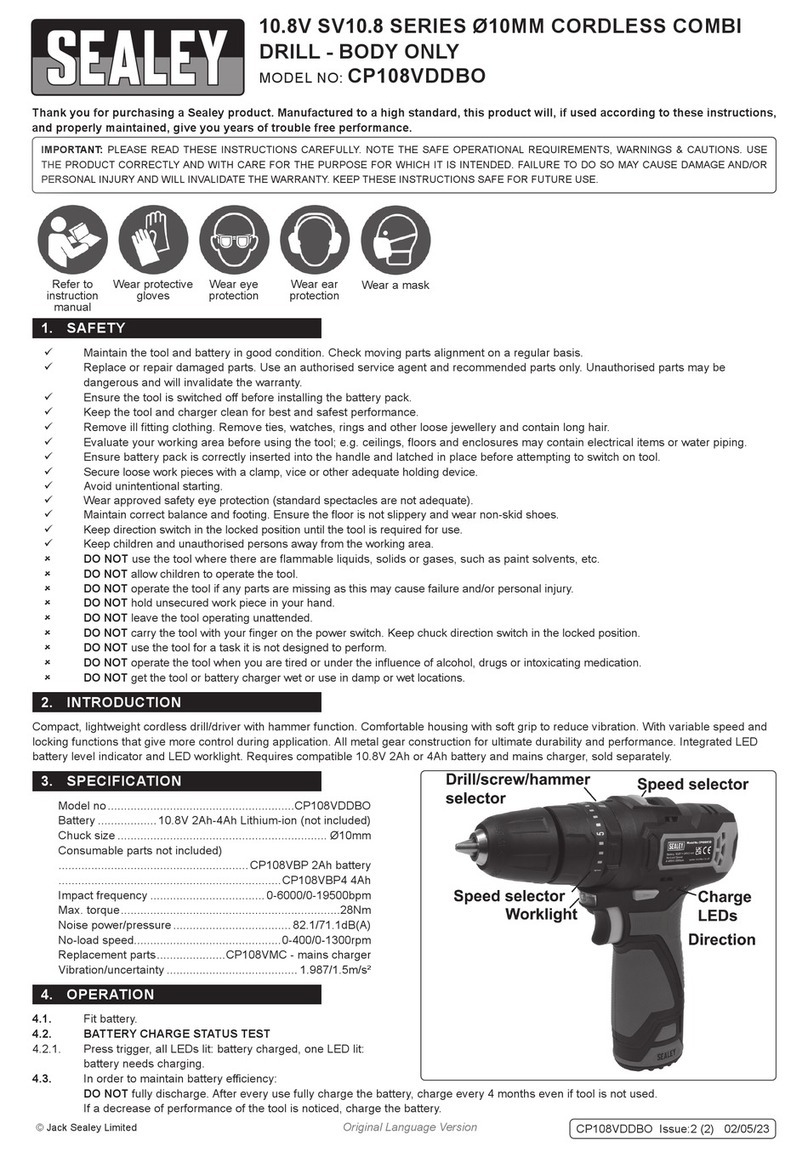

3. SPECIFICATION

Model no:................................................................SA27.V3

Chuck size: ............................................................... Ø13mm

Free speed:................................................................700rpm

Air consumption: ............................................................4cfm

Operating pressure: ...................................................... 90psi

Inlet size:...................................................................1/4”BSP

Weight:..........................................................................1.4kg

Noisepower/pressure: .......................................100/91dB(A)

Vibration/uncertainty: .........................................0.89/1.5m/s²

4. PREPARATION

4.1. AIR SUPPLY

WARNING!Ensuretheairsupplyiscleananddoesnotexceed90psiwhileoperatingthedrill.

Too high an air pressure and unclean air will cause excessive wear, and may be dangerous,

causingdamageand/orpersonalinjury.

4.1.1. Recommendedhook-upprocedureisshowning1.

4.1.2. Ensure the drill air valve (or trigger) is not depressed before connecting to the air supply.

4.1.3. Youwillrequireanairpressurebetween70-90psi,andanairowaccordingtothespecicationabove.

4.1.4. Drain the air tank daily. Water in the air line will damage the drill and invalidate your warranty.

4.1.5. Cleanairinletlterweekly.

4.1.6. Line pressure should be increased to compensate for unusually long air hoses (over 8 metres).

4.1.7. Theminimumhosediametershouldbe1/4”I.D.andttingsmusthavethesameinsidedimensions.

4.1.8. Keep hose away from heat, oil and sharp edges. Check hoses for wear, and make certain that all

connections are secure.

4.2. COUPLINGS

4.2.1. Vibration may cause failure if a quick change coupling is connected directly to the air drill.

Toovercomethis,connectaleaderhose-SealeymodelnumberAH2RorAH2R/38-tothedrill.

Aquickchangecouplingmaythenbeusedtoconnecttheleaderhosetotheairlinerecoilhose.Seegs.1&2.

4.3. FITTING HANDLE

4.3.1. Slide the split brass ring over the chuck and onto the main black body of the drill. Squeeze the split thread together and screw the

handle partially onto the ring. Move the handle to your desired orientation and continue to screw the handle until it is locked in

position.

5. OPERATION

WARNING! Ensure you read, understand and apply safety instructions before use.

5.1. DRILL BIT FITTING

WARNING! Unplug from the air supply before placing bit into chuck.

5.1.1. Regularly check the drill bit and always change if worn, cracked or otherwise damaged.

5.1.2. Openorclosethechuckjaws(g3.1)toapointwheretheopeningisslightlylargerthanthedrillortoolbittobeused.Insertthedrill

bitintothechuckasfarasitwillgo.Rotatetheforwardsectionofthechuck(g3.2)clockwise,inordertosecurethedrillbit.

5.1.3. Connectairsupplytodrill.Squeezethetrigger(g3.3)tocheckthatthedrillisworkingcorrectlybeforestartingwork.

8DO NOT allow drill to run freely for an extended period of time as this will shorten the life of bearings.

5.2. DRILLING INSTRUCTIONS.

WARNING!Ensureyouwearapprovedsafetygogglesandanyothersafetyitemrequiredforthejob.Ensurechuckislockedbefore

using the drill. Also ensure that all other safety requirements are followed.

5.2.1. Connect drill to air supply.

5.2.2. For drilling purposes ensure the drill is turning in the forward direction by

checkingthattheleveradjacenttothetriggerisnexttothe

forwardsymbol(F).Ifnot,iptheleverovertotheforwardposition.

5.2.3. Holdtoolrmlyandplacethebittiptothepointtobedrilled.

5.2.4. Depress the trigger to start drill. Move the drill bit into the work piece

applying only enough pressure to keep the bit cutting. DO NOT

force or apply side pressure to elongate the hole.

5.2.5. If the material to be drilled is free standing it should be secured in a vice

or with clamps to keep it from turning as the drill bit rotates.

5.2.6. When drilling metals, use a light oil on the drill bit to keep it from

overheating. Oil will prolong life of bit and improve the drilling action.

5.2.7. For hard smooth surfaces use a centre punch to mark desired hole

location. This will prevent bit from slipping as your start to drill.

5.2.8. Apilotholemaybenecessarytoassistthenaldrillsizethroughthe

workpiece.Lockapilotdrill(smallersizedrillthanthenished

holesize)intothechuckanddrillapilotholeinthemiddleofthecentrepunchmarkwherenalholeistobedrilled.Insertthenal

sizedbitinchuck.Holddrillrmlyandplacethebitattheentranceofthepilotholeanddepressthetrigger.

WARNING! Be prepared for drill binding on break through. When these situations occur the drill has a tendency to grab and kick in the

oppositedirectionwhichcouldcauselossofcontrol.Ifyouarenotprepared,thislossofcontrolcanresultindamageand/orpersonal

injury.

5.2.9. Ifthebitjamsintheworkpieceorifthedrillstalls,releasethetriggerswitchimmediately.Removethebitfromtheworkpieceand

determinethereasonforjamming.Itmaybenecessarytoreversethedirectionofrotationbymovingtheleveradjacenttothetrigger

tothereverse(R)position(thereverseactionisalsousefulforundoingxings).

fig.1

fig.2

fig.3

Original Language Version

© Jack Sealey Limited SA27.V3Issue:1-27/11/18