Table of Contents

CORRESPONDENCE....................................................................................................................................... 2

SealMaster® LIMITED WARRANTY............................................................................................................... 3

SAFETY PRECAUTIONS AND CAUTIONS ....................................................................................................... 4

PRECAUTIONS ........................................................................................................................................... 4

CAUTIONS ................................................................................................................................................. 4

OPERATING INSTRUCTIONS ......................................................................................................................... 5

STARTUP –HYDRAULIC AGITATION............................................................................................................. 5

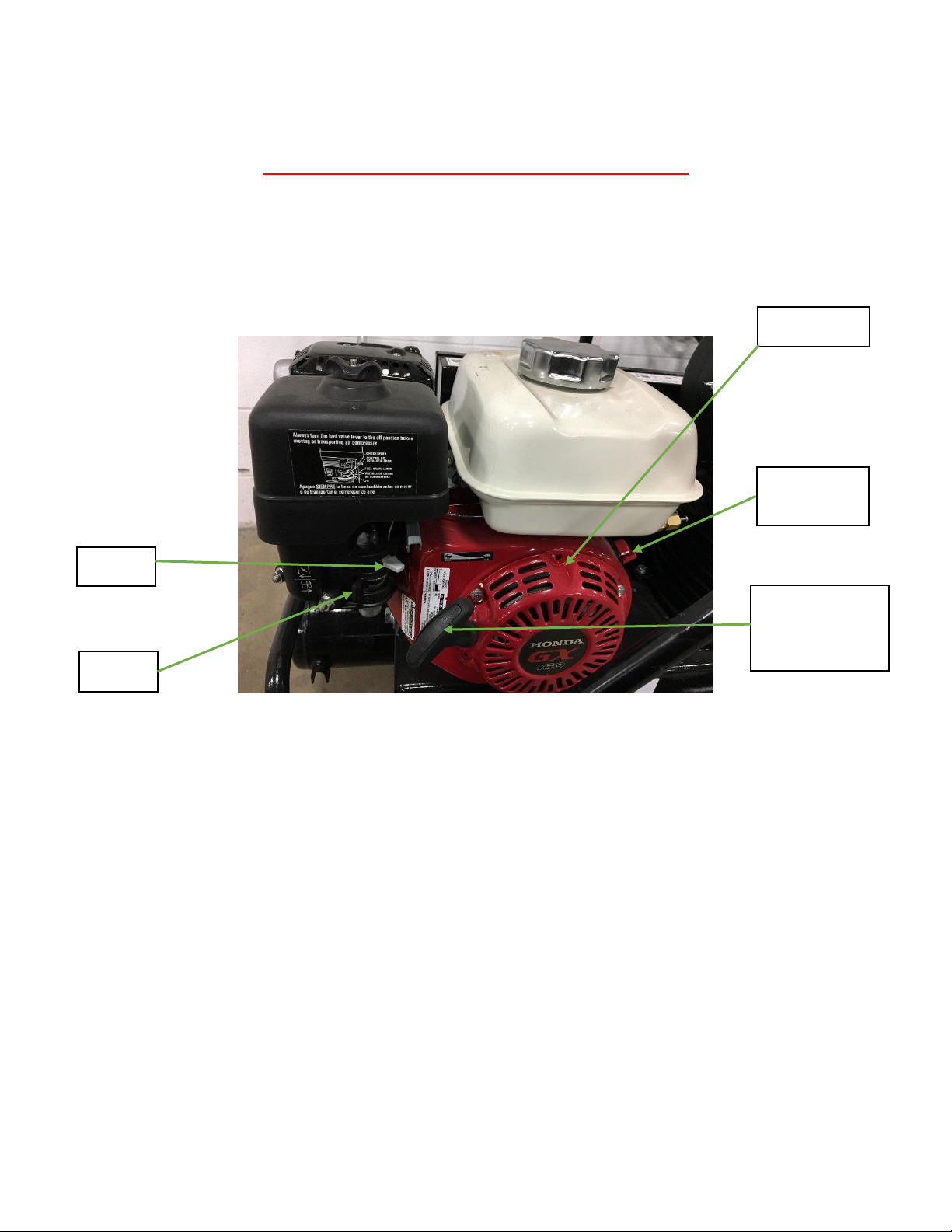

1-BEFORE STARTING THE ENGINE............................................................................................................. 5

STARTUP - COMPRESSOR............................................................................................................................. 6

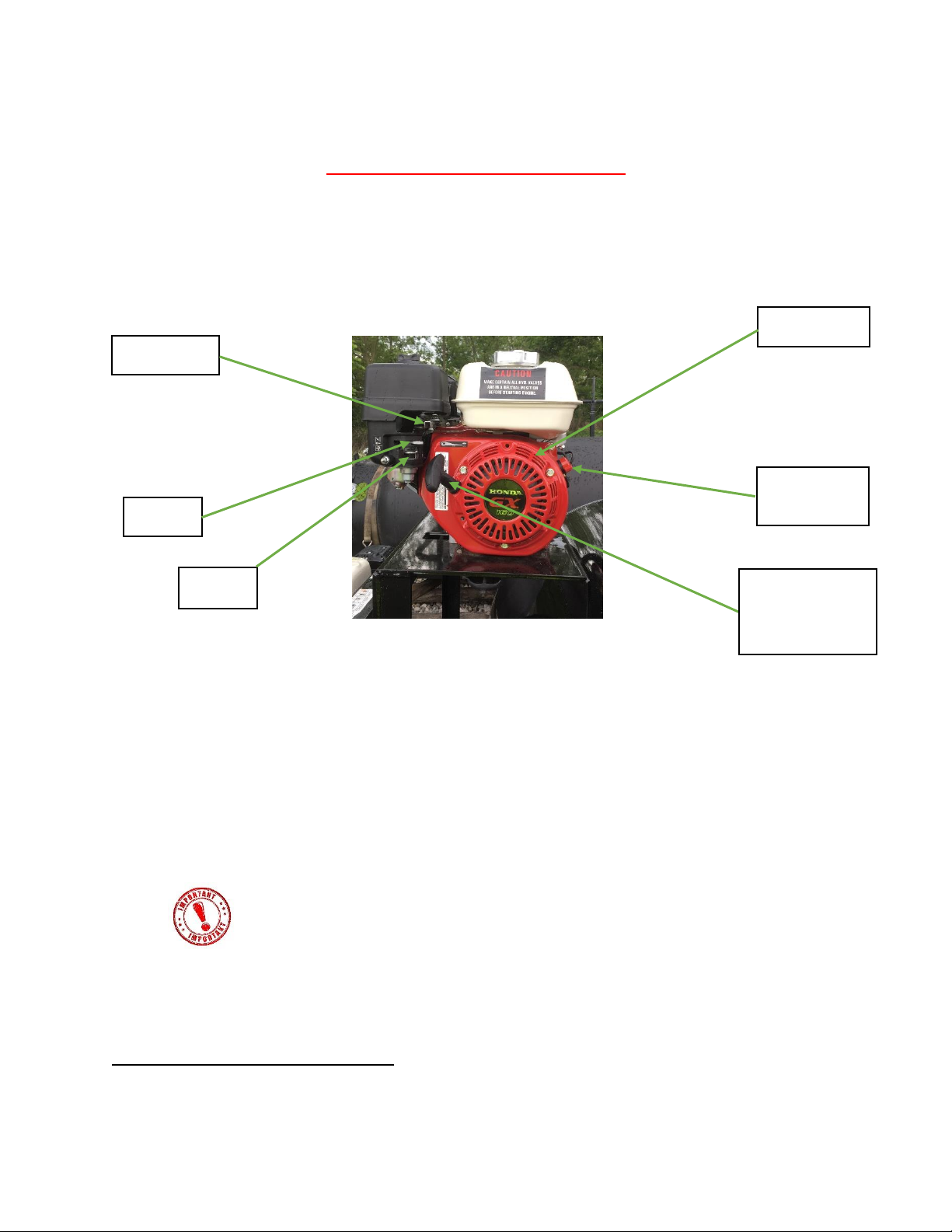

1-BEFORE STARTING THE ENGINE............................................................................................................. 6

2-STARTING THE ENGINE .......................................................................................................................... 7

3-START TO PUMP MATERIAL................................................................................................................... 9

4-START THE SPRAY WAND..................................................................................................................... 10

5-WATER FLUSH...................................................................................................................................... 12

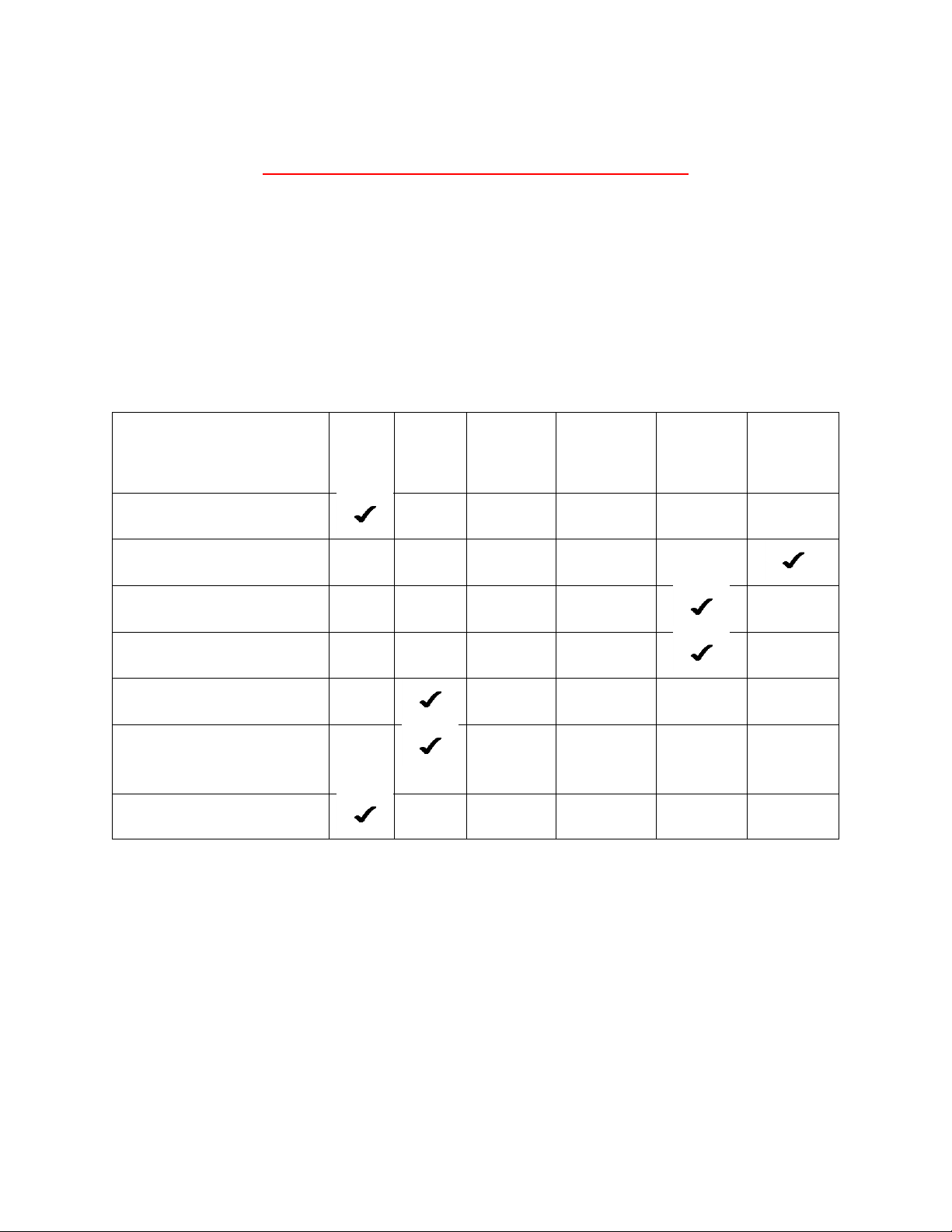

MAINTENANCE SCHEDULE .........................................................................................................................13

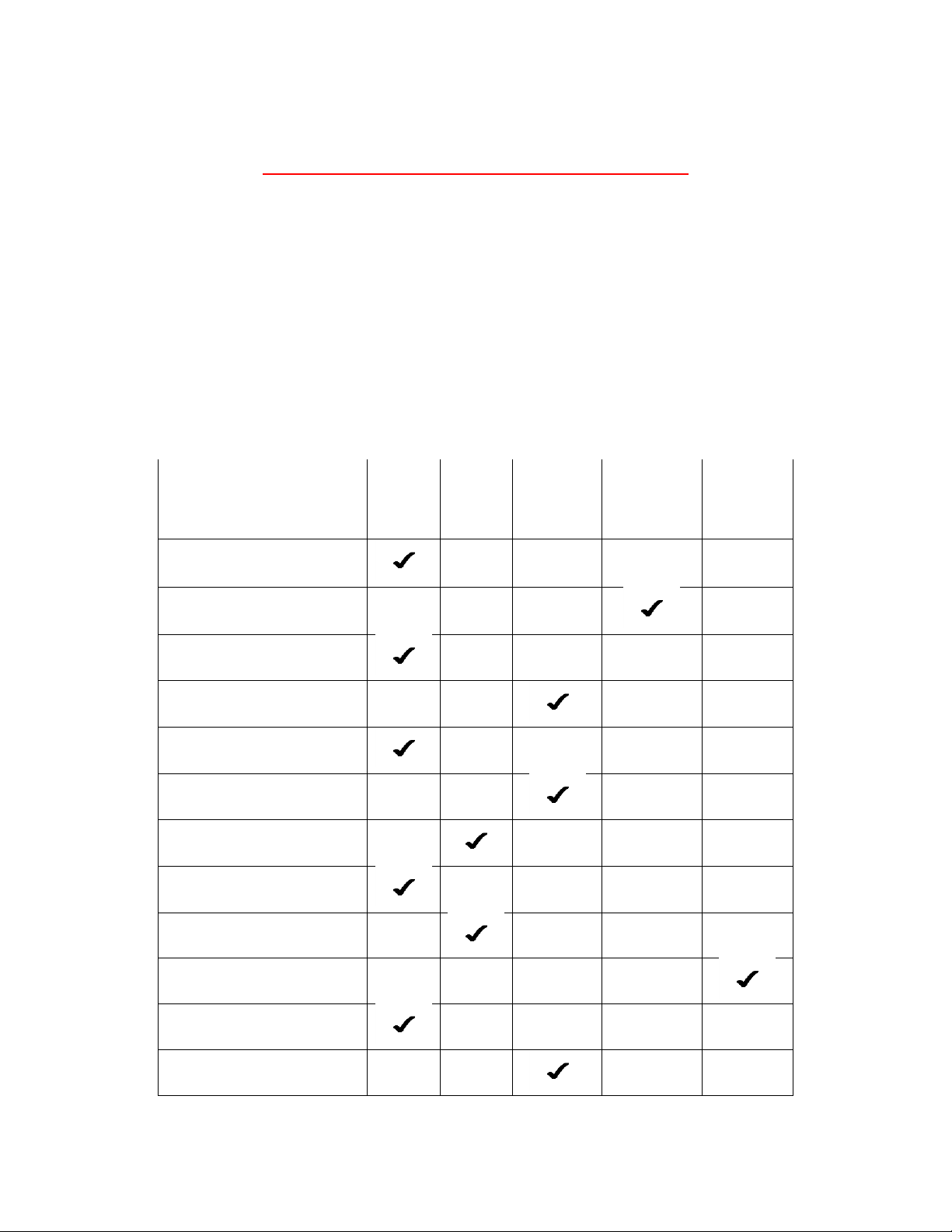

MAINTENANCE SCHEDULE...................................................................................................................... 13

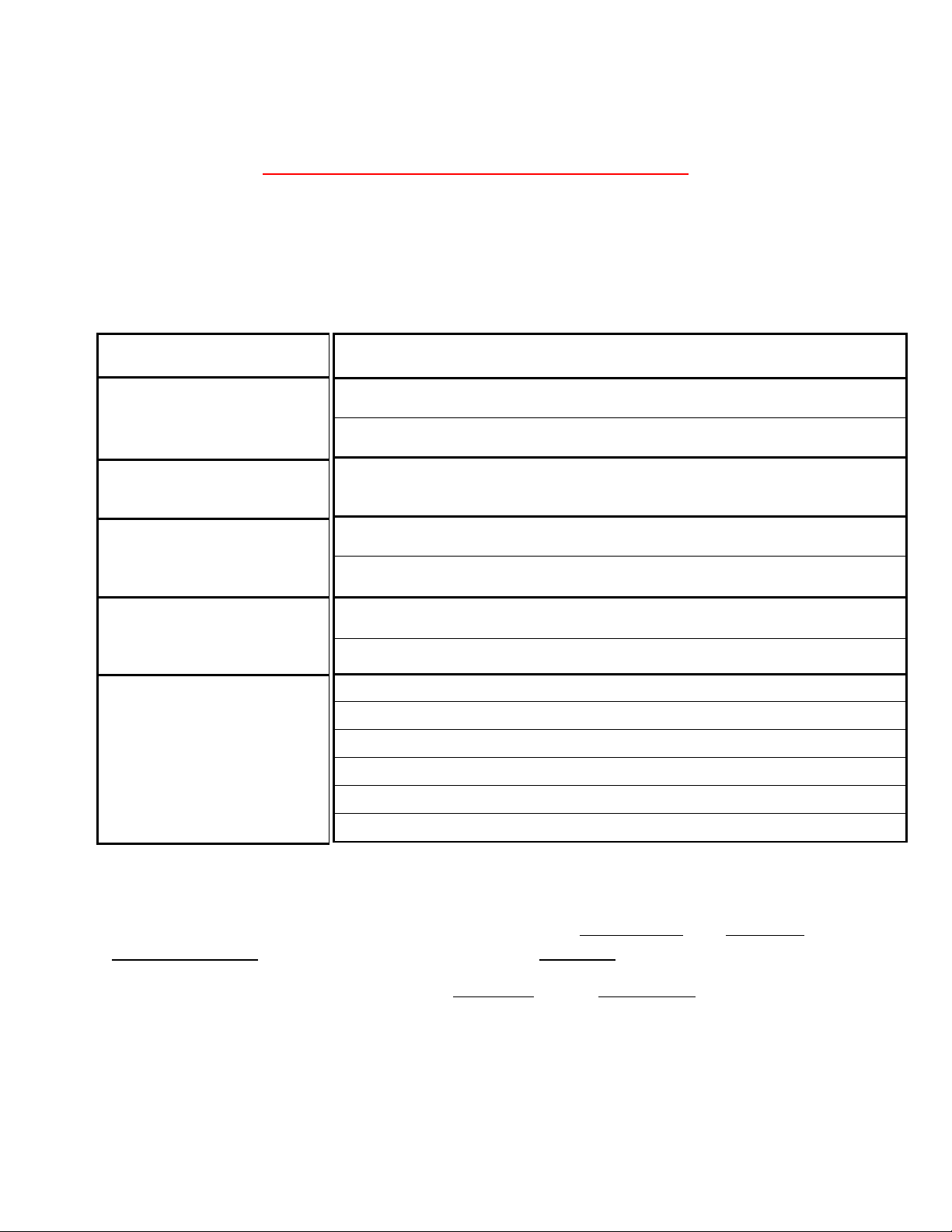

TROUBLE SHOOTING GUIDE ...................................................................................................................15

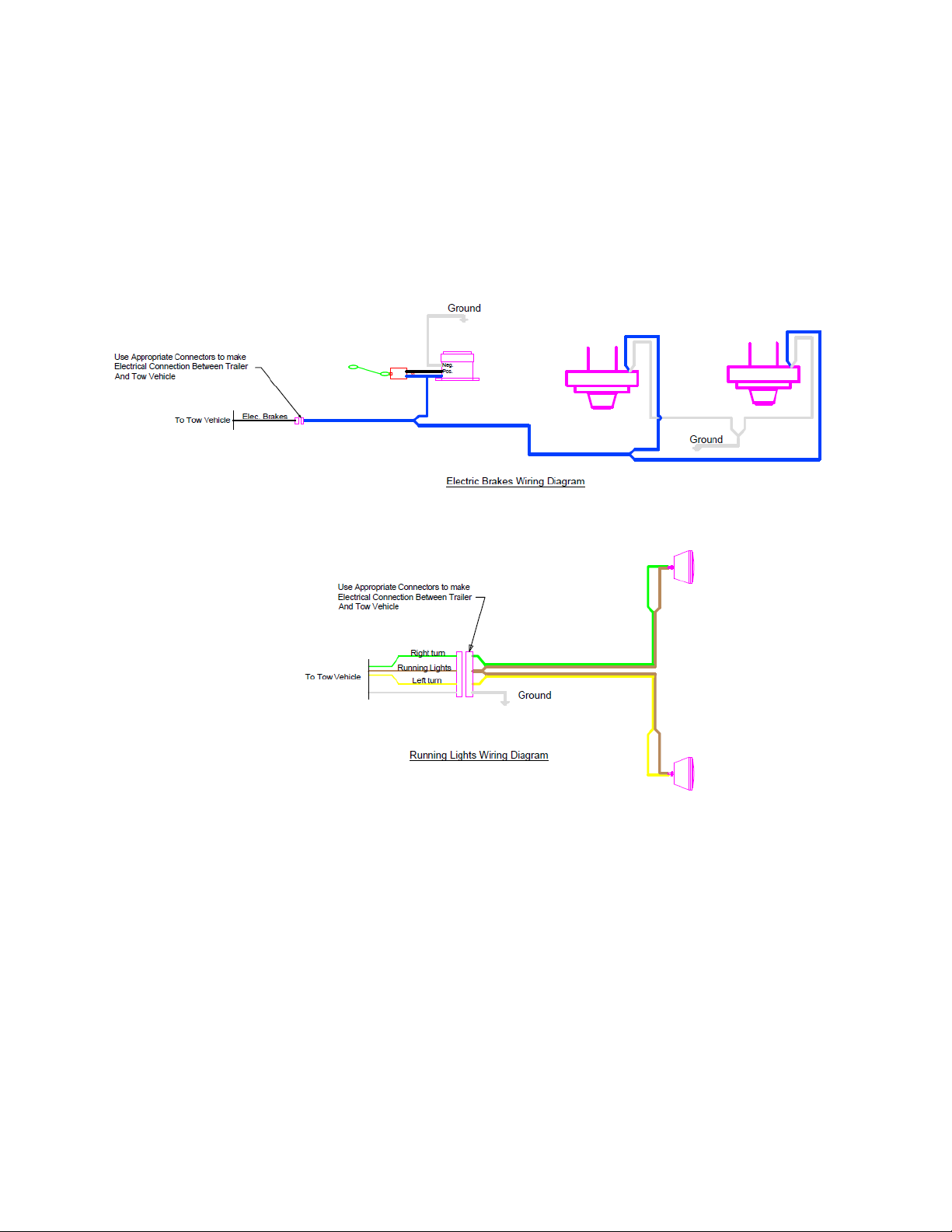

WIRING DIAGRAMS....................................................................................................................................17

ELECTRIC BRAKES AND RUNNING LIGHTS............................................................................................... 17

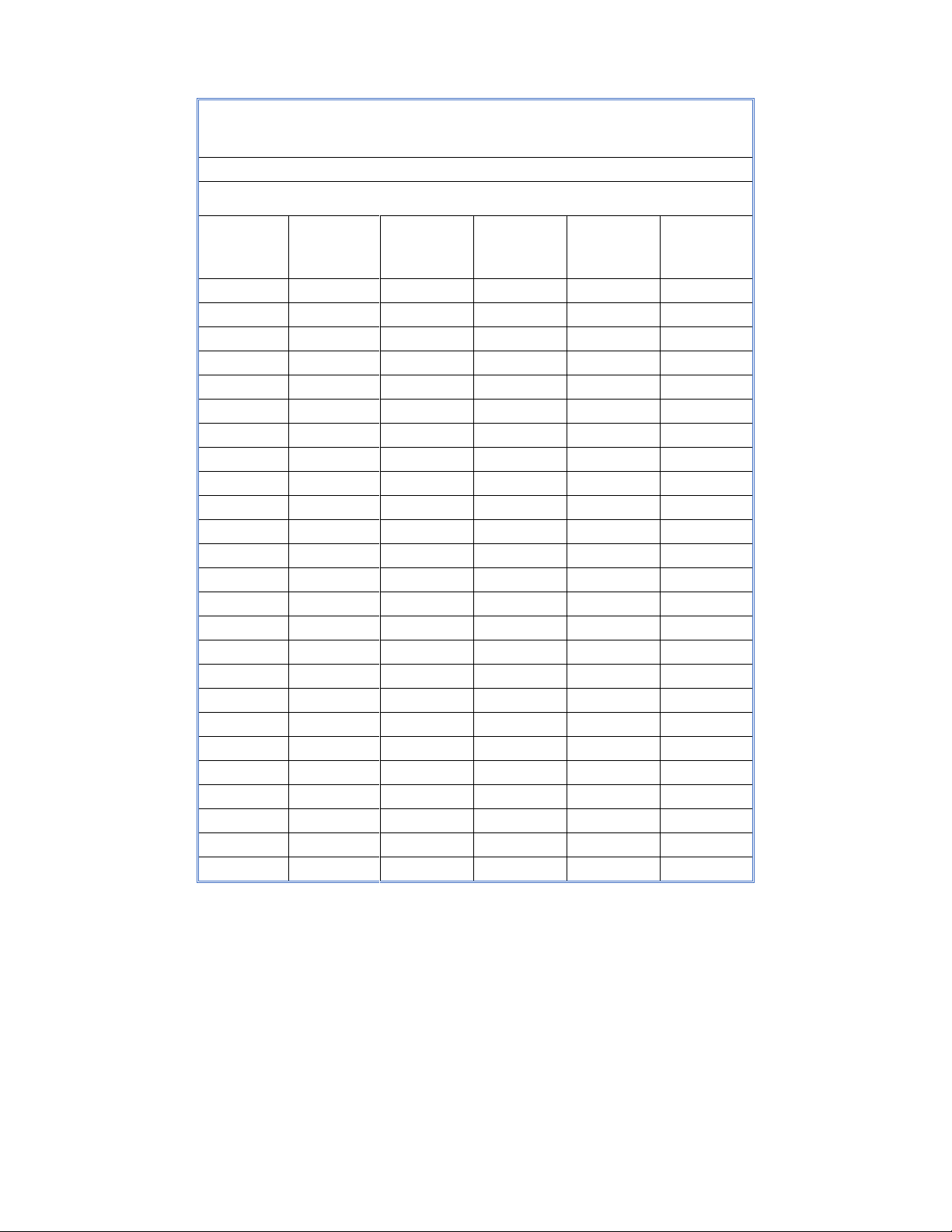

TANK CAPACITY CHART..............................................................................................................................18

MATERIAL DEPTH AND GALLON VOLUME.............................................................................................. 18

MACHINE PICTURES AND PARTS LIST........................................................................................................19

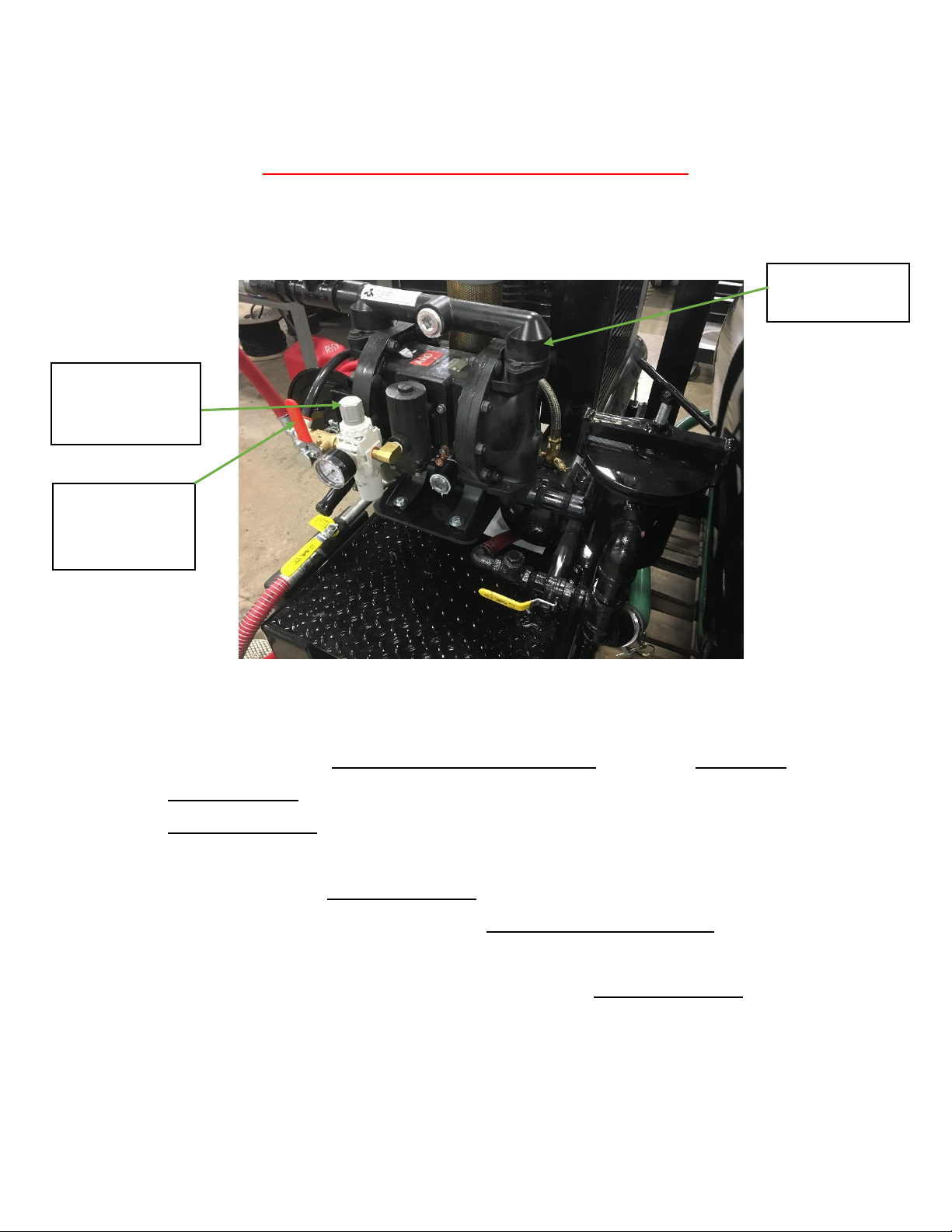

PARTS LIST PICTURE-1............................................................................................................................. 20

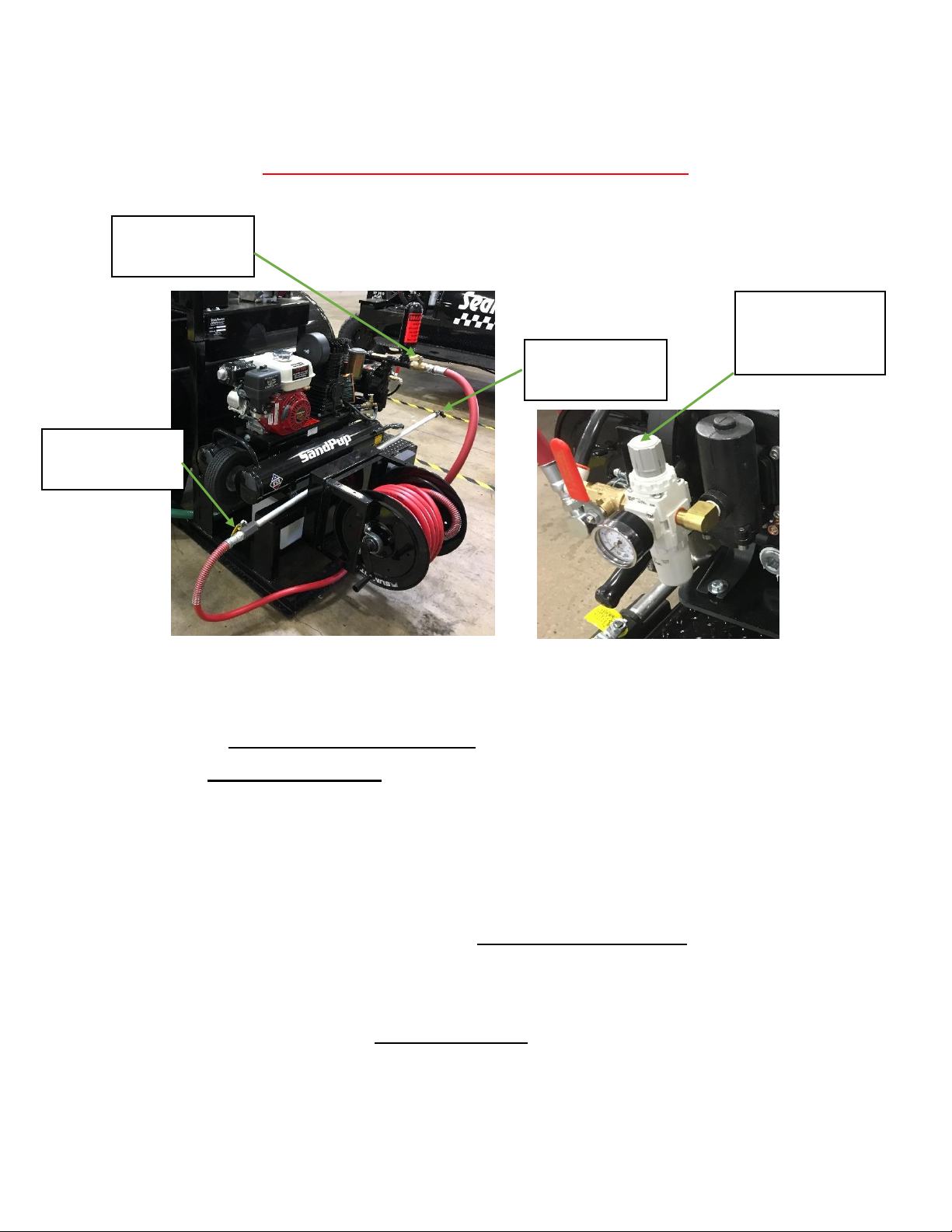

PARTS LIST PICTURE-2............................................................................................................................. 21

PARTS LIST PICTURE-3............................................................................................................................. 22

PARTS LIST PICTURE-4............................................................................................................................. 24

PARTS LIST PICTURE-5............................................................................................................................. 25

PARTS LIST PICTURE-6............................................................................................................................. 26

PARTS LIST FOR ARO 1” PUMP................................................................................................................27