-

above be sure to specify the shaft diameter of your

motor. Install the motor sothat the direction of rota-

tion of the Drive pulley is counter-clockwise when

viewed from the pulley side of the tool.

CONTROtS:

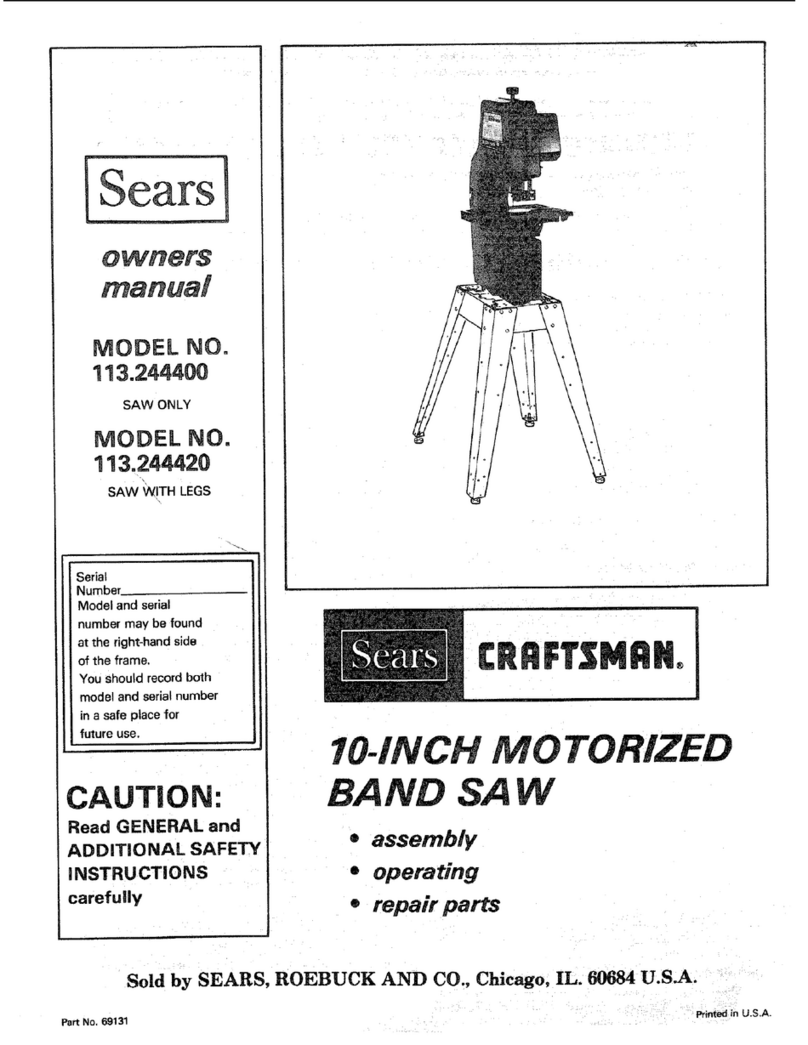

The table may be tilted from a level position to 45

degrees forward, after loosening the table tilt lock

with the handle provided.

The degree of tilt is shown on the calibrated trun-

nion scaleby . pointer asshown in figure l.

The upper g,rid. arrembly may be raised and

lowered to accommodate material of various thick-

ness after loosening the blade guide elevation lock

knob shown in 6gure l.

The blade thrust roller arsemblies and the lateral

guides in both the upper and lower blade euide

assemblies

may be reset after the set screw holding

each unit has been backed out several turns.

ADJUSTftTENTS:

This band saw was completely checked and tested

under power at the factory. Rough handling in ship-

ment may have caused some misalignment during

transit. Following are several points which might be

checked to insure proper operation.

The table should be square with the blade when the

pointer indicates zero on the trunnion scale. If this is

not the casethe tool will not produce accurate cuts

when set aeeording to thi,srcalc.-€orectionsmay be

made by resettingthe table squarewith the blade (use

an accuratesquare) and then readjusting the pointer

to the zero mark on the scale

by loosening the screw

which holds the pointer to the tool.

cover near the blade tension adiusting knob. The

cover may be removed for checking tension or t€'

placing blades after removing the three knobs directly

opposite the cover retaining nuts shown in 6gure l.

Tension adjustments for the variouswidth blades may

be made according to figure 2.

To remoye or replace a blade, remove the front

cover and the set screw in the table slot. Release the

tension until the blade may be slipped off easily. In-

stall the new blade with the teeth pointing down and

away from the drive pulley and apply the correct

tension. Turn the pulley forward by hand for at least

a dozen revolutions or more. Watch caret,,.'^ry

to see

that the blade tracks in the same spot consistently.

If the blade tends to ride off the wheel, two adjust-

ments are provided to return the blade to its proper

track at the center of the drive wheel.

For minor adjustment of blade tracking difficulties,

the blade alignment adjusting knob shown in figure

I may be turned slightly in or out causing the rear

idler wheel to pivot and retrack the blade. If this ad-

justment is not sufficient the shaft on which the up.per

idler wheel is mounted may be moved toward ot

away from the frame. It is held in place by the

square head screw in the casting over the shaft. Be

certain that this screw is securely tightened after any

adjustment of the upper idler wheel.

Check the blade for correct tension before re-in-

stalling the cover. Replace the set screw in the table

slot.

Blade guide assemblies are provided both above

and below the. table to support the blade against

lateral and direct thrust. The roller type guides be-

hind the blade should be set approximately | /64 inch

from the blade edge. The blade should touch these

rollers only when cutting, and not when the saw is

running free. The lateral guides should be set as

close as possible to the blade without touching. When

viewed from the side they should be in such a position

that if the blade is pushed against them, the flat sur'

face, and not the teeth will ride the guides. These

Iateral guides should be checked often and refaced

and reset when necessary, to keep them close to the

blade.

When the saw is turned by hand, or when running

free under power, the blade should track smoothly on

all three wheels, and should touch none of the guides,

upper or lower.

The complete lower guide assembly is held in place

by " set screw through the frame casting and may be

adjusted as a unit after loosening this set scre!r'.

After making any adjustment on the Band Saw,

check carefully by turning the mechanism by hand

several times before applying power.

BIADE:

Following are several common causes of band saw

blade breakage. Avoid these situations by frequently

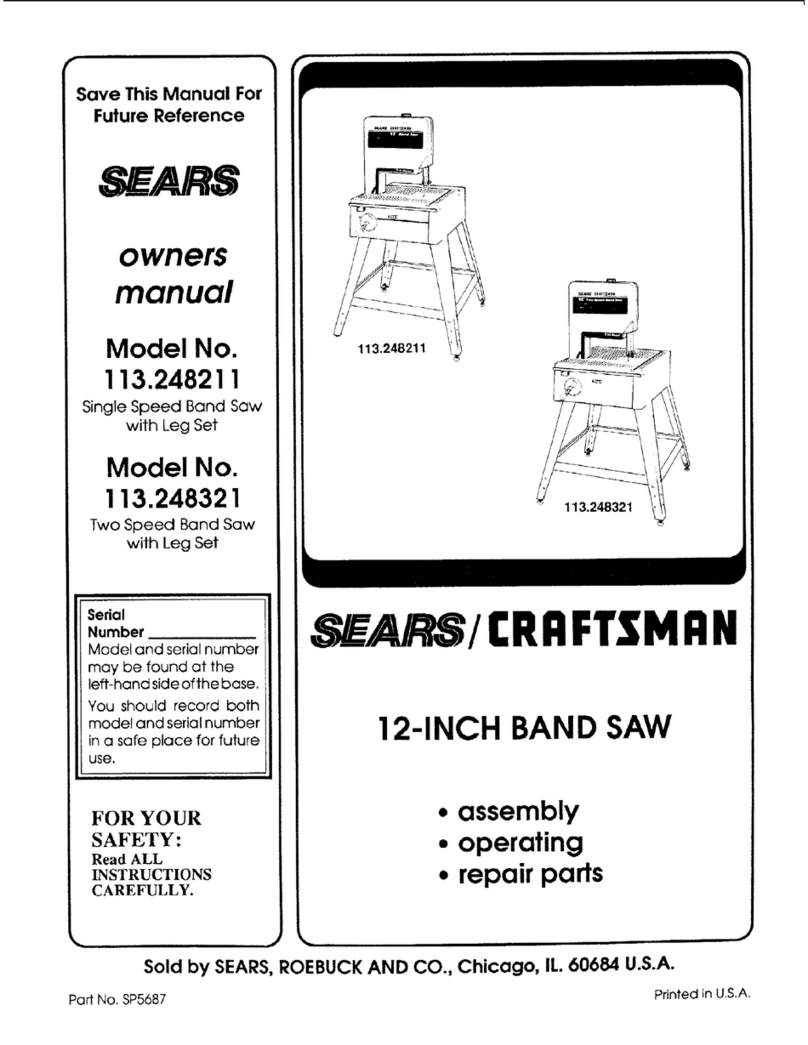

ADVANCE

WASHER

TOTHISPOSITION

TO

APPTYTHE

NECESSARY

TENSIONFOR 3/I

INCHWIDE

BIADES.

WITH

WASHER

AT THIS

POSIIIONPROPER

TENSION

HAS BEEN

APPTIED

FORBOTH

3/r6

AND r/r INCHBLADES.

FIGURE 2

A stop screw with lock nut may be found projecting

from the lower table surface over the frame casting.

This screw when properly set will allow accurate

return of the table to a true le.rcl position after it has

been tilted for an angular cut.

The proper tension for the 3/ | 6, | /4, or 378 inch

wide blades recommended is shown on the blade

tension indicator. This indicator is just inside the