8DO NOT operate the drill if any parts are missing or the drill is damaged as this may cause failure and/or possible personal injury.

8DO NOT operate the drill when you are tired, under the inuence of alcohol, drugs or intoxicating medication.

8DO NOT abuse the cord. Never use the cord for carrying, pulling or unplugging the power tool. Keep cord away from heat, oil,

sharp edges or moving parts. Damaged or entangled cords increase the risk of electric shock.

9Avoid body contact with earthed or grounded surfaces such as pipes, radiators,ranges and refrigerators. There is an increased risk

of electric shock if your body is earthed or grounded.

9 Use the power tool, accessories and tool bits etc. in accordance with these instructions and in the manner intended for the

particular type of power tool, taking into account the working conditions and the work to be performed. Use of the power tool for

operations dierent from intended could result in hazardous situation.

9 Avoid accidental starting. Ensure the switch is in the o position before plugging in. Carrying power tools with your nger on the

switch or plugging in power tools that have the switch on invites accidents.

9Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting edges are less likely to bind and are easier

to control.

9Store all safety notes and safety instructions for future reference. The term power tool in all of the warnings listed below refers to

your mains operated (corded) power tool or battery operated (cordless) power tool.

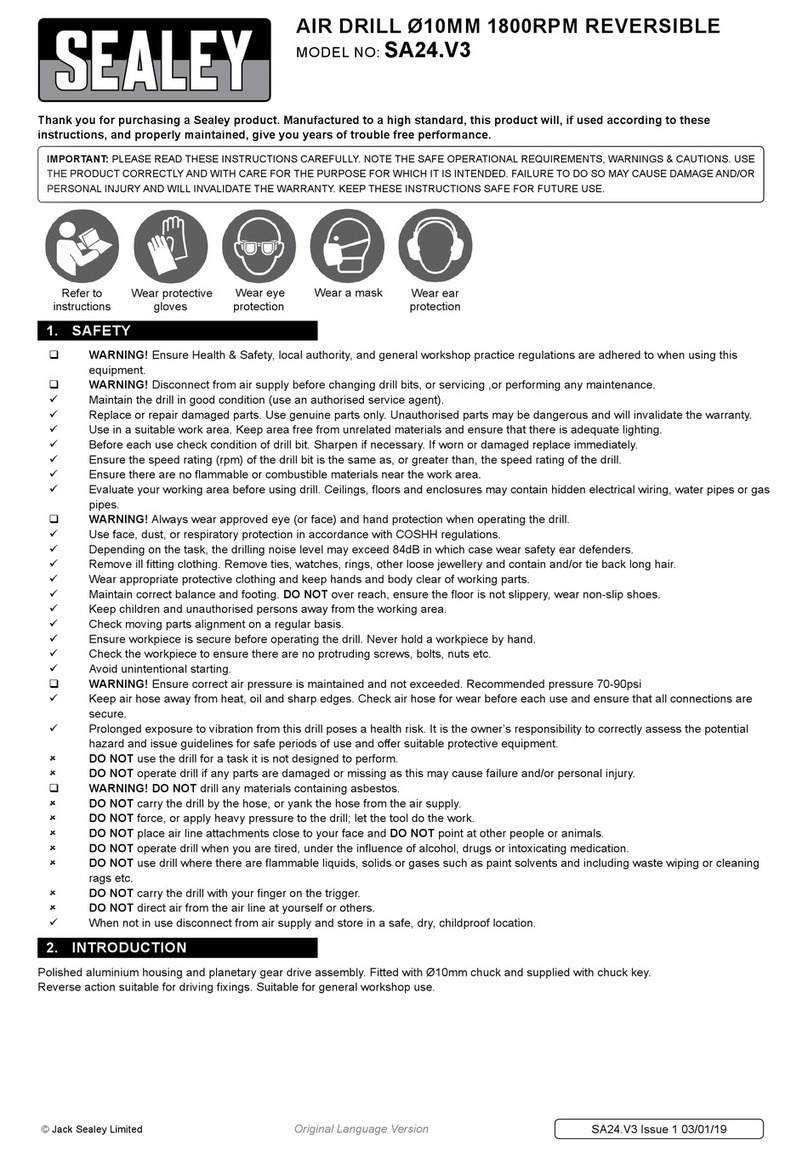

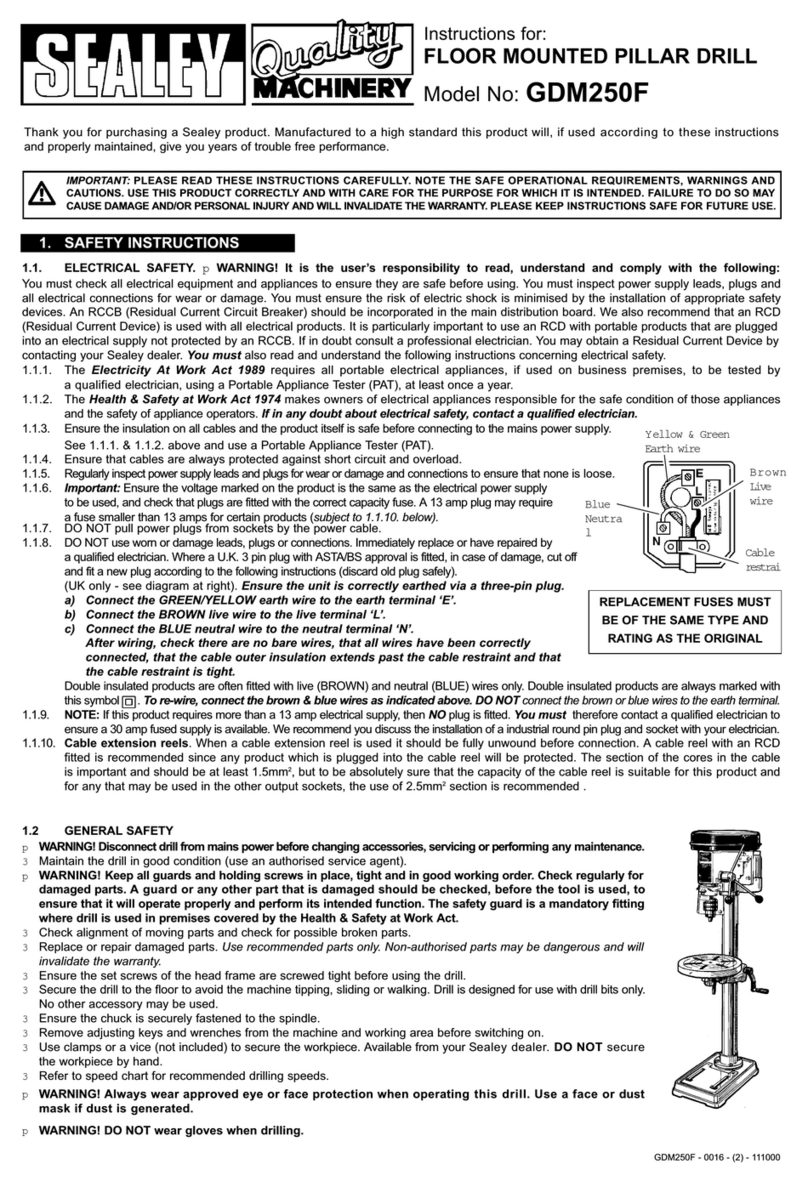

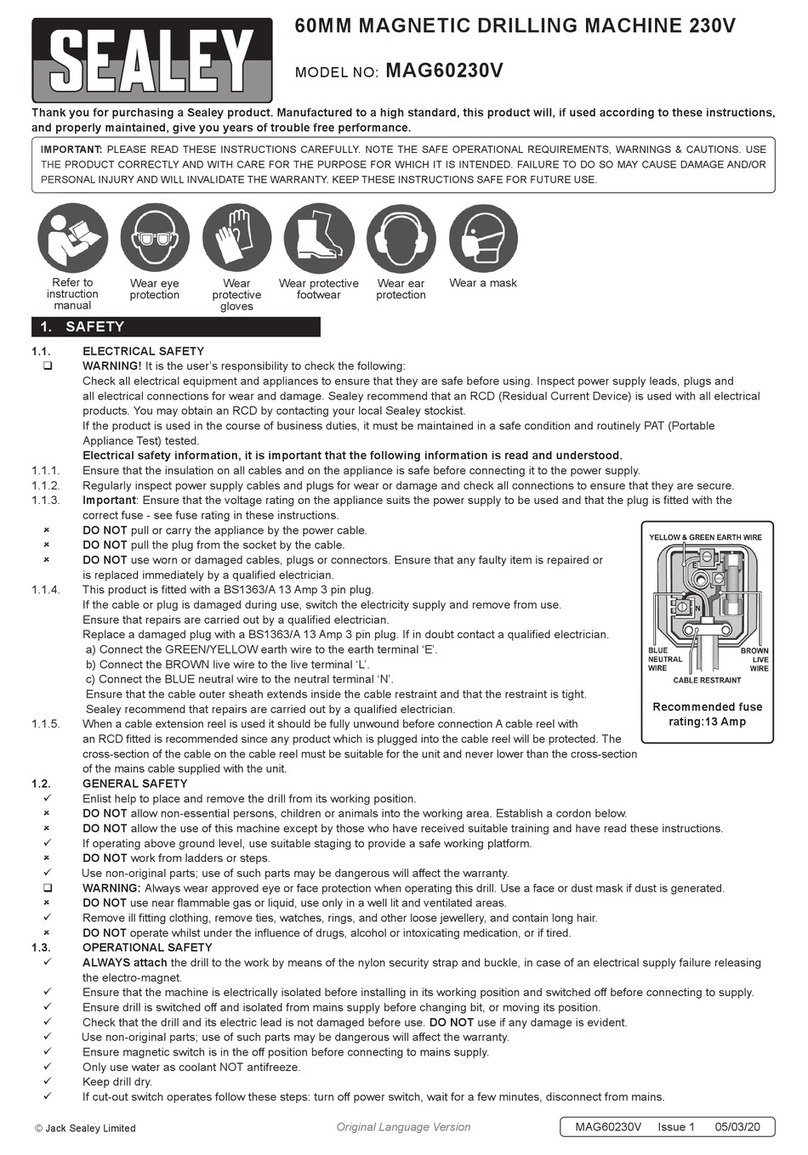

2. INTRODUCTION

Powerful rotary hammer drill with SDS Plus chuck. Four drilling functions. Anti-vibration shock absorbers built into body. Stepless variable

speed control trigger. Safety clutch system. LED Mains power indicator. Easy access grease plug for gear maintenance. Supplied in storage

case with 8mm, 10mm and 12mm masonry drill bits, pin and cold chisels, PVC dust cap and depth gauge. Fitted with 360° auxiliary handle.

3. SPECIFICATION

Model No:......................................................... SDSPLUS32

Chuck Type: ............................................................SDS Plus

Concrete Drilling Diameter: .......................................... 32mm

Impact Energy:................................................................... 6J

Impact Rate: ........................................................ 0-4500bpm

No Load Speed: ......................................................0-850rpm

4. CONTENTS

4.1. Check contents carefully

Hammer drill ........................................................................ 1

Additional handle ................................................................. 1

Depth stop ........................................................................... 1

Drill .....................................................................................3

Chasing bit ..........................................................................2

Drill dust catcher ..................................................................1

Operating instructions .......................................................... 1

5. ASSEMBLY

5.1. MOUNTING THE DEPTH STOP

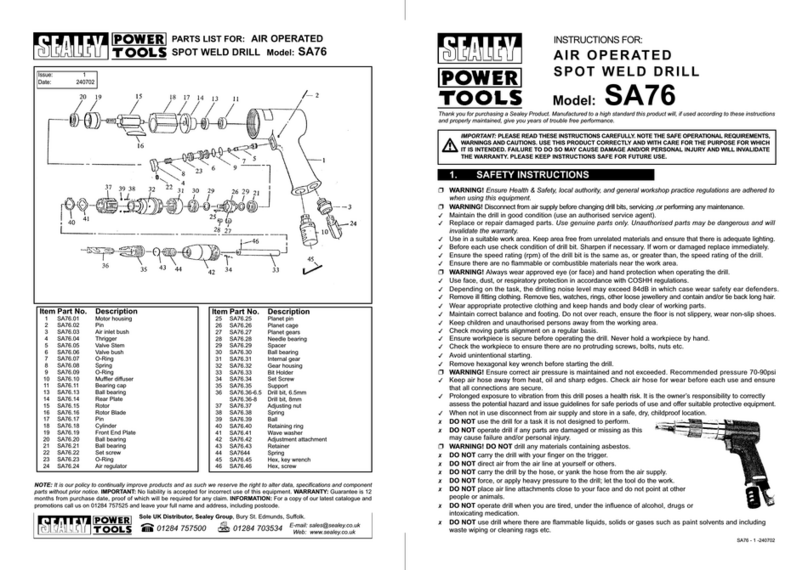

5.1.1. Unscrew the locking nut, on the depth holder (g.1.3).

5.1.2. Insert the depth stop to the holder.

5.1.3. Set the depth stop to the required depth.

5.1.4. Screw down the locking nut (g.1.3), but DO NOT over-tighten.

6. OPERATION

6.1. SAFETY NOTES FOR HAMMERING

9 Wear ear defenders when hammer drilling. The eects of noise may lead to loss of hearing.

9 Use the additional handles supplied with the unit. Loss of control may lead to injuries.

9Hold the device by the insulated surfaces when carrying out work, it is possible that the tool or screw may come across hidden

power cables or its own cable. Contact with a power-carrying cable may also put metal parts of the unit under power and cause

an electric shock.

▲DANGER! Prior to starting work, use appropriate tool to determine whether there are any hidden supply lines are located on the

area you are working in. If in doubt, ask the relevant supply services. Contact with power lines may cause re and electrical shock.

Damaging a gas pipe may cause an explosion. Damaging a water pipe leads to considerable property damage and may cause

electrical shock.

WARNING! Shortly after being used, the tool may be very hot. Risk of burning! Allow a hot tool to cool down. Never clean a hot tool

with ammable liquids.

9 The vibration values specied in the technical data represent the main uses of the device. The actual existing vibrations during use

may deviate from these as a result of the following factors:

• Incorrect use of the product;

• Unsuitable tools inserted;

• Unsuitable material;

• Insucient maintenance.

9You can reduce the risks considerably by following the tips below:

– Maintain the device in accordance with the instructions in the operating instructions.

– Avoid working at low temperatures.

– When it is cold, make sure your body and your hands, in particular, are kept warm.

– Take regular breaks and move your hands at the same time to promote circulation.

SDSPLUS32 Issue 1 27/08/19

Original Language Version

© Jack Sealey Limited