SIG PLB 291K Operating instructions

Page1

PLB 291 ROCKDRILL

SERVICE INSTRUCTIONS AND SPARE PARTS LIST

MODELS:

SIG.au PLB 291 DI

Page2

PLB 291 ROCKDRILL

Contents

PAGE

Safety Precautions 3

Technical Data, ratings 4

Operation 5

•Control elements

•Compressed air & flushing water

•Lubrication

•Drill Rods

Disassembling –Reassembling the Hammer 8

Parts & Maintenance Data 9

•Handle

•Backhead

•Control Lever

•Distribution system

•Piston

•Cylinder washer bush

•Rotating mechanism

•Chuck insert

Spare Parts List: SIG.au PLB-291DI 18

Exploded Drawing: SIG.au PLB-291DI 20

Page3

PLB 291 ROCKDRILL

SAFETY PRECAUTIONS

•During Operation of the drill, safety shoes, safety glasses, ear protection and safety helmet are to be

worn,

•Exposure to excessive noise can lead to hearing deficiency. APPROPRIATE ear protection must always

be worn.

•Distraction increases danger of accident.

•Only on actual operation of drill should the operating handle be touched.

•When working with the drill, sure and firm footing is necessary.

•The drill should not be brought near to the face.

•Never place the drill on your foot.

•Never point the drill at co-workers or yourself.

•The drill should never be put into operation if it is lying on the ground or if it is not held securely in

working position.

•Compressed air is dangerous! Never point a connected compressed air hose at co-workers or yourself.

Avoid the habit of blowing your clothes free of dust with compressed air.

•Be sure that all hose connections are tight and sealed. A loose hose not only causes loss of air; danger

exists that it comes completely off the drill, whips around injuring the operators and others in the

area. Secure hoses with safety cables or ropes to prevent danger of injury in case a hose gets broken.

•Never disconnect a pressurized air hose: First shut off air from the compressor and bleed the drill.

•The drill should only be operated with a specially suitable inserted drill rod. Operate with sufficient

pressure, avoid recoils. When the machine is under pressure, oilers may not be filled up and tools may

not be exchanged.

•The drill should always be held with both hands during operation.

•The operator must have a firm footing. If possible the operator’s feet should be so placed out of the

falling range of the drill, but without the danger of losing balance. In the case of breakage of drill rod,

there is danger of sudden falling of drill with protruding and broken drill rod part.

•Never operate drill astride, I.E., with one leg over the handle. In the case of breakage of the inserted

drill rod, serious injuries can result.

•Ensure that no cables, pipes and the like are in area of drill operation (electric, gas, water, telephone).

•In the event of drill contacting unknown objects during operation, switch off drill immediately.

Identification of object should be carried out by careful uncovering with shovel, not with the drill.

•In case a cleaning solvent is used for cleaning drill parts, make sure that this meets the current safety

and health regulations and that it is used in a well-ventilated area.

The safety precautions listed in the manual are intended to alert operator and helpers to the possible

physical dangers inherent in the various stages of operating and/or maintaining equipment of this kind. All

personnel involved in operating and/or maintaining this equipment must read and thoroughly understand

the operating instructions before attempting to operate, or perform maintenance on the drill machine. Non-

authorised, or untrained personnel must not under any circumstances attempt to operate or maintain the

machine.

Page4

PLB 291 ROCKDRILL

TECHNICAL DATA/RATINGS

Carefully memorize this tool’s operation and maintenance instructions.

PLB-29DI

PLB-29K

DIMENSIONS

Weight

30Kg

30Kg

Length

690mm

690mm

Piston diam.

90mm

90mm

Piston stroke

65mm

65mm

DRIVE

Impact rate

2700BPM

2700BPM

Optimal air pressure

5-6Bar

5-6Bar

Air Consumption

5.3m3/min at 6Bar

5.3m3/min at 6Bar

FLUSHING WATER

Water pressure: Always at least 0.5 bar LESS than actual air pressure

Water flow: 9 Litres/min with 2.4 long drill rod

Characteristics

Rotation: Left (Counter clockwise)

Exhaust Silencer: Integrated into hammer housing

Tool Insert: 22 x 108mm (7/8’’ x 4 1/4’’)

25 x 108mm (1’’ x 4 ¼’’ ) – alternative

Hoses

Air Hose: 25mm (1’’)

Water Hose: 13mm (1/2’’)

Page5

PLB 291 ROCKDRILL

OPERATION

1. Control Elements

A. Turning Handle for leg extension (SIG.au PLB-29K only)

B. Push button for leg retraction (SIG.au PLB-29K only)

C. Air pressure is shut off

D. Water flushing is ON

Reduced air pressure is ON (spot drilling)

E. Full air pressure is ON

F. Blow out of drill hole is ON

2. Compressed air and flushing water

Compressed air is to be CLEAN and DRY

Inner DIAMETER OF AIR HOSES to be 25mm or 1’’

Air hoses are to be BLOWN OUT BEFORE CONNECTION to the drill hammer

Inner DIAMETER OF WATER HOSES to be 13mm or ½’’

Water hoses are to be FLUSHED OUT BEFORE CONNECTION to the drill

Water pressure ALWAYS TO BE AT LEAST 0.5 Bar LESS than air pressure

SIG.au PLB 291K

SIG.au PLB 291DI

Page6

PLB 291 ROCKDRILL

3. Lubrication

When drilling, ALWAYS have the automatic oil feeder PLO 20 or a POB 15 fitted to the air

pressure line. (The closer the device is to the hammer, the safer it works).

Make Sure that oil shows up at the drill rod shank. The bit flange must be damp with oil. The

needed output may be regulated with the adjusting screw at the oil feeder.

ATTENTION: The oil feeder PLO 20 cuts off the air pressure when its reservoir runs out of

oil and/or when the air duct between oil feeder and hammer breaks.

The following oils for drill hammers are recommended:

AMBIENT TEMPERATURES

BRAND

TYPE

UNDER 100C

100C –350C

ABOVE 350C

TEXACO

RDL

32

100

SHELL

TORCULA

32

100

150

MOBIL

ALMO

525

527

529

4. Drill Rods

Rods

Shank ends are to be in good order, clean and

not worn or damaged. Percussion faces are to be

flat and perpendicular to the rod axis.

The flushing duct should not be clogged.

Bits

The correct section is to be ground (No cross cones!)

The flushing duct is not to be clogged.

For further details, please refer to the manufacturer’s instructions

Grinding –CAUTION!

If the cutting edge is ground

to a sharp corner like that on

the right, it may end up like the

broken edge on the left.

(See drawing to right)

The profile of the cutting head

should be wider than the mounting

steel to drill a hole with clearance.

(See drawing to right)

Page7

PLB 291 ROCKDRILL

Maintenance

The drill hammer is to be disassembled and cleaned periodically. At this opportunity the

particular wear parts are to be checked accordingly to chapter ‘Components and Servicing

Data’.

Dirt Restrictor

When replacing the dirt restrictor

Part 60, care should be taken to

insert it with Part 61 as shown.

All foreign matter must be removed

from the small holes and finally

blown out with compressed air.

Page8

PLB 291 ROCKDRILL

Disassembling the hammer

Screw off nuts, Part 13 with wrench B.

Push out frame bolts, Part 10.

So far, disassembly should be good enough for current servicing.

For directions concerning further disassembly, please refer to

‘Components and Servicing Data’.

Cleaning the parts

Carefully wash all parts with kerosene. Blow off residuals with compressed air and, with a

clean cloth, wipe the parts dry. After cleaning, coat all the parts with resin-free and acid-free

grease.

EXCEPTION: Do not grease but oil the valve plate, Part 74, the valve chest,

Part 72, and valve guide, Part 75.

Reassembling the Hammer

Replace all worn O-Rings as necessary,

Including control assemblies,

If found to be excessively leaking.

Reassemble the rock drill in accordance

With the exploded view. Make sure that the

distribution system, Parts 71, 72, 74, 75 & 76

are pressed vertically into the housing, Part 80.

Take care that the lubrication channel holes

In the cylinder washer, Part 84, and the

Housing, Part 80, line up.

Caution:

The frame-bolt nuts, Part 10,

Are to be screwed down alternatively

And in an uniform manner.

In the SIG.au PLB-29K and SIG.au PLB-291K

models, care is to be taken so not to jam

the valve piston, Part 128 inside the handle.

Page9

PLB 291 ROCKDRILL

Parts and Maintenance data

1. Handle (SIG.au PLB-29K and SIG.au PLB –291K models only)

Disassembly

Disassembly the left shaft bolt, Part 10.

Remove the head screw, Part 121.

Withdraw the left lever, Part 123.

Remove the supporting ring, Part 124.

Pull off the twist grip, Part 125, and check the

KSD –sealing rings, Part 126, and O-Rings, Part 127.

Assembly Instructions for KSD-rings

•Assembly tool, “spread bush”, is a self-made item, preferably made of nylon, delrin ore the

like.

•Twist grip 126 may be used as a calibrating tool.

•Lubricate KSD-rings with molycote, position O-ring once after the other in grooves via taper

guide.

•Add KSD-rings one after the other with aid of spread bush (handle gently)

•To recalibrate KSD-rings, use twist grip 125 in proper manner as shown.

Reassembly in reversed sequence:

Coat the KSD-rings 6 with MOLYCOTE

CAUTION: When mounting the twist grip 125 take care that the cylindric pin fits into the counter sunk

groove (b).

Page10

PLB 291 ROCKDRILL

Valve piston –inside handle (Model SIG.au PLB-29K and SIG.au PLB-291K only)

The valve piston, Part 130, may jam because of dirt or incorrect tightening of the side rod,

Part 10. Check it for easy movement.

To remove dirt that is causing jamming unscrew nut, Part 130, and remove the valve pin.

Clean and lubricate with a light, non-reinous oil before assembly. Tighten side rods, Part 10,

evenly to avoid binding.

2. Back Head (Handle Part)

The rubber seals must be in order to avoid water penetration inside the hammer. Defective

seals must be replaced by new ones, Parts 53 and 55.

Disassembly

Turn operating lever to position F and then pull off operating lever, Part 42, from valve, Part

33.

Eject throttle valve, Part 33, on air connection side.

If water emerges at the operating lever, Part 42, then O-ring 65 on valve pin, Part 66, must be

replaced.

Page11

PLB 291 ROCKDRILL

3. Control Lever

Disconnect the control lever from

The throttle valve by tapping the

Control lever, while it is in the

OFF position (C)

When reassembling the control lever

Into the housing,

Be careful not to jam it.

4. Distribution Systems: Standard & High performance

There is a standard and high performance

valve chest assembly. They are recognized

by a different diameter of the VALVE PLATE.

The high performance unit fitted to the SIG.au PLB-291K

and the SIG.au PLB-291DI models has a small outside

and a larger internal diameter valve plate.

NOTE: No separate parts

of the valve plate, valve guide

or valve chest, Parts 72,74 & 75

are interchangeable.

SIG.au PLB-29K & SIG.au PLB-29DI:

84mm Outside diameter

18mm Inside diameter

SIG.au PLB-291K & SIG.au PLB-291DI

70mm Outside diameter

20mm Inside diameter

Page12

PLB 291 ROCKDRILL

Disassembly –Distribution System

Loosen the 2 side nuts, Part 13

and separate the housing, Part 80

from the backhead, Part 70.

Press out the control section,

Parts 71, 72, 73, 74, 75 & 76,

And dismantle with the help of

Punch E as per drawing.

Check valve plate, Part 74, for indentations.

Max depth not to exceed 0.3mm.

5. Piston

Check guide and spiral flute for wear.

Maximum flute width 12mm if worn,

Substitute the piston.

Check the piston large diameter for

Wear.

Replacement is recommended when piston

Diameter is less than 89.85mm.

Check the percussion face for wear.

maximum depth of upset pocket 1.5mm.

The piston may be refaced by grinding.

CAUTION If replacing the piston,

Grind the UPLIFTED EDGE ONLY

DO NOT GRIND THE POCKETED SURFACE

6. Cylinder Washer Bush (Sealing Bush) Part 83

SIG.au PLB-29DI & SIG.au PLB-291DI Models only –

Replace Mounting Bracket Bush,

Item 04, when excessively worn.

NOTE:

Toavoid Bush slippage in the bore, do not

Apply oil or grease when replacing.

Page13

PLB 291 ROCKDRILL

Check inner diameter for wear.

Maximum inner diameter 38.2mm

If worn, push out sealing bush

using a 41.5mm diameter header,

(made on site), and a vice.

With the help of an old percussion

piston press in a new sealing bush.

CAUTION

The inner diameter of the sealing

bush must fit over the outer diameter

of the piston collar.

7. Rotating Mechanisms

Detent pawls, Part 96

Check the edges of the detent

pawls for wear.

Maximum radius of wear 1.5mm

If one edge is worn, reverse the

pawls. If both edges are worn, replace.

Detent pawl springs, Part 95

Check the detent pawl springs at

regular intervals.

Fatigued or defective springs

cause unsuitable rod rotation.

Substitute defective springs.

Pawl plunger, Part 94

Maximum acceptable wear of

Plunger keys 1.5mm.

If possible, replace the pawl plunger.

Ratchet Ring, Part 90

Page14

PLB 291 ROCKDRILL

Maximum wear on edge: Minimum twistspline width: 1mm

Radius 1.5mm after this limit, replace ratchet ring.

After this limit, replace

ratchet ring.

Chuck Nut, Part 91

Wear on splines:

min. spline width 1mm

If less than 1mm,

Replace guide bush.

CAUTION!

Left-Handed thread

Page15

PLB 291 ROCKDRILL

8. Chuck insert (drill socket), Part 93

At regular periods, check the

inner hexagon for face wear.

To do so, use the wear gauge.

Broken pistons and/or drill rods may be

The consequence of worn out drill sockets.

To Test:

1. Find the point of greatest wear ‘X’

2. Using a hexagonal gauge insert it at

This point

3. If the gauge goes in, right to the stop,

Change the chuck insert.

Page16

PLB 291 ROCKDRILL

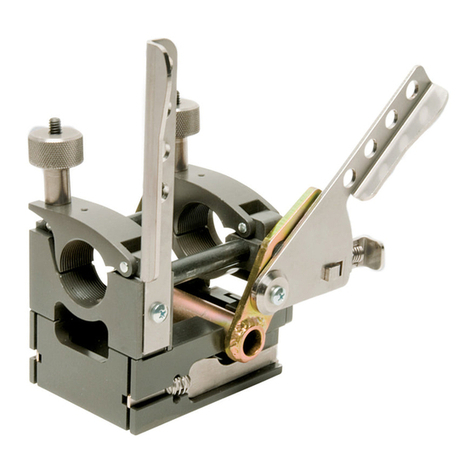

9. Cylinder Liner Replacement

In order to maintain good air compression, it is important to check the cylinder liner bore

for wear, cracks, corroded and pitted surface. If replacement is required proceed as follows:

•Use safety glasses and leather gloves to avoid injury. Place the housing vertically on

the top of the open bench vice or lock the housing hard on the side of the vice on the

pivoting eye section.

•As the grub screw, which locates cylinder liner, is secured with “Loctite”, it is not

required to extract it from the housing when the cylinder liner requires replacement.

•Ensure that cylinder liner can be gently knocked out from the housing.

•Rapidly apply heat externally all over the alloy section for several minutes by moving

the oxygen torch tip approximately 50mm away from the housing. Heat all over

quickly so as to create thermal expansion on the housing. DO NOT APPLY ANY HEAT

TO THE CYLINDER LINER BOAR!

CAUTION!

Apply only 100 –125 degree heat to the housing. Do not apply excessive heat as this will

cause the alloy to lose its heat treated properties. This can be checked either by quick hand

touch or by applying a drop of water on the alloy housing. Knock out the cylinder liner with

a hammer and drift.

Inspect the surface and quickly clean if required. Re-lock the housing eye now in a vertical

position. Align the locating groove on the cylinder liner with the grub screw end which

protrudes in the bore, quickly slide the housing in the position and push the liner fully to the

spigot end.

*NOTE* This procedure should be completed quickly in order to ensure that the heat from

the housing will not transfer to the liner and cause it to jam before it is located fully in the

position. Allow to cool in air before assembling the drill. Ensure that there are no burrs or

sharp points inside the cylinder bore in order to avoid irreparable damage on the piston.

Page17

PLB 291 ROCKDRILL

Replacement of chuck insert

NOTE: Where possible, use a hydraulic press when changing the chuck insert.

CAUTION! If the chuck insert and chuck nut have to be changed at the same time, it is

preferable to change the chuck nut first, as the old chuck insert forms a better support

than the new one.

1. Position the chuck, Part 92,

in dismantling sleeve C.

2. Tap out the old chuck insert, part 93,

using dismantling drive D.

3. Tap new chuck insert gently and

Perpendicularly into position

NOTE: The radius at the collar

must point outwards

4. Use a press to force the chuck insert

Up to the stop using a cut off drill steel

as a driver.

NOTE: To avoid risk of chuck

insert slippage in the chuck bore,

do not apply oil or grease when

replacing.

Page18

PLB 291 ROCKDRILL

SIG.au PLB 29 Rockdrill Parts List

ITEM

QTY

DESCRIPTION

PART NUMBER

1

1

Mounting Bracket Bolt

64 000 111

2

1

Mounting Bracket Assembly (Inc 1 & 5)

For 3600rotation of airleg assembly

64 000 103

4

1

Bush

64 000 140

5

1

Nut

64 000 120

10

2

Side Rod Bolt

64 262 380

12

2

Spring Washer

64 255 460

13

2

Side Rod Nut

64 255 451

20

1

Water Hose

Inc. 21, 22, 23, 24, 25 & 26

64 258 401

21

1

Cylinder Liner

64 263 340

23

1

Gooseneck swivel –water

64 255 120

24

1

Connection Nipple –water

64 255 110

25

1

Rubber Ring

64 255 130

26

1

Strainer

64 259 730

30

1

Connection Nipple –air

64 258 060

31

1

Gooseneck Swivel –air

64 262 210

32

1

O’ring

64 996 170

33

1

Throttle Valve

64 262 030

34

1

O’ring

64 996 330

40

1

Hexagonal Nut

64 992 070

41

1

Spring Washer

64 994 270

42

1

Operating Lever

64 258 041

43

1

Laid in Spring Key

64 257 040

44

1

Latch or Index Pin

64 256 291

45

1

Pressure Spring for Latch Pin

64 256 300

50

1

Plug

64 258 080

51

1

O’ring

64 979 300

52

1

Copper Gasket Seal

64 258 090

53

1

Rubber Seal

64 255 170

54

1

Water Tube

64 248 082

55

1

Gasket Seal

64 262 410

56

1

Flush Water Tube Sleeve

64 262 401

60

1

Dirt Restrictor

64 263 231

61

4

Rubber Seal

64 262 200

62

1

Water Valve Screw Includes Part 63

64 262 060

63

1

O’ring

64 996 240

64

1

Water Valve Ball

64 259 080

65

1

O’ring

64 996 500

66

1

Water Valve Pin Includes Part 65

64 259 102

70

1

Backhead

64 262 020

71

1

O’ring

64 996 290

Page19

PLB 291 ROCKDRILL

72

1

Valve Chest

64 263 260

73

1

Cylindrical Pin

64 258 130

74

1

Valve Plate

64 244 320

75

1

Valve Guide

64 263 270

76

1

Damper Ring

64 914 091

80

1

Housing, Silenced

64 263 173

82

1

Piston

64 262 364

83

1

Cylinder Washer Bush

64 262 350

84

1

Cylinder Washer

64 262 120

90

1

Ratchet Ring Complete

64 262 332

9001

1

Rifle Nut/Ratchet Bush

64 262 333

9002

1

Ratchet Ring

64 262 340

91

1

Chuck Nut

64 262 320

92

1

Chuck

64 262 280

93

1

Chuck Insert 7/8’’ x 108mm

64 262 300

94

4

Pawl Plunger

64 258 352

95

4

Pawl Spring –Stainless

64 258 344

96

4

Pawl

64 257 111

97

1

Front Head

64 262 270

100

1

Steel Retainer 7/8’’ x 108mm

64 261 100

101

2

Heavy Type Dowel Pin

64 995 770

102

1

Steel Retaining Bolt

64 261 090

103

1

Rubber Mounting

64 262 220

110

1

D-Handle Complete

64 000 162

111

2

Nuts for Connection Stud

64 000 030

112

1

Connection Stud of D-Handle assembly

64 000 020

113

1

Left Hand Side of D-Handle assembly

64 000 210

114

1

Hand Grip of D-Handle assembly

64 000 240

115

1

Right Hand Side of D-Handle assembly

64 000 220

OPTIONS

93

1

Chuck Insert 1’’ x 108mm

64 262 310

100

1

Steel Retainer 1’’ x 108mm

64 261 130

Page20

PLB 291 ROCKDRILL

This manual suits for next models

3

Table of contents

Other SIG Tools manuals