4.1. TO COMPRESS STRUT FITTED TO VEHICLE.

4.1.1. Put the jaws into position and engage them on the spring as far apart as possible

and in line with one another. Ensure the safety lips (fig 1.7), are correctly engaged

and insert the retaining pins wherever possible.

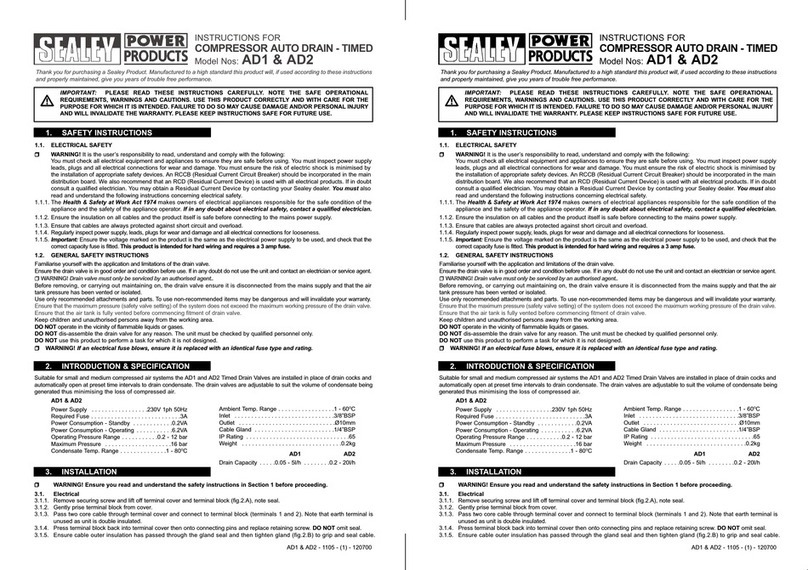

4.1.2. Put the RE222 body into position as show in fig 2, (A = MacPherson strut),

and engage the interlocks into the jaws.

4.1.3. Ensure the jaws and body are correctly aligned and the retaining pin is inserted

whenever possible.

4.1.4. Extend compressor by hand then turn the 24mm hex drive (fig1.3) clockwise using

air or hand tools and compress the spring without allowing it to become coil bound.

4.1.5. Remove spring when it is fully compressed and is free to rotate.

4.1.6. To decompress the spring, reverse the compress procedure.

4.3. TO COMPRESS STRUT REMOVED FROM VEHICLE.

4.3.1. Align the body mating interlocks, ensuring that they face in the correct direction and engage the jaws.

4.3.2. To keep jaws from moving, insert the retaining pins (fig 1. 5) through the jaws and carriers, and secure

with pin nuts (6).

4.3.3. Extend the compressor using the 24mm hex drive nut (fig 1.3). Grasp as many spring coils as possible

and ensure that the spring is correctly seated in the jaws.

4.3.4. Turn the 24mm hex drive nut clockwise using air or hand tools to compress the spring.

4.3.5. Observe end of stroke restrictions to keep the spring from becoming coil bound.

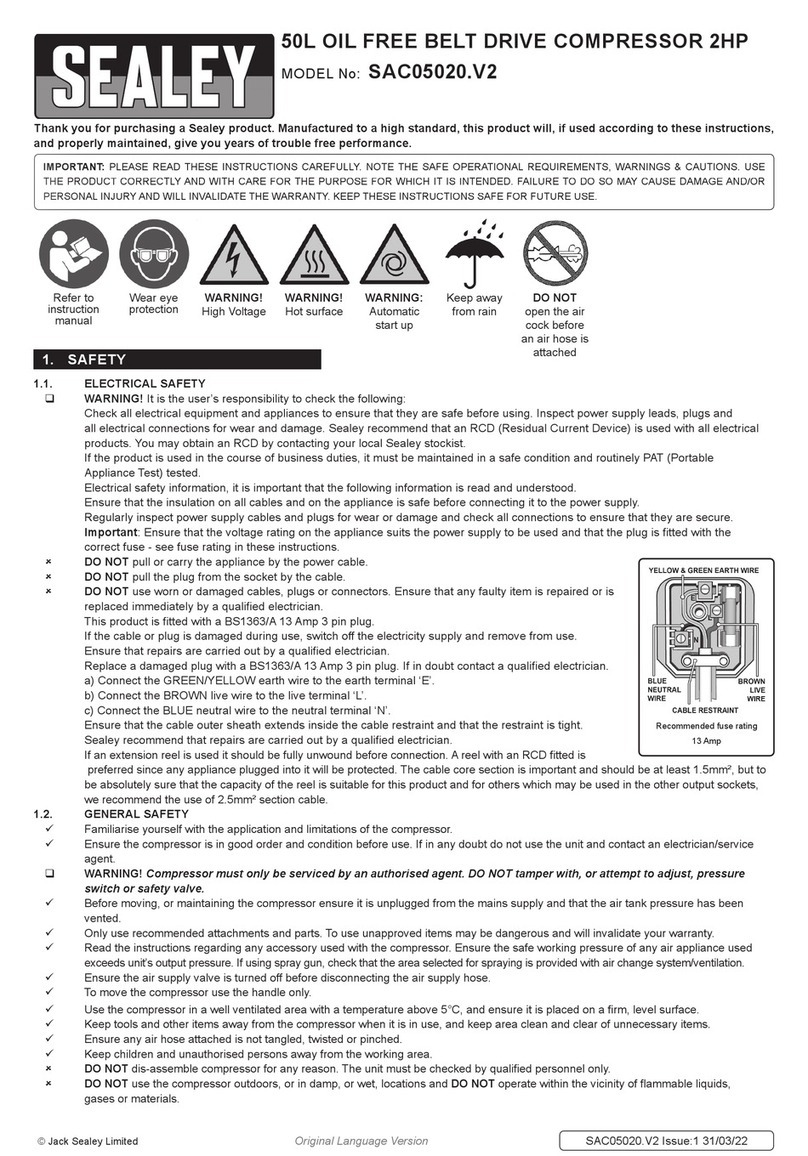

4.2. CONICAL ADAPTOR 369/1590-1

4.2.1. The shape of some coil springs which have a diameter at the top

of the spring much greater than at the bottom (fig 3). will not

permit the use of the standard RE222. Safe compression of the

conical coil spring can only be achieved if the spring compressor

remains at a right angle to the top spring coil.

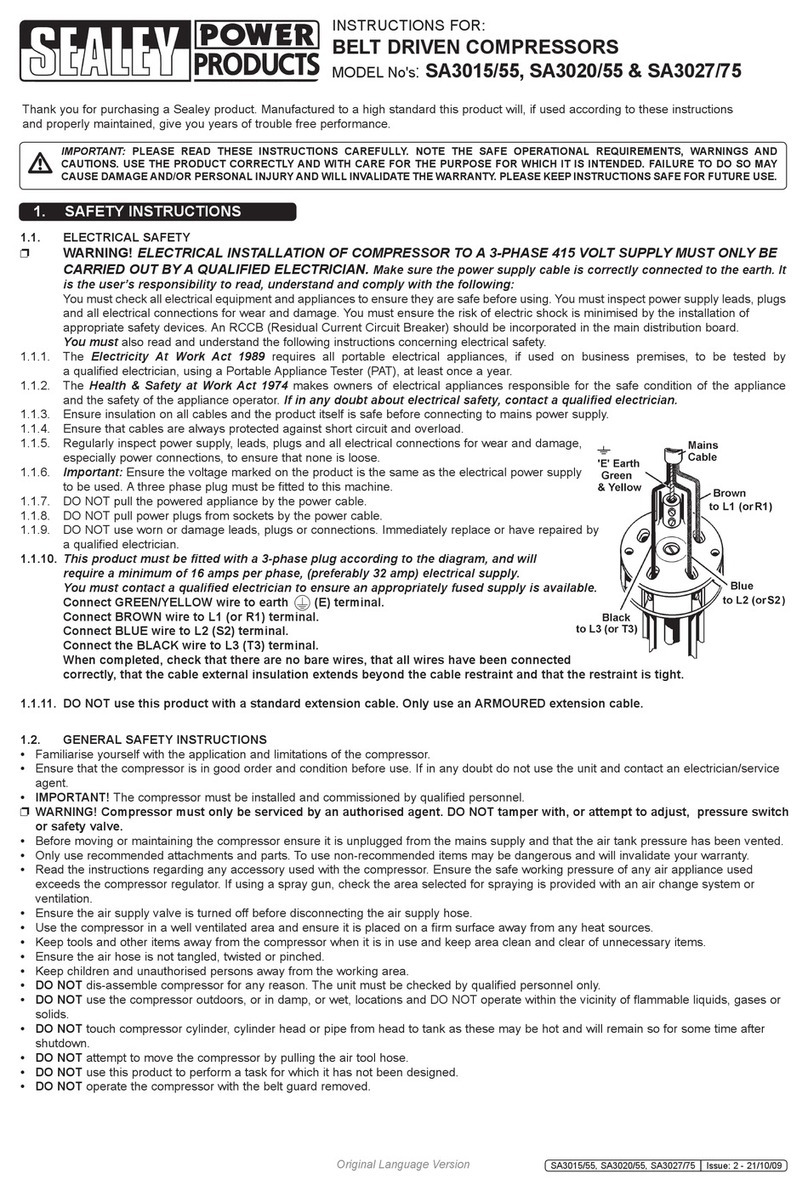

4.2.2. Conical Adaptor 369/1590-1 has a simple locking jaw system to fit

spring sizes from 85mm to 195mm diameter. Used with the

appropriate jaws on the bottom spring coil will bring the spring

compressor into required alignment for safe compression (fig 4).

4.2.3. Adaptor is supplied with retaining bolt/nut which must be inserted.

The RE222 is designed to allow the replacement of both coil springs and

MacPherson strut inserts without the removal of the strut from the vehicle.

It is a cylinder type spring compressor system designed for use on all

MacPherson strut coil springs and conventional front and rear suspensions.

5.1. Before each use check the compressor to ensure it is not damaged or worn. If suspect do not use the

unit, but contact your your local Sealey Dealer who will be able to advise you regarding repair kits and

spare parts.

5.2. Keep the compressor spindle lubricated. IMPORTANT: Use Molycot GN lubricant only.

5.3. Keep the compressor clean, and when not in use store in a safe, dry, childproof location.

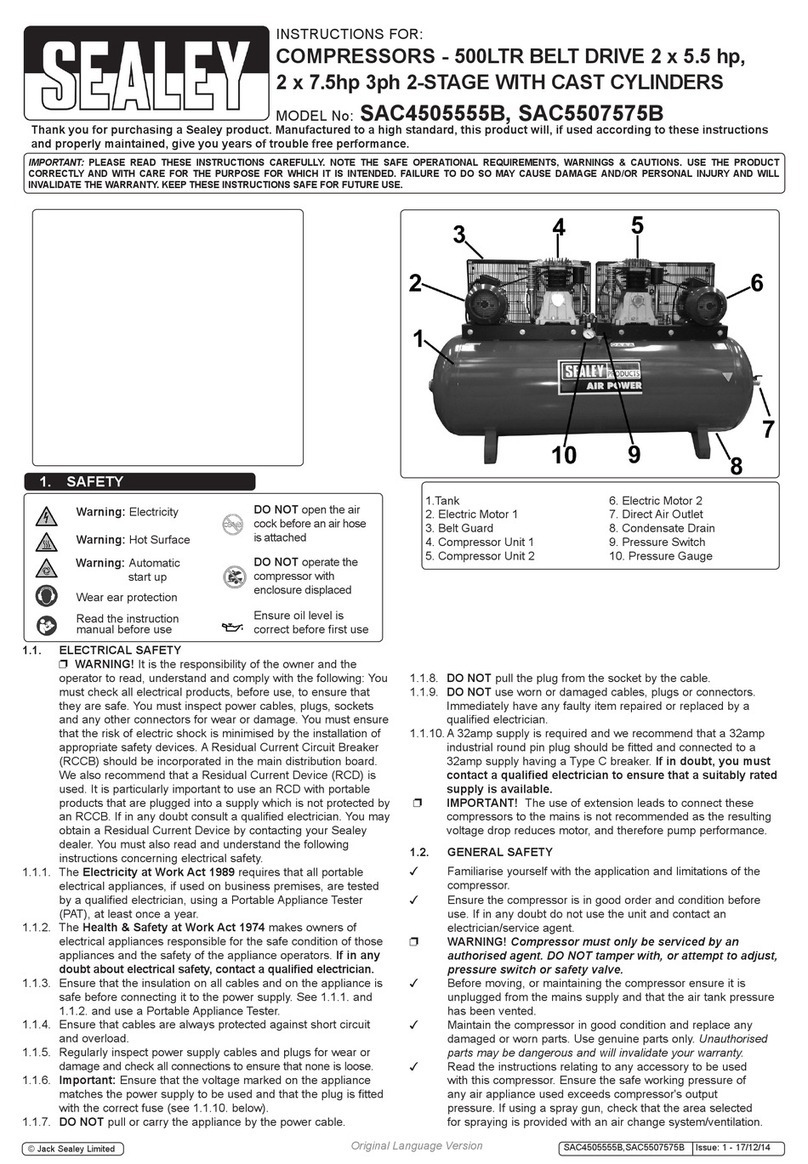

Component description (refer to fig 1).

The compressor consists of a solid steel body or cylinder mounted with

two forged jaw interlocks, one on the body and the other on a centrally

mounted spindle.

1. . . . . .Body cylinder

2. . . . . .Shear Pin

3. . . . . .Hex nut

4. . . . . .Jaws

3. INTRODUCTION & DESCRIPTION

5. MAINTAINING THE COMPRESSOR

4. INSTRUCTIONS FOR USE

fig 1

fig 2

fig 4

6. PARTS LIST

RE222 - 0403 - (1) - 010799

Original Date: 010899

Issue Date: 010899

Version No: 0

Date Modified: N/A

mThe spindle (which is driven by a 24mm hex nut), is located in two axial bearings which absorb the tension and

friction forces during operation and reduce effort.

mThe complete assembly is case hardened to increase tensile strength.

mThere are two shear/fracture points for increased safety. Should the compressor become overloaded one of the

shear/fracture points will break leaving the spring safely compressed.

mA range of drop forged jaws are available to match all current MacPherson strut spring sizes.

mEach jaw has a safety lip to eliminate slip and is designed to fit the pitch of the spring to ensure maximum

surface contact between jaws and spring, thus eliminating the risk of the compressor slipping around the spring.

mThe jaws are unique in their design as they interlock with the compressor body without requiring a retaining or

load bearing bolt. The load is transmitted through the machined mating faces to nitrided compressor spindle.

mThe ability to engage jaws with an interlock, enables the tool to be used without removing the MacPherson strut

from the vehicle.

5. . . . . .Retaining pins

6. . . . . .Retaining pin nuts

7. . . . . .Safety lips

fig 3