INSTRUCTIONS FOR

SUBMERSIBLE DIRTY WATER PUMP

AUTOMATIC 133LTR/MIN 230V

MODEL NO: WPD133A

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these instructions,

and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAFETY

1.1. ELECTRICAL SAFETY

WARNING! It is the user’s responsibility to check the following:

Check all electrical equipment and appliances to ensure that they are safe before using. Inspect power supply leads, plugs and all

electrical connections for wear and damage. Sealey recommend that an RCD (Residual Current Device) is used with all electrical

products. You may obtain an RCD by contacting your local Sealey dealer.

If the product is used in the course of business duties, it must be maintained in a safe condition and routinely PAT (Portable Appliance

Test) tested.

Electrical safety information: it is important that the following information is read and understood.

1.1.1. Ensure that the insulation on all cables and on the appliance is safe before connecting it to the power supply.

1.1.2. Regularly inspect power supply cables and plugs for wear or damage and check all connections to ensure that they are secure.

1.1.3. Important: Ensure that the voltage rating on the appliance suits the power supply to be used and that the plug is tted with the correct

fuse - see fuse rating in these instructions.

8DO NOT pull or carry the appliance by the power cable.

8DO NOT pull the plug from the socket by the cable.

8DO NOT use worn or damaged cables, plugs or connectors. Ensure that any faulty item is repaired or

replaced immediately by a qualied electrician.

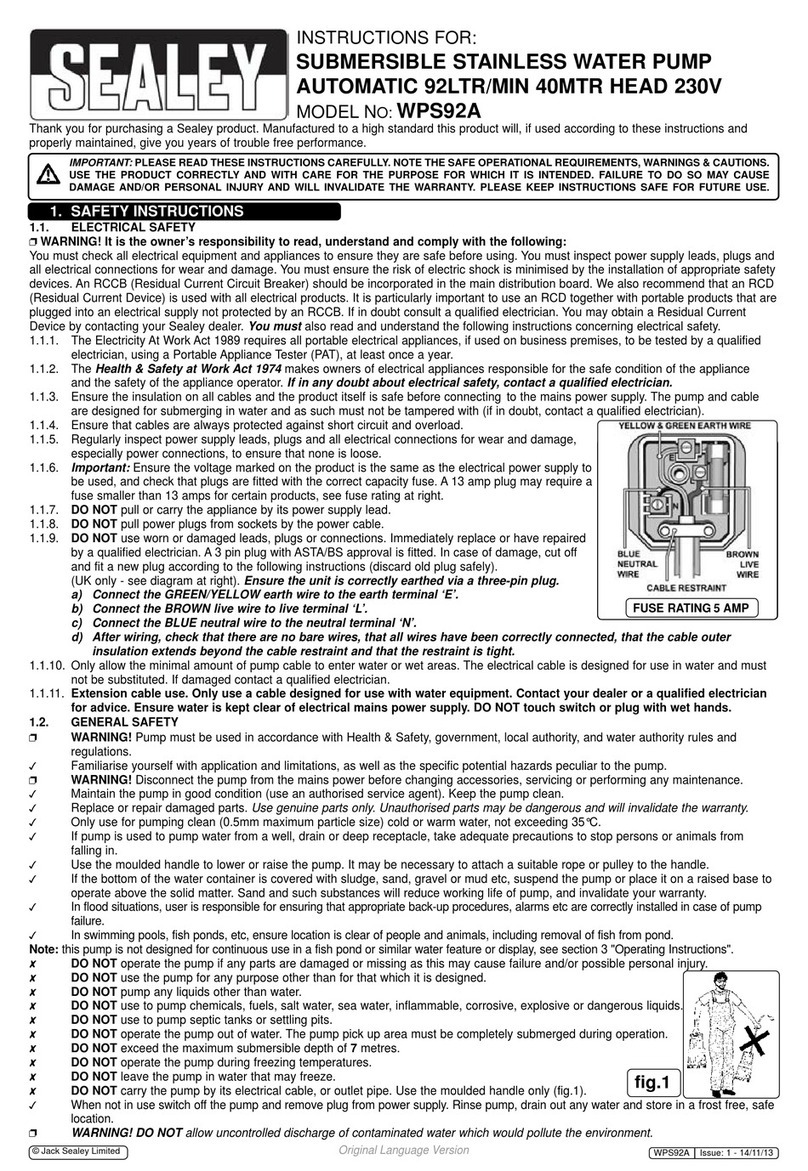

1.1.4. This product is tted with a BS1363/A 13 Amp 3 pin plug.

If the cable or plug is damaged during use, switch the electricity supply and remove from use.

Ensure that repairs are carried out by a qualied electrician.

Replace a damaged plug with a BS1363/A 13 Amp 3 pin plug. If in doubt contact a qualied electrician.

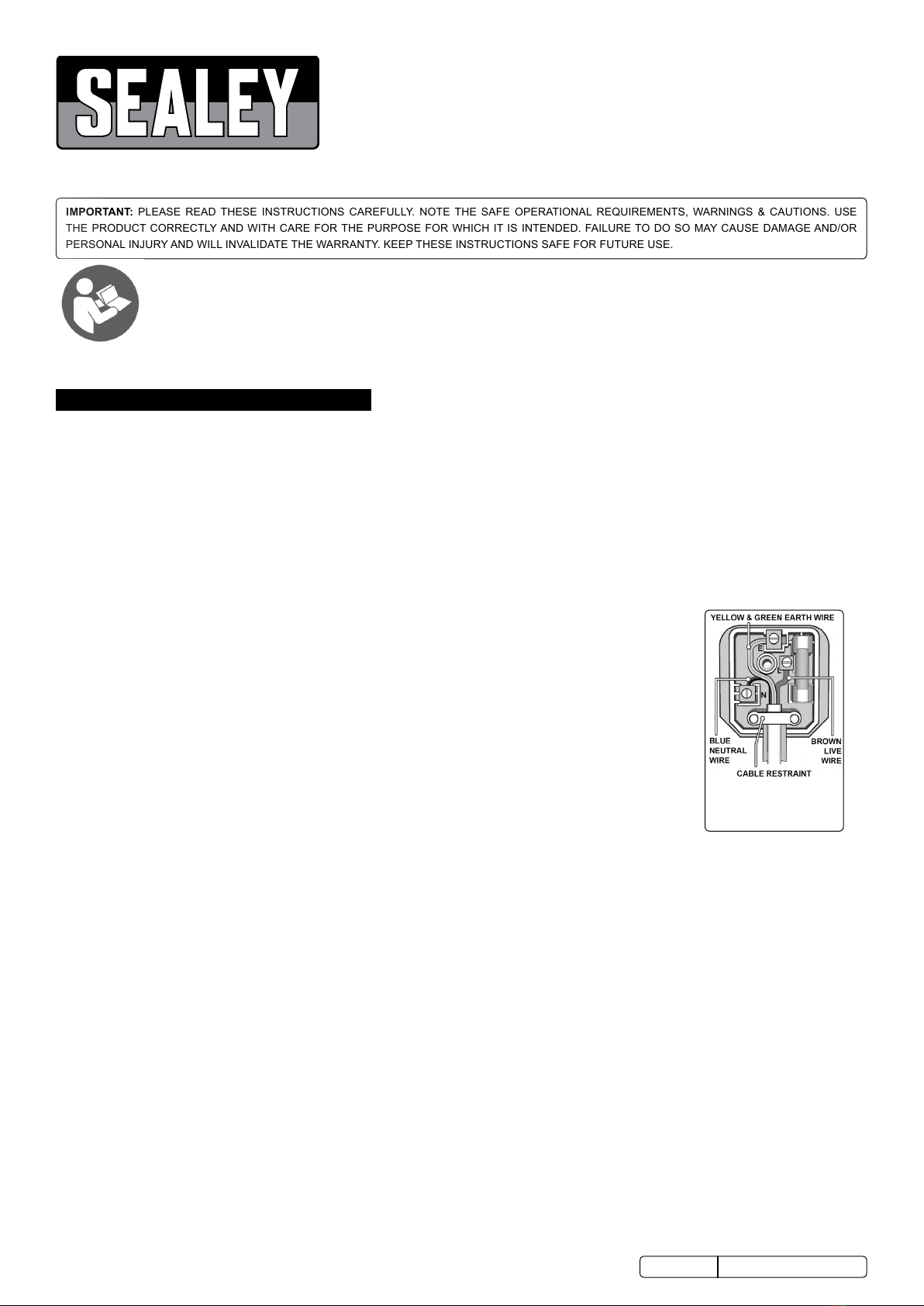

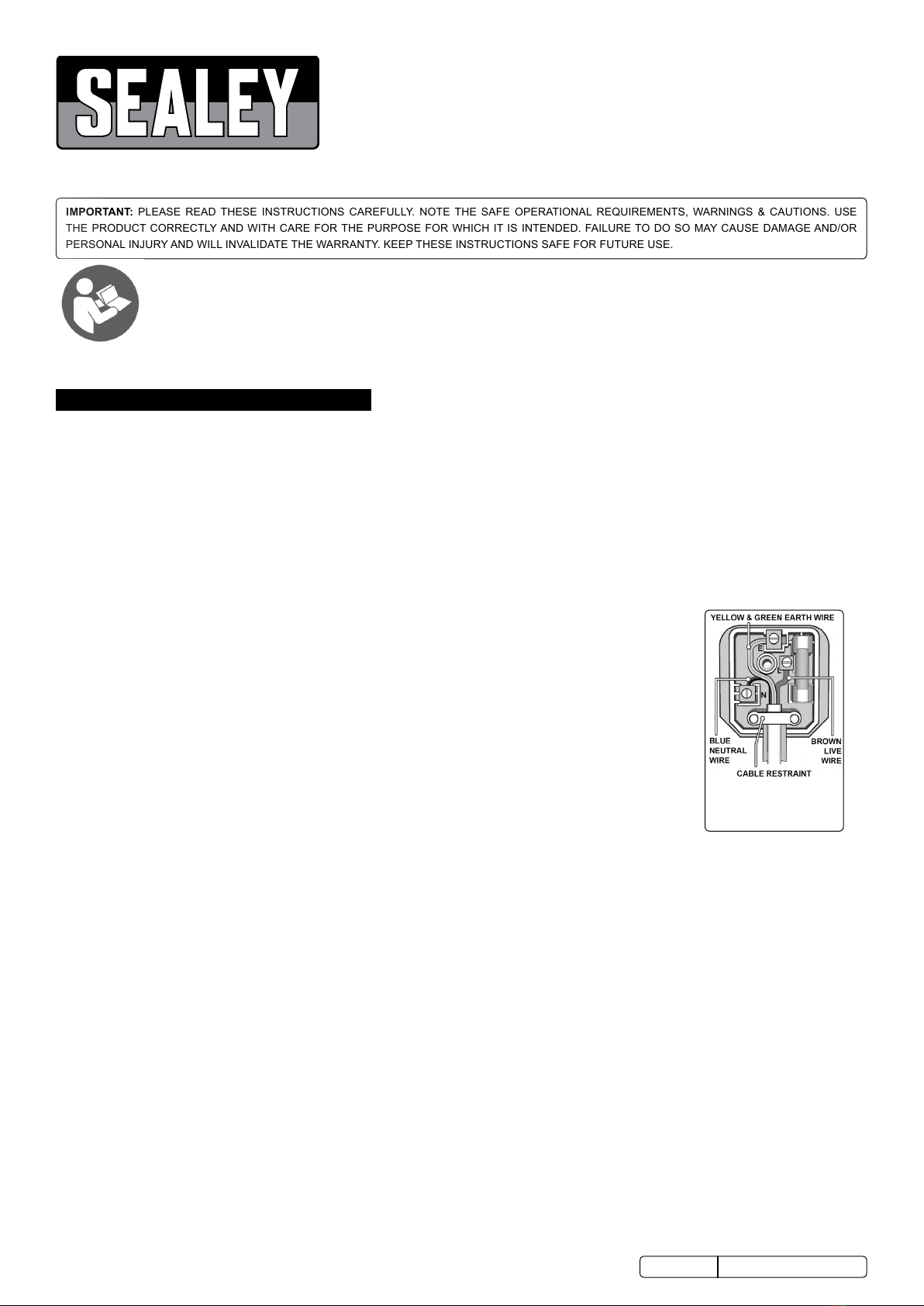

A) Connect the GREEN/YELLOW earth wire to the earth terminal ‘E’.

B) Connect the BROWN live wire to the live terminal ‘L’.

C) Connect the BLUE neutral wire to the neutral terminal ‘N’.

Ensure that the cable outer sheath extends inside the cable restraint and that the restraint is tight.

Sealey recommend that repairs are carried out by a qualied electrician.

1.1.5. Only allow the minimal amount of pump cable to enter water or wet areas. The electrical cable is designed

for use in water and must not be substituted. If damaged contact a qualified electrician.

1.1.6. Extension cable use. Only use a cable designed for use with water equipment. Contact your dealer or a qualified electrician

for advice. Ensure water is kept clear of electrical mains power supply. DO NOT touch switch or plug with wet hands.

1.1.7. Only allow the minimal amount of pump cable to enter water or wet areas. The electrical cable is designed for use in water and must

not be substituted. If damaged contact a qualified electrician.

1.1.8. Extension cable use. Only use a cable designed for use with water equipment. Contact your dealer or a qualified electrician

for advice. Ensure water is kept clear of electrical mains power supply. DO NOT touch switch or plug with wet hands.

1.2. GENERAL SAFETY

WARNING! Pump must be used in accordance with Health & Safety, government, local authority, and water authority rules and

regulations.

9Familiarise yourself with application and limitations, as well as the specific potential hazards peculiar to the pump.

WARNING! Disconnect the pump from the mains power before changing accessories, servicing or performing any maintenance.

9Maintain the pump in good condition (use an authorised service agent). Keep the pump clean.

9Replace or repair damaged parts. Use genuine parts only. Unauthorised parts may be dangerous and will invalidate the warranty.

9If pump is used to pump water from a well, drain or deep receptacle, take adequate precautions to stop persons or animals from

falling in.

9Use the moulded handle to lower or raise the pump. It may be necessary to attach a suitable rope or pulley to the handle.

9If the bottom of the water container is covered with sludge, sand, gravel or mud etc, suspend the pump or place it on a raised base to

operate above the solid matter. This is not essential but will increase the efficiency and longevity of the pump.

9In flood situations, the user is responsible for ensuring that appropriate back-up procedures, alarms etc are correctly installed in case of

pump failure.

9In swimming pools, fish ponds, etc, ensure location is clear of people and animals, including removal of fish from pond.

Note: this pump is not designed for continuous use in a fish pond or similar water feature or display, see section 4 “Operating

Instructions”.

8DO NOT operate the pump if any parts are damaged or missing as this may cause failure and/or possible personal injury.

Replacement fuse

rating: 5 AMP

WPD133A Issue 2 (H, F) 02/01/18

Original Language Version© Jack Sealey Limited

Refer to

instruction

manual