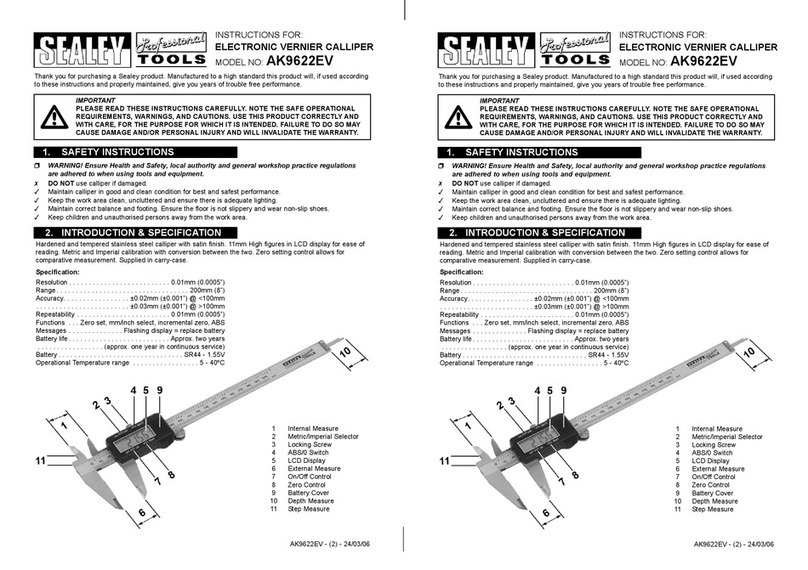

3.1. Air Supply

3.1.1. Ensure that the tool air valve is in the "Off" position before connecting to the air supply.

3.1.2. p WARNING! Ensure the air supply is clean and does not exceed 90 psi (6.2 bar) while

operating the tool. Too high an air pressure and/or unclean air will shorten the life of the tool

due to excessive wear and may be dangerous causing damage and/or personal injury.

3.1.3. Drain the compressor air tank daily. Water in the air line will damage the tool.

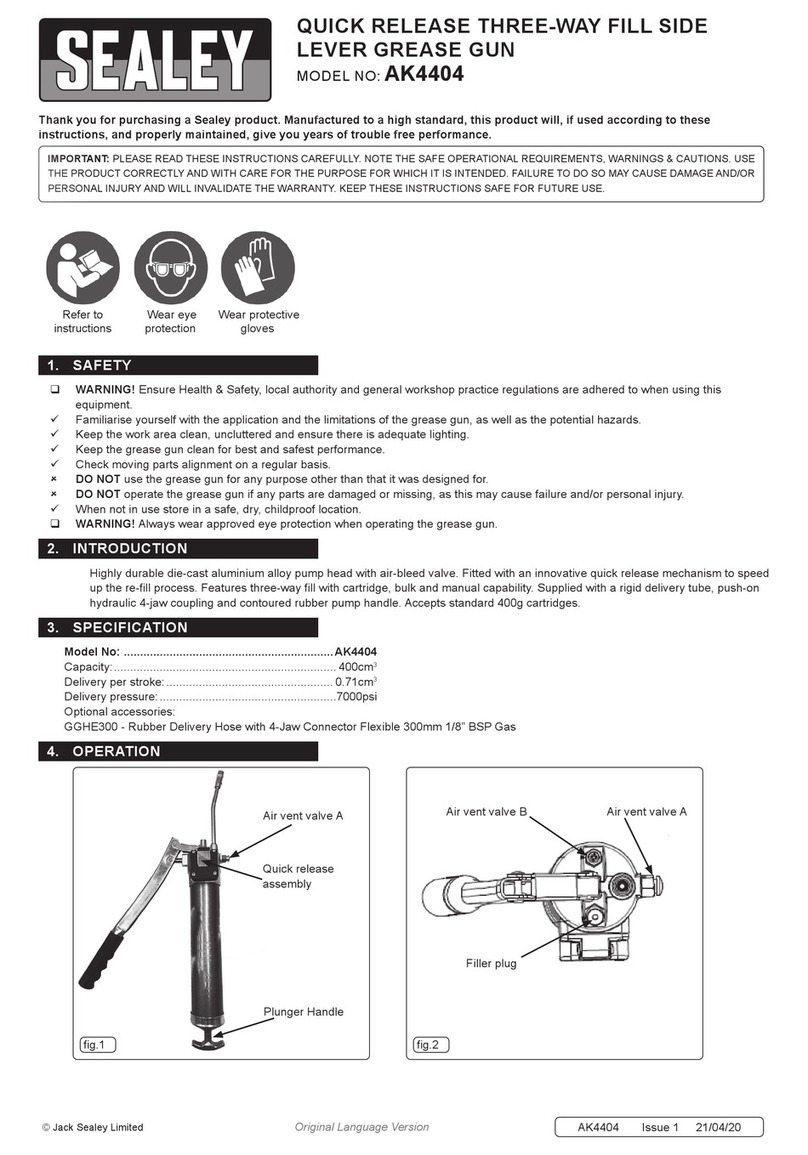

3.1.4. Clean the compressor air inlet filter weekly. Recommended hook-up is shown in fig. 1.

3.1.5. Line pressure should be increased to compensate for unusually long air hoses (over 8 metres).

The minimum hose bore should be 3/8 and fittings must have the same inside dimensions.

3.1.6. Keep the hose away from heat, oil and sharp edges. Check hose for wear, and make certain

that all connections are secure.

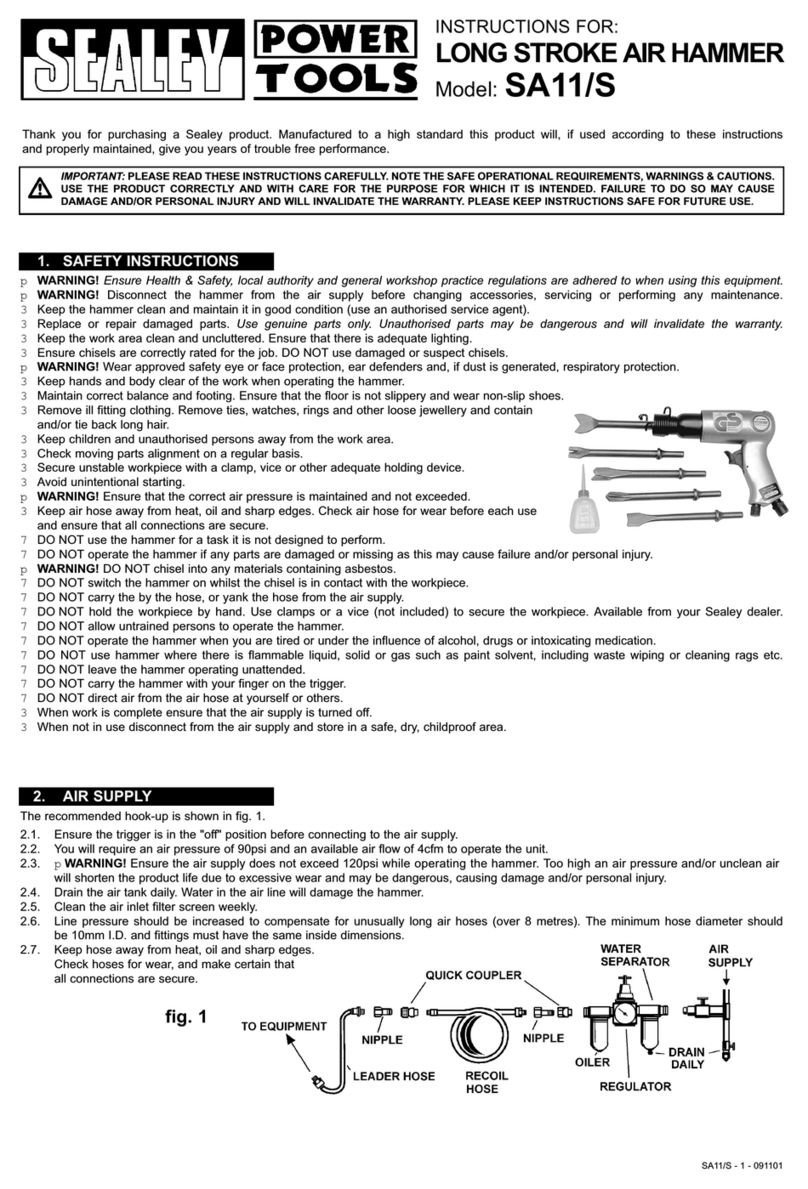

3.2. Couplings

Vibration may cause failure if a quick change coupling is connected directly to the tool.

To overcome this, connect a leader hose to the tool. A quick change coupling may then be

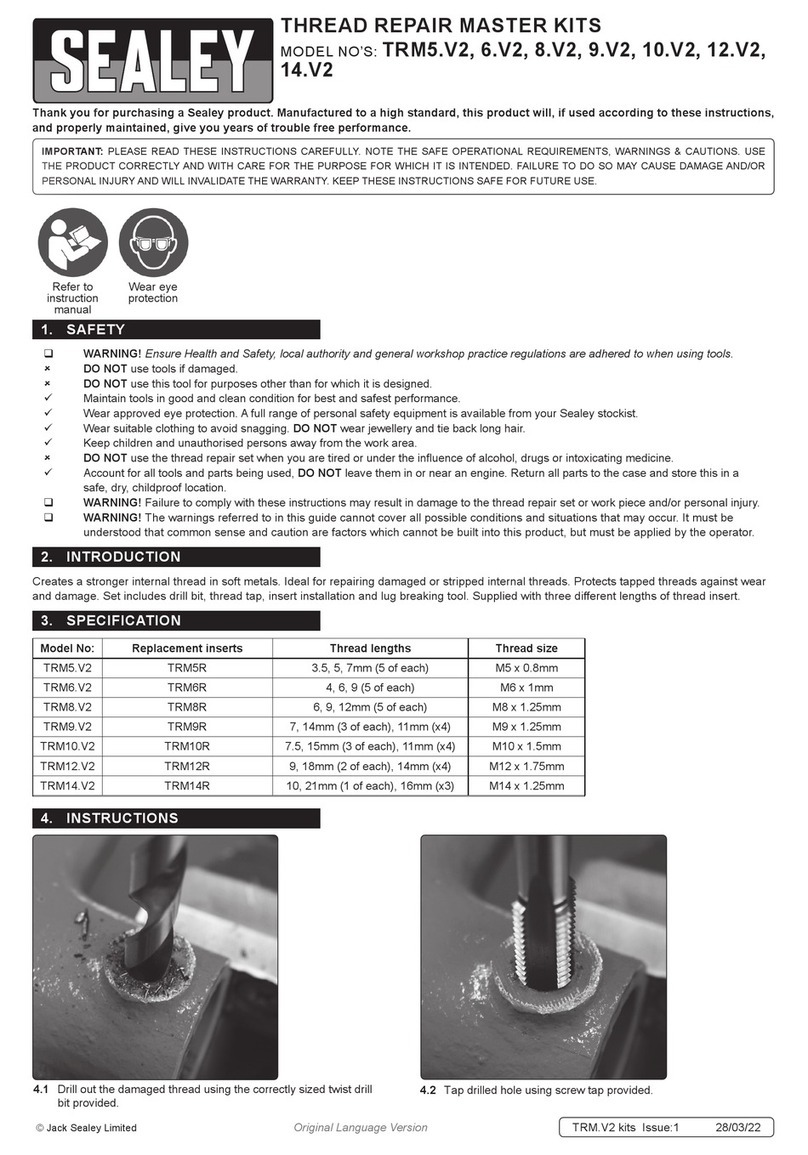

used to connect the leader hose to the air line recoil hose. See figs. 1 & 2.

3. PREPARING FOR USE 5. MAINTENANCE

6. DECLARATION OF CONFORMITY

pWARNING! Ensure that you read, understand and apply the safety instructions.

4.1. Connect the tool to the air supply.

4.2. To start the tool, hold firmly and squeeze the throttle lever. The clamp will move down,

punching a hole/forming a flange, as required.

4.3. Release the lever and the clamp will rise allowing the tool to be positioned for the next operation.

4.4. After use, disconnect the tool from the air supply, clean and store in a safe, dry, childproof location.

4. OPERATION

fig. 1

fig. 2

Declaration of Conformity We, the sole importer into the UK, declare that the product listed here is in conformity

with the following standards and directives. The construction file for this product is held by the Manufacturer and may be

inspected, by a national authority, upon request to Jack Sealey Ltd.

For Jack Sealey Ltd. Sole importer into the UK

of Sealey

Power Tools.

Air Punch/Flange Tool Model: SA36.V2

98/37/EC Machinery Directive

93/68/EEC Marking Directive

27th August 2002

Signed by Mark Sweetman

SA36.V2 - 1 -290802

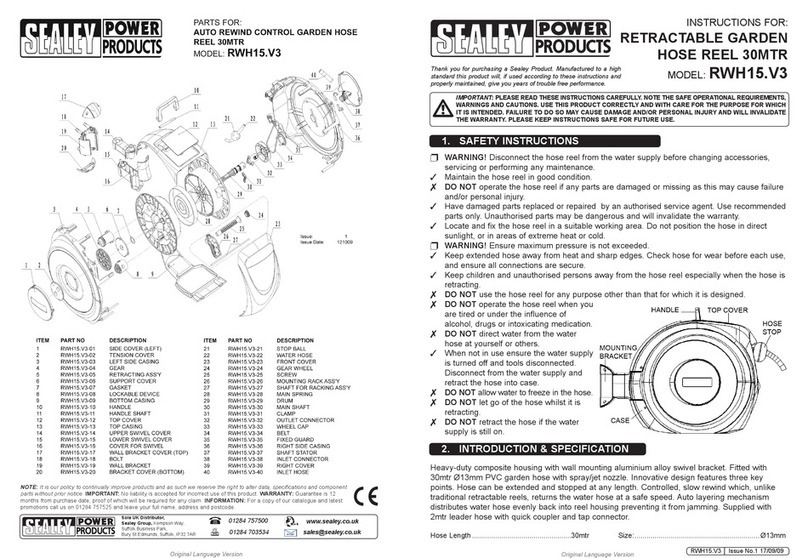

Note: Numbers/letters in brackets refer to those on the parts diagram.

pWARNING! Disconnect the tool from the air supply before changing accessories, servicing or

performing maintenance. Replace or repair damaged parts. Use genuine parts only.

Unauthorised parts may be dangerous and will invalidate the warranty.

5.1. If the compressed air system does not have an integral oiler then lubricate the tool daily with

a few drops of Sealey air tool oil dripped into the air inlet.

5.2. Regularly check oil, and top-up if necessary, via the oil plug (13). Use Sealey Hydraulic Jack

Oil, Part No. HJO/500ML, HJO/5L or HJO/25L.

5.3. Clean the tool after use.

5.4. Loss of power or erratic action may be due to the following:

a) Excessive drain on the air line. Moisture or restriction in the air pipe. Incorrect size or type of

hose connectors. To remedy, check the air supply and follow instructions in Section 3.

b) Grit or gum deposits in the tool may also reduce performance. If your model has an air

strainer (located in the area of the air inlet), remove the strainer and clean it. Flush out

the tool with gum solvent oil or an equal mixture of SAE 10 oil and paraffin. Allow to

dry before use.

5.5. For a full service contact your local Sealey service agent.

5.6. To remove and replace the punch (6) and/or die (3) proceed as follows:

1) Remove screws (7) and slide off cover plate (8).

2) Slacken set screw (2) and strike rear edge of clamp(1) with a soft-headed hammer in

order to unscrew it from the shaft of the hydraulic piston (31). If necessary the shaft may

be locked by removing the oil plug (13) and inserting a suitable rod into a hole in the shaft.

3) Fully unscrew the clamp (1) and anvil (9) assembly from the shaft.

4) Separate the anvil (9) and the clamp (1) to replace the

punch (6) and/or die. The die (3) is a push fit in

the clamp (1) and can be tapped out via the

waste bore (A). Push/tap in the replacement.

5) Reassemble the anvil (9), clamp (1) and the

replacement punch (6) and screw onto

the shaft. Tap with a soft-headed

hammer to ensure tightness and

lock with the set screw (2).

6) Refit the cover plate (8)

and retain with

screws (7).