9Avoid unintentional starting.

8DO NOT use the polisher for any purpose other than that for which it is designed.

8DO NOT operate the polisher if any parts are damaged or missing as this may cause failure and/or personal injury.

8DO NOT switch the polisher on until the head is in contact with the panel and switch the unit off before removing the head from the panel.

8DO NOT use the polisher with abrasive cleaners or rubbing compounds as excessive paint removal may result.

8DO NOT get the polisher wet or use in damp or wet locations or areas where there is condensation.

8DO NOT allow untrained persons to operate the polisher.

8DO NOT operate the polisher when you are tired or under the influence of alcohol, drugs or intoxicating medication.

8DO NOT use the polisher where there are flammable liquids, solids or gases such as paint solvents, etc.

8DO NOT leave the polisher operating unattended.

8DO NOT carry the polisher with your finger on the power switch.

8DO NOT pull the cord from the power supply.

9Use a qualified person to maintain the polisher.

9When not in use, unplug from the charger from the mains power supply and store in a safe, dry, childproof area.

2. INTRODUCTION

Cordless random orbital polisher with Ø240mm foam pad and polishing bonnet. Smooth operation provides even buffing/polishing with no hot spots.

Adjustable handles provide a choice of 3 working positions, making it suitable for various tasks. Impact resistant housing with soft grip handles.

Supplied with 18V Lithium-ion battery pack and battery charger.

3. SPECIFICATION

Model no:....................................................................CP2518L

Battery: ...........................................................18V 1.3Ah Li-ion

Speed: ........................................................................ 2500rpm

Pad size:.....................................................................Ø240mm

Replacement battery pack:....................................CP2518LBP

Replacement backing pad:................................ CP2518L.SBP

Replacement bonnet terry cloth: ............................ ER230P.TB

Replacement bonnet synthetic fleece: ...............CP2518L.BSF

Noise power: .................................................................. 88dBA

Noise pressure: .............................................................. 77dBA

Vibration: ...................................................................3.325m/s²

Uncertainty: ...................................................................1.5m/s²

4. OPERATION

IMPORTANT WARRANTY INFORMATION:

The battery pack fitted to this cordless tool is considered to be a consumable item and its ability to accept charge will reduce over

time. We will warranty it against mechanical and electrical defect for a period of one year - this does not cover fair wear and tear. If the

battery is not properly charged before first use, or regularly conditioned, its capacity will diminish. Under these circumstances we will

not replace the battery pack even if it is less than one year old.

4.1. BATTERY CHARGING

4.1.1. Plug the charger into a mains electric socket. When switched on, the left hand charger LED will be red.

4.1.2. To release the battery press the battery latch and slide the battery out.

4.1.3. Slide the battery into the charger.

4.1.4. Whilst charging the left hand LED will be green and the right hand LED will be red.

4.1.5. When fully charged the left LED will go off and the right hand LED will be green.

4.1.6. Retthebatteryintothepolisher,ensureitclickshome.

NOTE: When new, the battery may have been shipped in a low charge state. It will take longer to charge the battery initially and

several subsequent charges may also take a little longer, compared with when the battery reaches its optimum performance.

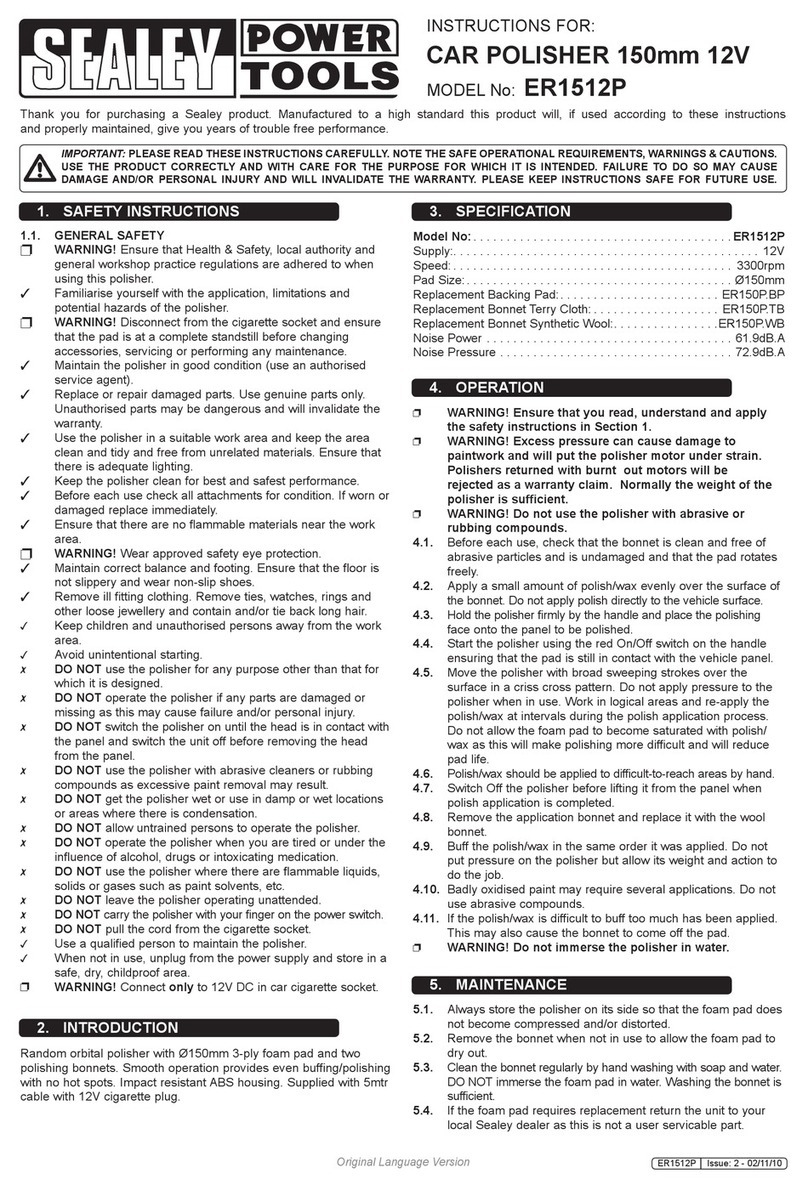

4.2. OPERATION

WARNING! Ensure that you read, understand and apply the safety instructions in Section 1.

WARNING! Do not use the polisher with abrasive or rubbing compounds.

WARNING! Excess pressure can cause damage to paintwork and will put the polisher motor under strain. Polishers returned

withburntoutmotorswillberejectedasawarrantyclaim.Normallytheweightofthepolisherissufcient.

4.2.1. Regularly check that the bonnet is clean and free of abrasive particles and is undamaged and that the pad rotates freely.

4.2.2. Apply a small amount of polish/wax evenly over the surface of the bonnet. DO NOT apply polish directly to the vehicle surface.

4.2.3. Hold the polisher firmly by the handles and place the polishing face onto the panel to be polished.

4.2.4. Start the polisher using the switch built into the underside of the right hand handle. Squeeze and hold the switch ensuring that the pad is

still in contact with the vehicle panel.

4.2.5. Move the polisher with broad sweeping strokes over the surface in a criss-cross pattern. DO NOT apply pressure to the polisher when in

use. Work in logical areas and re-apply the polish/wax at intervals during the polish application process. DO NOT allow the foam pad to

become saturated with polish/wax as this will make polishing more difficult and will reduce pad life.

4.2.6. Polish/wax should be applied to difficult-to-reach areas by hand.

4.2.7. Switch Off the polisher by releasing the ON/OFF switch before lifting it from the panel when polish application is completed.

4.2.8. Remove the application bonnet and replace it with the wool bonnet.

4.2.9. Buff the polish/wax in the same order it was applied. DO NOT put pressure on the polisher but allow its weight and action to do the job.

4.2.10. Badly oxidised paint may require several applications. DO NOT use abrasive compounds.

4.2.11. If the polish/wax is difficult to buff too much has been applied. This may also cause the bonnet to come off the pad.

WARNING! DO NOT immerse the polisher in water.

CP2518L | Issue 1 25/11/16

Original Language Version

© Jack Sealey Limited