9Wear appropriate protective clothing. When handling lubricants refer to manufacturer’s instructions and conform to local regulations.

9Use the gun in a suitable working area. Keep area clean and tidy and free from unrelated materials and ensure there is adequate lighting.

9Maintain correct balance and footing whilst performing the task.

9Ensure floor is not slippery and wear non-slip shoes.

9Keep children and unauthorised persons away from the work area.

9Dispose of waste grease in accordance with local authority regulations.

9When not in use ensure the battery is removed.

8DO NOT allow unauthorised persons to operate the gun.

WARNING! DO NOT tamper with or open pump unit. Doing so will invalidate your warranty.

8DO NOT point grease gun at yourself or other persons or animals.

8DO NOT pull the grease gun unit by the hose.

8DO NOT use the gun for a task it is not designed to perform.

8DO NOT operate the gun when you are tired or under the influence of alcohol, drugs or intoxicating medication.

9When not in use, clean the unit and store in a dry, safe, childproof area.

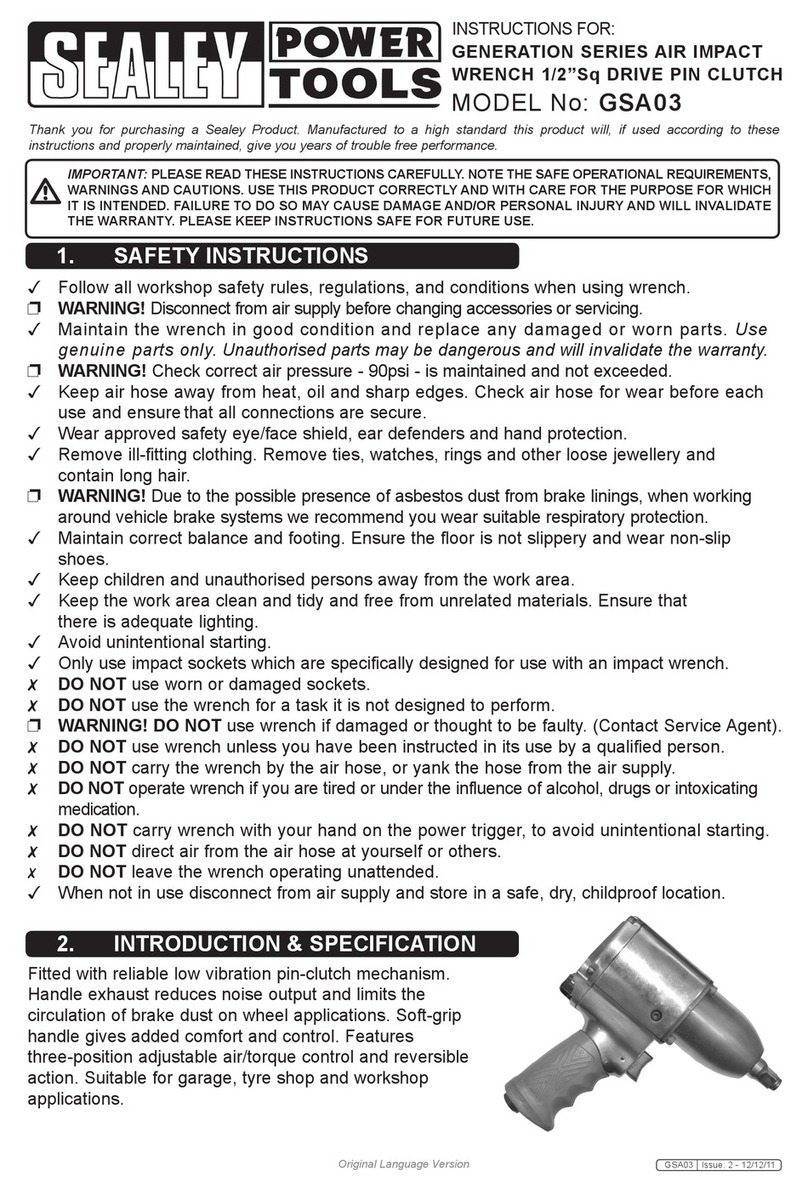

2. INTRODUCTION

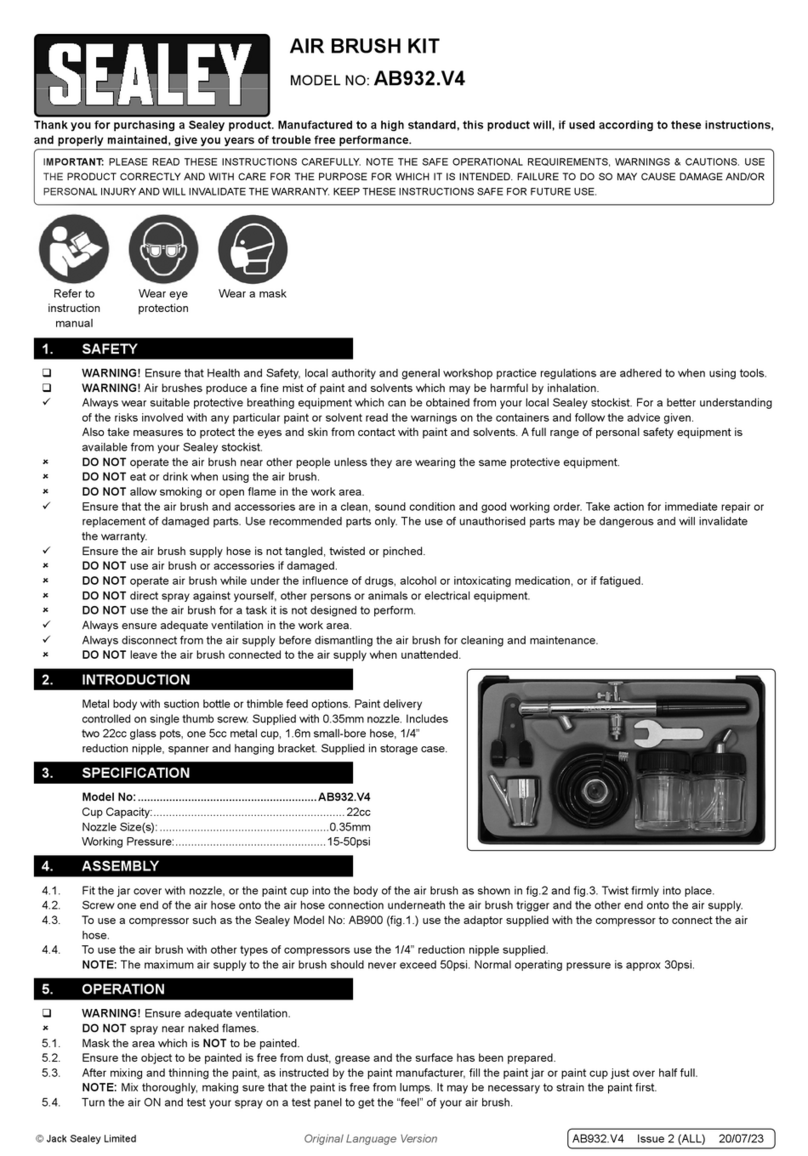

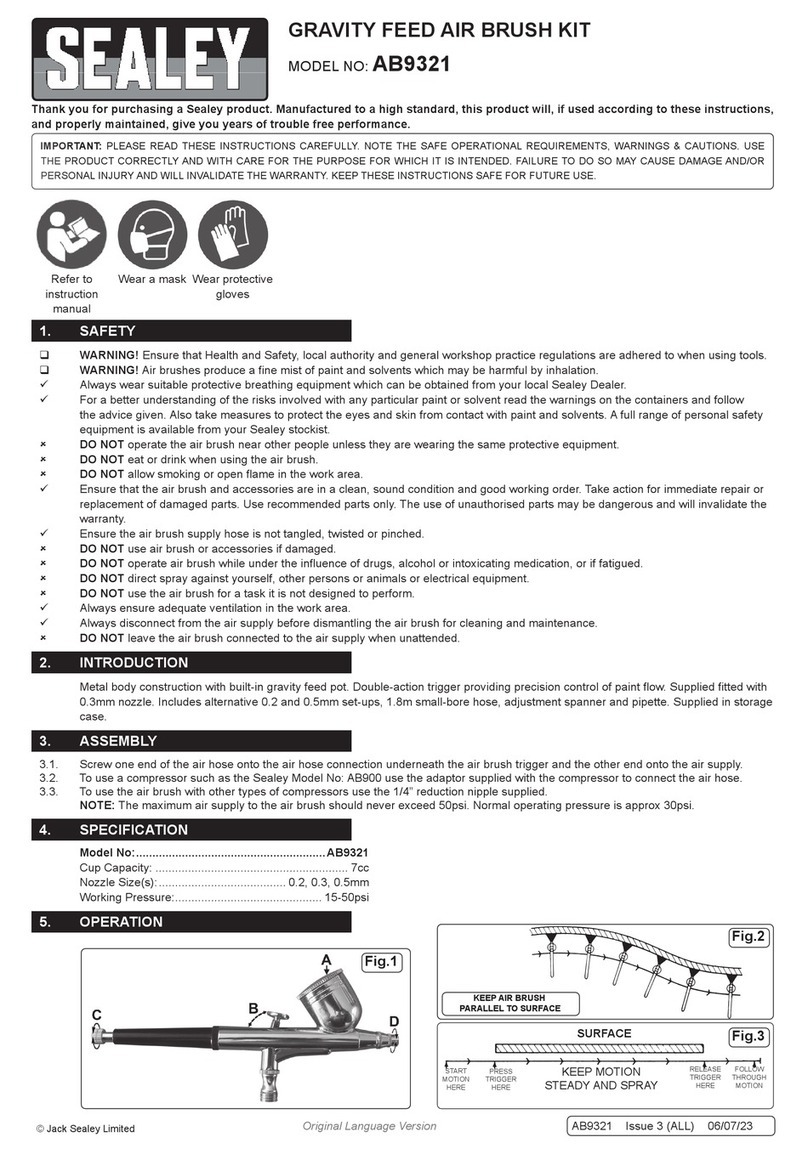

High power, professional, cordless grease gun, developing 8000psi. Ideal for in-field lubrication where power and speed are required. Suitable for

screw type and standard 400g cartridges, manual or bulk filling. Features LCD battery condition indicator, air bleed and heavy-duty aluminium

pressure head. Supplied with 18V 2Ah Lithium-ion battery and mains charger. Supplied in a carry-case.

3. SPECIFICATION

Model No:............................................................ CPG18V.V3

Battery: .......................................................... 18V 2Ah Li-Ion

Pressure:....................................................................8000psi

Flow Rate:............................................................... 100g/min

Hose Length:.............................................................. 700mm

Replacement Battery:.......................................... CPG18VBP

4. OPERATION

IMPORTANT WARRANTY INFORMATION: the battery pack fitted to this cordless tool is

considered to be a consumable item and its ability to accept charge will reduce over time. We will provide warranty against mechanical

and electrical defect for a period of one year - this does not cover fair wear and tear. If the battery is not properly charged before 1st use

or regularly conditioned, its capacity will diminish. Under these circumstances we will not replace the battery pack even if it is less than

one year old.

4.1. CHARGING THE BATTERY

4.1.1. Important: Before using the grease gun for the first time the battery must be charged for a minimum 1.5 hours.

4.1.2. To charge the battery, slot the battery onto the charger (fig.1.1).

WARNING! DO NOT obstruct the vents situated on the top and bottom of the charger as this will cause the charger to overheat.

4.1.3. Once plugged in correctly and the mains has been switched on, the red light situated at the front of the charger (fig.1.2) will illuminate.

When charging is complete the green light will illuminate.

4.2. REMOVING THE BATTERY PACK - FIG 1

4.2.1. To remove the battery from the unit press the two buttons located each side of the battery

simultaneously and pull the battery away from the body.

4.2.2. To insert the battery, line up the ridges on the battery with the slots on the handle base and push

towards the unit firmly until you hear a click.

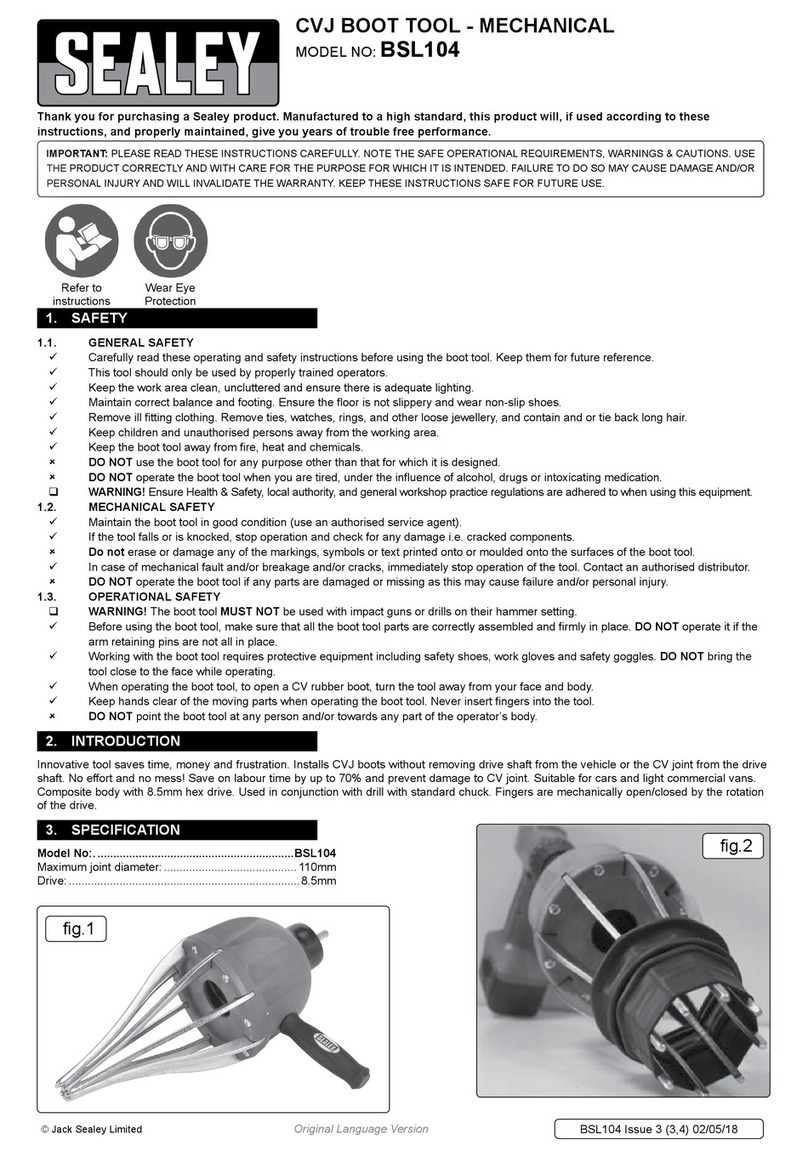

4.3. CARTRIDGE LOADING - FIG 2 (UNSCREWED - SEALEY PART NO’S SGC1, SGC12)

4.3.1. Unscrew the grease tube from the grease gun.

4.3.2. Fully draw back the plunger handle.

4.3.3. Inserttheopenendofthecartridgeintothegreasetubeandpushitallthewayin(g.2).

4.3.4. Remove the seal or pull tab end from the cartridge.

4.3.5. Screw the grease tube back into the grease gun. Press the catch plate and release the plunger rod.

4.3.6. Push down on the plunger handle.

4.4. CARTRIDGE LOADING - (SCREWED - SEALEY PART NO’S SCS107, SCS108)

4.4.1. Unscrew the grease tube from the grease gun.

4.4.2. Removebottomcapandunscrewtopcap.Forceinternalpusherplateintocartridgesothatgreaseoverowsoutletby1.5cm.

4.4.3. Screw capsule into gun head.

4.4.4. Insert top cap followed by bottom cap into rear of cartridge for storage.

4.5. SUCTION FILLING - FIG 3

4.5.1. Unscrew the grease tube from the grease gun.

4.5.2. Ensure the handle has been released (by pressing the catch plate).

4.5.3. Submerge the open end of the grease tube into grease bucket by

approximately50mm(2”)andslowlypulltheplungerhandleoutfully(g.3).

4.5.4. Screw the grease tube back in to the grease gun. Press the catch plate and release the

plunger rod. Push down on the plunger handle.

4.6. BULK FILLING

4.7. Press the catch plate to release the plunger handle.

Connectalowpressurebulkgreasingunittothebulkllernippleatthetopofthe

gunandlluntilplungerisfullyextended.

4.7.1. Press and hold the catch plate and push the plunger handle down until some

resistance is felt.

4.7.2. Open the pressure release valve until grease appears.

Original Language Version

© Jack Sealey Limited CPG18V.V3 | Issue 1 24/11/17

fig.1

fig.2

fig.3