The Headlamp Beam Tester (Floor Mounted version only) is equipped with a spirit level located on the base of the optical box which is visible

through the transparent panel by turning on the vehicle head lights. To level the box, open the clutch lever located on the side of the box

and move the box until the spirit level registers correctly. Re-tighten the clutch lever L. The box level must be checked every time it is used

on a different working surface.

14. 1. The paint work is detergent resistant. Clean with a damp cloth, removing any stains. A small amount of alcohol may be applied

to stubborn areas of grime.

14. 2. DO NOT leave the machine in areas where corrosive vapour is present, i.e. Battery charging or painting shops etc.

14 .3. DO NOT oil the column.

14 .4. An optical box dust cover is available upon request.

13. OTHER INFORMATION

14. CARE OF THE BEAM TESTER

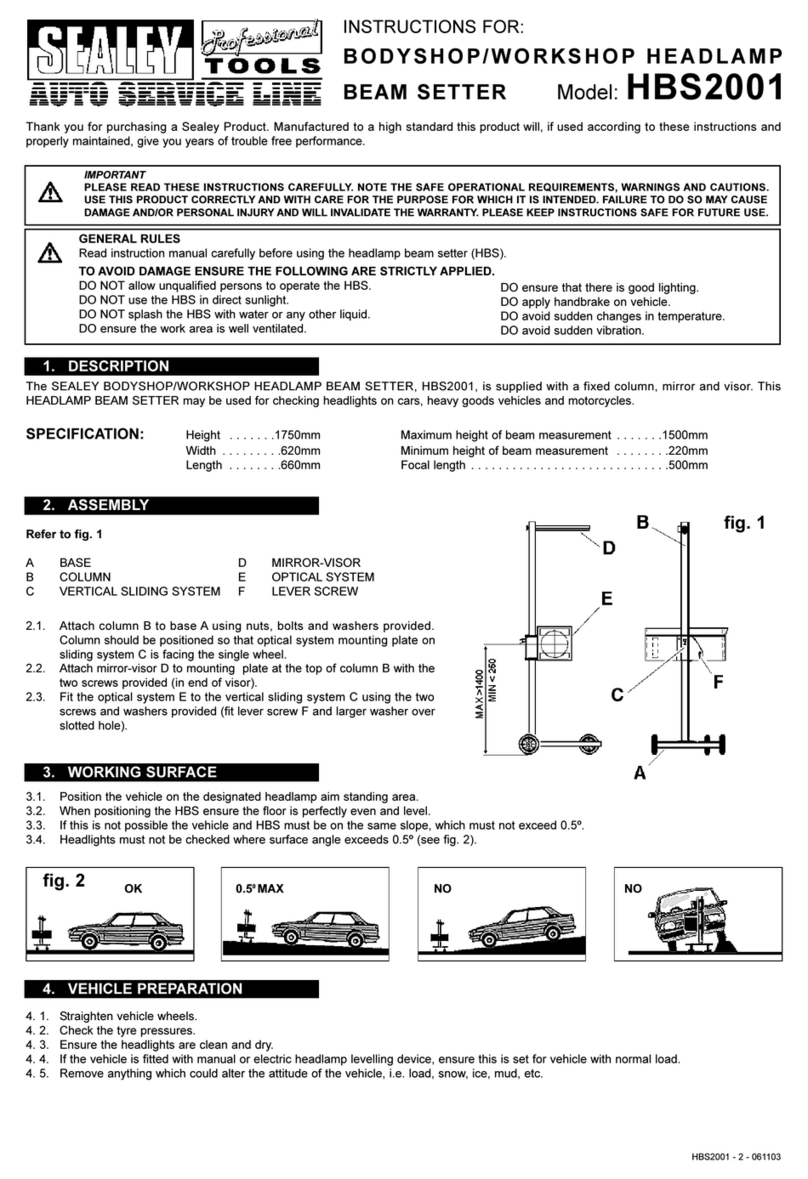

1A TC024010004 Wheel for rails

1B TC024010005 Wheel for rails

2 TC024010001 Base rail

3TC025010003 Case for column

4 TC020010045 Front wheel shaft

5 TC025010002 Turning column

6 TC025010004 Spring for vettical sliding system

7 TC024010002 Optical box

8 TC025030011 Black handle

9TC025030014 Glass Ø200mm

10 TC025030013 Lens stand

11 TC027010037 inner panel

15 TC020010038 Spirit level

16 TC025020009 Brake spring

17 TC021010006 Coloured luxmeter

18 TC020010028 Steel cover

20 TC020020018 Electronic card wqith photodiode

21 TCNR5020033 Stopper 22x30mm

22 TC020010050 Plexiglass cover

23 TC025020005 Vertical sliding system (VSS)

24 TC025020007 Spring pusher

26 TC025020008 Stopper

27 TC025020006 Brakr got VSS

30 TC025020011Mirror visor

35 TCNA2010037 Screw M8x110mm

36 TCNR5020008 Wheel handle Ø35mm

38 TC020010047 Wheel axle 15x45mm

39 TC022040010 Brake pedal

40 TC022040006 Brake pivot thread

61 TC025020010 Lower closing

64 TC025010068 Washer

65 TCND1010002 Bearing B/6005-RS

68 TC025010122 Plate for mirror visor

69 TC025010121 Compass for mirror visor

70 TC025010123 PVC Washer

72 TC025010119 OT Washer

73 TCNA1010034 Screw M10x80mm

74 TCNA2010011 Screw M8x60mm

75 TC021010023 Frame for luxmeter

76 TCNA0010009 Screw M6x16mm

77 TCNA1010034 Screw M4x16mm

78 TCNB1010006 Nut M8

79 TCNA0010026 Screw M8x20mm

80 TCNA0010005 Screw M6x50mm

81 TC020010037 Spring for spirit level

82 TCNB0010005 Nut M8

83 TCNA4010006 Screw 3.9x9.5mm

84 TC025020059 Rail kit complete

15. PARTS LIST

ITEM PART NO DESCRIPTION

Origin Date: 011297

Issue Date: 011297

Version No: 1

Modified Date: 071098

We suggest the unit is periodically checked for calibration in situ. If the unit is covered by a service agreement with the MOT package installer,

they will carry this out on your behalf. Should you wish to regularly check the calibration yourself, we recommend you purchase an Alignment

Device from your local dealer. Full instructions are provided with the re-calibration tool.

12. CALIBRATION

01284 757500 01284 703534 E-mail: sales@sealey.co.uk

Sealey Group,

Bury St. Edmunds,

Suffolk. HBS97HBS971- 010798

NOTE: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

IMPORTANT: No liability is accepted for incorrect use of product. WARRANTY: Guarantee is 12 months from purchase date, proof of which will be required

for any claim. INFORMATION: Call us for a copy of our latest catalogue on 01284 757525 and leave your full name and address including your postcode.