table of contents

Paae

General Safety Instructions for Power Tools . . . . . . . '’2

Additional Safety Instructions for Band Saw . . . . . . . 3

Before Using the Saw . . . . , . . . . . . . . . . . . . . . . . . . 3

When Installing or Moving the Saw . . , . . . . . . . . . 3

Before Each Use . . . . . . . . . . . . . . . . . . . . . , . . . . . . 3

Before Sanding . . . . . . . . . . . . . . . . . . . . . . . . . , , . , 4

Whenever Saw is Running . . . . . . . . . . . . . . . . . . . . 4

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Glossary of Terms for Woodworking . . . . . . . . . . . . . 5

ElectricalConnections . . . . . . . . . . . . . . . . . . . . . . . . . 6

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Motor Safety Protection. . . , . . . . . . . . . . . . . . . . . . . 6

Wire Sizes . . . . . . . . . . . . . . . . , . . . . . . . . . . . . . . . . 7

Unpacking and Checking Contents . , . . . . . . . . . . . . 7

Tools Needed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table of Loose Parts . . . . . . . . . . . . . . . . . . . . . . . . . 8

Assembly and Alignment . . . . . , . . . . , . . . . . . . . . . . . 10

Assembling Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . lo

Mounting the Motor . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Selecting Blade Speed . . . . . . . . . . . . . . . . . . . . . . . 14

Recommended Speed Settings . . . . . . . . . . . . . . . 14

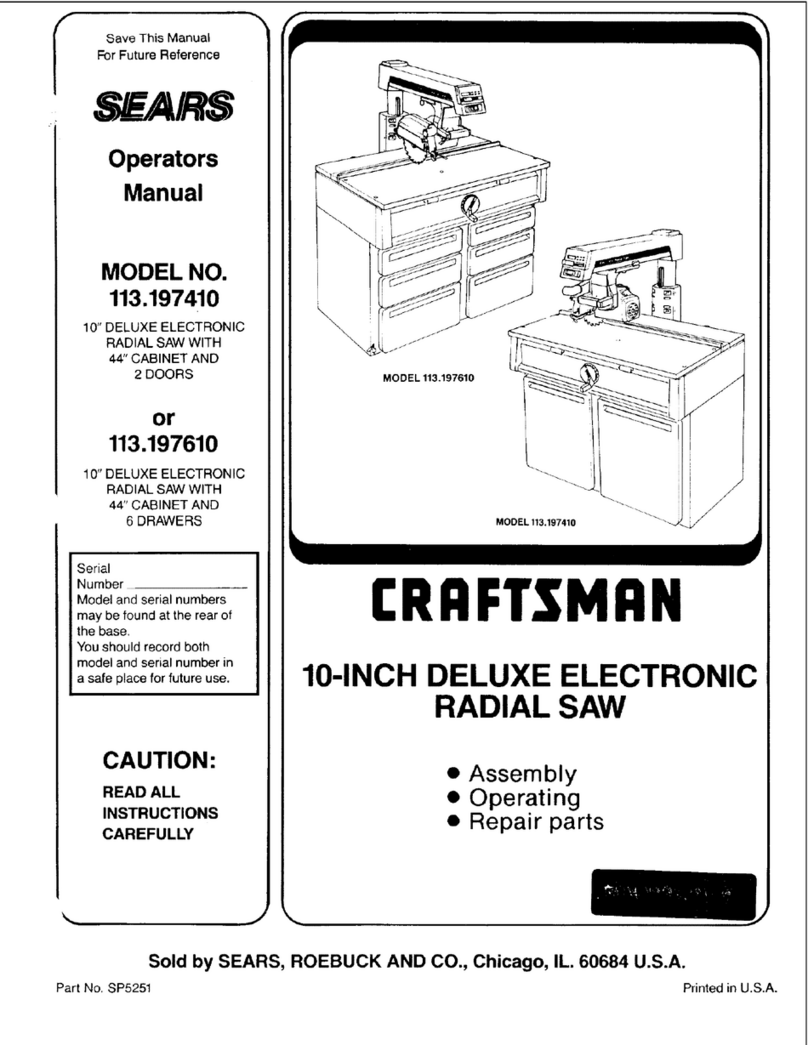

Mounting the Saw to the Cabinet . . . . . . . . . . . . . . 15

Mounting Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

AttachingTrim Caps and Trim Ledge . . . . . . . . . . . 16

Attaching Handwheel . . . . . . . . . . . . . . . . . . . . , . , . 16

glossary of terms

Bevellng

An anglecutting operationthrough the faceof the

board ,

,\

Cro$§eut

A cutting operation made across the width of the

workpiece.

CompoundCutting

A simultaneousbevel and miter cutting operation.

FPM

Feet per minute. Used in reference to surface speed

of blade.

Freehand (as used for band 8aw)

Performing a cut without the workpiece properly

supported on the work table.

Gum

A sticky, sap based residue from wood products.

KerI

The material removedby the blade in a through cut

or theslot produced by the blade in a non-through or

partial Cut.

LeadIngEnd

The end of the workpiece wh,ich is pushed into the

cutting tool first.

in\

Miterlng

An angle cutting operation madeacross the width of

the workpiece.

Page

Getting to Know Your Band Saw . . . . . . . . . . . . . . . . i7

Location and Function of the Electronic ' '

Indicator System , . . . . . . . . . . . . . . . . . . . . . . . . . , . . . 18

Digital Readout Display . . . . . . . . . . . . . . . . . . . . . . 18

Function Keys . . . . . . . . . . . . . . . . . . . . . . . . . . , . . . 18

Battery Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Using the Electronic Indicator System . . . . . . . . . . 19

Installing the Blade . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Aligning the Blade and Blade Guides . . . . . . . . . . . 21

Mounting the Front Table . . . . . . . . . . . . . . . . , . . . . 23

Squaring the Blade to the Table , . . . . . . . . . . . . , . 28

Location and Function of Controls . . . . . . . . . . . . . . . 26

g)n-OffSwitch ....,,,.,,,................... 26

Tilting Head for BevelCut . . . . . . . . . . . . . . . . . . . . ii

BasiJuBsIIg sl:FEES StEP?. : : : : : : : : : : : : : : : : : : : iS

Circle Cutting . . . . . . . . . . . . . . . . , . . . . . . . . . . . . . . jy

Sawdust Collection . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Installing Sanding Attachment . . . . . . . . . . . . . . . . .. :i

Installing the Sanding Belt . . . . . . . . , . . . . . . . . . . . 26

Final Assembly of Front Table,

Front Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Adjusting Band Saw Bevel Travel . . . . . . . .-. . . . . . 29

Ac:iVstjrg Upper Blade Guide Travel . . . . . . . . . . . 29

Trouble Shooting . . . . . . . . . . . . . . , . . . . . . . . . . . . . . . ia

Repair Parts . . . , . . . . . . . . . . . . . . . . . . . . . . . . . . . . . , ii

for woodworking

PushStIck

A device used to feed the workpiecethrough the saw

during narrow ripping type operations so the opera-

tor’shands are keptwell away fromthe blade.

Resaw

A cutting operation to reduce the thickness of the

workpieceto make thinner pieces.

Resin

A sticky, sap based substance that has dried.

RIpping

A cutting operation along the length of the work-

piece.

SawbladePath

The areaof the worktable or workpiecedirectly in

line with the saw blade.

Set

The distance the tip of the saw bladetooth is bent

outward from the faceof the blade.

TraiIIngEnd

The workpiece end last cut by the saw blade.

Workpiece

The itemon which the cutting operation is being

performed. The surfaces of a workpieceor commonly

referred to as faces,ends, and edges.

Worktable

The surface on which the workpiece rests while

performing a cutting or sanding operation.

5