Floeter AirWave 2 User manual

OPERATING INSTRUCTIONS

OPERATING INSTRUCTIONS

1

Contents

Safety guidelines 2

Air cushion types – Type 7 filler 3

Air cushion types – Type 8 wrapper 4

Machine overview 5

Technical data 5

Recommended settings 6

Accessories and spare parts 8

Initial operation 9

Operating instruction 11

Preset function – quick selection 13

Lock function 14

Change the knife 15

Change the Teflon belt 18

Change the transport belt 21

Film guide pins 24

Error codes 25

Options and expandability 26

Advanced settings 28

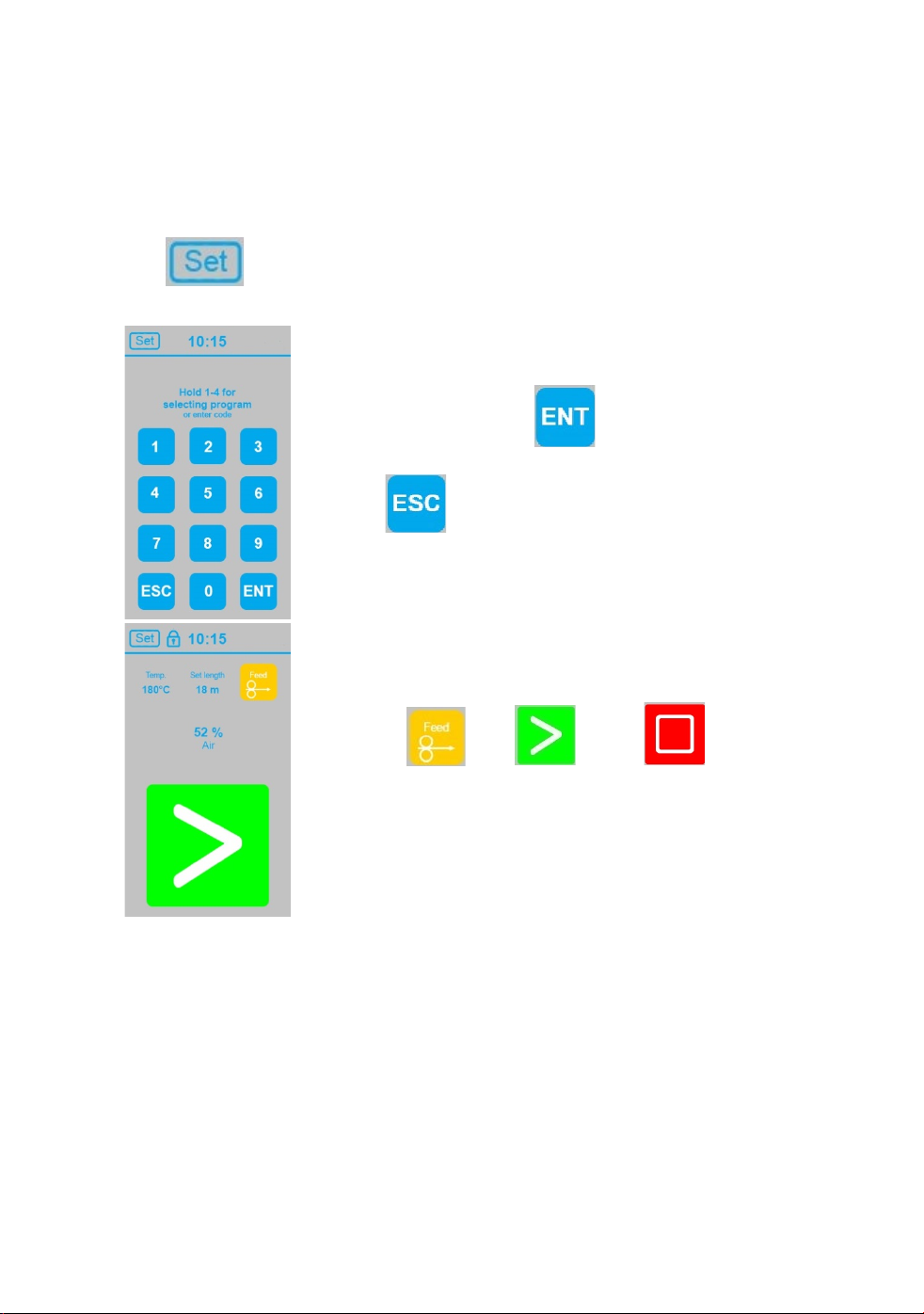

To change advanced settings touch at start screen. 28

Enter code “1-3-5”, continue with and choose desired submenu. 28

Maintenance & Cleaning 29

Warranty 30

Declaration of Conformity 30

Support and Service 31

Document version 25.04.2019

OPERATING INSTRUCTIONS

2

Safety guidelines

Please read the safety guidelines and operating instruction closely before using the

machine.

- Turn off the machine and disconnect power before opening the machine or performing

any repair or maintenance work on the machine.

- Switch off the machine if it will not be used for an extended period of time.

- Do not insert any objects into the machine when it is connected to power.

- To prevent the risk of electric shock, ensure that the machine does not come into contact

with liquids.

- Do not operate the machine without the covers for the machine components.

- Keep hair and loose clothing away from the film feed mechanism.

- Place the machine only on surfaces that are adequately large, stable, flat, and horizontal.

This machine is designed for safe operation in compliance with the use, instructions, and

guidelines specified in these operating instruction.

All persons who use this machine must be familiar with the content of

these operating instructions and must carefully follow the safety

guidelines.

FLOETER shall not be responsible for damage resulting from improper use of the machine

or non-observance of the safety guidelines.

OPERATING INSTRUCTIONS

3

Air cushion types – Type 7 filler

Our standard version – Polyethylene 20 µm

7.1-7.3 with 700 m; 7.4-7.5 with 600 m

Type 7.1 AirWave air cushion filler 100 x 210 mm

Ideal for filling small voids and for use as an intermediate layer

Type 7.2 AirWave air cushion filler 150 x 210 mm

Ideal for filling medium-sized voids and for use as an air cushion ring

Type 7.3 AirWave air cushion filler 200 x 210 mm

Ideal for filling large voids

Type 7.4 AirWave air cushion filler 130 x 300 mm

Ideal for filling large voids

Type 7.5 AirWave air cushion filler 240 x 300 mm

Ideal for filling large voids

All type 7.x are also available as Jumbo rolls with more running meters per roll,

and also in 15µm or 12µm, in pink antistatic version, in our „Heavy Duty“ version made of laminated

material, or as 100% biodegradable material.

Get in touch with us.

OPERATING INSTRUCTIONS

4

Air cushion types – Type 8 wrapper

Our standard version – Polyethylene 20µm

8.1-8.6 with 450 m; 8.3 600 with 300 m

Type 8.1 AirWave wrapper 420mm 2 large chambers

2 large chambers for large volumes and for use as a top layer

Type 8.2 AirWave wrapper 420mm 2 small chambers

2 chambers for moulded components, edge protection, and

wrapping

Type 8.3 AirWave wrapper 420mm 4 chambers

4 chambers for use as an intermediate layer, wrapping, and

envelope

Type 8.4 AirWave wrapper 420mm 8 chambers

8 chambers for use as an envelope and intermediate layer

Type 8.5 AirWave wrapper 420mm 7 wavy chambers

7 chambers for use as an envelope and intermediate layer

Type 8.6 AirWave wrapper 420mm cloud type chambers

4 chambers for use as an envelope and intermediate layer

Type 8.3-600 AirWave wrapper 600mm 6 chambers

6 chambers for use as an envelope and intermediate layer

All type 8.x are also available as Jumbo rolls with more running meters per roll,

and also in 15 µm or 12 µm, in pink antistatic version, in our „Heavy Duty“ version made of laminated

material, or as 100% biodegradable material.

Get in touch with us.

OPERATING INSTRUCTIONS

5

Machine overview

Technical data

Power supply: 115-240 V; 50-60 Hz

Power consumption: 200 W

Production speed: 20 m / min resp. 10 m / min

Weight: 6,25 kg

Color: Standard: anthracite / blue (individual on request)

AirWave2 dimensions (l / w / h): 413 / 316 / 232 mm

(extendible base 150mm)

Control panel

Filling pipe for

air supply

Sensor end of film

Film channel

Film roll shaft

Power cord, power switch

Interface for external

control (optional)

Extendable base

Connection jumbo roll

holder

(optional)

Spare part

compartment

OPERATING INSTRUCTIONS

6

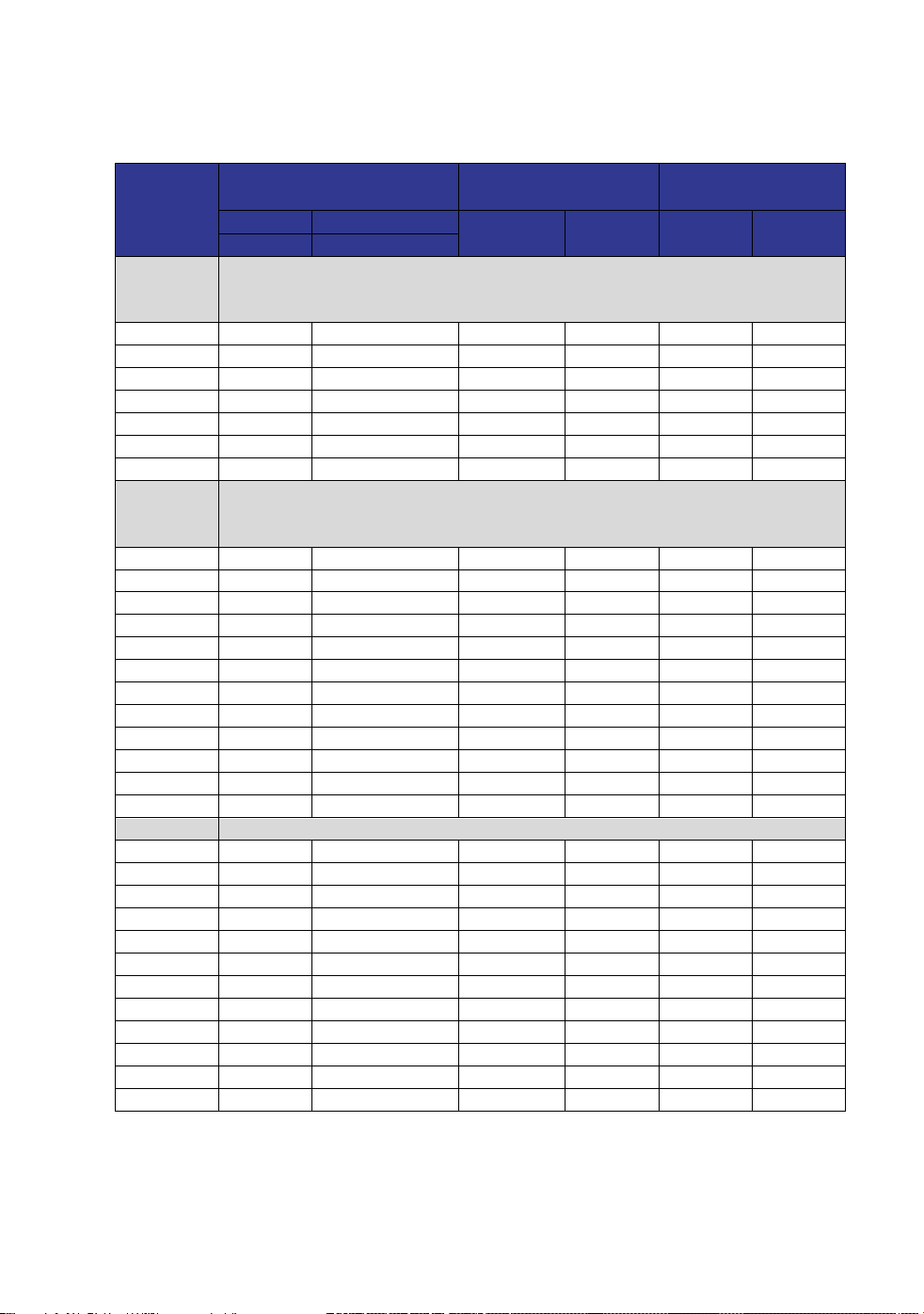

Recommended settings

*Recommended speed: 12m/min **Guiding pins recommended

Cushion

Type

Recommended

Temperature [°C]

Recommended Air

Volume

Blowing Time

12m/min

20m/min

12m/min 20m/min 12m/min 20m/min

°C

°C

PE

(20µm):

7.1

235-250

250-270

30-45

30-50

0

0

7.2

235-250

250-270

30-45

35-50

0

0

7.3

235-250

250-270

35-50

35-50

+0,1

+0,3

7.4

235-250

250-270

35-50

35-50

+0,1

+0,3

7.5

235-250

250-270

40-60

45-65

+0,1

+0,3

*8.1

235-250

-

60-80

-

0

-

*8.2

235-250

-

60-80

-

0

-

**8.3

235-250

250-270

70-90

80-95

-0,1

0

**8.4

235-250

250-270

70-90

80-95

-0,1

-0,3

8.5

235-250

250-270

75-95

90-100

-0,1

-0,3

8.6

235-250

250-270

75-95

90-100

-0,3

-0,3

*8.3-600

235-250

-

90-100

-

-0,3

-0,3

ECO

(15µm):

7.1

210-230

230-250

30-45

30-50

0

0

7.2

210-230

230-250

30-45

35-50

0

0

7.3

210-230

230-250

35-50

35-50

+0,1

+0,3

7.4

210-230

230-250

35-50

35-50

+0,1

+0,3

7.5

210-230

230-250

40-60

45-65

+0,1

+0,3

*8.1

210-230

-

60-80

-

0

-

*8.2

210-230

-

60-80

-

0

-

**8.3

210-230

230-250

70-90

80-95

-0,1

0

**8.4

210-230

230-250

70-90

80-95

-0,1

-0,3

8.5

210-230

230-250

75-95

90-100

-0,1

-0,3

8.6

210-230

230-250

75-95

90-100

-0,3

-0,3

*8.3-600

210-230

-

90-100

-

-0,3

-0,3

Super

ECO

(12µm):

7.1

200-220

220-240

30-45

30-50

0

0

7.2

200-220

220-240

30-45

35-50

0

0

7.3

200-220

220-240

35-50

35-50

+0,1

+0,3

7.4

200-220

220-240

35-50

35-50

+0,1

+0,3

7.5

200-220

220-240

40-60

45-65

+0,1

+0,3

OPERATING INSTRUCTIONS

7

*Recommended speed: 12m/min **Guiding pins recommended

Listed values are recommendations to warrant durability of machine at good results. These values

should not be exceeded. But temperature and air volume can slightly vary dependent on ambient

conditions or application.

Cushion

Type

Recommended

Temperature [°C]

Recommended Air

Volume

Blowing Time

12m/min

20m/min

12m/min 20m/min 12m/min 20m/min

°C

°C

Super

ECO

(12µm):

*8.1

200-220

-

60-80

-

0

-

*8.2

200-220

-

60-80

-

0

-

**8.3

200-220

220-240

70-90

80-95

-0,1

0

**8.4

200-220

220-240

70-90

80-95

-0,1

-0,3

8.5

200-220

220-240

75-95

90-100

-0,1

-0,3

8.6

200-220

220-240

75-95

90-100

-0,3

-0,3

*8.3-600

200-220

-

90-100

-

-0,3

-0,3

Heavy

Duty

(26µm)

7.1

235-250

250-280

30-45

30-50

0

0

7.2

235-250

250-280

30-45

35-50

0

0

7.3

235-250

250-280

35-50

35-50

+0,1

+0,3

7.4

235-250

250-280

35-50

35-50

+0,1

+0,3

7.5

235-250

250-280

40-60

45-65

+0,1

+0,3

*8.1

235-250

-

60-80

-

0

-

*8.2

235-250

-

60-80

-

0

-

**8.3

235-250

250-280

70-90

80-95

-0,1

0

**8.4

235-250

250-280

70-90

80-95

-0,1

-0,3

8.5

235-250

250-280

75-95

90-100

-0,1

-0,3

8.6

235-250

250-280

75-95

90-100

-0,3

-0,3

*8.3-600

235-250

250-280

90-100

-

-0,3

-0,3

Bio:

7.1

170-180

180-200

30-45

30-50

0

0

7.2

170-180

180-200

30-45

35-50

0

0

7.3

170-180

180-200

35-50

35-50

+0,1

+0,3

7.4

170-180

180-200

35-50

35-50

+0,1

+0,3

7.5

170-180

180-200

40-60

45-65

+0,1

+0,3

*8.1

170-180

-

60-80

-

0

-

*8.2

170-180

-

60-80

-

0

-

**8.3

170-180

180-200

70-90

80-95

-0,1

0

**8.4

170-180

180-200

70-90

80-95

-0,1

-0,3

8.5

170-180

180-200

75-95

90-100

-0,1

-0,3

8.6

170-180

180-200

75-95

90-100

-0,3

-0,3

*8.3-600

170-180

-

90-100

-

-0,3

-0,3

OPERATING INSTRUCTIONS

8

Accessories and spare parts

Power cord (1 pcs)

Hex key (3 pcs)

Teflon belt (1 pcs)

Knife (1 pcs)

Fuse (1 pcs)

Film guide pins (2 pcs)

OPERATING INSTRUCTIONS

9

Initial operation

Switch on machine

Connect power to the machine and switch on the

machine.

The start screen will appear automatically after

approximately 3 seconds on the display.

OPERATING INSTRUCTIONS

10

Insert film roll

Please rotate the spindle anti-clockwise

(about 1/2 turn) to unlock the core holder.

To load and also to unload a film roll.

Turn clockwise to lock.

Please note that the roll sits all the way on

the spindle.

Load the roll of film onto the film roll shaft.

Please note the side of air fill channel of the film.

The channel must be on the side closest to the

machine.

Guide the air fill channel of the film onto the air

nozzle. Slide the film on the air nozzle a few more

cm forward in direction of sealing unit.

That will simplify the next step.

Pull the film above the air nozzle and through the

film channel and press the “IN/OUT button”

while pulling the film all the way through.

The corner of the film can be cut at an angle to

make it easier to fit the film over the air nozzle.

OPERATING INSTRUCTIONS

11

Operating instruction

Use the touch display to set the sealing temperature, film length, and air volume.

Start, Stop function

Once machine is powered on the sealing unit starts heating

up. When set target temperature is achieved „Start panel“

change color.

and machine is ready to use.

When a roll of film is loaded and all settings are correct,

touch to start the production of air cushions.

During production of air cushions display show Stop panel.

Touch to stop production of air cushions

Adjust air volume

Adjust air volume of the air cushions between 0 and 100, by touching

or at touch display.

The air volume can be adjusted before production of air cushions at start screen and also

during air cushion production at stop screen.

Please see recommended settings for adequate air volume for the different cushion types.

OPERATING INSTRUCTIONS

12

Adjust seal temperature

Adjust seal temperature by touching temperature panel

Touch or to adjust target temperature.

Then touch to close setting page and return to start

screen. The machine starts heating or cool down until set

temperature.

Please have a little patience. Air cushion production can

only start when target temperature is achieved.

If you touch during heating up or cooling down

process the machine will get in waiting position and will

start air cushion production by itself once target

temperature is achieved.

Please see recommended settings for the different cushion types.

To change displayed unit, please see “advanced settings”.

Preset film length

The length of the air cushion film you want to produce can be preset in meters, as needed.

This value is set to 0 by default, which tells the machine to produce air cushions

continuously.

To set requested length of air cushion strand, touch at start screen.

Enter the requested length

Touch to confirm and return to start screen

Touch to discontinue and return to start screen

without changed setting.

Please note that preset length will be kept until delete or

new adjustment.

To change displayed unit, please see “advanced settings”.

OPERATING INSTRUCTIONS

13

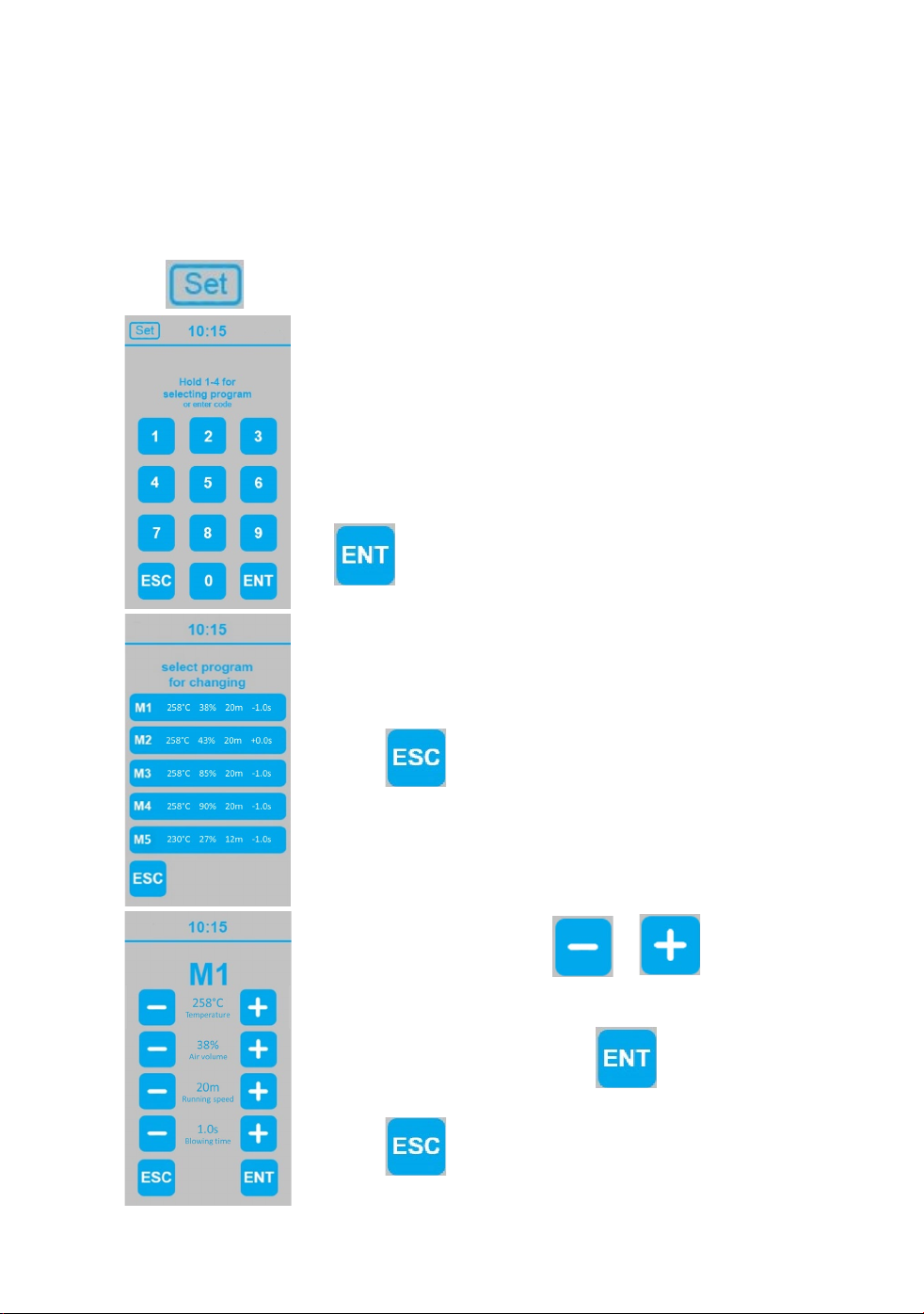

Preset function – quick selection

Five presets with temperature, air volume, running speed and Blowing time are possible

for a quick selection. Programming can be done at programming level.

Touch at start screen to get to the screen for selecting program

For quick selection of a preset touch assigned number (1, 2,

3, 4, or 5) and keep in touch until return to start screen.

Settings will automatically be transferred in start screen

Factory-adjusted: M1 for type 7.1 PE-Film 20µm; M2 for

type 8.3 PE-Film 20µm

To program or change a preset enter “4-5-6” and touch

Select one program by touching M1, M2, M3, M4 or M5 to

get to the corresponding programming level.

Touch to return to start screen with without any

changes.

To change displayed unit, please see “advanced settings”.

At programming level touch or to adjust

temperature, air volum, running speed or blowing time.

When all settings are done, touch to continue

changes and get back to program quick selection page.

Touch to return to program quick selection page

without any changes.

OPERATING INSTRUCTIONS

14

Lock function

Control panel can be locked, to prevent setting changes by unauthorized person.

Touch at start screen to get to the screen for entering code.

Enter code “1-2-3”, touch to confirm and return to

start screen

Touch to return to start screen without lock

function.

A little padlock symbol show that touch display is locked.

If so, it is only possible to

feed film , start , or stop air cushion

production.

Temperature, air volume or production length is not

possible to change. Therefore display needs to be unlocked.

Touch “SET” enter code and touch “ENT” to confirm and

return to start screen.

OPERATING INSTRUCTIONS

15

Change the knife

You can easily change the knife for AirWave2 yourself.

Step 1: Switch off the machine and disconnect power

Always switch off the machine before opening it.

Disconnect power to the machine by removing

the power cord completely from the machine.

Allow the machine to cool down!

You must follow this step. It is for your safety.

Step 2: Remove cover

Undo both screws of upper cover with appropriate

hex key and remove cover

OPERATING INSTRUCTIONS

16

Step 3: Remove the knife

Undo the locating screw with the provided hex key.

Remove the blade bracket.

Caution!!

Even used blades are extremely sharp!

Step 4: Change blade

Undo the little screw which fixes the blade with

the provided hex key.

Turn around the blade one time 180° or

apply a new one if both sides were already

used.

Fix the blade with the corresponding screw.

OPERATING INSTRUCTIONS

17

Step 5: Insert the knife

Insert the knife into the slot at the machine

and fix it with the screw.

Remount the upper cover and fix it with the

screws with provided hex key.

OPERATING INSTRUCTIONS

18

Change the Teflon belt

You can easily change the Teflon belts at AirWave2 yourself.

Step 1: Switch off the machine and disconnect power

Always switch off the machine before opening it.

Disconnect power to the machine by removing

the power cord completely from the machine.

Allow the machine to cool down!

You must follow this step. It is for your safety.

Step 2: Remove covers

Undo both screws of upper cover with appropriate

hex key and unscrew lower cover with provided

hex key and remove it.

OPERATING INSTRUCTIONS

19

Step 3: Loosen transport rolls

Turn the tension lever to move the transport rolls

apart.

Step 4: Release Teflon belts

Push the lower of the two guiding rollers to the

right against the spring to release the tension

for the lower Teflon belt.

Remove the slackened Teflon belt from the rollers.

Step 5: Insert new Teflon belts.

Place the new Teflon belt over the left transport

rollers

And press the roll again to the right against the

spring until the Teflon belt can be placed on the

right roll.

Table of contents

Other Floeter Packaging Equipment manuals