BEL 507 TILT CASE PACKING STATION 5

65-14-8 2/19/2007

S

SA

AF

FE

ET

TY

Y

C

CA

AU

UT

TI

IO

ON

N

Although BEL 507 packing stations can be used in conjunction with competitive case

taper/sealers, BELCOR cannot assume responsibility for safety issues resulting from these

applications.

We specifically do not recommend using these packing stations in close proximity with

conventional back flap kickers and three-flap folders.

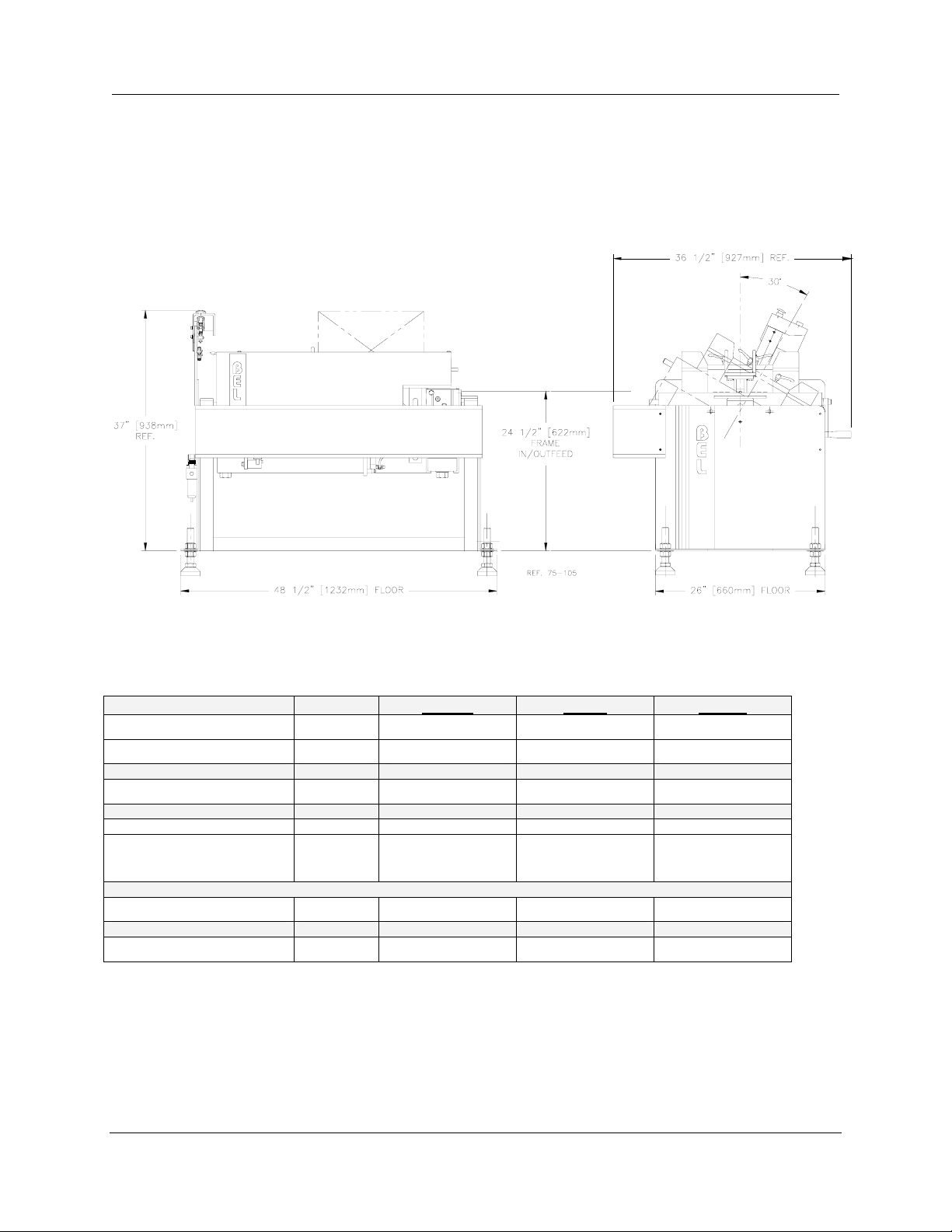

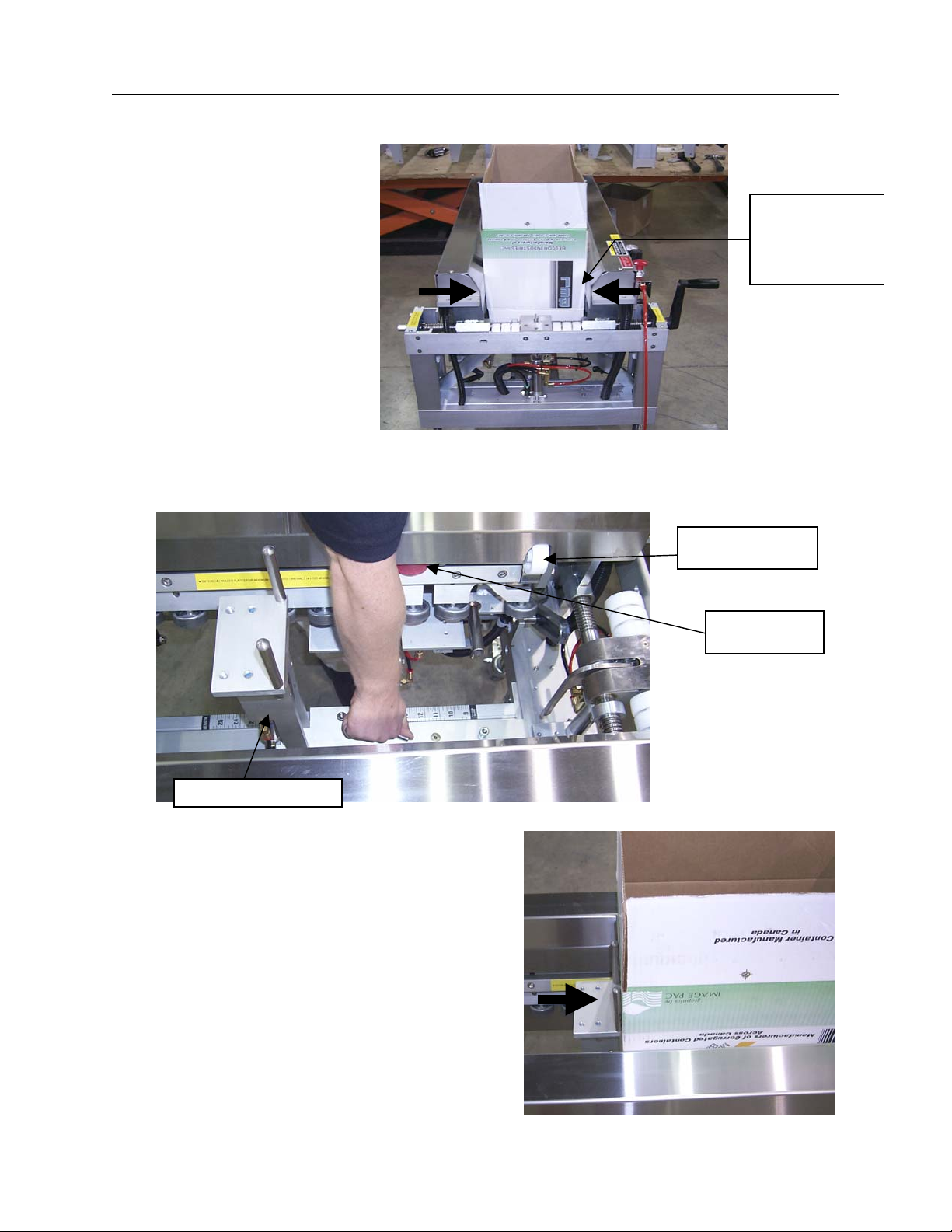

INSTALLATION OF THE BEL 507 TILT CASE PACKING STATION

Uncrate the machine and remove any packing material from the interior or supports from underneath used

to protect components during shipping.

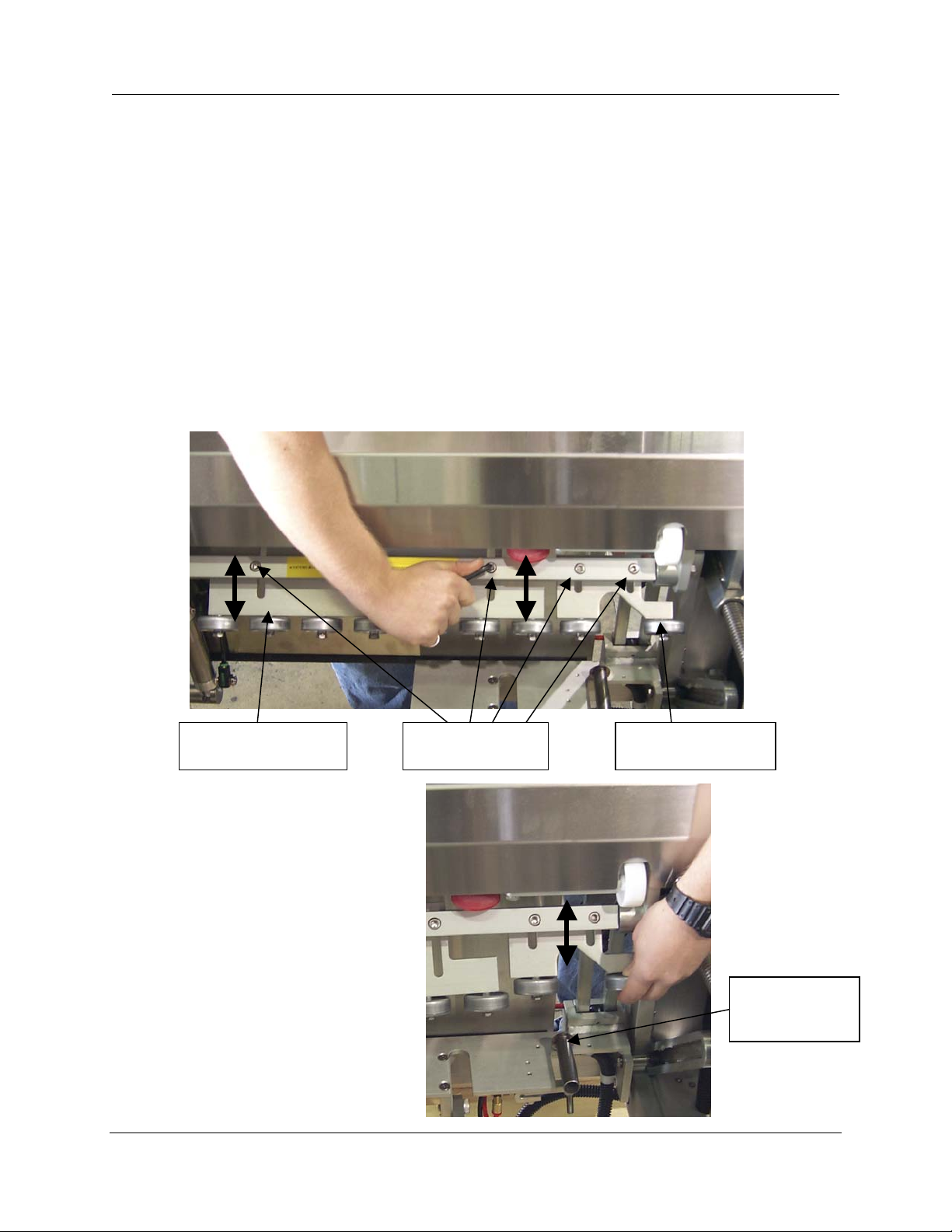

Leveling the Machine

The base of the tilting frame should be made level to ensure personnel safety, provide optimum

performance and avoid frame stress.

The machine should be securely mounted to the floor and/or adjoining equipment to prevent the machine

moving as it operates.

AIR CONNECTION

S

SA

AF

FE

ET

TY

Y

C

CA

AU

UT

TI

IO

ON

N

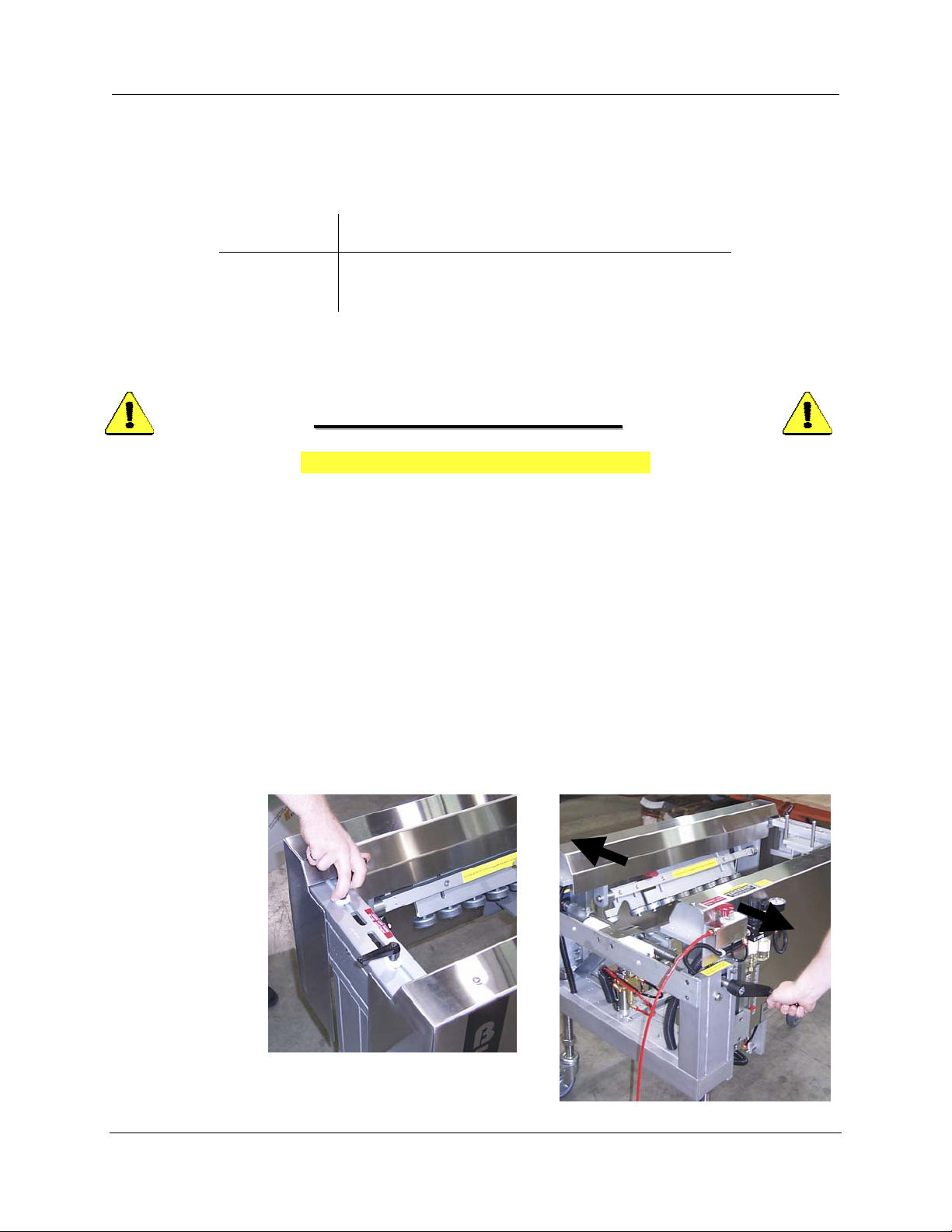

The tilt packing station will immediately move into the tilted position when first pressurized

from an air supply if the position of the red emergency stop button is in the operating position

(UP).

Make sure that the main on/off valve at the air connection is shut off and that the red emergency stop

button is pushed down before connecting an air supply to the machine.

Connect the machine to an air supply via the port in the combined shut-off valve, air filter, regulator and

lubricator attached to the machine end guard.

The air may come from either a separate source or by tapping off the supply of an adjoining case closer.

The supply must be clean factory air and must be lubricated. Pressure should be set to a minimum of 65

psi., maximum of 100 psi.