3

1. - General information 5

1.1 - Introduction

1.2 - General information

2. - Description of the machine 6

2.1 - Type of machine 6

Manufacturer’s rating plate

Position of the rating plate

Position of the machine serial number

2.2 - Description of the machine 7

2.3 - Machine size 8

2.4 - Technical data 8

3. - Machine transportation 9

3.1 - Transportation

4. - Using the machine 10

4.1 - Operating principle 10

4.2 - Pumpable materials 10

Applications 11

Choice of pump

Choice of spray gun

4.3 - Preliminary operations 12

Machine position

Electrical connection

Hoses 13

Hose anchorage

Couplings

Connections 14

4.4 - Starting 15

Preventive checks

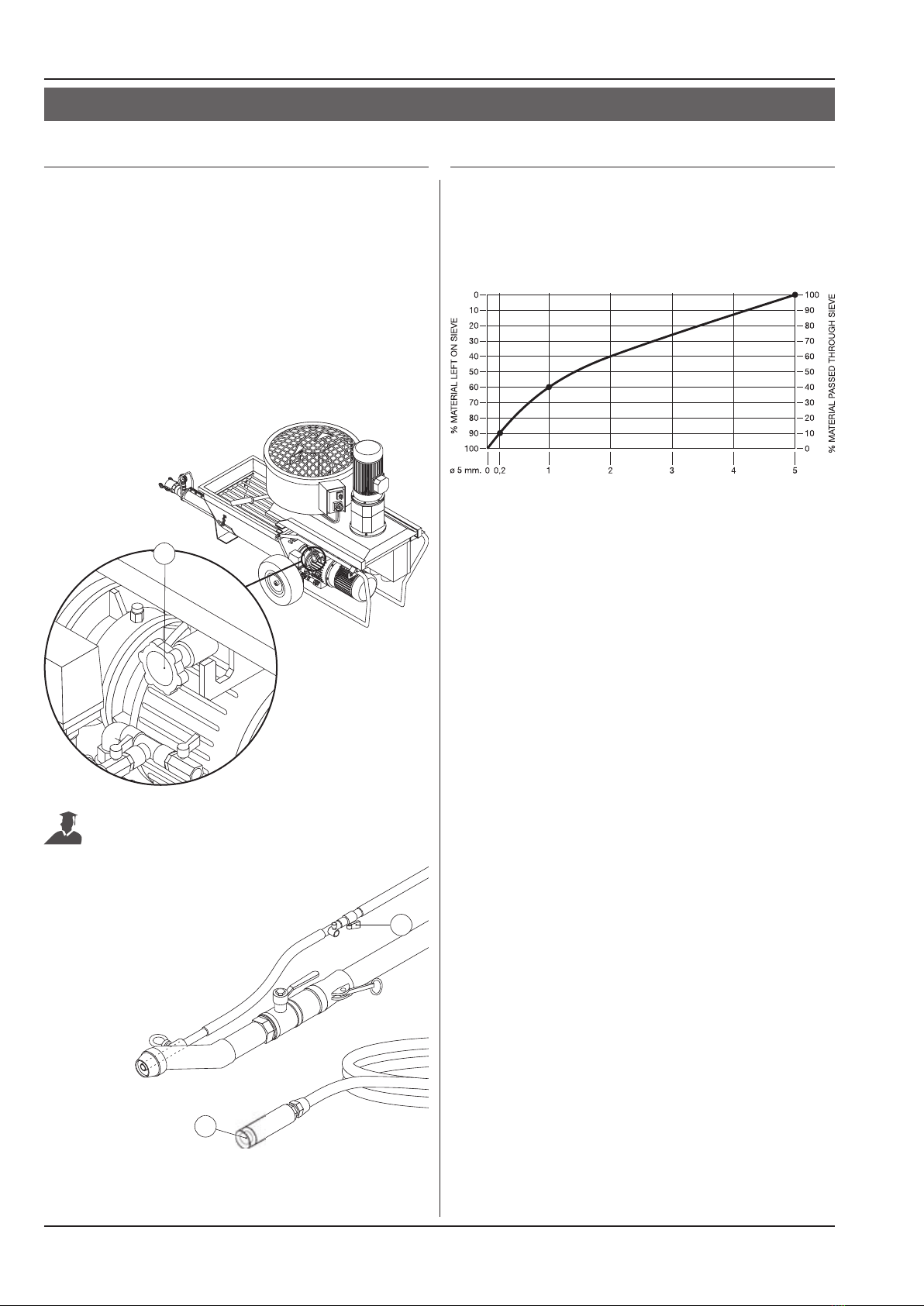

Calibrating the pump 16

Starting 18

Preparing the batch 20

Conveying and spraying the mix

4.5 - Clean-up at end of work 22

4.6 - Replacing the pumping unit 24

5. - Machine maintenance 26

5.1 - Maintenance for which

the operator is responsible 26

Daily operations

5.2 - Maintenance to be carried out

by qualied personnel 27

6. - Troubleshooting 28

6.1 - No material comes out the spray gun 28

6.2 - Other problems 29

6.3 - Work by the operator 30

6.4 - Work by qualied personnel 30

7. - Responsibility of the operator 32

Table 1 - Machine casing 34

Table 2 - Motor – Drive unit 36

Table 3 - Pump 2L6 38

Table 4 - Pump T25 40

Table 5 - Pump 60.12 42

Table 6 - Oversize pan mixer 44

Table 7 - Switchboard 46

Table 8 - Remote control 48

Table 9 - Vibrating sieve 50

Table 10 - Complete compressor code 216.415 52

Table 10 A -Compressor 54

Table 11 - Accessory box code 201.112

for traditional mortars 56

Table 11 A - Accessory box code 201.112

Gun and hoses 58

Table 12 - Accessory box code 201.067

for ready-mix materials 60

Table 12 A - Accessory box code 201.067

Spray gun 62

Table 12 B - Accessory box code 201.067

Hoses 64

Table 13 - Accessory box code 201.071

for skim coats 66

Table 13 A - Accessory box code 201.071

Gun and hoses 68

Table 14 - Accessory box code 201.089

for self-levelling screeds 70

ACCESSORIES

Table 15 - Extensions 74

Table 16 - Guns 76

Table 17 - Nozzles 78

Table 18 - Injection device 80

Table 18 A - Pressure limiting device unit 82

Table 18 B - Gun - Hoses 84

Table 19 - Litre-counter 86

WIRING DIAGRAMS

Table 20 - Wiring diagram 90

CONTENTS

USE AND MAINTENANCE SPARE PARTS