4.2. Assemblingthetrolley(refertog.1).

4.2.1. Attach the wheels (F) and castors (G) to the platform (A) using the nuts and bolts

provided.

4.2.2. Slide the support bracket (C) then the securing hook (D) onto the handle (B).

Attach the handle (B) to the platform (A) and secure with the grub screw (E).

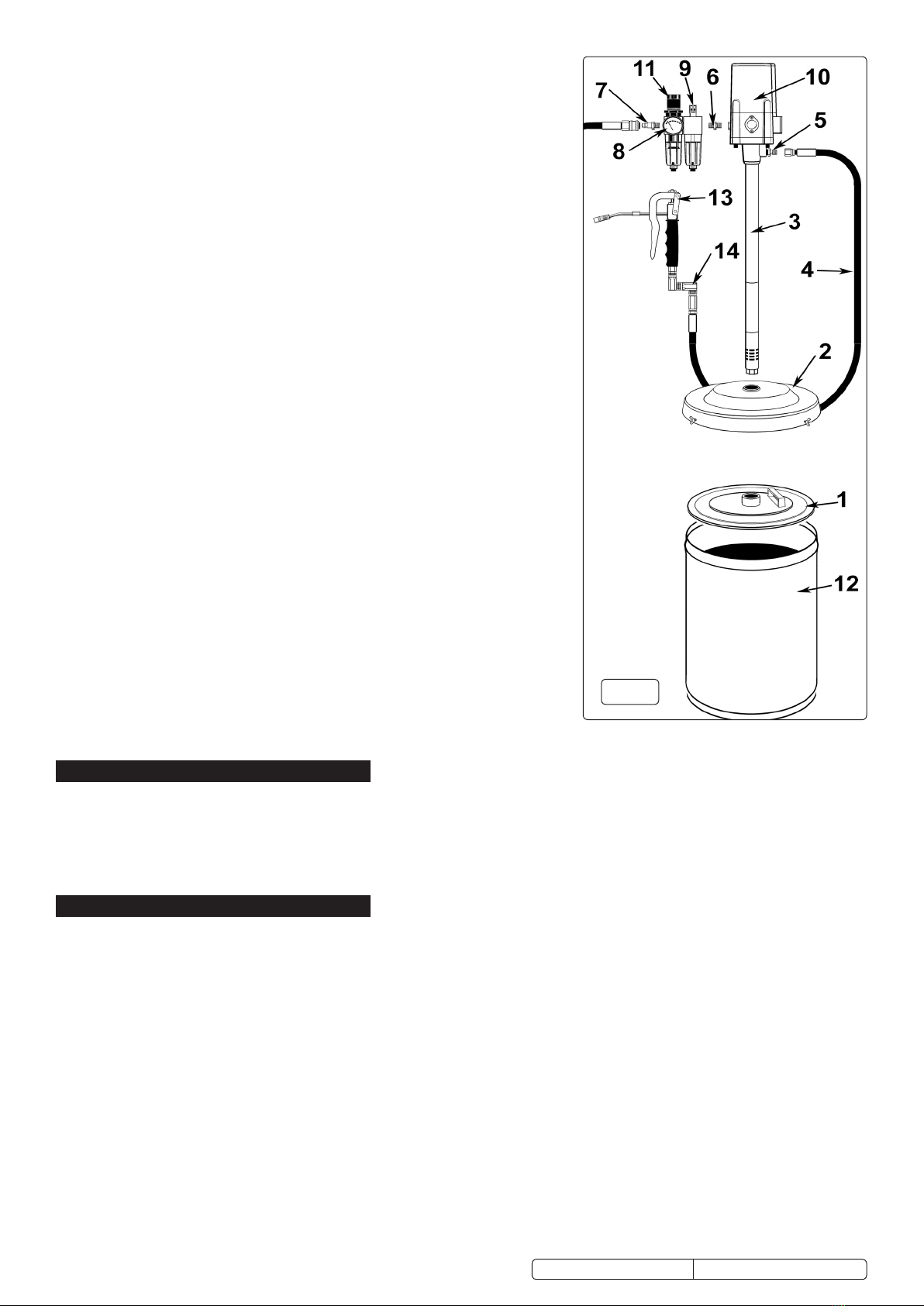

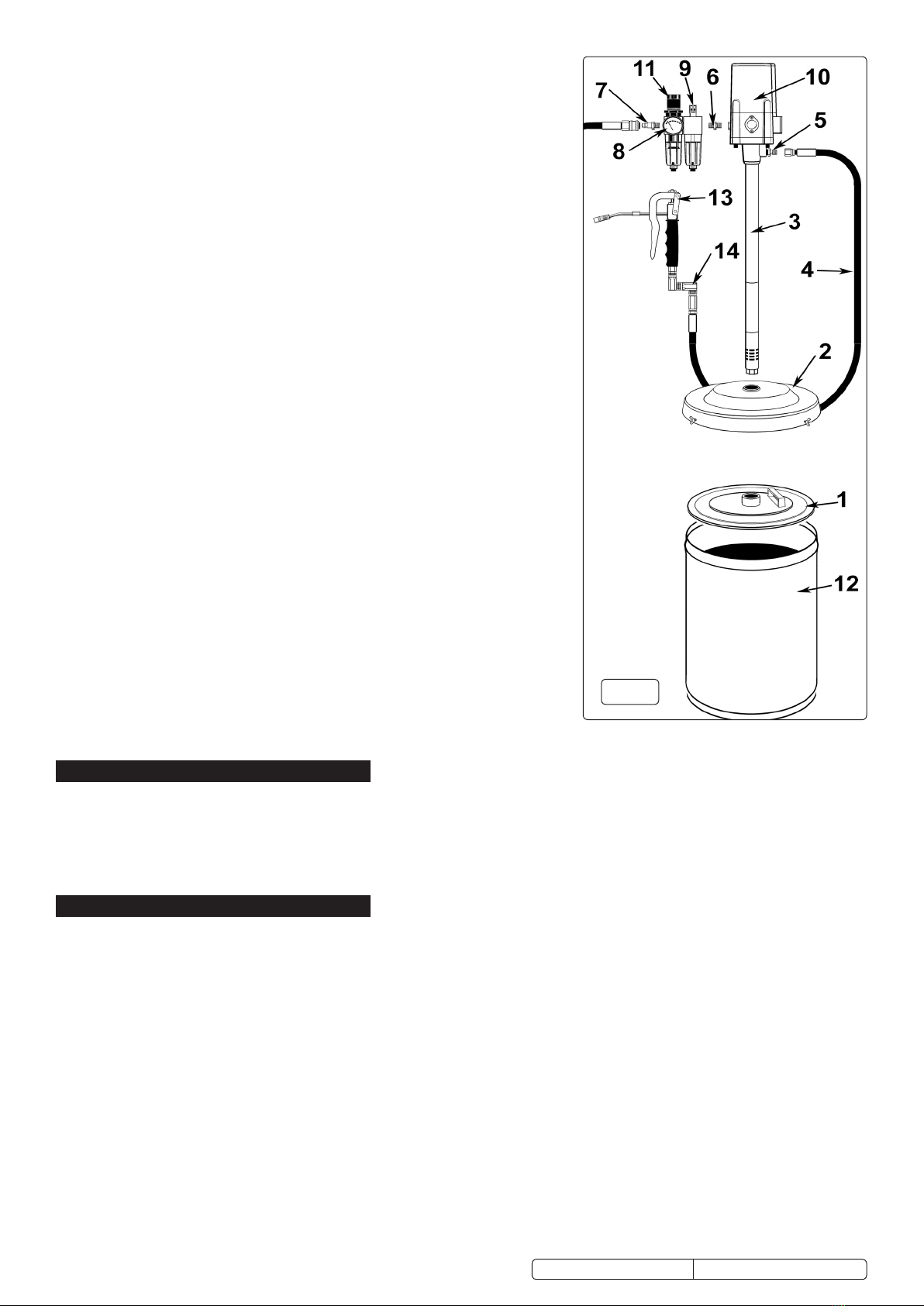

4.3. Assemblingthepumpunit(refertofig.2).

WARNING! Clean new delivery lines ensuring all metal shavings have been

removed before connecting the pump and control valves. Any dirt in the inlet hoses

will damage the unit and may invalidate your warranty.

NOTE: It is recommended that PTFE sealing tape is used on all connections.

4.3.1. Place the grease bucket (12) onto the platform of the trolley.

4.3.2. Remove the original lid supplied with the grease bucket and store it for future use.

4.3.3. Insert the follower plate (1) into the top of the grease bucket (12) with the handle

uppermost and settle it down onto the surface of the grease. The follower plate

is drawn down by the suction of the air pump and compresses the grease during

operation to prevent air pockets.

4.3.4. Secure the grease bucket to the trolley by sliding the securing hook over the rim of

the grease bucket and locking with the hand screw.

4.3.5. Place the dust cover (2) onto the grease bucket (12), but do not secure.

4.3.6. Lower the pump assembly through the support bracket on the trolley.

4.3.7. Align the pump shaft (3) over the dust cover (2) and allow the shaft to pass through

the dust cover (2), and the follower plate (1) then sink down to the bottom of the

grease bucket (12).

4.3.8. Align the position of the trolley support bracket so that the pump shaft is vertical

and perpendicular to the trolley base and the support bracket is set to the correct

position.

4.3.9. Tighten the trolley support bracket hand screws and tighten the three butterfly

screws to secure the dust cover (2) to the grease bucket (12).

4.3.10. Connect the air regulator (11) and air oiler (9) together using the long bolts and

Nuts provided (The nuts slide into the recesses in the front and back of the

regulator body). Ensure that the air flow arrows moulded into the top of each unit

body are pointing in the same direction and that both arrows are pointing towards

the pump air inlet. The air oiler (9) should be situated between the air regulator (11)

and the pump (10).

4.3.11. Screw the circular pressure gauge (8) into which ever side of the regulator (11)

is most convenient for reading. Seal the unused mounting position using the

blanking plug provided.

4.3.12. Connect the regulator (11) assembly to the pump air inlet using the 1/4”BSP fitting

(6) provided.

4.3.13. Connect the Z-swivel (14) to the grease gun (13) and connect the grease hose (4)

to the Z-swivel (14). Connect the other end of the grease hose (4) to the grease

outlet (5) on the pump.

5. OPERATION

5.1. Turn the air pressure on and check there are no leaks in the system.

5.2. Adjust the air pressure using the air knob on top of the air regulator. Unlock the knob by pulling it upwards and turning it until the gauge

indicates the recommended operating pressure of 115psi. Push the knob down again to lock it. It is important to maintain the correct

operating pressure to ensure that the control valves and connectors are not damaged, and to prevent leakage in the delivery lines.

5.3. Prime unit by operating grease control valve until lubricant emerges from end of the gun. The unit is now ready for use.

5.4. When not in use, turn the air supply off and disconnect the unit from the air supply. Store in a safe, clean, dry, childproof location.

6. MAINTENANCE

WARNING! Disconnect the pump from the air line before attempting any service or maintenance. Replace or repair damaged parts.

Use genuine parts only. Non-authorised parts may be dangerous and will invalidate the warranty.

6.1. Air line lubricator. This unit is designed to automatically lubricate the pump through the air intake. The unit must be kept topped up

withgoodqualityairoil(Sealeyref:ATO/500500mlsizeorAT/10001ltrsize).Toadjusttheoilowturntheoilregulatorscrewon

thetopoftheunit.Turnanti-clockwisetoincreasetheowandclockwisetodecreasetheow.Theoilsuppliedtolubricatethepump

is minimal. For an initial setting turn adjusting screw on top of the unit fully home and then open by ¼ of a turn. To change and clean

theoilunitunscrewthebowlandretainthesealingring.Empty,clean,re-lltomaximumlineandreplaceensuringthesealingringis

ttedcorrectly.DO NOT overtighten the bowl. Contact your local Sealey service agent for parts and information.

6.2. Cleaning. Clean pump and air units with clean damp cloth. Mild detergents may be used to remove grease. DO NOT use solvents or

abrasives and DO NOT get the pump or air units wet.

6.3. For a full service, contact your local Sealey service agent.

WARNING! When exchanging a polycarbonate bowl ensure the suction tube is protected to avoid dirt particles being transmitted to a

new bowl. Always clean new delivery lines ensuring all metal shavings have been removed before connecting the pump and control

valves. Failure to do so may damage the unit and will invalidate your warranty.

Original Language Version

© Jack Sealey Limited

fig.2

AK452X.V4, AK453X.V3 Issue 3 (H, F) 06/07/18