100MM POWER BELT SANDER/LINISHER

MODEL NO: SM100.V2

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these instructions,

and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY.

1. SAFETY

1.1. ELECTRICAL SAFETY

WARNING! It is the user’s responsibility to check the following:

Check all electrical equipment and appliances to ensure that they are safe before using. Inspect power supply leads, plugs and

all electrical connections for wear and damage. Sealey recommend that an RCD (Residual Current Device) is used with all electrical

products. You may obtain an RCD by contacting your local Sealey stockist.

If the product is used in the course of business duties, it must be maintained in a safe condition and routinely PAT (Portable

Appliance Test) tested.

Electrical safety information, it is important that the following information is read and understood.

Ensure that the insulation on all cables and on the appliance is safe before connecting it to the power supply.

Regularly inspect power supply cables and plugs for wear or damage and check all connections to ensure that they are secure.

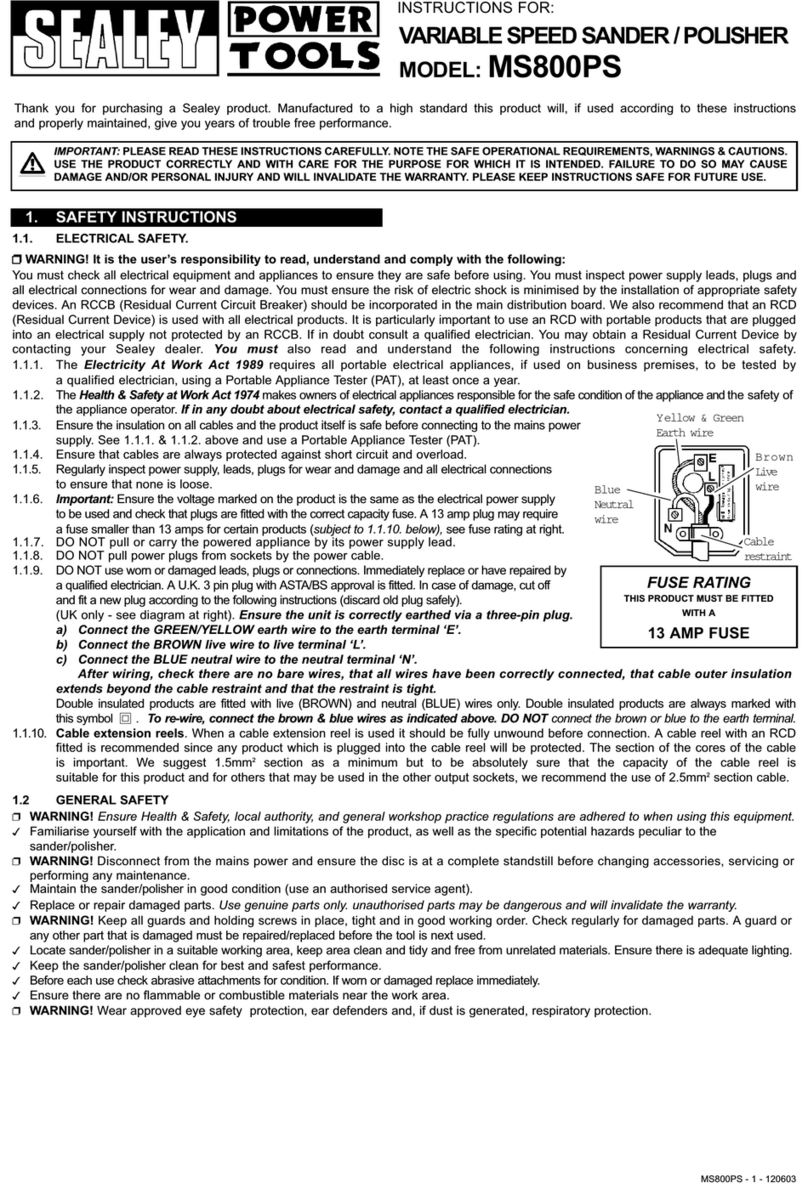

IMPORTANT: Ensure that the voltage rating on the appliance suits the power supply to be used and that the plug is tted with the

correct fuse - see fuse rating in these instructions.

8DO NOT pull or carry the appliance by the power cable.

8DO NOT pull the plug from the socket by the cable.

8DO NOT use worn or damaged cables, plugs or connectors. Ensure that any faulty item is repaired

or is replaced immediately by a qualied electrician.

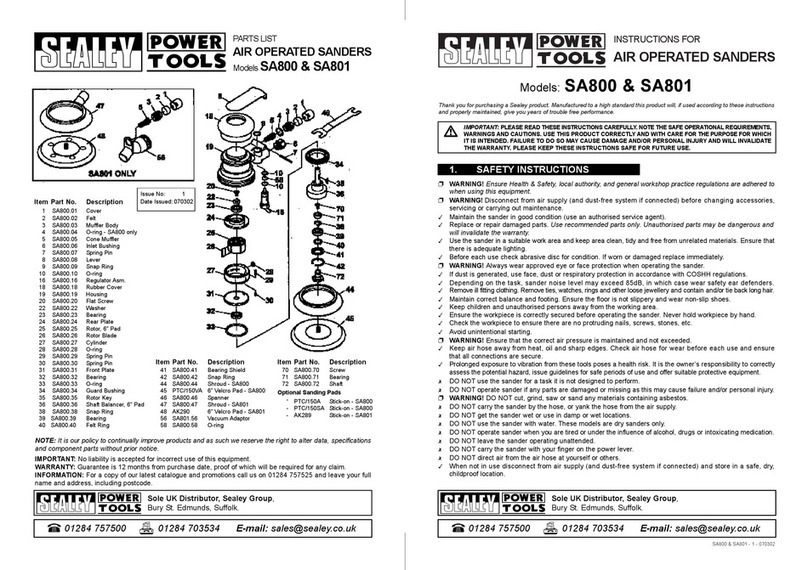

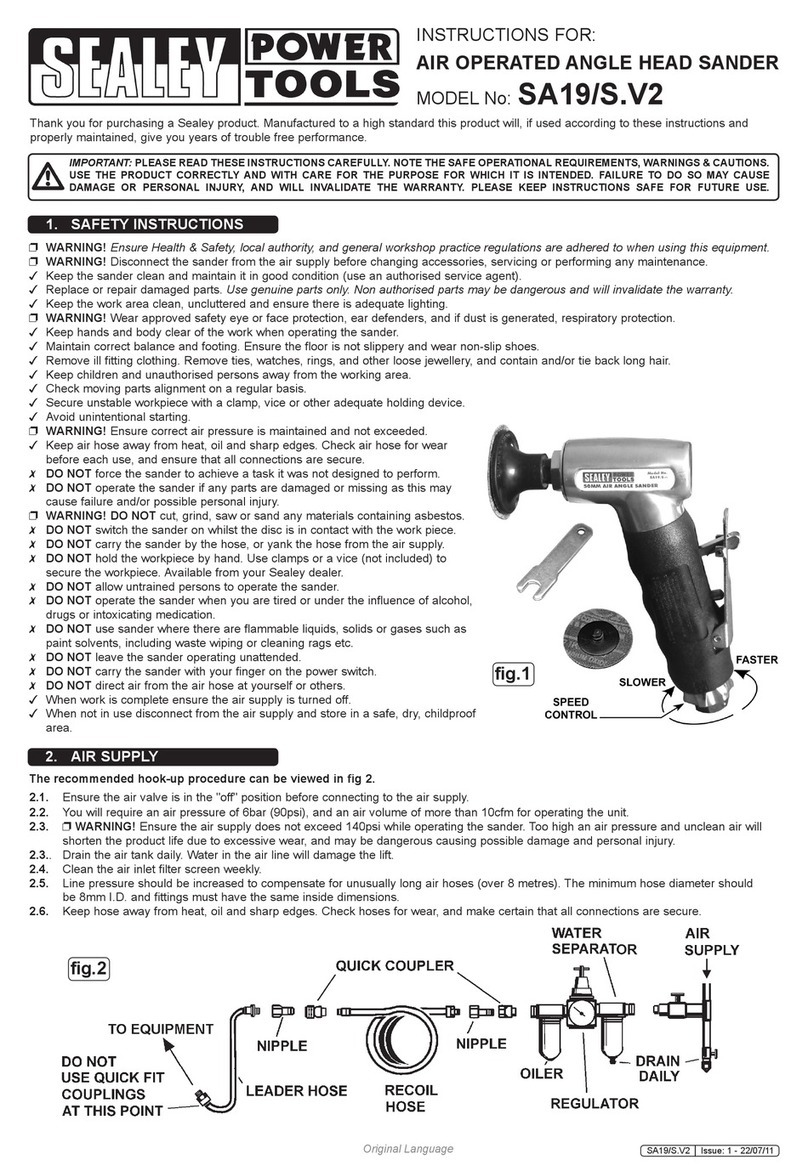

This product is tted with a BS1363/A 13 Amp 3 pin plug.

If the cable or plug is damaged during use, switch o the electricity supply and remove from use.

Ensure that repairs are carried out by a qualied electrician.

Replace a damaged plug with a BS1363/A 13 Amp 3 pin plug. If in doubt contact a qualied electrician.

a) Connect the GREEN/YELLOW earth wire to the earth terminal ‘E’.

b) Connect the BROWN live wire to the live terminal ‘L’.

c) Connect the BLUE neutral wire to the neutral terminal ‘N’.

Ensure that the cable outer sheath extends inside the cable restraint and that the restraint is tight.

Sealey recommend that repairs are carried out by a qualied electrician.

1.2. GENERAL SAFETY

9Wear approved safety goggles, ear defenders, mask and safety shoes.

9Remove ill tting clothing. Remove ties, watches, rings, and other loose jewellery, and contain long hair.

9Use sander in a suitable work area, keep area clean, tidy and free from unrelated materials, and ensure adequate lighting.

9Keep children and visitors away from the work area.

9Maintain correct balance and footing. DO NOT over-reach and ensure the oor is not slippery. Wear non-slip shoes.

8DO NOT operate the sander when you are tired or under the inuence of alcohol, drugs or intoxicating medication.

9Disconnect the sander from the mains power before changing accessories, making adjustments, servicing or performing any

maintenance.

9 Read the manual before using the machine. Learn the machine’s limitations and specic hazards to minimise the possibility of

accidents and injury.

9 Use common sense and exercise caution when using the machine.

8DO NOT use the machine outdoors or expose to damp or rain.

8DO NOT modify the machine or use it in any other way except the tasks it was designed for. Never use the machine exceeding the

limits shown in the specication.

9 Use machine in good light and clean conditions with the correct space around it as dened in the Installation section.

9 Before starting the machine make sure that all safety guards are in their active positions and check their function.

8DO NOT use the machine when any safety device is suspended or removed. If any defect is noticed stop using the machine.

9Maintain the machine in top condition according to the Maintenance Section.

9 Before using the machine check for damaged parts. Check for damage to, alignment and operation of parts. Any damaged guard or

any other part should be properly repaired or replaced.

9 Avoid unintentional starting, ensure the switch is in the o position before plugging in the mains plug. In the event of power failure,

switch the machine o.

9 Remove adjusting keys/spanners before using the machine. Tools or scrap pieces can be ejected at high speed.

9Only use recommended accessories.

9Secure the workpiece using clamps etc when practicable.

Refer to

instruction

manual

Wear eye

protection

No reaching in Wear a mask Wear ear

protection

Wear safety

footwear

Recommended fuse rating

13 Amp

Original Language Version

© Jack Sealey Limited SM100.V2 Issue:2 22/07/2020