7.3.9. Carefullyreleasethedrumlatch,andslowlyallowthehosetowindontothereel.

7.3.10. ApplyTeontapeorpipesealanttotheoutletttingonthenewhosethenattachittoadesiredtool,ornozzle.Pressurizethereel

andcheckalltheconnectionsforleakage.

7.3.11. Ifneeded,adjustthespringtension.SeeSpringTensionAdjustmentintheOperationsection.

7.4. SWIVEL SEAL REPLACEMENT

7.4.1. Turnoffthepressuresource,releasepressurefromthesystem,andremovethesupplyhoseconnectionfromtheswivel.

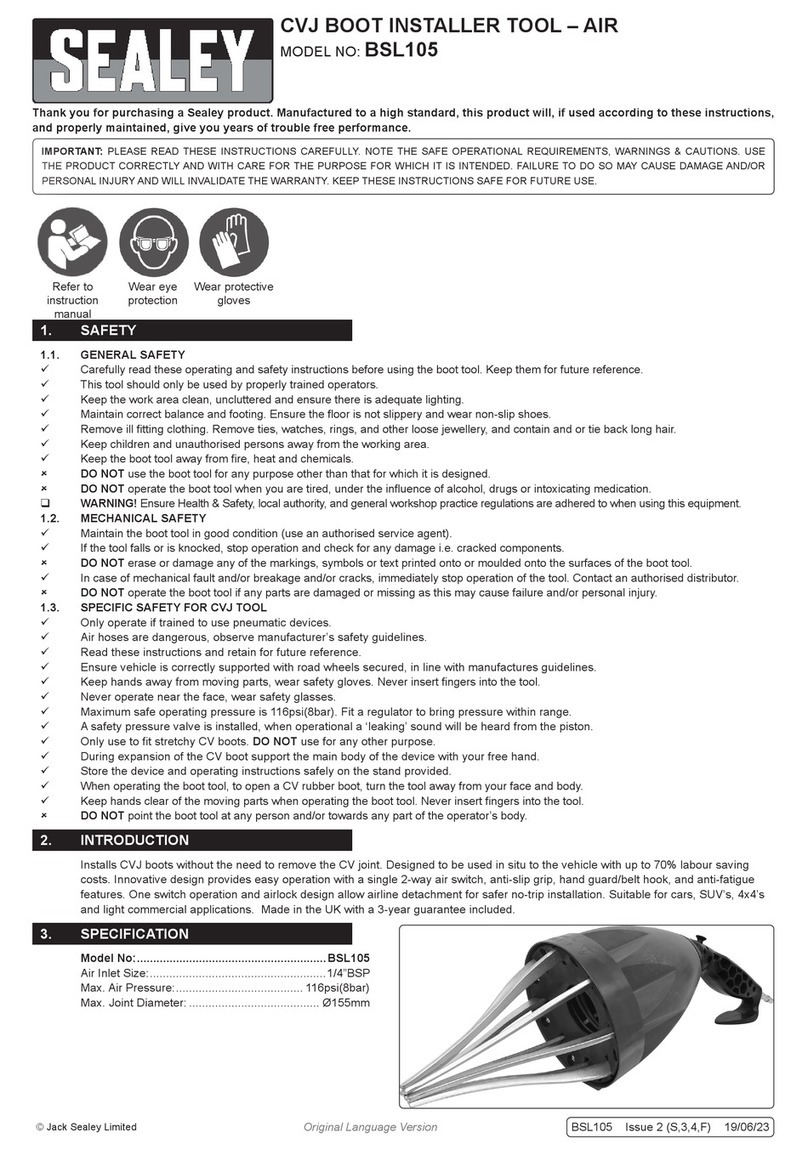

7.4.2. Removetheswivelassembly(g.6)fromreelaxle.

NOTE: Removaloftheswivelisnotabsolutelynecessaryunlessanewswivelisbeinginstalled.

7.4.3. Removethecirclipfromswivel,andtakeitapart.Pleaseseethediagramaboveforreference.

7.4.4. Replacethesealsandreassembletheswivel.

7.4.5. UseTeontapeorthreadsealantontheswivelthreadsandreconnecttheswivelwiththeaxle.

7.4.6. UseTeontapeorthreadsealantontheinletsupplyhosethreadsandreconnectittotheswivel.

7.4.7. Pressurizethesystemandcheckforleaks.

7.5. Thehosereeldoesnotrequirespecialmaintenanceasitislubricatedforlife.Toensurereliableoperation,cleanthehoseand

casingregularly.

8DO NOTsprayorwettheproduct,butcleanwithaclothandwarmwater.

8DO NOTusesolventsordetergents,asthesemaypermanentlydamagetheplastic.

NOTE: Therearenouserserviceableparts.Allmaintenanceandrepairswhichrequirethecasetobeopenedordismantledshouldbe

carriedoutbyanauthorisedserviceagentonly.

WARNING! DO NOTdismantlethehosereelcasing,orattempttoremovethescrewsandcoversonthesides.Todosomayresult

indamagetotheapplianceand/orpersonalinjuryandwillinvalidatethewarranty.

7.6. STORAGE

7.6.1. Shouldyouwishtostorethehose,ensureitiscleananddry.Placetheiteminadark,safe,dry,childprooflocation,wherethe

temperaturewillremainreasonablystable.

8DO NOTstoreinanylonorplasticbag,asthiswillencouragecondensation.

8. TROUBLESHOOTING

PROBLEMS POSSIBLE CAUSE SOLUTION

Hose will not retract Hosebunchingwithinreel.

Springtensiontootight.

Replacement hose too heavy

Spring has lost all tension or has possibly

broken.

Pullhoseoutofreelandguidebackin.

Havespringtensionadjustedbyauthorised

serviceagent.

Havecorrecthosettedbyauthorised

serviceagent.

ReinstallSpringTension

ReplaceSpringCanister.

Hose will not fully retract OutletNozzle,gunortoolistooheavy.

Springisfatigued.

Fieldinstalledhoseistoolong.

Addspringtension.See“SpringTension

Adjustment”.

Addspringtension.See“SpringTension

Adjustment”.Replacespringcanisterif

required.

CalllocalDistributorforcorrectspecied

hoselength.

Reel will not latch The hose has been pulled past the latching

teeth.

Brokenlatchingpawlorpawlspring.

Allowreeltoretractslowlyafterhearing1st,

2ndor3rdclick.

Havenewlatchingpawlorpawlspringtted

byauthorisedserviceagent.

ReelLeaks Damagedhose. Havenewhosettedbyauthorisedservice

agent.

FluidleaksfromSwivel Swivelsealsaredamagedorworn.

Inlethoseisnotexible.

Replaceswivelseals.See“SwivelSeal

Replacement.

Caution:BesureleakisnotHosetting!

Hoselocksupwhenfullyextended HoseClampisintheincorrectposition Relocatehoseclamptooptionallocation.

SwivelAssemblyisnotmovingfreelyof

lockingup

Inlethosettinghasbeenover-tightened.

Inlethoseisnotexiblecausing

Sideforceonswivel.

Removeandexamineswivelassemblyfor

damage.Replaceasnecessary.

Properlytighteninlethose.Handlightens

tting,plus1/2tumwithwrench.

g.6

WHR1512Issue130/07/19

Original Language Version

©JackSealeyLimited