Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these

instructions, and properly maintained, give you years of trouble free performance.

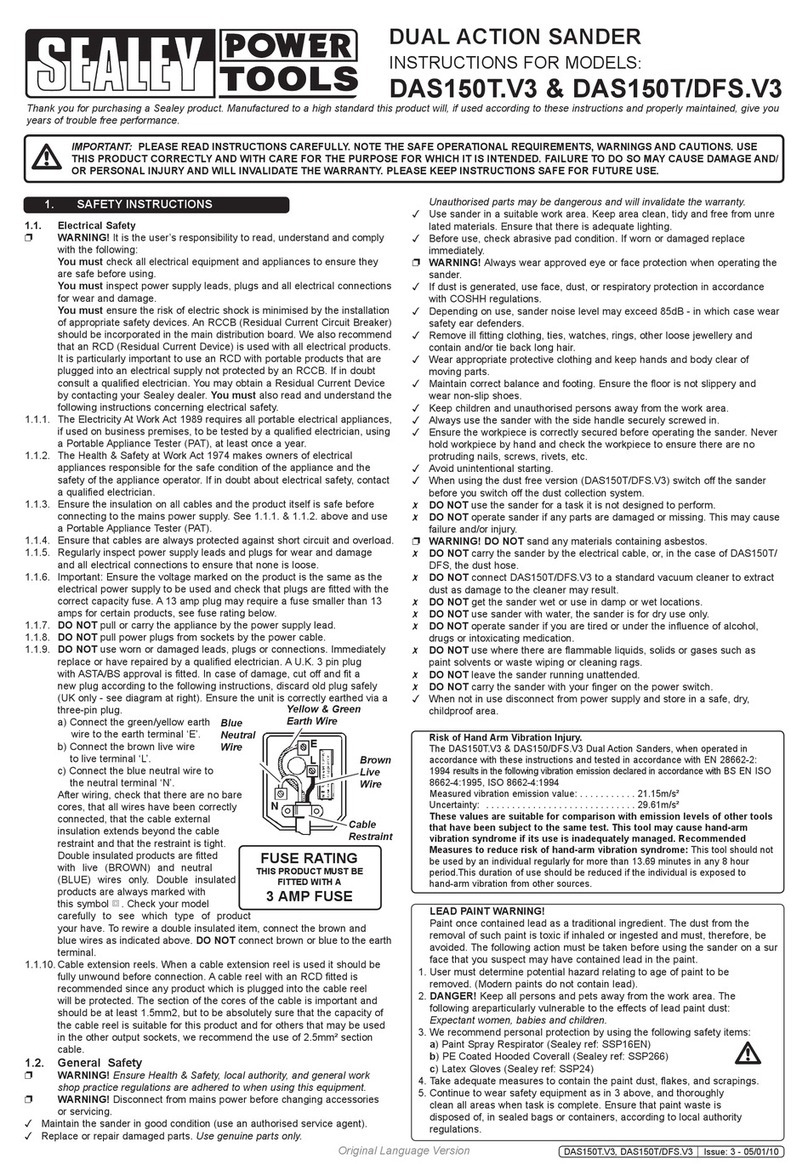

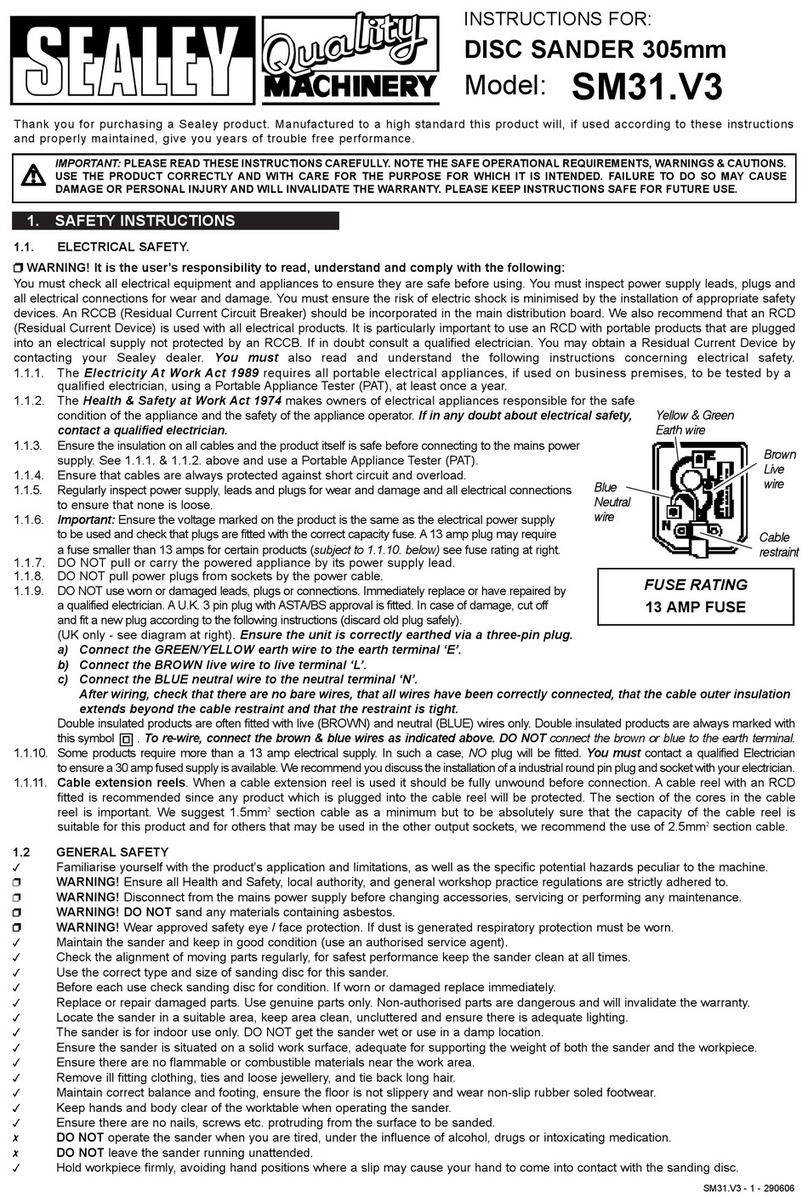

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAFETY

WARNING! Ensure that Health & Safety, local authority, and general workshop practice regulations are adhered to when using this equipment.

WARNING! Disconnect from air supply and dust-free system before changing accessories, servicing or maintenance.

9Maintain the sander in good condition (use an authorised service agent).

9Replace or repair damaged parts. Use recommended parts only. Unauthorised parts may be dangerous and will invalidate the warranty.

9Use the sander in a suitable work area. Keep area clean, tidy and free from unrelated materials. Ensure that there is adequate lighting.

9Before each use check abrasive pad for condition. If worn or damaged replace immediately.

9Ensure that there are no flammable or combustible materials near the work area.

WARNING! Always wear approved eye or face protection when operating the sander.

9If dust is generated, use face, dust, or respiratory protection in accordance with COSHH regulations.

9Depending on the task, sander noise level may exceed 85dB, in which case wear safety ear defenders.

9Remove ill fitting clothing. Remove ties, watches, rings and loose jewellery. Contain and/or tie back long hair.

9Wear appropriate protective clothing and keep hands and body clear of working parts.

9Maintain correct balance and footing. Ensure that the floor is not slippery and wear non-slip shoes.

9Keep children and unauthorised persons away from the work area.

9Check moving parts alignment on a regular basis.

9Ensure that the work piece is correctly secured before operating the sander. Never hold a workpiece by hand.

9Check the work piece to ensure that there are no protruding nails, screws, stones, etc.

9Avoid unintentional starting.

WARNING! Ensure that the correct air pressure is maintained and not exceeded.

9Keep air hose away from heat, oil and sharp edges. Check air hose for wear before each use and ensure that all connections are secure.

9Prolonged exposure to vibration from these tools poses a health risk. It is the owner’s responsibility to correctly assess the potential hazard,

issue guidelines for safe periods of use and offer suitable protective equipment.

8DO NOT use the sander for a task it is not designed to perform.

8DO NOT operate sander if any parts are damaged or missing as this may cause failure and/or personal injury.

WARNING! DO NOT cut, grind, saw or sand any materials containing asbestos.

8DO NOT carry the sander by the hose, or yank the hose from the air supply.

8DO NOT get the sander wet or use in damp or wet locations. These models are dry sanders only.

8DO NOT operate sander when you are tired or under the influence of alcohol, drugs or intoxicating medication.

8DO NOT use sander near flammable liquids, solids or gases, such as paint solvents and including waste wiping or cleaning rags etc.

8DO NOT leave the sander operating unattended.

8DO NOT carry the sander with your finger on the power lever.

8DO NOT direct air from the air hose at yourself or others.

9When not in use disconnect from air supply and dust-free system, and store in a safe, dry, childproof location.

1.1. LEAD PAINT WARNING!

IMPORTANT! Paint once contained lead as a traditional ingredient. Contact with the toxic dust from the removal of such paint must

therefore be avoided. The following action must be taken before using the sander on a surface that you suspect may contain lead paint.

1.1.1. User must determine potential hazard relating to age of paint to be removed (modern paints do not have lead content).

▲DANGER! Keep all persons and pets away from the work area.

1.1.2. The following are particularly vulnerable to the effects of lead paint dust: Pregnant women, babies and children.

1.1.3. We recommend personal protection by using the following safety items:

a) Paint Spray Respirators.

b) PE Coated Hooded Coverall.

c) Latex Gloves.

1.1.4. Take adequate measures to contain the paint dust, flakes and scrapings.

1.1.5. Continue to wear safety equipment as in section 1.1.3 and thoroughly clean all areas when task is complete.

1.1.6. Seal paint waste in bags or containers for disposal according to local regulations.

Original Language Version

© Jack Sealey Limited

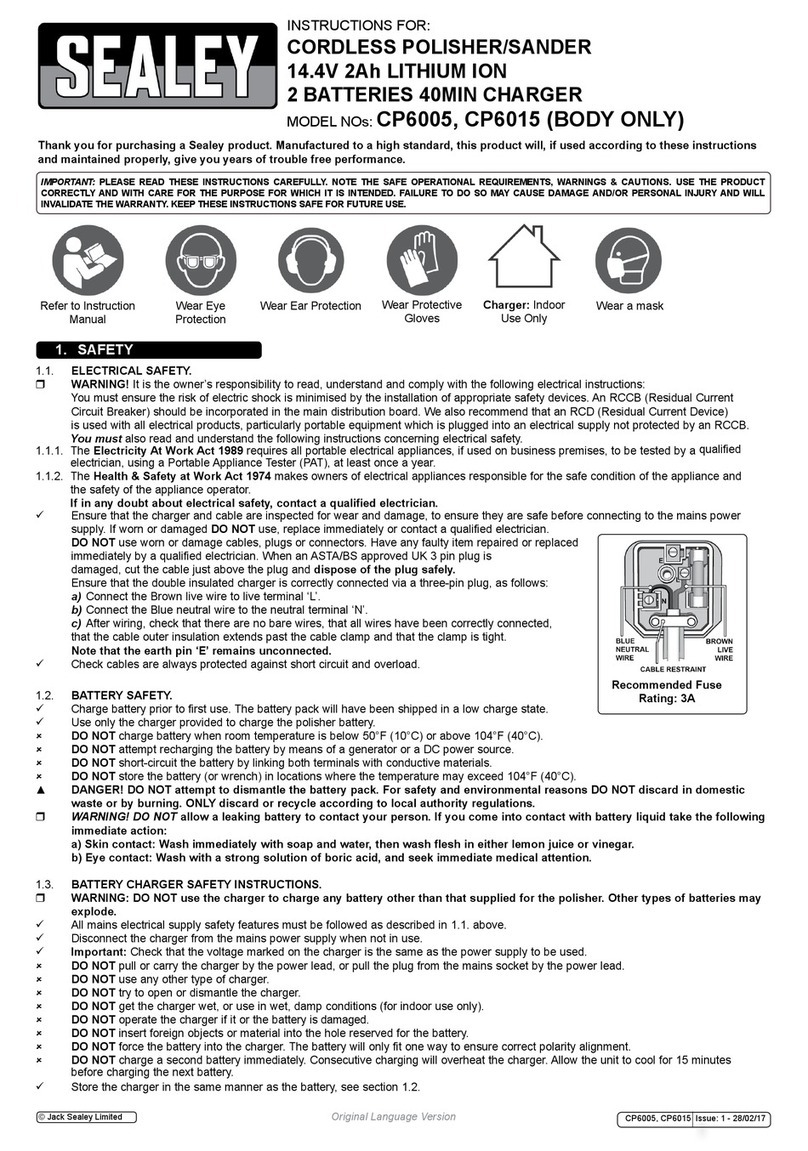

Refer to

instructions

Wear eye

protection

Wear protective

gloves

Wear ear

protection

Wear a mask

150MM PREMIER AIR PALM SANDER/

150MM PREMIER DUST-FREE AIR PALM

SANDER

MODEL NO: SA800.V5 / SA801.V5

SA800.V5, SA801.V5 Issue 2 (H,F) 19/06/2020