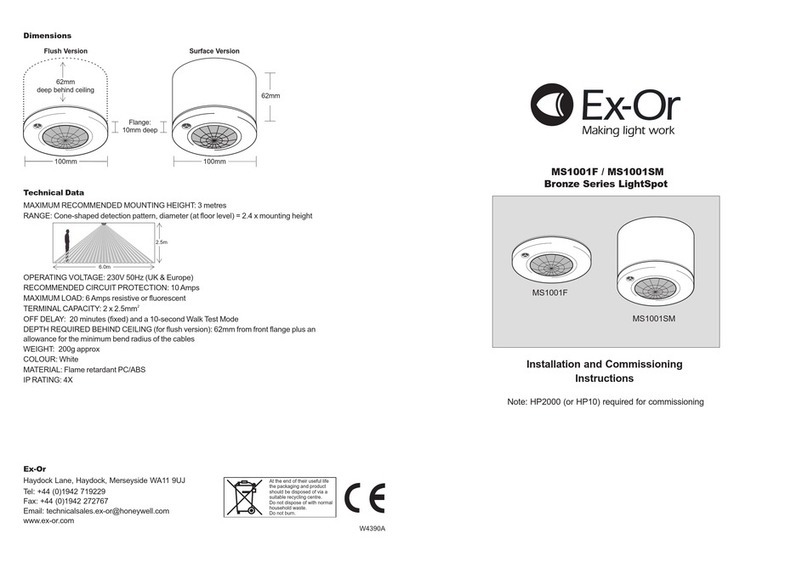

Figure 2.1 SeaHawk 10K Physical Inputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 2.2 Mount the SeaHawk 10K. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 2.3 Relay Output (TB1) and Sensing Cable Connection (TB2) . . . . . . . . . . . . . . 15

Figure 2.4 Power and Modbus Connections (TB3 and TB4) . . . . . . . . . . . . . . . . . . . . . 15

Figure 2.5 Relay Output Connection TB1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 2.6 DIP Switch 5, SW1 - Latched or Unlatched Alarms. . . . . . . . . . . . . . . . . . . . 16

Figure 2.7 Cable Connection TB2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 2.8 DIP Switch 6, SW1 - Display Cable Length in Feet or Meters. . . . . . . . . . . . 16

Figure 2.9 DIP Switch 7, SW1 - Ohms per Foot Resistance . . . . . . . . . . . . . . . . . . . . . 17

Figure 2.10 TB3 and TB4 Power Supply and Modbus Connections . . . . . . . . . . . . . . . . 18

Figure 2.11 DIP Switch Settings for Modbus Baud Rate . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 2.12 SW2 DIP Switch Settings for Modbus Unit Address . . . . . . . . . . . . . . . . . . . 18

Figure 2.13 DIP Switch 8, SW 1 - Audible Alarm Settings . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 2.14 DIP Switches 3 and 4, SW1 - Re-Alarm Interval . . . . . . . . . . . . . . . . . . . . . . 19

Figure 2.15 SeaHawk Sensing Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 2.16 Secure the Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 3.1 Front Panel Controls and Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4 Modbus Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 4.1 DIP Switch Settings for Ohms/Foot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5 Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

A Configuration Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure A.1 SW1 Dip Switch Configuration Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Figure A.2 SW2 DIP Switch Settings for Modbus Unit Address . . . . . . . . . . . . . . . . . . . 41

rletech.com 8 970.484.6510

Tables

rletech.com 9 970.484.6510

1 Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2 Installation and Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Table 3.1 Front Panel Controls and Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4 Modbus Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Table 4.1 Exception Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Table 4.2 Read Output Register Packet Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Table 4.3 Output Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Table 4.4 Read Input Registers Packet Structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 4.5 Input Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 4.6 Status Flags (Register 30001) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 4.7 Response Sample. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5 Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Table 6.1 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

A Configuration Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

970.484.6510 10 rletech.com

www.rletech.com 11 970.484.6510

CHAPTER

CHAPTER 0PRODUCT OVERVIEW

1.1. Description

As RLE’s most cost effective distance-read leak detection solution, the SeaHawk 10K reports

the presence of water and other liquids as detected by sensing cable.

Capable of accommodating up to 10,000 feet (3048m) of sensing cable, the SeaHawk 10K has

an audible alarm and can communicate via Modbus. As a stand-alone solution, the

SeaHawk 10K provides alarm notification and numeric distances on its front panel.

Integration into a Modbus network allows the activity and status of one or multiple

SeaHawk 10Ks to be managed from one central location.

1.2. Operation

Supervised System

The SeaHawk 10K is a supervised system – it continually monitors sensing cable and spot

detectors for continuity – and produces alarms for the following conditions:

Leak detection

Cable break

Cable contamination

Distance-Read Leak Detection

When the SeaHawk 10K's circuitry measures a current in excess of the user-defined leak

threshold, the unit's microprocessor computes the distance to the leak. The SeaHawk 10K then

annunciates the leak and communicates via Modbus to a master controller or a Modbus-

equipped monitoring system. The summary relay sends notification to an alarm panel or

monitoring system.

www.rletech.com 12 970.484.6510

1Product Overview

User Configuration and Communication

The SeaHawk 10K’s front panel display – which includes a four-digit LED panel and six LED

indicators – provides information about its status, including the following:

Leak detected

Cable fault detected

Power status

Configured unit of measure

Leak detection cable’s amperage value

Distance to leak or contamination

Length of installed leak detection cable

Self-test results

The two blocks of DIP switches on the SeaHawk 10K’s front panel are used for configuration.

DIP SW1 configures parameters such as leak and contamination thresholds, latching alarms,

and realarm time interval. The DIP SW2 is used to set the Modbus address for the unit.

The SeaHawk 10K also provides configuration capability and status information to a Modbus-

equipped system via its EIA-485 port.

www.rletech.com 13 970.484.6510

CHAPTER

CHAPTER 0INSTALLATION AND CONFIGURATION

2.1. Prepare for Installation

To install the SeaHawk 10K, you’ll need following supplies:

Included with the SeaHawk 10K

15 foot (4.57m) leader cable

End-of-line terminator (EOL)

Available from RLE, sold separately

12-24 VAC/VDC, 50-60Hz isolated power supply

SeaHawk Sensing Cable, up to 10,000 feet (3048m)

J-Clips

Available from other vendors

Electrostatic discharge (ESD) protection

2.2. Physical Connection Overview

The SeaHawk 10K contains two circuit boards:

The top circuit board houses operational controls and displays. SeaHawk 10K operational

information is found in Chapter 3.

The lower circuit board houses the connectors for:

– AC/DC power

– Relay output

– Leak detection cable

– Modbus communications.

www.rletech.com 14 970.484.6510

2Installation and Configuration

Figure 2.1

SeaHawk 10K Physical Inputs

2.3. Mount the SeaHawk 10K

The SeaHawk 10K can be mounted inside a panel or on a DIN rail. The device has two

adjustable orange clips on the bottom. Push the clips out to expose two screw holes that allow

the device to be mounted in a panel; push the clips in to mount it on a DIN rail.

Figure 2.2

Mount the SeaHawk 10K

AC/DC Power Connections (2)

and

Modbus EIA-485 Ports (2)

Relay

Output

Sensing Cable

Connection

www.rletech.com 15 970.484.6510

2Installation and Configuration

2.4. Establish Physical Connections

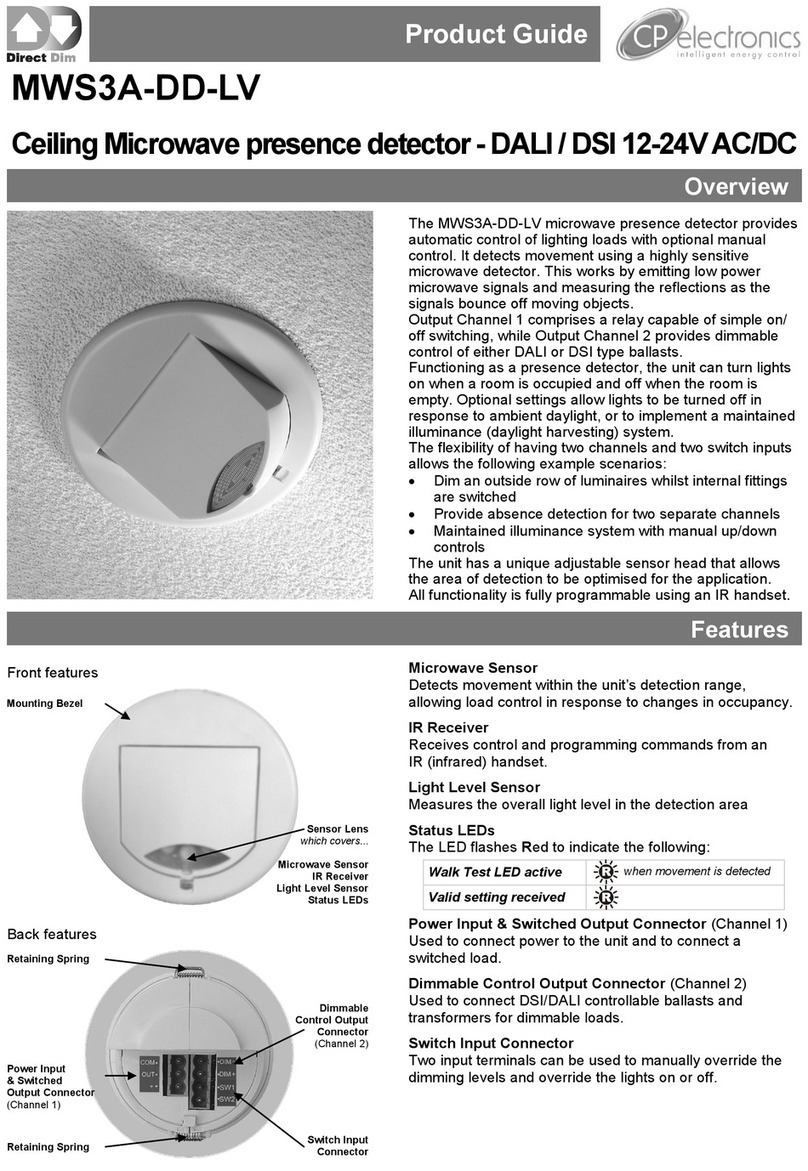

Figure 2.3

Relay Output (TB1) and Sensing Cable Connection (TB2)

Figure 2.4

Power and Modbus Connections (TB3 and TB4)

2.4.1 TB1: Summary Relay (optional)

Terminal Block 1 is a Form C relay output. This relay enables alarm notification through a

local or remote panel, master controller, or BMS whenever a leak, cable fault, or cable

contamination is detected.

1Insert the wires into the appropriate slots on TB1 to connect the relay output to the desired

panel or controller.

Figure 2.5

Relay Output Connection TB1

Relay Output

Sensing Cable

Connection

AC/DC Power Connections (2)

and

Modbus EIA-485 Ports (2)

www.rletech.com 16 970.484.6510

2Installation and Configuration

2Use DIP switch 5 on the SW1 DIP switch block to configure this relay as latched or

unlatched.

An unlatched alarm resets itself once a detected leak or cable problem has been resolved.

A latched alarm must be manually reset, even if the detected leak or cable problem is no

longer present.

Figure 2.6

DIP Switch 5, SW1 - Latched or Unlatched Alarms

2.4.2 TB2: Leader Cable

1A 15-foot (4.57m) section of non-sensing leader cable is supplied with each SeaHawk 10K.

The leader cable connects sensing cable to the SeaHawk 10K, since sensing cable cannot

connect directly to the unit. Insert its four stripped wires into the appropriate slots in TB2 –

from left to right: white, black, green, and red.

Figure 2.7

Cable Connection TB2

Note If the terminal connector is removed from the end of the cable, make sure the wires are in

this same order, W - B - G - R, when the connector is reapplied.

2Use DIP switch 6 in block SW1 to designate whether the distance on the display is shown in

feet or meters:

Figure 2.8

DIP Switch 6, SW1 - Display Cable Length in Feet or Meters

3RLE’s orange sensing cable has a resistance of 2.8 ohms per foot. Most other sensing cables

have a resistance of 4.0 ohms per foot. If you have questions regarding the resistance of

www.rletech.com 17 970.484.6510

2Installation and Configuration

your cable, please reference the cable’s data sheet. Set DIP switch 7 in block SW1 to the

appropriate resistance-per-foot value.

Figure 2.9

DIP Switch 7, SW1 - Ohms per Foot Resistance

2.4.3 TB3 and TB4: Input Power and EIA-485 Modbus Port

The SeaHawk 10K operates on either 12-24VAC or 12-24VDC power. A power supply is not

included with the SeaHawk 10K.

An isolated power supply must be provided for the SeaHawk 10K. A dedicated

circuit breaker must also be provided within close proximity to the SeaHawk 10K

and clearly be marked as the disconnecting device for the SeaHawk 10K leak

detection controller.

Do not connect 120/230 VAC to the unit, or damage will occur to the circuitry.

1Run a power supply to the location of the SeaHawk 10K, or use a DIN rail mountable

power supply and mount it next to the SeaHawk 10K.

2If you are installing just one SeaHawk 10K, use the two left-most pinouts on either TB3 or

TB4 (marked AC/DC) to connect power to the SeaHawk 10K. Insert the positive and

negative wires of the power supply into either of the pinouts; the SeaHawk 10K’s circuitry

will auto-correct.

If you are installing more than one SeaHawk 10K, use TB3 and TB4 to create a daisy-

chained power connection.

3If you are installing just one SeaHawk 10K and it will communicate via Modbus to a

Modbus-enabled controller, use the three right-most pinouts on TB3 or TB4 to connect the

SeaHawk 10K to an EIA-485 network.

If you are installing more than one SeaHawk 10K, use the appropriate pinouts of TB3 and

TB4 to create a daisy-chained Modbus connection.

WARNING

www.rletech.com 18 970.484.6510

2Installation and Configuration

A grounded shield contact is provided for connection to shielded cable. If the shield contact

is used, verify the power connector is properly grounded and there is no voltage potential

between units on the Modbus network.

Figure 2.10

TB3 and TB4 Power Supply and Modbus Connections

4Set the baud rate for the EIA-485 port using DIP switches 1 and 2 on SW1:

Figure 2.11

DIP Switch Settings for Modbus Baud Rate

Note The EIA-485 port is set to 8 databits, no parity, and 1 stop bit (8, N, 1).

5DIP SW2 is used to set the address of the Modbus device, which should be a number

between 1 and 254. Adjust the individual switches until their sum equals the Modbus

address. The following illustration shows the values of the DIP switches on the SW2 block

as well as two examples of how the DIP switches would be set for specific unit addresses.

Figure 2.12

SW2 DIP Switch Settings for Modbus Unit Address

www.rletech.com 19 970.484.6510

2Installation and Configuration

2.5. Select Alarm Options

2.5.1 Enable and Disable the Audible Alarm

The audible alarm is disabled by default. To modify this setting, adjust switch 8 on DIP SW1:

Figure 2.13

DIP Switch 8, SW 1 - Audible Alarm Settings

2.5.2 Set the Re-Alarm Interval

The SeaHawk 10K can be set to re-alarm – after a leak or cable fault has been detected, the

alarm will be re-sent at a designated interval until the alarm condition has been resolved. This

re-alarm triggers both the audible alarm and the Modbus register 30001 readout. The SeaHawk

10K can be configured to re-alarm after 4 hours, 8 hours, or 24 hours have passed.

The re-alarm option is disabled by default. Adjust the re-alarm setting with DIP switches 3 and

4 of SW1:

Figure 2.14

DIP Switches 3 and 4, SW1 - Re-Alarm Interval

2.6. Connect the SeaHawk Leak Detection Cable

IMPORTANT To avoid faulty leak detection readings, connect a minimum length of 35 feet (10.7m) of

sensing cable to the SeaHawk 10K.

The SeaHawk 10K is shipped with a 15-foot (4.57m) leader cable. This leader cable was

connected to the SeaHawk 10K in Section 2.4.2 on page 16. The following directions help you

connect sensing cable to the SeaHawk 10K.

2.6.1 Connect Lengths of Sensing Cable

1Unscrew the end-of-line (EOL) terminator from the end of the leader cable.

www.rletech.com 20 970.484.6510

2Installation and Configuration

2Attach the first length of sensing cable to the leader cable. Insert the male pins into the

female connector, and twist the collar on the female side of the connector to secure.

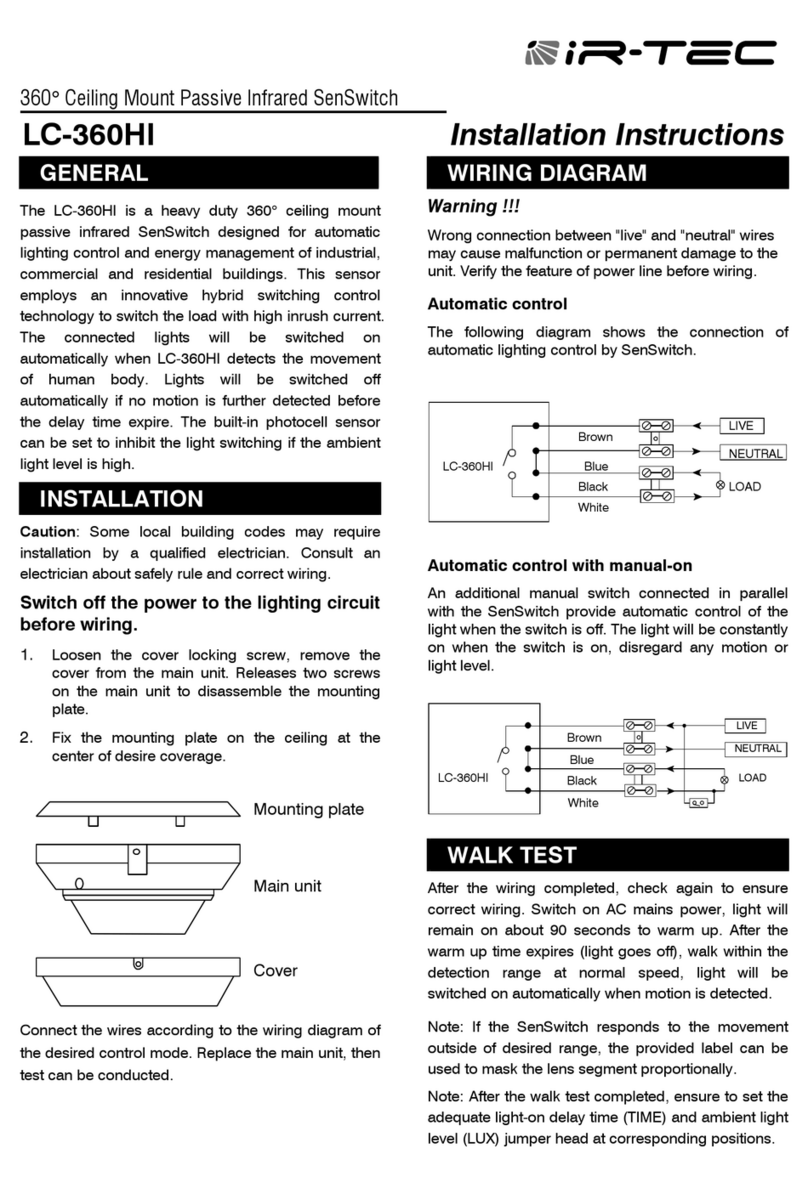

Figure 2.15

SeaHawk Sensing Cable

3Route the sensing cable according to your cable layout diagram. Attach additional lengths

of sensing cable as necessary.

4Secure the EOL terminator to the unoccupied end of the last length of sensing cable.

Note If the EOL terminator is not present at the end of the cable run, a cable fault will register.

5If you are using a reference map, compare it with the actual cable installation. Revise any

discrepancies created through the physical installation of the cable.

2.6.2 Secure Sensing Cable to the Floor

Secure the sensing cable to the floor with either J-clips (RLE part #JC), or one of the other

approved methods shown in Figure 2.16. Available from RLE and designed specifically for

use with sensing cable, J-clips are the manufacturer's recommended installation method.

To avoid contaminating the cable, clean the entire floor as much as possible. Use isopropyl

alcohol to clean the spots on the floor where J-clips will be placed.

Place one J-clip every 5 to 6 feet (1.52 to 1.83m) along the length of the sensing cable and

one at each turn of the cable. Use more J-clips if a tighter configuration is required.

If the cable is installed over an obstruction, clip the cable on both sides, as close to the

obstruction as possible.

The J-clip’s adhesive backing does not work well on porous concrete floors. RLE

recommends using a drop of silicone or another nonconductive adhesive to help secure the

J-clip to the floor.

IMPORTANT Do not install the cable directly in front of an air conditioner. Allow a minimum of 4 to 6 feet

(1.22 to 1.83m) between the unit and the cable. If the cable is too close to the air conditioning

unit’s air stream, the moisture from the humidifier may cause false leak readings. If the cable

must be installed in front of an air conditioning unit, place the J-clips 3 feet (0.91m) apart.

Table of contents

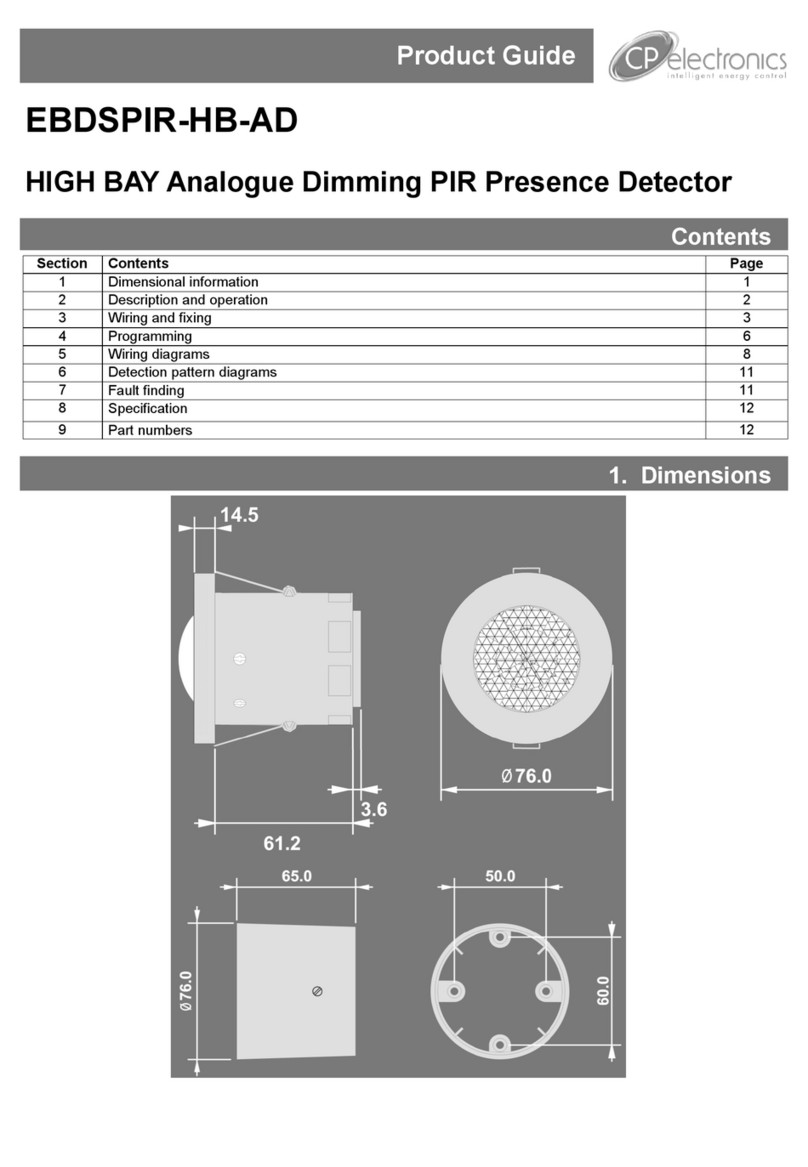

Popular Security Sensor manuals by other brands

C.P. Electronics

C.P. Electronics MWS3A-PRM-VFC-LV installation guide

GSM Activate

GSM Activate IR BEAM manual

Blackline Safety

Blackline Safety G7 Technical user's manual

C.P. Electronics

C.P. Electronics EBDSPIR-HB-AD Product guide

SignalFire

SignalFire Sentinel-RTD Series Interface manual

UseTECH

UseTECH FlowTimer+ Detect Set operating manual

C.P. Electronics

C.P. Electronics EBDSPIR-DD installation guide

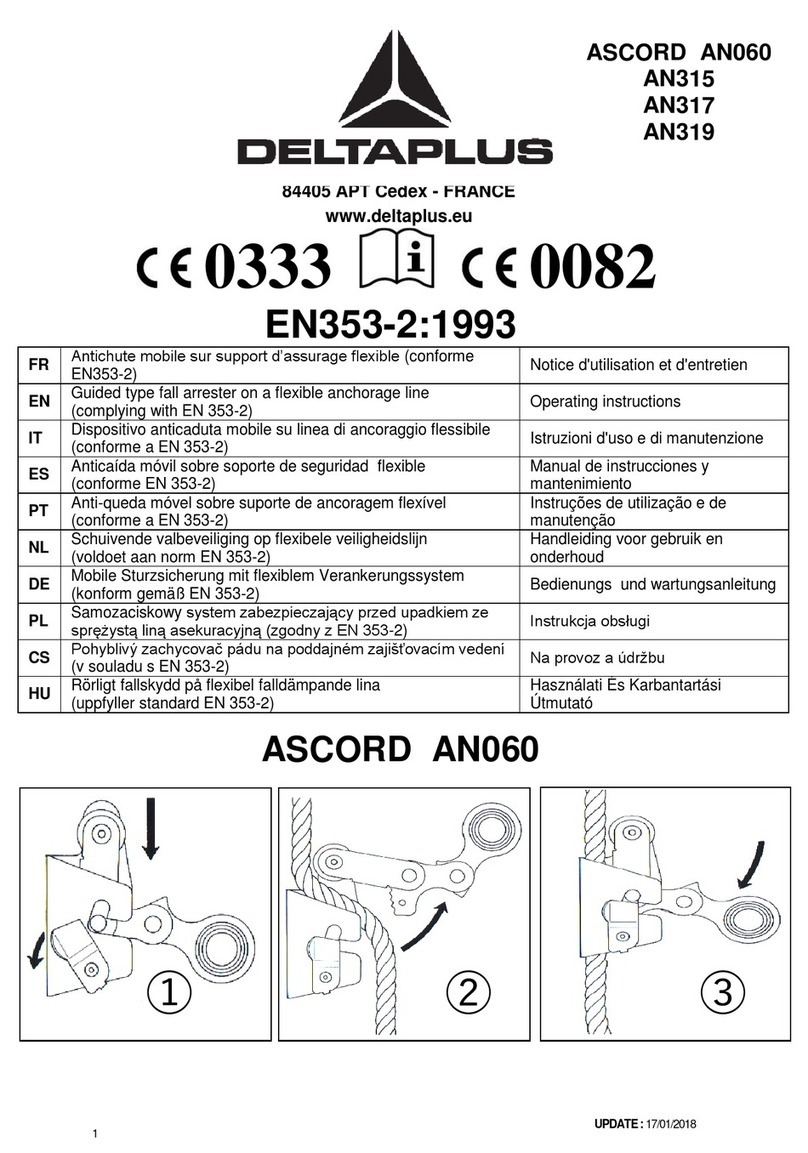

DELTA PLUS

DELTA PLUS ASCORD AN060 instructions

Stealth Tronic

Stealth Tronic Extension Cord Detector user manual

In-situ

In-situ SludgeWatch 715 Operator's manual

Contro l4

Contro l4 C4-KNX-BW180 Series user guide

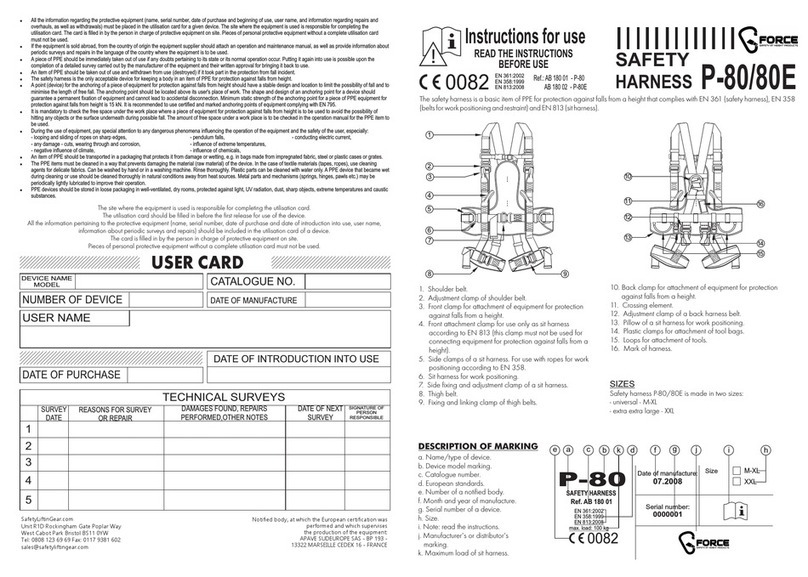

G-Force

G-Force P-80 Instructions for use