SealMaster 300 User manual

S:\Engineering\13-Operator Manuals\Current\HEATED_ASPHALT_DIST_V2.8_NOV_2023.docx

HEATED ASPHALT DISTRIBUTOR

Owner’s Manual

Version 2.8

Issue Date: November 2023

Effective Date: January 2018

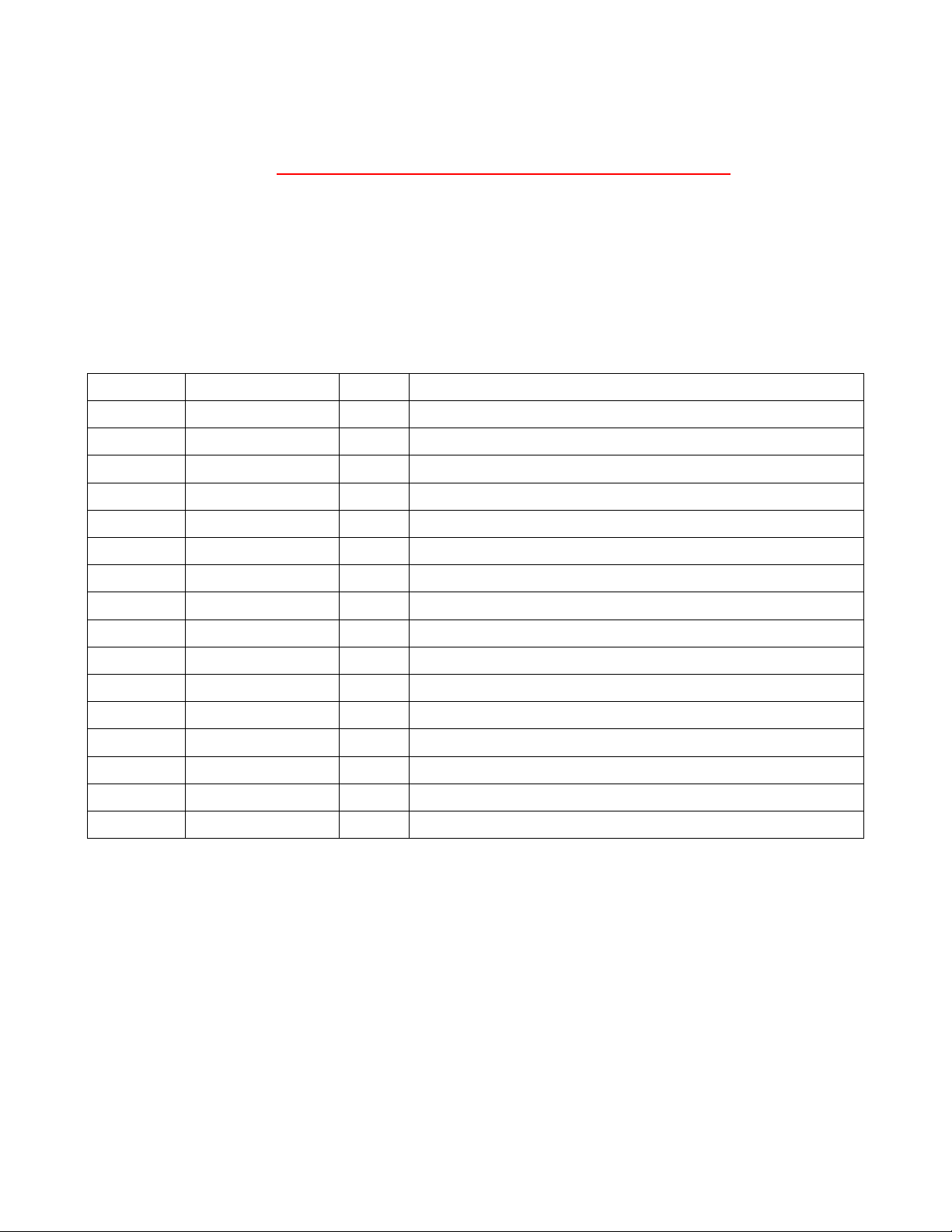

Version

Date

Changes

Approval

1.0

Original Issue

2.0

4/19

New Format and Updates

DS

2.1

6/19

Updated Wiring Diagrams

EK

2.2

10/20

Item 49 was P601A014

JG

2.3

10/21

Item 47 was P474A029

JG

2.4

1/22

Winterize Sheet Added

JG

2.5

4/22

Added Paint Page

JG

2.6

5/22

Breakaway Kit Change

JG

2.7

7/23

Item P932A001 Removed

JG

2.8

11/23

Picture / List Sequence

JG

Table of Contents

CORRESPONDENCE................................................................................................................ 3

SealMaster® LIMITED WARRANTY ......................................................................................... 4

SAFETY PRECAUTIONS AND CAUTIONS.................................................................................. 5

PRECAUTIONS......................................................................................................................... 5

CAUTIONS............................................................................................................................... 5

FIRST AID ................................................................................................................................ 6

STARTING THE ENGINE ........................................................................................................... 7

OPERATING INSTRUCTIONS ................................................................................................... 8

HEATING THE MATERIAL......................................................................................................... 8

PUMPING MATERIAL .............................................................................................................. 9

SPRAY BAR.............................................................................................................................. 9

DIESEL FLUSH........................................................................................................................ 10

MAINTENANCE TIPS.............................................................................................................. 10

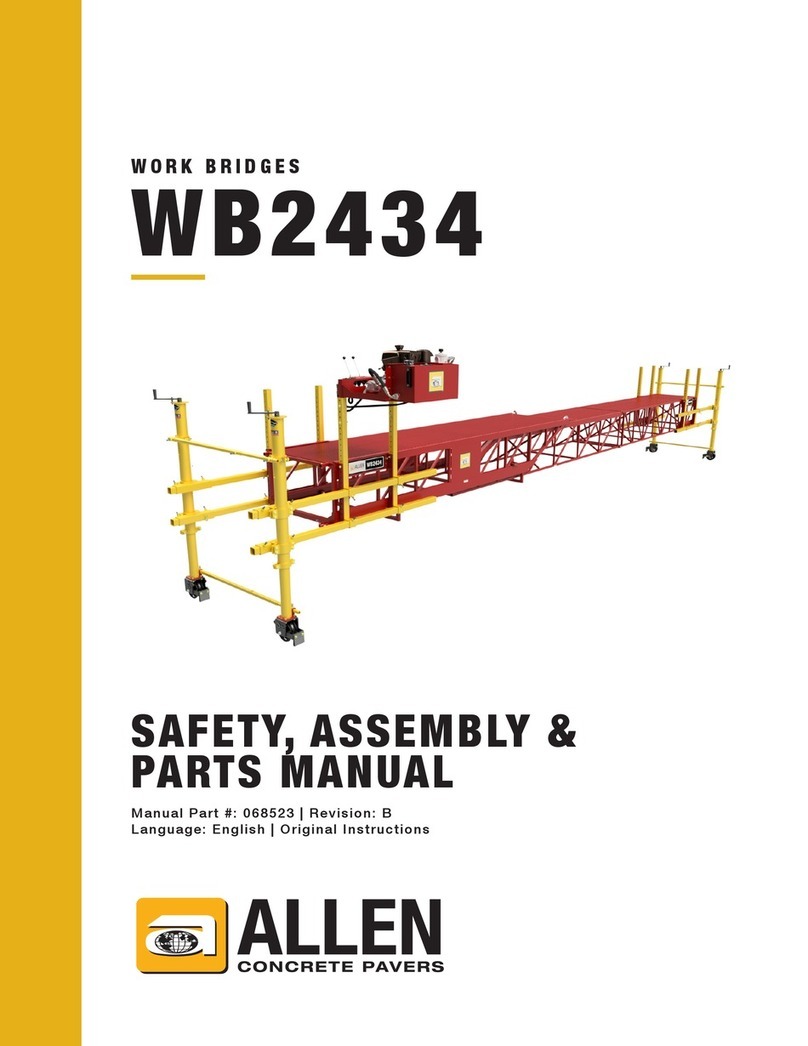

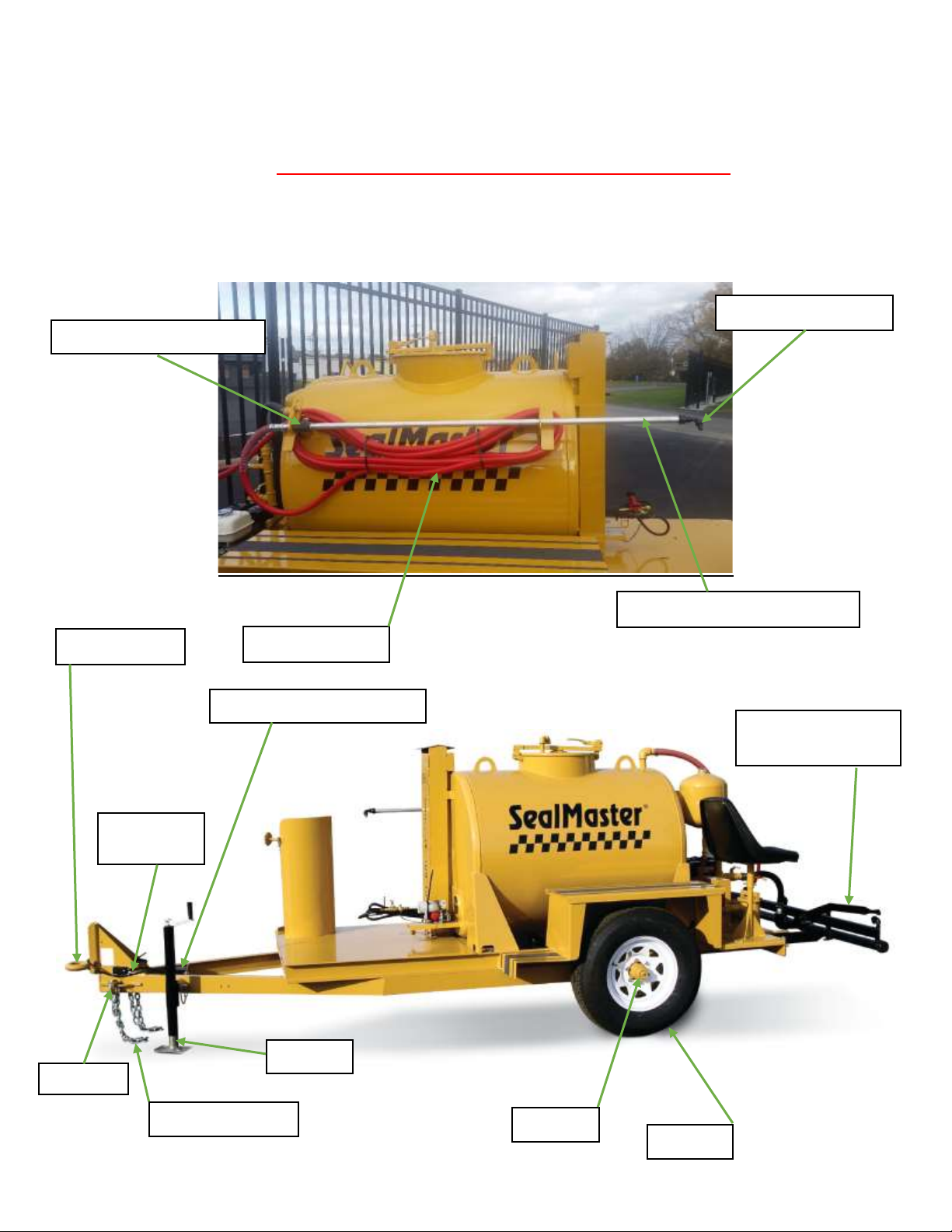

PARTS LIST PICTURE –1 ........................................................................................................ 11

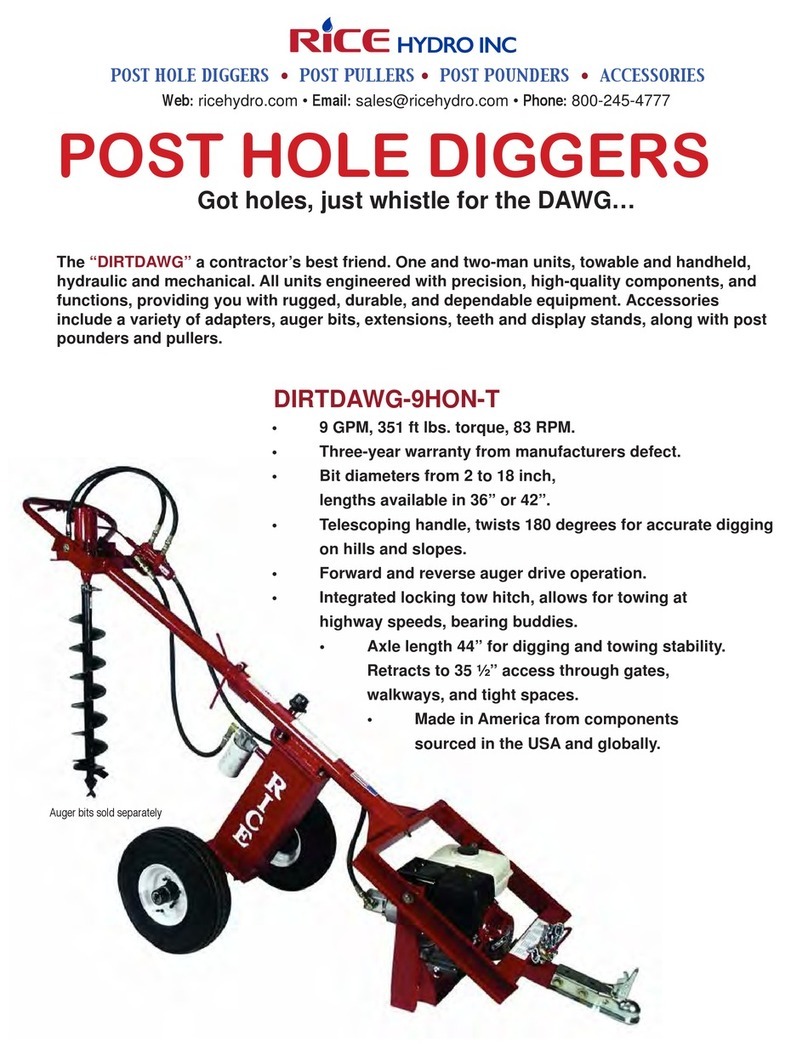

PARTS LIST PICTURE –2 ........................................................................................................ 12

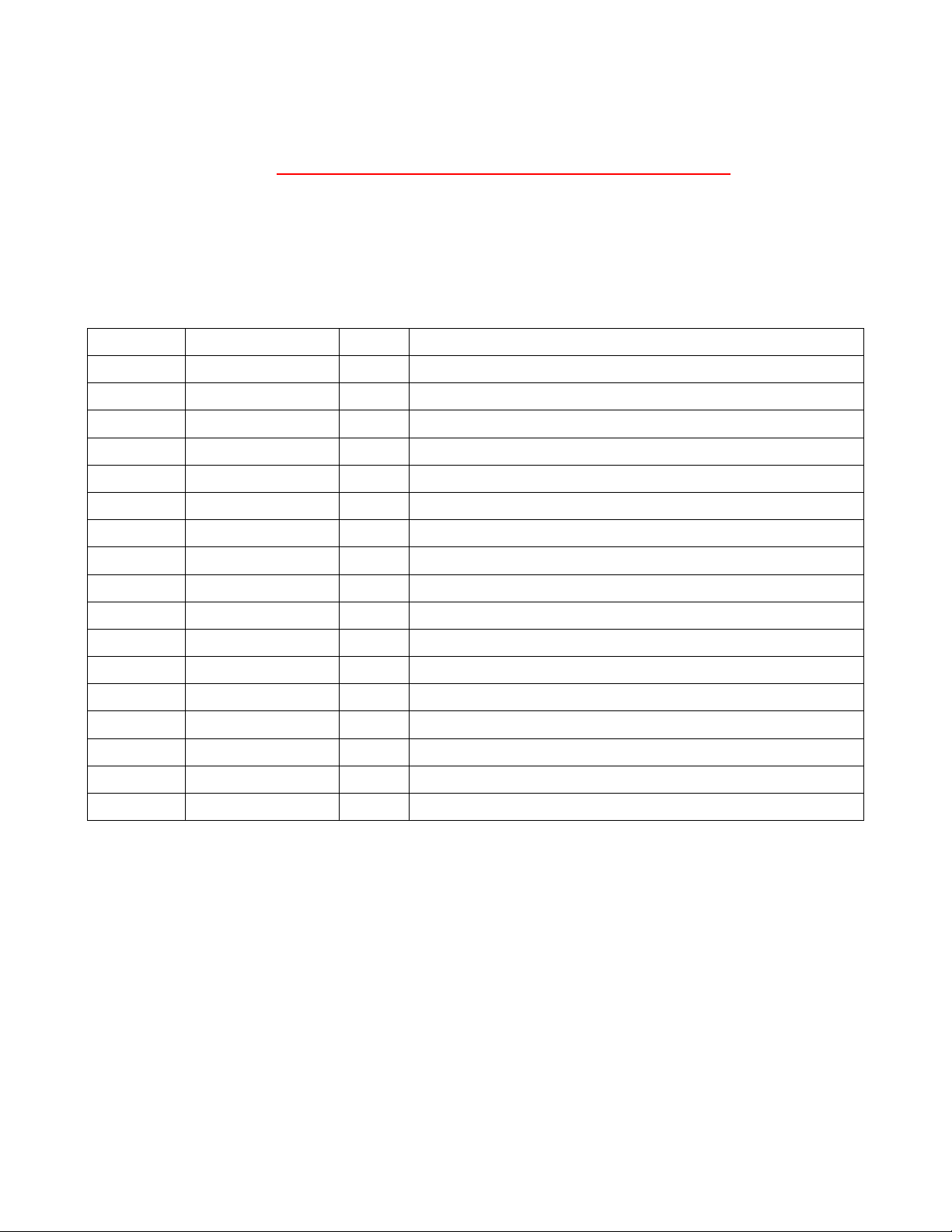

PARTS LIST PICTURE –3 ........................................................................................................ 14

PARTS LIST PICTURE –4 ........................................................................................................ 16

PARTS LIST PICTURE –5 ........................................................................................................ 18

CHECKLIST............................................................................................................................. 19

BEFORE STARTING THE ENGINE............................................................................................ 19

STARTING THE ENGINE ......................................................................................................... 20

OPERATING INSTRUCTIONS WITH HYDRAULIC DRIVE .......................................................... 21

HEATING THE MATERIAL....................................................................................................... 21

PUMPING MATERIAL ............................................................................................................ 22

SPRAY BAR............................................................................................................................ 22

DIESEL FLUSH........................................................................................................................ 23

MAINTENANCE TIPS.............................................................................................................. 23

2

PARTS LIST PICTURE –6 ........................................................................................................ 24

PARTS LIST PICTURE –7 ........................................................................................................ 25

PARTS LIST PICTURE –8 ........................................................................................................ 27

PARTS LIST PICTURE –9 ........................................................................................................ 29

PARTS LIST PICTURE –10 ...................................................................................................... 31

PARTS LIST PICTURE –11 ...................................................................................................... 31

HEATED TACK TANK MACHINE MAINTENANCE.................................................................... 32

MAINTENANCE SCHEDULE.................................................................................................... 32

TROUBLESHOOTING GUIDE .................................................................................................. 33

HOW TO WINTERIZE YOUR EQUIPMENT............................................................................... 34

WIRING DIAGRAMS............................................................................................................. 35

ELECTRIC BRAKES AND RUNNING LIGHTS ............................................................................. 35

TANK CAPACITY CHART ....................................................................................................... 36

MATERIAL DEPTH AND GALLON VOLUME............................................................................. 36

ROPER 1-1/4” PUMP............................................................................................................ 37

PARTS LIST ............................................................................................................................ 37

PUMP DIAGRAM................................................................................................................... 38

ROPER 2” PUMP 3611 HZRV ................................................................................................ 39

PARTS LIST ............................................................................................................................ 39

PUMP DIAGRAM................................................................................................................... 40

MAINTENANCE AND STORAGE ............................................................................................ 41

MAINTENANCE ..................................................................................................................... 41

STORAGE .............................................................................................................................. 41

3

`ThorWorks Industries, Inc.

Purchased by __________________________ Model NO. _______________________

Company Name _______________________ Serial NO. _______________________

Address ________________________________ Acceptance Date ________________

City _____________ State______ Zip _______

CORRESPONDENCE

All Correspondence regarding this equipment, as well as general correspondence should be addressed to:

ThorWorks Industries, Inc.

PO Box 2277

Sandusky, OH 44870

In referring to the equipment, kindly state the Model Number, Serial Number and any part number involved

`

4

SealMaster® LIMITED WARRANTY

SealMaster warrants that its products are of quality material and workmanship. SealMaster agrees to replace,

within a period of one (1) year from date of delivery, or at its option, repair, without charge, any part of their

manufacture which proved defective. The repair or replacement will be free of charge F.O.B. Sandusky, Ohio,

providing the damaged part or parts are returned, freight prepaid, to SealMaster and investigation shows such

repair or replacement is made necessary by an inherent defect of material or workmanship.

It is hereby understood that engines, motors, pumps, or other components purchased by SealMaster for use

on its equipment are not warranted by SealMaster and are sold only with the standard warranty of the

manufacturer of that component.

SealMaster will make no allowances for repairs or alterations completed by outside sources unless

authorization is in writing and approved by an authorized SealMaster representative.

Any claims for defective material or workmanship must be made prior to the expiration of thirty (30) days

from the date failure occurs, and in all cases prior to the expiration of the warranty period of one (1) year. It is

the intent of this paragraph to limit SealMaster’s liability solely to the cost of replacement parts, F.O.B.

factory, or at the option of SealMaster to repair of the defective part or parts. No allowances for damages, lost

time, or any other claim will be recognized.

This warranty is null and void if other than genuine SealMaster parts are used.

SealMaster is constantly striving to improve their products. Changes in design and improvement will be made

whenever the manufacturer believes the efficiency of the product will be improved, without incurring any

obligation to incorporate such improvements in any machines which have been shipped or are in service.

In an effort to continue to improve product quality, SealMaster reserves the right to change specifications

without notice.

Any modification or alteration of this machine without prior approval of the manufacturer may void this

warranty.

5

SAFETY PRECAUTIONS AND CAUTIONS

PRECAUTIONS

•The operator must be aware that he is working with a mechanical device that

contains HOT materials, and must exercise caution at all times.

•Always wear eye and ear protection, long sleeve shirt, and gloves.

•Be aware of all CAUTION, WARNING, and DANGER signs on the machine.

•All employees should be trained in Emergency Burn First Aid.

•Read all Owners Manuals that come with this Machine.

•Make sure the operator is familiar with machine operation.

•Know the procedures for safe operation of propane-fired devices.

•Read and understand the MSDS Sheets for the material you are applying.

•Replace any hoses that show signs of wear, fraying or splitting.

•Be sure all fittings and joints are tight and leak proof.

•Do not operate the machine in the rain or closed building or confined area.

•Do not do maintenance work on the machine while in operation.

•The machine should not be left unattended when running.

CAUTIONS

•Never refuel engine while the burner is lit.

•Never expose the material to an open flame.

•Keep hands, feet, and clothing away from moving parts.

•Do not operate the machine without all guards in place.

•Do not point the spray nozzle at another person.

•Wear eye protection when operating the spray wand or spray bar.

6

SAFETY PRECAUTIONS AND CAUTIONS

FIRST AID

7

HEATED ASPHALT DISTRIBUTOR

APPLIES TO ALL TRAILER AND SKID VERSIONS

OPERATING INSTRUCTIONS

STARTUP

STARTING THE ENGINE

NOTE: If equipped with optional hydraulic drive upgrade refer to pages 18-26

•Set the fuel shutoff and choke levers to the on position.

•Set the throttle lever at ½ open.

•Set the engine on/off switch to on position.

•Pull start the engine.

•It is important that when you are done running the engine that the

fuel shutoff lever is turned to the off position. This keeps gasoline from

mixing with oil as you are driving.

Refer to the engine manual.

ENGINE

PULL

HANDLE

CHOKE

FUEL

THROTTLE

ON/OFF

SWITCH

8

HEATED ASPHALT DISTRIBUTOR

APPLIES TO ALL TRAILER AND SKID VERSIONS

OPERATING INSTRUCTIONS

HEATING THE MATERIAL

1. Attach Nut & Nipple #1 to your LP Gas tank.

The burner uses vapor propane, NOT liquid.

2. Slowly open the valve on the LP Gas Tank. Opening too fast can cause a check valve to

slam closed, reducing the available flow of gas.

3. Regulator #3 is pre-set for 30 psi. Turn the knob counter-clockwise to lower the

pressure. The burner #11, is rated for maximum heat output at 30 psi. Open gas shut-off

valve #7 slightly, depress the red push on gas pilot valve #8. This allows gas to flow thru

the burner, at the same time use the striker flint #10 to produce a spark.

Strike repeatedly until the gas ignites.

If the gas does not light within 5 seconds, release the red push button

and wait 10 minutes before trying again.

Once you have ignition, you must continue to depress the red push button on gas pilot valve

#8 for at least 10 seconds. This allows the thermocouple #9 to heat up, allowing the gas valve

to continue the gas flow. If the flame stays on, then open gas shut-off valve #7 all the way to

get maximum heat from the burner.

If the flame goes out, you will need to start over with the lighting process.

Anytime you want to decrease the flame intensity, slightly close gas shut-off valve #7.

4. The thermocouple #9 also acts as a safety. Should the flame go out because of wind, the

thermocouple immediately starts to cool off and stops the signal to the gas valve, which

then stops the flow of gas. This may take up to 30 seconds.

WAIT 10 MINUTES BEFORE TRYING TO RE-LIGHT THE BURNER.

5. Monitor material temperature on thermometer #13. As the material reaches the

desired temperature you can slightly close gas shut-off valve #7 to decrease the flame,

or just shut off the valve completely.

NEVER DRIVE WITH THE BURNER LIT!!

9

HEATED ASPHALT DISTRIBUTOR

APPLIES TO ALL TRAILER AND SKID VERSIONS

OPERATING INSTRUCTIONS

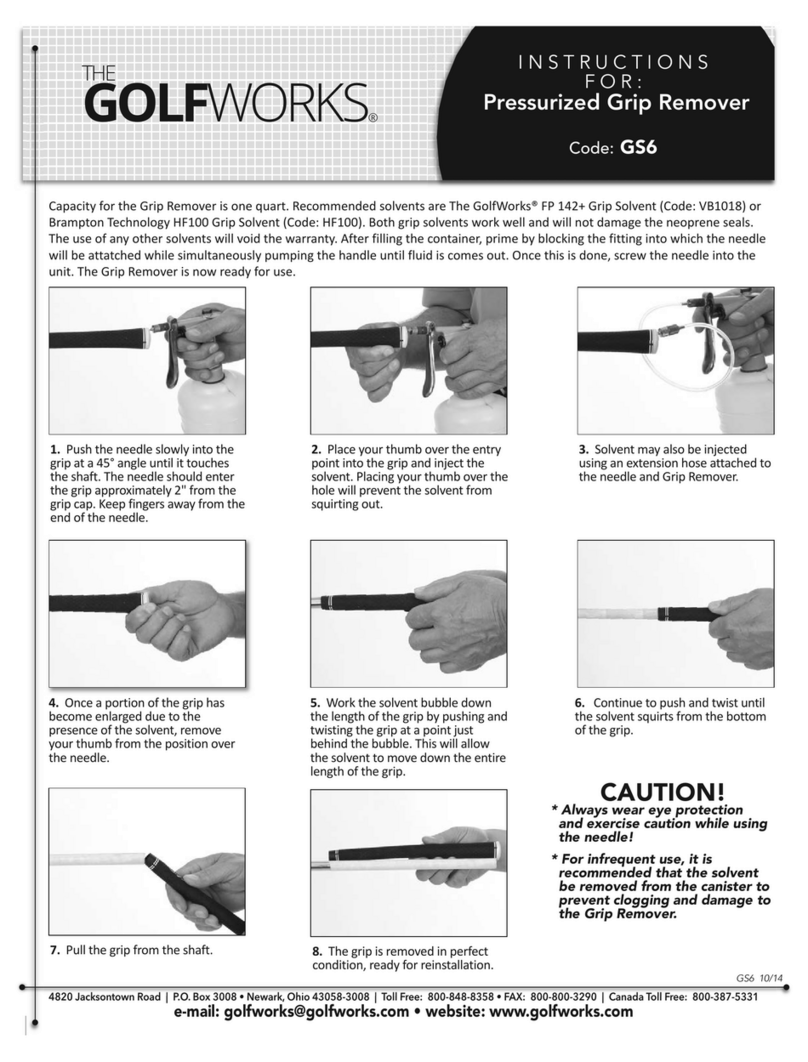

PUMPING MATERIAL

6. Open main tank valve #16 and recirculation valve #24. Close all other valves.

7. Start engine #23 only after reading the engine manual, provided with your

machine. Engine speed will determine the gallons per minute pumped.

8. Start by recirculating material. The material pump #22 draws material from

the tank, thru the basket strainer #17, thru the recirculation valve #24 and

into the top of the tank.

9. Uncoil the spray hose from the side hangars on the tank. Open spray hose

feed valve #25 and spray wand valve #27. Slowly start to close recirculation

valve #24. This will send some product down the spray hose and out the

wand spray tip 80/20 #28. Partially closing this valve allows you to adjust the

desired spray pressure.

NEVER CLOSE RECIRCULATION VALVE #24 COMPLETELY

SPRAY BAR

10. When using the spray bar #31, spray hose feed valve #25 and spray wand

valve #27 remain closed. Once you have recirculated product, slowly close

recirculation valve #24. Open spray tip valves #32 on the spray bar #31.

Position the machine, motion for the driver to start forward at approx. 4mph,

open spray bar feed valve #38,and also the #55 spray bar lever, to start

spraying. This opens all of the spray tip valves #32 at the same time. Once

again, recirculation valve #24 determines spray pressure, adjust accordingly.

11. The throttle on the engine #23 needs to be set to 3/4 or full position to

ensure there is enough speed is available for the material pump #22.

12. Run the pump pressure and speed at the lowest acceptable application

pressure to help reduce overspray.

13. You can control pressure by using the recirculation valve #24.

10

14. Close spray bar feed valve #38 or the #55 spray bar lever when you reach the

end of your pass, leave all the pump controls set. The spray will continue

when you open the spray bar feed valve #38 or the #55 spray bar lever.

15. Position the tires right next to the previous pass, this will give you the proper

overlap.

16. When finished, turn off the engine and close all valves and follow flushing

instructions below.

DIESEL FLUSH

17. Close main tank valve #16 and recirculation valve #24. Start engine #23.

18. Open diesel flush valve #15 on the bottom of the diesel tank #12.

19. Open spray hose feed valve #25 and spray wand valve #27 to flush the spray

hose and wand. To flush the spray bar open spray bar feed valve #38 or the

#55 spray bar lever on the spray bar #31 to the open position. When done,

turn off the engine and close all open valves.

20. Use only diesel fuel for flushing purposes.

21. Remove the lid from the basket strainer #17 and clean the basket.

Anytime you notice the spray pressure is decreasing, the

basket strainer #17 probably needs to be cleaned. Make sure you close main

tank valve #16 before you remove the lid.

MAINTENANCE TIPS

22. Adjust the V-belt #20 tension, by going halfway between the center of the

two pulleys and moving the belt up and down. It should move about ½”.

23. The material pump #22 has a mechanical seal, some leakage is normal. When

the seal plate cannot be tightened any more, the seal must be replaced.

24. The orifice is inside burner #11, needs to be cleaned occasionally. Soot and

spider webs can cause blockage of the flow of gas.

25. Always leave the LP gas hose #6 connected to a tank. If left

disconnected, insects will make their nest inside of it and block the flow of

gas.

11

HEATED ASPHALT DISTRIBUTOR

APPLIES TO ALL TRAILER AND SKID VERSIONS

PARTS LIST

PICTURE –1

PARTS LIST PICTURE –1

ITEM #

PART#

QTY.

DESCRIPTION

1

P933A001

1

NUT AND NIPPLE

3

P735A015

1

REGULATOR

5

P935A001

2

COUPLER

6

P669A005

1

LP GAS HOSE –10 FT.

7

P397A011

1

GAS SHUT-OFF VALVE

8

P735A016

1

GAS PILOT VALVE

9

P679A003

1

THERMOCOUPLE 24”

10

SS107A1

1

STRIKER FLINT

11

P662A003

1

BURNER COMPLETE

8GAS PILOT

10 STRIKER FLINT

1NUT & NIPPLE

3REGULATOR

5COUPLER

7GAS SHUT-OFF

11 BURNER

9THERMOCOUPLE

6LP GAS HOSE

12

HEATED ASPHALT DISTRIBUTOR

APPLIES TO ALL TRAILER AND SKID VERSIONS

PARTS LIST

PICTURE - 2

PARTS LIST PICTURE –2

ITEM #

PART#

QTY.

DESCRIPTION

13

P659A002

1

THERMOMETER

17

P50147B007

1

BASKET STRAINER COMPLETE

P50147B010

1

BASKET STRAINER COMPLETE - OPTIONAL

22

P640A029

1

1-1/4" ROPER MATERIAL PUMP

P640A084

1

2" ROPER MATERIAL PUMP - OPTIONAL

23

P458A022

1

ENGINE –HONDA 5HP

P458A050

1

ENGINE –HONDA 8HP - OPTIONAL

38

P397A012

1

SPRAY BAR FEED VALVE-1-1/4" BALL

P397A002

1

SPRAY BAR FEED VALVE-2" BALL - OPTIONAL

23 ENGINE

17 BASKET STRAINER

ASSEMBLY

22 MATERIAL PUMP

38 SPRAY BAR FEED

13 THERMOMETER

13

HEATED ASPHALT DISTRIBUTOR

APPLIES TO ALL TRAILER AND SKID VERSIONS

PARTS LIST

PICTURE - 3

24 RECIRCULATION

25 SPRAY HOSE FEED

12 DIESEL TANK

38 SPRAY BAR FEED

17 BASKET STRAINER

ASSEMBLY

39 BASKET

13 THERMOMETER

16 MAIN TANK

15 DIESEL FLUSH

14 CAP

14

HEATED ASPHALT DISTRIBUTOR

APPLIES TO ALL TRAILER AND SKID VERSIONS

PARTS LIST

PARTS LIST PICTURE –3

ITEM #

PART#

QTY.

DESCRIPTION

12

P50400B003

1

DIESEL TANK

13

P659A002

1

THERMOMETER

14

P464A002

1

TWIST CAP

15

P397A001

1

DIESEL FLUSH VALVE-3/4“BALL

16

P397A012

1

MAIN TANK VALVE-1-1/4" BALL BRASS

P397A002

1

MAIN TANK VALVE- 2" BALL BRASS - OPTIONAL

P397A002

1

GRAVITY VALVE- 2" BALL BRASS - OPTIONAL

17

P50147B007

1

BASKET STRAINER COMPLETE

P50147B010

1

BASKET STRAINER COMPLETE - OPTIONAL

24

P397A012

1

RECIRCULATION VALVE-1-1/4" BALL

P397A002

RECIRCULATION VALVE-2" BALL –OPTIONAL

25

P397A001

1

SPRAY HOSE FEED VALVE-3/4“ BALL BRASS

38

P397A012

1

SPRAY BAR FEED VALVE-1-1/4" BALL

P397A002

1

SPRAY BAR FEED VALVE-2" BALL - OPTIONAL

39

P50313B

1

STRAINER BASKET

P50313A

1

STRAINER BASKET - OPTIONAL

15

HEATED ASPHALT DISTRIBUTOR

APPLIES TO ALL TRAILER AND SKID VERSIONS

OPERATING INSTRUCTIONS

PICTURE - 4

19 SHEAVE

21 SHEAVE

40 BUSHING

18 BUSHING

20 V-BELT

32 SPRAY TIP VALVE

29 SEAT

28 SPRAY TIP 80/20

31 SPRAY BAR ASSEMBLY

16

HEATED ASPHALT DISTRIBUTOR

APPLIES TO ALL TRAILER AND SKID VERSIONS

PARTS LIST

PARTS LIST PICTURE –4

ITEM #

PART#

QTY.

DESCRIPTION

18

P740A006

1

BUSHING 1” BORE

19

P661A033

1

SHEAVE 14-3/4” O.D.

20

P660A030

1

V-BELT B70

21

P661A034

1

SHEAVE 4-3/4” O.D.

28

P449A011

6

SPRAY TIP 80/20 1/4" NPT STEEL

29

P602A003

1

SEAT - OPTIONAL

31

P50246TAW

1

SPRAY BAR ASSEMBLY - OPTIONAL

32

P397A009

5

SPRAY TIP VALVE-1/2” BALL BRASS

40

P740A043

1

BUSHING 3/4” BORE

17

HEATED ASPHALT DISTRIBUTOR

APPLIES TO ALL TRAILER AND SKID VERSIONS

PARTS LIST

PICTURE - 5

26 SPRAY HOSE

27 SPRAY WAND VALVE

28 SPRAY TIP 80/20

41 SPRAY WAND ASSEMBLY

34 TIRE

37 COUPLERS

33 AXLE

35 SAFETY BREAK-AWAY

36 JACK

55 SPRAY BAR

LEVER-KIT

43 SAFETY CHAIN

45 TRAILER

PLUG

44 HOOK

18

HEATED ASPHALT DISTRIBUTOR

APPLIES TO ALL TRAILER AND SKID VERSIONS

PARTS LIST

PARTS LIST PICTURE –5

ITEM #

PART#

QTY.

DESCRIPTION

26

P754B025

1

SPRAY HOSE –50 FT.

27

P397A010

1

SPRAY WAND VALVE-3/4” BALL CARBON STEEL

28

P449A011

6

SPRAY TIP 80/20 1/4" NPT STEEL

33

P511A013

1

TR 300 AXLE

33

P511A013

2

TR 575 AXLE

34

P514A017

2

TR 300 TIRE ASSEMBLY

34

P514A017

4

TR 575 TIRE ASSEMBLY

35

P518A008

1

BREAKAWAY KIT –4 BOLTS

P518A004

1

BREAKAWAY KIT BEFORE 10/2019

36

P551A008

1

JACK ASSEMBLY

37

P553A008

*

2-5/16” BALL COUPLER

37

P646A003

*

PINTLE EYE COUPLER

41

P50273E

1

SPRAY WAND ASSEMBLY

43

P531A004

2

SAFETY CHAIN

44

P517A002

2

HOOK (PART OF SAFETY CHAIN)

45

P51PA007

1

TRAILER PLUG

55

P50247LK

1

SPRAY BAR LEVER KIT

This manual suits for next models

4

Table of contents

Other SealMaster Construction Equipment manuals

Popular Construction Equipment manuals by other brands

Volvo

Volvo L150H manual

Schmalz

Schmalz SK-JU-110-2000-SRS63-3000-VSL-EX Operating and maintenance instructions

MULTIQUIP

MULTIQUIP MC12PH Operation and parts manual

Talet Equipment

Talet Equipment Mini Auger Bucket Parts and operation manual

Dynapac

Dynapac CA702 instruction manual

Rockler

Rockler 42826 manual