Ensure that the pulley block is in sound condition and good working order.

Take action for immediate repair or replacement of damaged parts.

Use recommended parts only. The use of unauthorised parts may be

dangerous and will invalidate the warrentry.

Ensure the support for the pulley block is capable of withstanding a load of

at least 1½ times the safe working load of the block.

Keep the pulley block clean for the best and safest performance.

Locate the pulley block in a suitable, well-lit area.

Keep work area clean and tidy and free from unrelated materials.

Ensure all non-essential persons keep a safe distance whilst the pulley

block is in use.

Ensure load slings are fully engaged in the load hook and that the hook

safety bar is in the closed position.

Raise and lower a load on the pulley in a smooth, controlled manner. DO

NOT shock load the pulley block by allowing the attached load to fall freely,

even for very short distances.

DANGER: Use the pulley block for lifting only, NOT for suspending the lifted

load.

Use a qualified person to lubricate and maintain the pulley block.

DO NOT operate the pulley block if it is damaged.

DO NOT allow untrained persons to operate the pulley block.

DO NOT exceed the rated capacity (working load) of the pulley block. (See

Section 5).

DO NOT raise or lower the load with jerky or abrupt movements of the rope.

DO NOT attempt to lift a load if the load rope is kinked or knotted.

DO NOT try to raise a load with two, or more, pulley blocks - use a single

block of adequate capacity.

DO NOT use the pulley block to drag the load across the floor. Always

position the load directly below the block.

DO NOT wrap the load rope around the load - always use separate,

suitable, ropes or slings of the correct capacity.

DO NOT allow anyone to stand, or pass beneath, the raised load.

DO NOT use the pulley block for purposes other than that for which it is

intended.

Store the pulley block in a dry, childproof area when not in use.

IMPORTANT: Use only with wire rope of the specified diameter.

DO NOT attempt to free a jammed rope or pulley while a load is attached.

Use alternative means to support the load and unhook the rope from the

load before rectifying the jam.

BEWARE! Broken rope strands or unfinished rope ends present risk of

personal injury, i.e. a puncture wound.

INSTRUCTIONS FOR:

PULLEY BLOCKS

MODEL Nos: PB1000.V2, PB2000.V2

1. SAFETY INSTRUCTIONS 2. SPECIFICATION

3. OPERATION

IMPORTANT: Before using the pulley block ensure that you have read,

understood and applied the safety instructions in Section 1.

NOTE: This pulley block will normally be used in conjunction with a

mechanical pulling device and should never be operated by hand. Wear safety

gloves and keep hands away from moving pulley wheels.

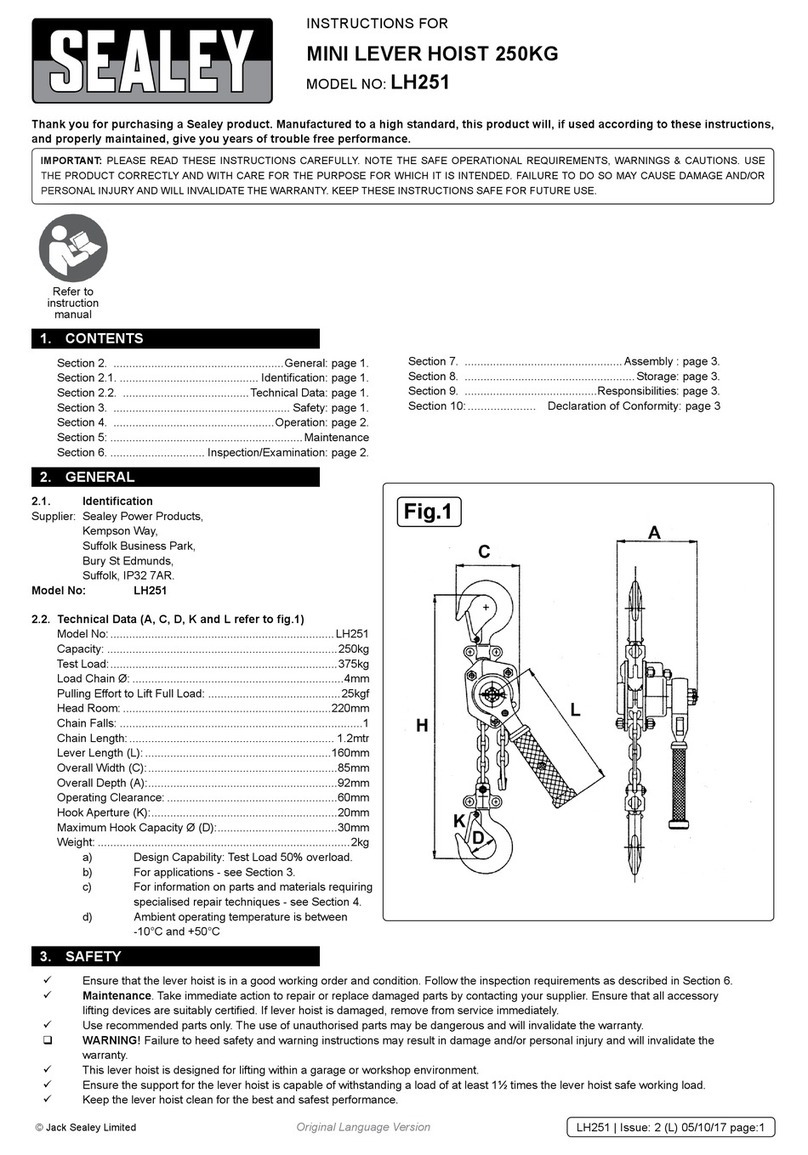

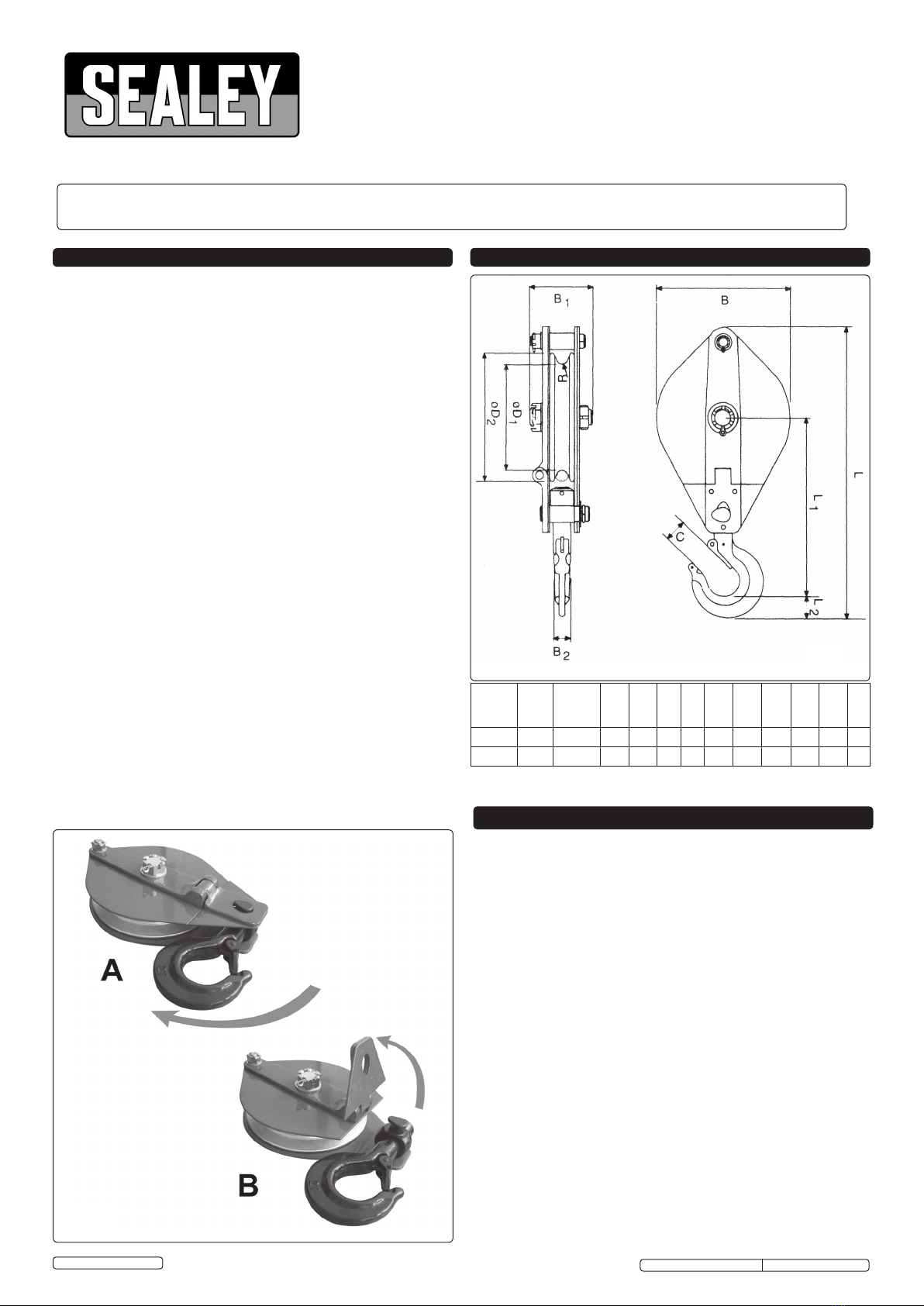

3.1. Rotate the hook through 90° as shown in fig.1A to release the hinge plate.

Move the hinge plate upwards as shown in fig.1B and place the rope into

the pulley groove. Close the hinge plate and rotate the hook through 90° to

lock it. DO NOT attempt to use the pulley block with the hinge plate open.

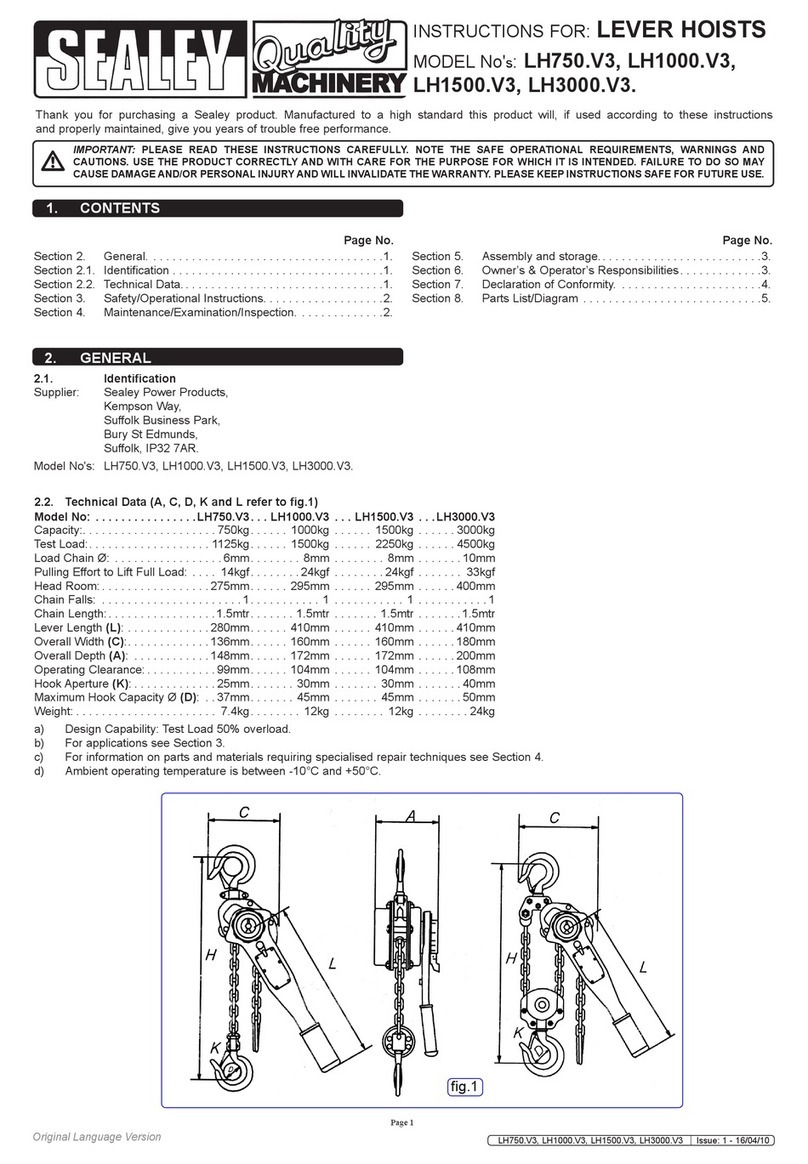

3.2. If using the pulley block for simple lifting as shown in fig.3A ensure that it is

suspended from a structure capable of supporting at least 1½ times the safe

working load of the block.

3.3. Ensure that the block hook is fully engaged with the safety bar closed.

Confirm that the total load does not exceed the working load of the block.

See Section 4.

3.4. Ensure that the lifting rope is securely and safely attached to the load and

that the load is directly below the block.

3.5. Take up the tension in the rope until the load rope is taut and not pulling at

an angle.

3.6. Start to raise the load and ensure that it is level, with no possibility of the

load tilting and/or slipping from its restraints. If necessary, lower the load

and readjust the attachment point to obtain a safe, level lift.

NOTE: DO NOT suddenly release the pulley rope, as the pulley has no braking

system attached to it.

3.7. Continue to raise the load to the required height in a slow, controlled

manner. DO NOT raise the load so far that the hook comes into contact with

the block.

3.8. Lower the load slowly and smoothly, avoiding jerky or abrupt movements.

3.9. If, at any time, the rope will not move in either direction do not attempt to

force it but, after arranging safe support for any suspended load, have the

block inspected by an Authorised Service Agent.

Fig.2

Fig.1

Original Language Version PB1000.V2, PB1500.V2 Issue: 3(L) - 15/05//17

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE THE PRODUCT

CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR PERSONAL INJURY AND WILL

INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these

instructions and maintained properly, give you years of trouble free performance.

© Jack Sealey Limited

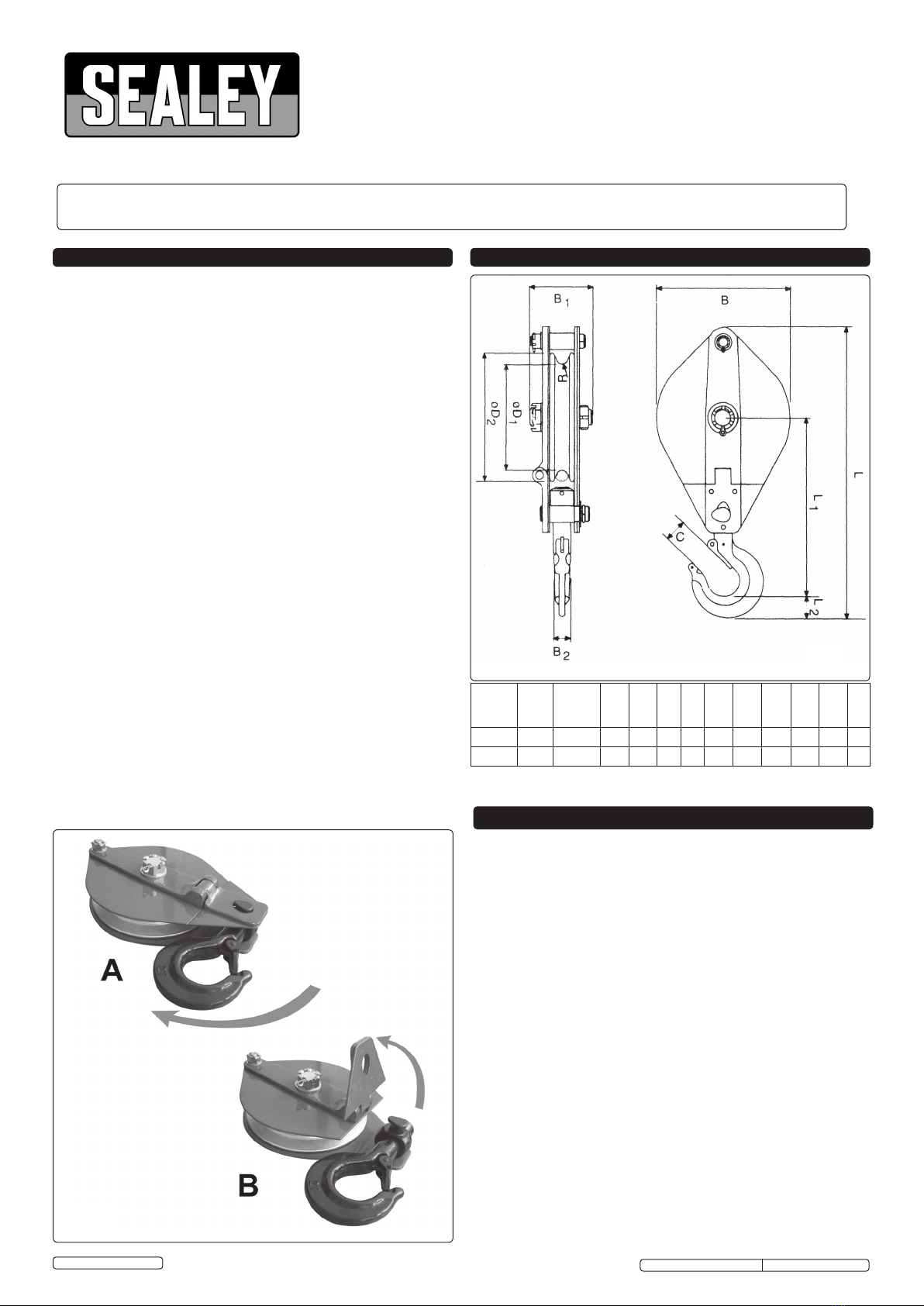

*Ambient operating temperature range: -10°C to +50°C.

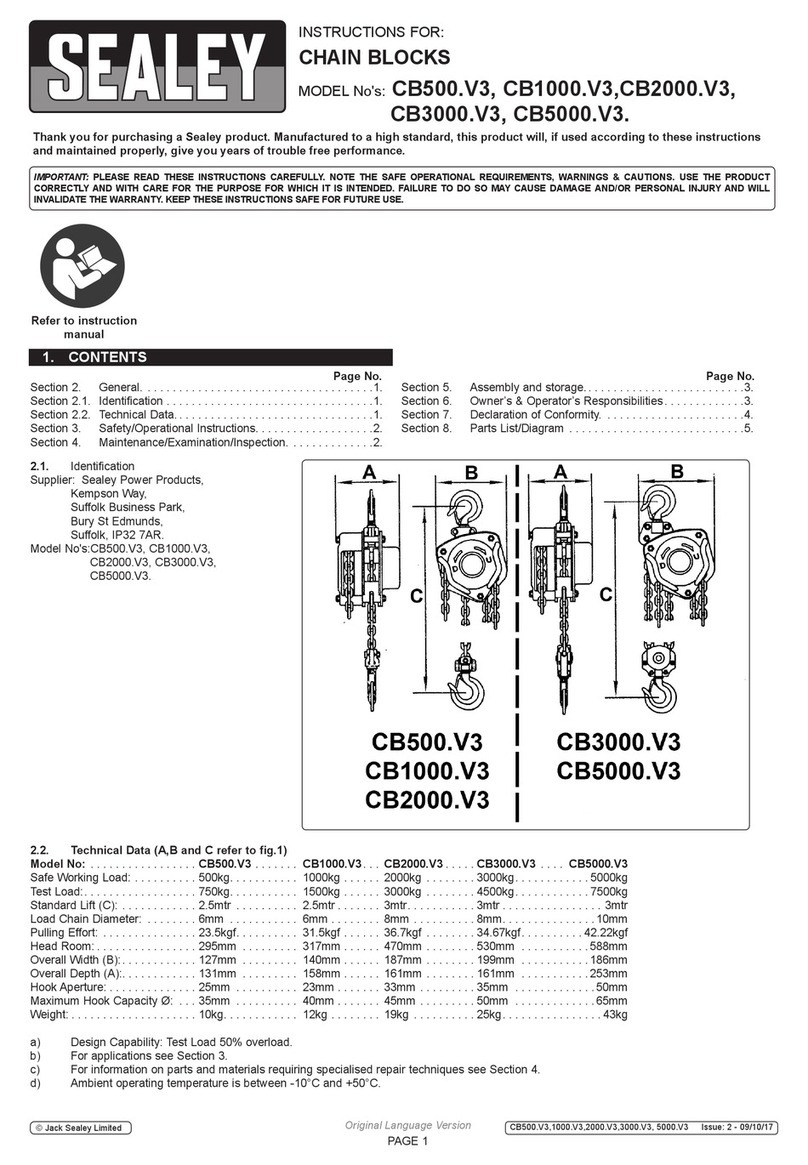

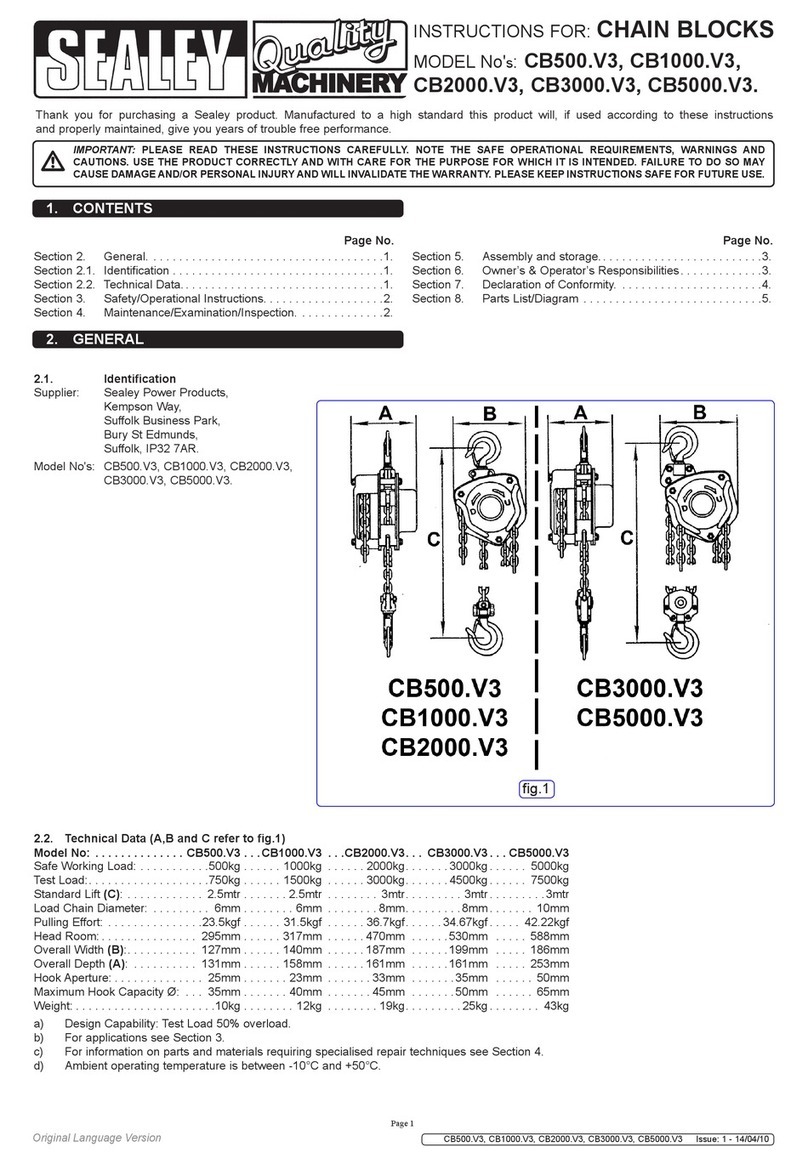

Working

load

kg

Rope

Ø

mm

Net

weight

kg

B B1 B2 C

D1

Ø

D2

ØL L1 L2 R

1000 Ø7 3.3 118 76 17 23 85 105 305 200 23 4

2000 Ø13 8.9 199 92 24 27 150 190 425 263 30 7