7

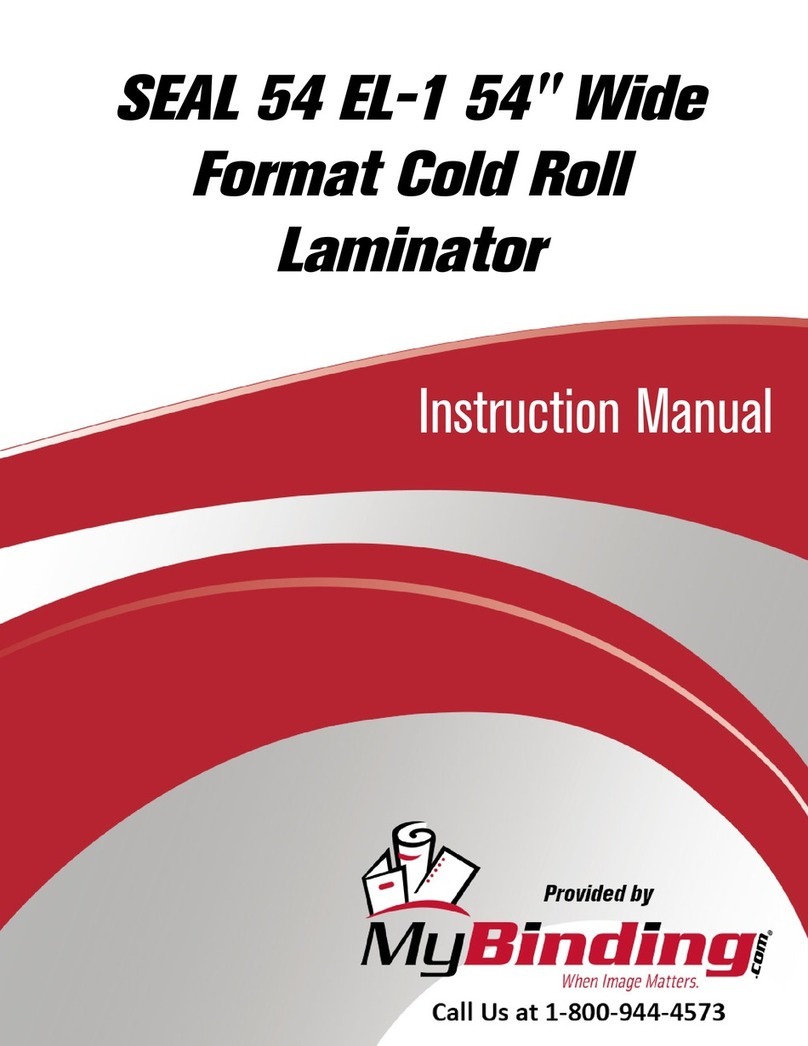

WEBBING FILM FOR APPLICATIONS

Pressure Sensitive Applications (Laminate & Adhesive)

LEADER CARD

9

4

6

7

5

10

8

1. Insert (upper/lower) Autogrip Shaft into film core with the tension control knob to the

operators right (from the front of the machine) and align the films top to bottom by sight.

2. Remove the Safety Cover and set aside (reinstall after step #10).

3. Remove feed table and print guide, set aside (reinstall after step#10).

4. Web upper pressure sensitive film (w/release liner) under the stationary idler, then up onto

the take up shaft core, making sure the film is centered on the core. Note: using a 3" wide

strip of double sided adhesive w/release liner, apply it to the take up core, removing 1/4"

strips of release liner when needed to expose enough adhesive to tack film securely to the

core.

5. Set the Nip Adjustment Lever to the fully open Position (Orange 3/8 - 1/2").

6. Position the release point of the lower adhesive film roll so that it unwraps from the top of the

roll. Now pull the film away from the roll and extend to the mid point of the upper teflon

coated roll and then slide downward and tuck to the nip.

7. Place a 10"x40"x1/16" leader card squarely into the crease of the lower supply roll at its

separation point. Now take the lead edge of the adhesive (currently tucked to the nip) and

press up to the backside of the leader card.

8. Insert the leader card with attached adhesive into the nip. Push leader card through to the

pull rolls, leaving approximately 2" of the leader card still visable. Make sure film is taught

without wrinkles before proceeding, if required, reinsert.

9. Lower the nip selector position to the Lamination Mode (Sea Foam - Closed).

10. Using a piece of tape, place the sticky side to a corner of the release liner backed adhesive

film and pull the film & adhesive away from the release liner. Pull the entire width of film

away from the liner (now tacked to the take up core). Once the adhesive film has been pulled

cleanly away from the liner, pull the film down over the Upper Teflon Coated roller and press

against the lower adhesive just in front of the leader card, making sure to pull the film taught

and even across the roll face.

11. Reinstall table, print guide and film cover.

12. Press the run button or foot switch to process the leader card through the main nip and pull

rollers.

13. Choose from one of the pre-programmed settings for cold lamination or adjust speed and

temperature as desired.

14. Process images to be decal'ed.