4. CONTENTS

5. OPERATION

5.1. GENERAL NOTES

WARNING!Ensureyouhavereadandunderstoodthesafetyinstructions.

5.1.1. Checkthetyreforphysicalsignsofdamage.

NOTE:Iftheholeortearisgreaterthan6mmitisprobablytoobigtox.Considerseekingassistance.

8DO NOTpulloutanyobjectsstuckinthetyre,thismightmaketherepairhardertoachieve.

NOTE:Ifpossible,workonthetyrewiththehole/tearneartothelowermostpointofthetyre.Thesealantwillworkbetterthatway.

NOTE: Wheninating/repairingatotallyattyrestillttedonavehicle,thereshouldnotbeanyweightonit.Thevehiclemust,

therefore,bejackeduptotaketheweightoffthetyre.Reviewjacksafetyinstructionsandvehiclemanufacturer’sguidelinesfor

jacking.

5.1.2. Positioncompressoronarm,atsurfaceandlocatedsothattheairhosereachesthetyrevalve.

IMPORTANT:Inationwillonlybeeffectiveiftheconnectorsarefullytted.

WARNING!Thecompressormustbeswitchedofffortwentyminutesaftereachtwentyminuteperiodofcontinuousoperationto

preventexcessiveheatbuild-up.

5.2. PUNCTURE REPAIR

NOTE:ReviewSection5.1beforebeginningthisprocess.

5.2.1. Unpacktheunitandcheckthatallitemsarepresentandingoodworkingcondition.

5.2.2. CheckthatthecompressorOn/OffswitchisintheOFFpositionandplugthe12Vplugintothevehicle’saccessorysocket.

5.2.3. Gentlyshakethesealantbottletomixitthoroughly.

IMPORTANT:Repairwillonlybeeffectiveiftheconnectorsarecorrectlytted.

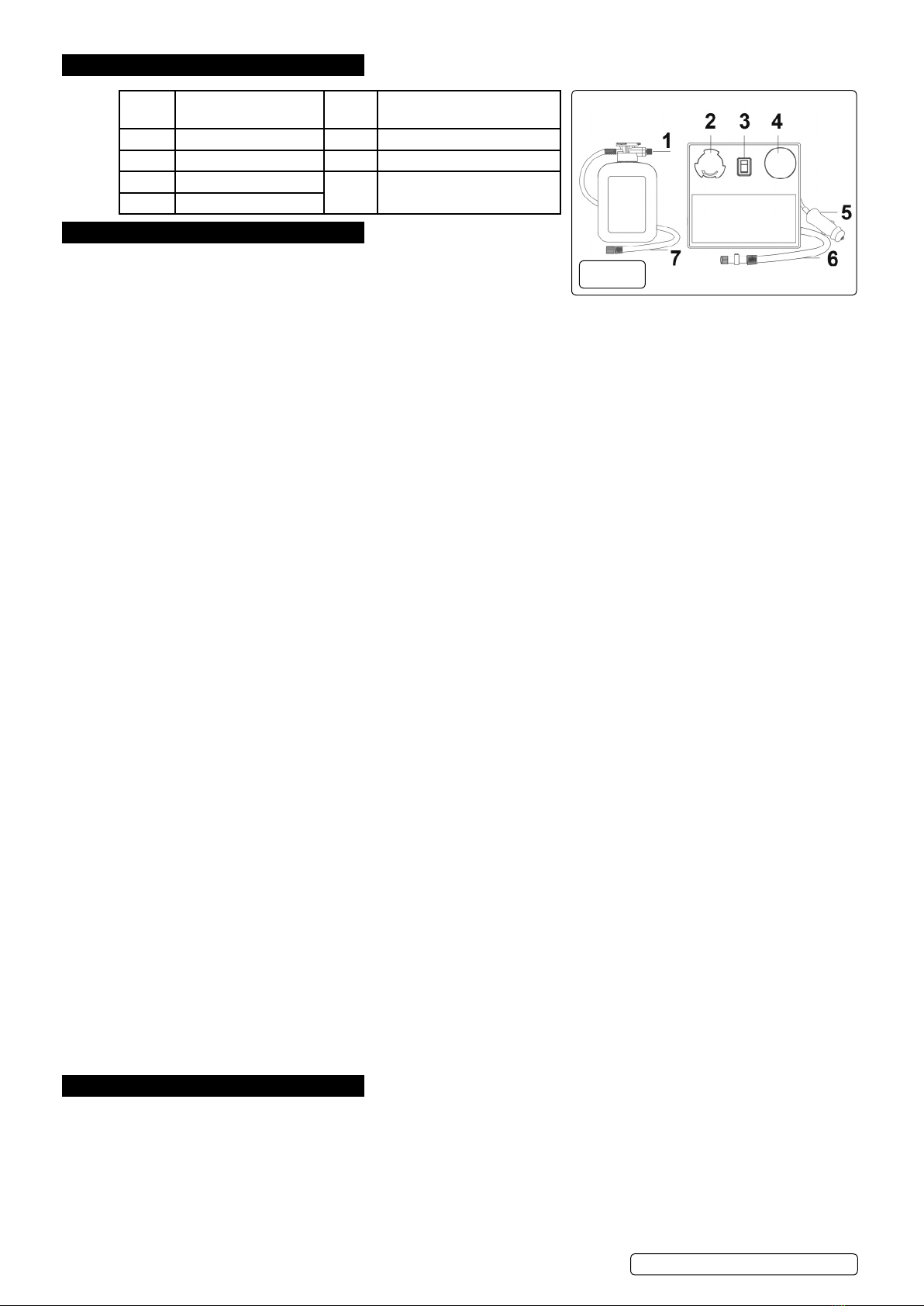

5.2.4. Connectairhose(g.1.6)tosealantairinletconnector(g.1.1)

5.2.5. Invertsealantbottleandlocateintofaceofcompressor(g.1.2).Rotateclockwisetolockinplace.

5.2.6. Connectsealantoutlet(g.1.7)totyrevalve.

5.2.7. Turnthecompressorontobegintheprocess.Oncethetyrereachestherequiredpressureturnthecompressoroff.

NOTE:Ifthetyrehasnotinatedafterapproximately10minutescheckallconnectionsforleakage/blockage.Ifnoneisevident

considerseekingassistance.

NOTE: Ifthetyreisaccidentallyover-inated,usethereliefvalveonairhose(g.1.6)toallowairoutofthetyre.

WARNING!Afterrepairingthetyre,theairhoseanditsconnectorsmaybehot.Leavetocoolfor2to3minutesbeforeremoving.

5.2.8. Removeallttingsandthepowersupply.Stowtheitemsincarrycaseandplaceusedsealantbottleinaleak-proofbagifavailable.

5.2.9. Driveforabout2miles(~3km)sothatsealantcansealthedamagedarea.Stopandchecktyrepressure,topuptyrepressureif

required.

8DO NOTdrivefasterthan50mph(80kph)ontherepairedtyre.

8DO NOTdrivefurtherthan125miles(200km)ontherepairedtyre.

8DO NOTcontinuedrivingifanyvibrations,unsteadysteeringornoisesoccur.Considerseekingassistance.

5.3. TYRE / INFLATABLES INFLATION

NOTE:ReviewSection4.1beforebeginningthisprocess.

5.3.1. CheckthatthecompressorOn/OffswitchisintheOFFpositionandplugthe12Vplugintothevehicle’saccessorysocket.

5.3.2. Removethevalvedustcapandscrewtheconnectorontothevalvestem.

IMPORTANT:Inationwillonlybeeffectiveiftheconnectorisfullyttedontothevalve.

5.3.3. PressthecompressorOn/OffswitchtotheONpositionandthecompressorwillbegintooperate.

5.3.4. InatethetyretothedesiredpressureandturnoffthecompressorbypressingtheswitchtotheOFFposition.

NOTE: Thegaugemaybesubjecttouctuationwhilstpumping.

5.3.5. Removetheairhosefromthetyrevalvebyunscrewingconnectorfromthetyrevalve,takingcaretominimiseairlossinthe

process.Replacethedustcap.

5.3.6. Disconnectthe12Vplugfromthevehicle’saccessorysocket.

NOTE:Thepressuregaugeisnotacalibratedinstrument.Itisrecommendedtouseacalibratedtyrepressuregaugeforan

accuratenalreading.

NOTE:Thecompressormayalsobeusedonitemssuchasinatabledinghies,sportsballs,airbedsetc.usingoneofthetwo

adaptorssupplied.

NOTE: Ifthetyre/inatableisaccidentallyover-inated,usethereliefvalveonairhose(g.1.6)toallowairout.

CAUTION: Someitemsmaynotindicatethepressurerequiredorthesafemaximumpressure.Beverycarefulnottoover-inate.

6. MAINTENANCE

6.1. Beforeeachusecheckallhosesandttingsaresoundandserviceable.

6.2. Wipedownunitwithdampclothanddrythoroughlyifsoiled.DO NOTgettheunitwet.

6.3. Replaceallhosesbackintorelativecompartmentsincompressorbodyandplace

MAC10SIssue131/10/19

Original Language Version

©JackSealeyLimited

Item

no.

Description Item

no.

Description

1 Connector-airinlet 5 Powercable

2Sealantlocation 6 Airhose+deationvalve

3 On/Offswitch

7

Tyrevalve

Connector

4 Pressuregauge

g.1