Presto Lifts P3 All-Around Air User manual

Presto Lifts P3 All-Around Air Manual

Model: P3 All-Around Air

Serial Number: __________________________

Date placed in

service:

__________________________

P3 All-Around Air

Owner’s Manual

Presto Lifts Inc.

50 Commerce Way, Norton, MA 02766

Phone: 800.343.9322

Fax: 888.788.6496

www.PrestoLifts.com

Email: servi[email protected]

March 9, 2020

Presto Lifts P3 All-Around Air Manual

2

Contents

1 Introduction............................................................................................................. 4

1.1 Specications........................................................................................................................ 4

1.2 Responsibilities of Owner and Users.................................................................................. 4

1.3 Responsibilities of Operators.............................................................................................. 5

2 Safety....................................................................................................................... 7

2.1 Safety Alert Symbols ............................................................................................................ 7

2.2 Signal Words ......................................................................................................................... 7

3 Labeling................................................................................................................... 8

3.1 Label Part Numbers & Quantity........................................................................................... 8

3.2 Label Location Diagram ....................................................................................................... 8

4 Setup........................................................................................................................ 9

4.1 Component Identication..................................................................................................... 9

4.2 Machine Setup..................................................................................................................... 10

5 Operation................................................................................................................11

5.1 Manual Loading & Unloading..............................................................................................11

5.2 Fork Truck or Stacker Loading & unloading .................................................................... 12

5.3 Transporting ........................................................................................................................ 12

5.3.1 Transporting with Fork Trucks and Stackers........................................................... 12

5.3.2 Transporting with Portability Kits ............................................................................. 12

6 Maintenance & Repair.......................................................................................... 14

6.1 Maintenance Pins................................................................................................................ 14

6.2 Periodic Maintenance ......................................................................................................... 15

6.2.1 Weekly ......................................................................................................................... 15

6.2.2 Every Six Months........................................................................................................ 15

6.3 Ordering Replacement Parts.............................................................................................. 16

7 Troubleshooting ................................................................................................... 17

8 Warranty & Contact Information ......................................................................... 18

Presto Lifts P3 All-Around Air Manual

3

Cancer and Reproductive Harm -

www.P65Warnings.ca.gov

WARNING

This label (part # 10095524) is

required by California Law. For

more information visit:

www.P65Warnings.ca.gov

Presto Lifts P3 All-Around Air Manual

4

1. Introduction

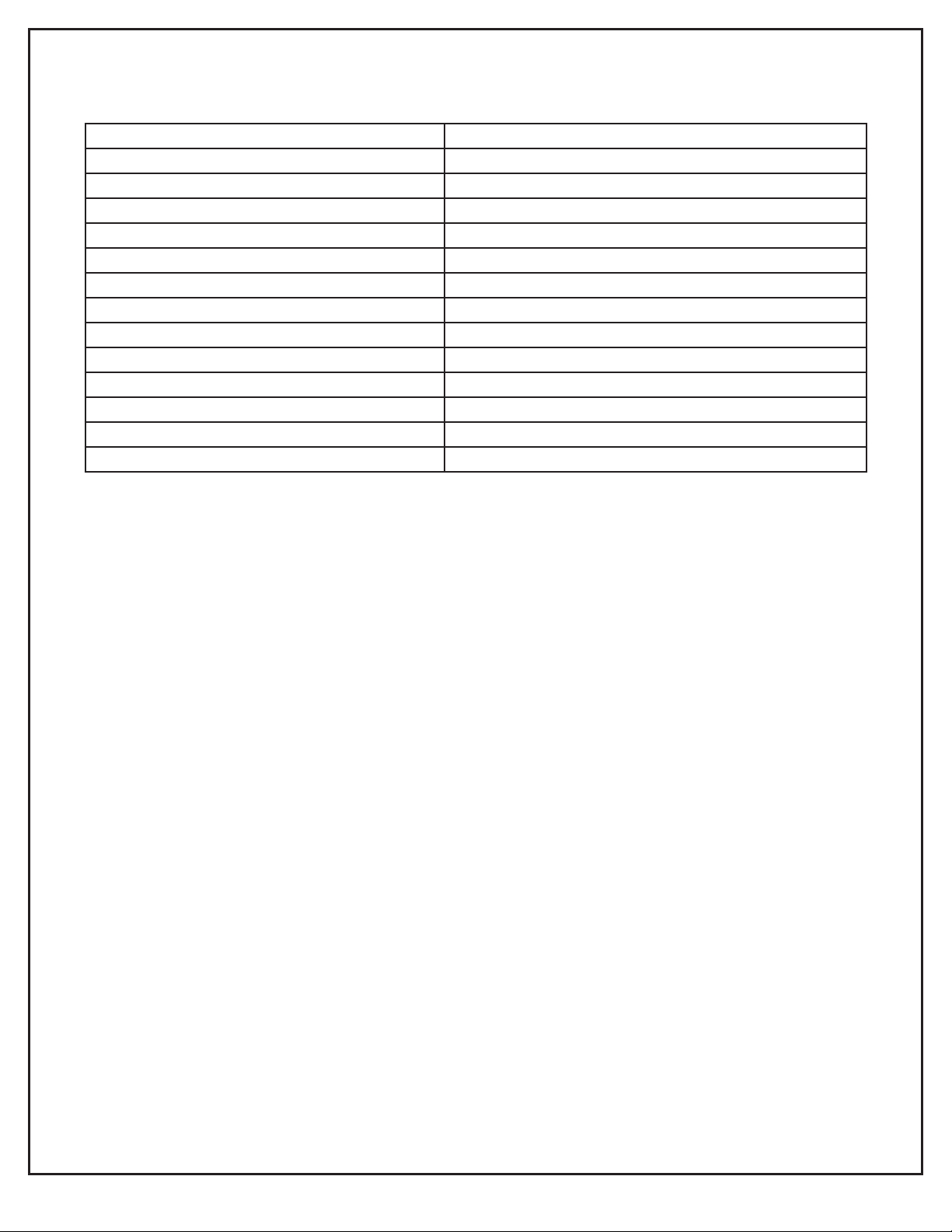

1.1 Specications

1.2 Responsibilities of Owner and Users

Basic Principles - Owners/users shall apply sound principles of safety, training, inspection,

maintenance, and expected operating environment. It shall be the responsibility of the owner/user

to advise the manufacturer where deection may be critical to the application.

Manuals - Owners/users shall keep and maintain a copy of the operating and maintenance

manual(s) and ensure its availability to operating and maintenance personnel.

Inspection and Maintenance - It shall be the responsibility of the users to inspect and

maintain the machine as required to ensure proper operation. The frequency of inspection and

maintenance shall be based upon the manufacturer’s recommendations and be compatible with

operating conditions and the severity of the operating environment. Machinery that is not in proper

operating condition shall be immediately removed from service until repaired. Maintenance and

repairs shall be made by a qualied person and the repairs shall be in conformance with the

manufacturer’s recommendations.

Maintenance Safety Precautions - Before adjustments and repairs are started on the machine,

the following precautions shall be taken as applicable:

1. Remove the load from the machine.

2. Other precautions and directions as specied by the manufacturer.

Replacement Parts - When parts or components are replaced, they shall be replaced with parts

or components approved by the original manufacturer.

Maintenance Training - The user shall ensure only qualied personnel inspect and maintain the

machine in accordance with the manufacturers recommendations.

Load Capacity 400 to 4500 lb. / 180 to 2040 kg.

Load Dimensions 50” x 50” x 72” / 1270 mm x 1270 mm x 1800 mm

Base Frame 36” x 36” / 915 mm x 915 mm

Compressed Height 9 1/2” / 240 mm

Extended Height 27 3/4” / 705 mm

Air Source 80 PSI / 5.5 BAR

Maximum System Pressure (Unloaded) 30 PSI / 2.1 BAR

Maximum System Pressure (Loaded) 65 PSI / 4.5 BAR

Safety Relief Valve Setting 125 PSI / 8.6 BAR

Rotating Ring, Outer Diameter 43 5/8” / 1110 mm

Rotating Ring Inner Diameter 40 5/8” / 1030 mm

Shipping Weight 450 lb. / 205 kg. (Approximately)

Operating Environment Indoor Only

Operating Temperature 0°F to 120°F / -18°C to 50°C

Presto Lifts P3 All-Around Air Manual

5

Operator Training - An owner/user, who directs or authorizes an individual to operate the

machine shall ensure that the individual has been:

1. Trained in accordance with the manufacturer’s operating manual.

2. Made aware of the responsibilities of operators as outlined in this manual.

3. Retrained, if necessary, based on the owners/user’s observation and evaluation of the

operator.

Modications and additions shall not be performed without the manufacturer’s prior written

approval. Where such authorization is granted, capacity, operation, and maintenance instruction

plates, tags, or decals shall be changed accordingly.

1.3 Responsibilities of Operators

Basic Principles - Operators shall apply sound principles of safety and good judgment in

the application and operation of the machine with consideration given to its intended use

and expected operating environment. Since the operator is in direct control of the machine,

conformance with good safety practices is the responsibility of the operator. The operator shall

make decisions on the use and operation with due consideration for the fact that his or her own

safety as well as the safety of other personnel on or near the machine is dependent on those

decisions.

General Training - Only personnel who have received general instructions regarding the

inspection, application and operation of the machine, including recognition and avoidance of

hazards associated with the operation, shall operate the machine. Such topics covered shall

include, but not necessarily be limited to, the following issues and requirements:

1. A pre-use inspection

2. Responsibilities associated with problems or malfunctions affecting the operation of the

machine.

3. Factors affecting stability

4. The purpose of placards and decals

5. Workplace inspection

6. Safety rules and regulations

7. Authorization to operate

8. Operator warnings and instructions

9. Actual operation of the machine. Under the direction of a qualied person, the trainee shall

operate the machine for a sufcient period of time to demonstrate prociency in actual

operation of the machine.

Pre-start Inspection - Before use each day or at the beginning of each shift, the machine shall

be given a visual inspection and functional test including but not limited to the following:

1. Pneumatic system leaks

2. Loose or missing parts

3. Nameplates, precautionary and instructional markings and/or labeling.

4. Items specied by the manufacturer.

Problem or Malfunctions - Any problems or malfunctions that affect the safety of operations shall

be repaired prior to the use of the machine.

Table of contents

Popular Packaging Equipment manuals by other brands

AirSaver

AirSaver F2 Safety instructions, setup & installation manual

HUALIAN

HUALIAN M-PE Series Operation manual

Pro Pack Solutions

Pro Pack Solutions Eagle 710 Operation manual

Oliver

Oliver 1808-D User's operation

Kronos

Kronos H-46 Series Operation, safety and spare parts manual

Robopac

Robopac ROBOT S7 Use and maintenance manual