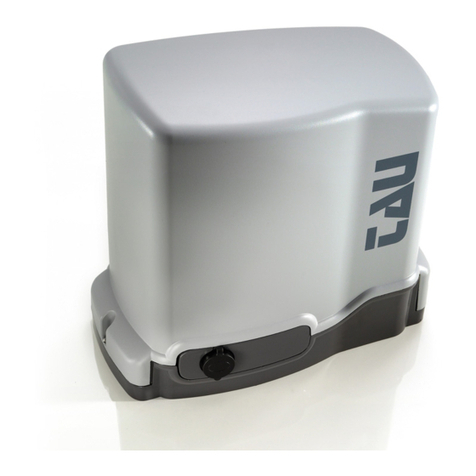

Seco VINCO 600 User manual

Sliding Gate Opener

VINCO

600 - 800 - 1000 - 1500 - 2000 - 2500

MANUAL

Rwww.seco.gr

Tel. 0030 210 9846222

Fax 0030 210 9822276

Agiou Dimitriou 263, TK. 17342, Athens, Greece

ENG GR

Safety Protection and Precautions

THIS SERIES OF DOOR OPENERS MUST BE INSTALLED BY

PROFESSIONALS.

1. ATTENTION! Please operate the machine carefully in strict compliance with

instructions of this Manual. It is very important to personal safety . Incorrect

installation or improper use of the machine may cause serious damage to the person

and/or property.

2. Read this Manual carefully before installation.

3. The installation must comply with relevant national codes and specifications and the

mechanical parts used must meet with national standards.

4. The power supply should have a voltage meeting the requirements of the machine,

be reliably grounded, and have both leakage protection and short circuit protection.

5. Before system overhaul, cut off the power and check if the grounding system is

correct and reliable.

6. The machine must be equipped with safety devices (such as infrared intrusion

protector) (optional) and should be inspected on a frequent basis for normal

operation.

7. We will accept no responsibility for any consequences resulting from inappropriate

use of the machine or from use beyond the specified purposes.

8. We will accept no responsibility for any problem incurred due to neglect of the

process requirements of precision components or due to deformation of such

components during the installation.

9. The product was designed and manufactured in strict compliance with the operating

instructions given in this Manual. Any use or operation against these instructions

may damage the product or bring a hazard.

10. We will accept no responsibility for any safety problem or operation failure caused by

the use of any component not produced by us.

11. Don’t make any change to the components of the system.

12. The installer must explain in detail to the user the operating rules of the machine and

relevant regulations in case of an emergency, and provide the user with the Manual.

13. Keep children and other unauthorized persons away from the installation site and

make sure there is no risk factor existing in the vicinity of the installation site.

14. Clean off any obstacle from the motion route of the door before the electric control

system is put into operation, and stop the flow of vehicles and pedestrians when the

door is in motion.

15. The main control box should be installed in such a position and to such a height that

should be appropriate, ventilated, and properly protected from rain, sunshine,

playing kids, and the operation of remote control and control panel switch by

mistake.

16. An external housing may be added if necessary. In doing so, the shielding effect of

the external housing (usually made of metal) against the receiving of remote control

signals should be taken into account since it may affect the product’s functionality

and bring inconvenience to the user.

17. Keep the remote control out of the reach of children. Failure to do so may incur

accident to children.

18. Don’t try to repair or adjust the system by yourself. Contact professionals instead.

19. Keep the Manual properly for future use.

R

VINCO

Sliding Gate Opener

2

Main Technical Specifications:

Working Principle and Main Components and Functions

The door opener mainly consists of a high-strength aluminum alloy box, a high-quality

single-phase motor, a frictional overrun clutch, a worm-gear reducer, a gear clutch and

an output gear. During the operation, the motor spindle drives both the reducer and

output gear by means of the frictional overrun clutch, and the output gear then push

racks mounted on the sliding door to move the door horizontally so that the door can be

opened and closed in the energized state.

When the special key is turned clockwise, the gear clutch is engaged and the motor

power transmitted by the worm gear drives the output gear to rotate via the gear clutch

so as to drive the rack mounted on the door, pushing the door to move (or to open and

close) horizontally. Meanwhile because of the reverse self-locking feature of the worm

gear mechanism, the door is locked as well, keeping closed against an external force.

When the special key is turned counterclockwise, the left and right parts of the gear

clutch are disengaged from each other and the output gear is freed from the influence of

the motor, allowing the door to be opened and closed manually.

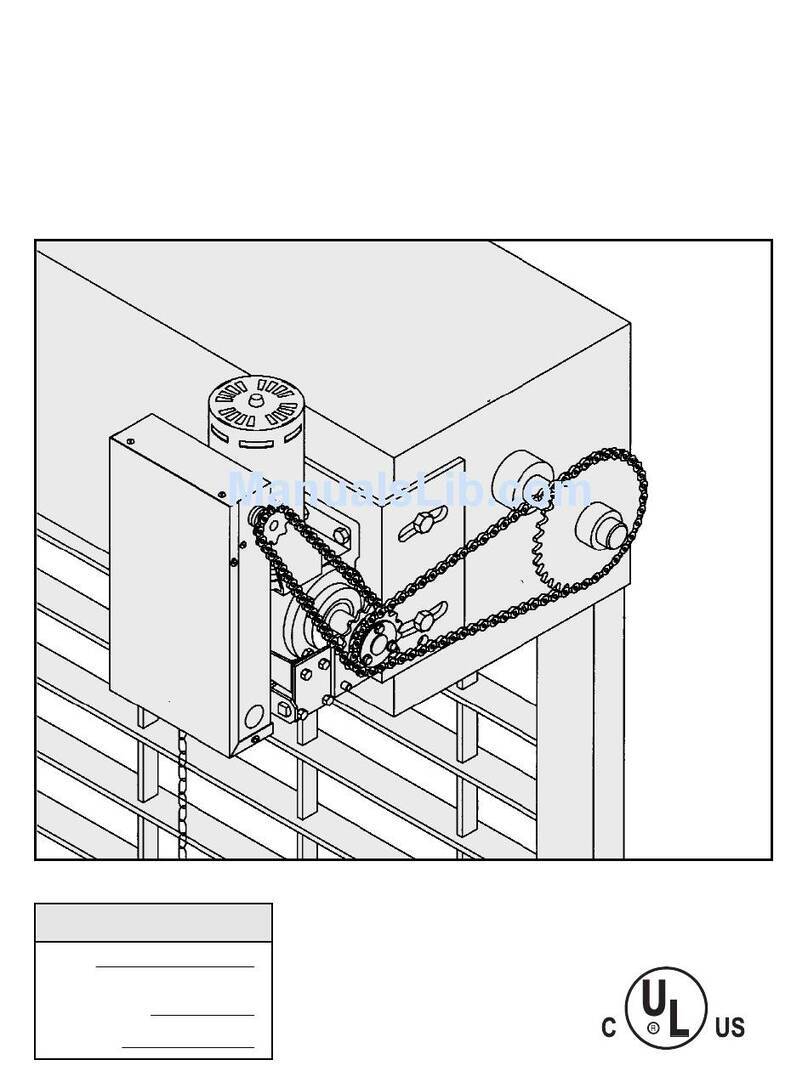

Install the Metal Base

The door opener should be mounted on a metal base with bolts. As for how to install the

metal base, see Fig. 1.

MODEL VINCO 600

Supply Voltage(V)

Motor Power(W)

Torque

Maximum Weight Of Gate

Motor Rotation Speed(Rated)

Gate Speed

Limit Switch

Noise

Operating Environment Temperature

Certicates

MODEL

Supply Voltage(V)

Motor Power(W)

Torque

Maximum Weight Of Gate

Motor Rotation Speed(Rated)

Gate Speed

Limit Switch

Noise

Operating Environment Temperature

Certicates

AC230/120V

280W

20Nm

600kg

1400r/min

12M/Minute

Spring switch/magnetic switch

≤56dB

-45oC - 65oC

CCC, CE

AC230/120V

370W

20Nm

800kg

1400r/min

12M/Minute

Spring switch/magnetic switch

≤56dB

-45oC - 65oC

CCC, CE

AC230/120V

550W

20Nm

1000kg

1400r/min

12M/Minute

Spring switch/magnetic switch

≤56dB

-45oC - 65oC

CCC, CE

AC230/120V

750W

20Nm

1500kg

1400r/min

12M/Minute

Spring switch/magnetic switch

≤56dB

-45oC - 65oC

CCC, CE

AC230/120V

1200W

20Nm

2000kg

1400r/min

12M/Minute

Spring switch/magnetic switch

≤56dB

-45oC - 65oC

CCC, CE

AC230/120V

1500W

20Nm

2500kg

1400r/min

12M/Minute

Spring switch/magnetic switch

≤56dB

-45oC - 65oC

CCC, CE

VINCO 800 VINCO 1000

VINCO 1500 VINCO 2000 VINCO 2500

3

www.seco.gr

Tel. 0030 210 9846222

Fax 0030 210 9822276

Agiou Dimitriou 263, TK. 17342, Athens, Greece

Mount the Rack

The easiest way to install a rack is to place it on the gear teeth of the door opener first,

disengage the door opener, and then push the door slowly to move the tack bit by bit to

the desired position. In this way, you can make sure that the teeth of the rack are

perfectly engaged with the teeth of the gear. When doing so, don’t forget to mark each

mounting point. (See Fig. 2.) Be noted not to lay the entire weight of the door onto the

gear.

Door Opener Release Device (Open the door manually)

The door opener is designed with a lockable release device which enables you to open

the door manually in case of blackout. For the release device and its operations, see

Fig.3 and Fig. 4.

Install the Limit Switch

Install the switch bracket onto the rack by reckoning the final travel position. (See Fig. 5).

For a spring switch, adjust until to an inclination that the spring comes into contact with

the switch flapper. For a magnetic switch, the magnet should point to the motor and be

located according to the position of the magnetic limit switch inside the housing.

SC - SDCB102

Control Panel for Sliding Gate Motors

R

4

For wiring, see Fig. 6

For control panel wiring, see Control Panel Manual.

Energizing & Trial Run

1. Before use, check the power supply voltage, frequency and other data carefully and

make sure they are in line with the requirements, and check if the ground wire is in

good condition and the electrical wiring is correct.

2. A special key is provided along with the shipment of the door opener. Turn the key

counterclockwise (to disengage the clutch), push the sliding door and let the door

opener to operate without load. If the door opener works properly, then turn the key

clockwise (to engage the clutch).

3. Turn on the power, start the door opener, and observe the sliding operation of the

sliding door.

4. Adjust the magnet’s position until the door is able to open and close in positions to

your satisfaction.

Care and Maintenance

1. Apply some antirust grease to the end of the worm gear spindle located inside the

hole of the special key.

2. Check frequently if the electrical grounding is in good condition.

3. Check frequently if all parts and components are in good condition.

4. The device uses advanced lubricant that requires no replacement or replenishment.

www.seco.gr

Tel. 0030 210 9846222

Fax 0030 210 9822276

Agiou Dimitriou 263, TK. 17342, Athens, Greece

5

Possible Faults and Trouble shooting

No. Fault Possible Causes Troubleshooting

1 Motor cannot be started.

No power supply. Check the power supply.

Fuse is blown. Replace the fuse.

Capacitor breaks down. Replace the capacitor.

Overloaded. Check for any obstruction on

the door rail.

Thermal protector is activated. Restart in 20 minutes

Sensor switch is damaged. Replace the sensor switch.

Cable becomes broken, loose

or detached. Connect up the cable.

2

The door can be opened

(closed) but cannot be

closed (opened)

Sensor switch is damaged. Replace the sensor switch.

A/COM/C line is incorrectly

wired.

Connect the line as per the

wiring diagram.

Check controller and motor Check if the line is open.

3 Limit operation fails.

Sensor switch is far apart. Adjust the position

Sensor switch is incorrectly

located.

Magnetic steel become

detached and incorrectly

located.

Sensor switch is damaged Replace the sensor switch.

W, V, or COM line is

incorrectly wired

Connect the line as per the

wiring diagram

4 Manual clutch fails. Clutch lever is damaged. Replace the clutch lever.

Rotation direction is wrong. Rotate in the direction as

indicated.

Clutch gets stuck. Turn left and right to output

R

6

the gear.

5

Press “OPEN” button but

“CLOSE” operation is

activated.

W and V lines are incorrectly

wired.

Connect the line as per the

wiring diagram.

6Motor rotates but the

device doesn't work.

Clutch compression spring

fails or lacks of elasticity. Check, adjust or replace

Clutch is in the disengaged

position. Engage the clutch correctly.

The compression spring of the

friction clutch fails or becomes

loose.

Replace or adjust the spring

pressure.

www.seco.gr

Tel. 0030 210 9846222

Fax 0030 210 9822276

Agiou Dimitriou 263, TK. 17342, Athens, Greece

7

R

Agiou Dimitriou 263, TK. 17342, Athens, Greece

Tel. 0030 210 9846222

Fax 0030 210 9822276

www.seco.gr

This manual suits for next models

5

Table of contents

Other Seco Gate Opener manuals

Popular Gate Opener manuals by other brands

SOMFY

SOMFY MASTER PRO 180 Operating and installation guide

DITEC

DITEC 0DT872 Installation manual, maintenance, use

FAAC

FAAC 415 Series manual

CAME

CAME F7000 instruction manual

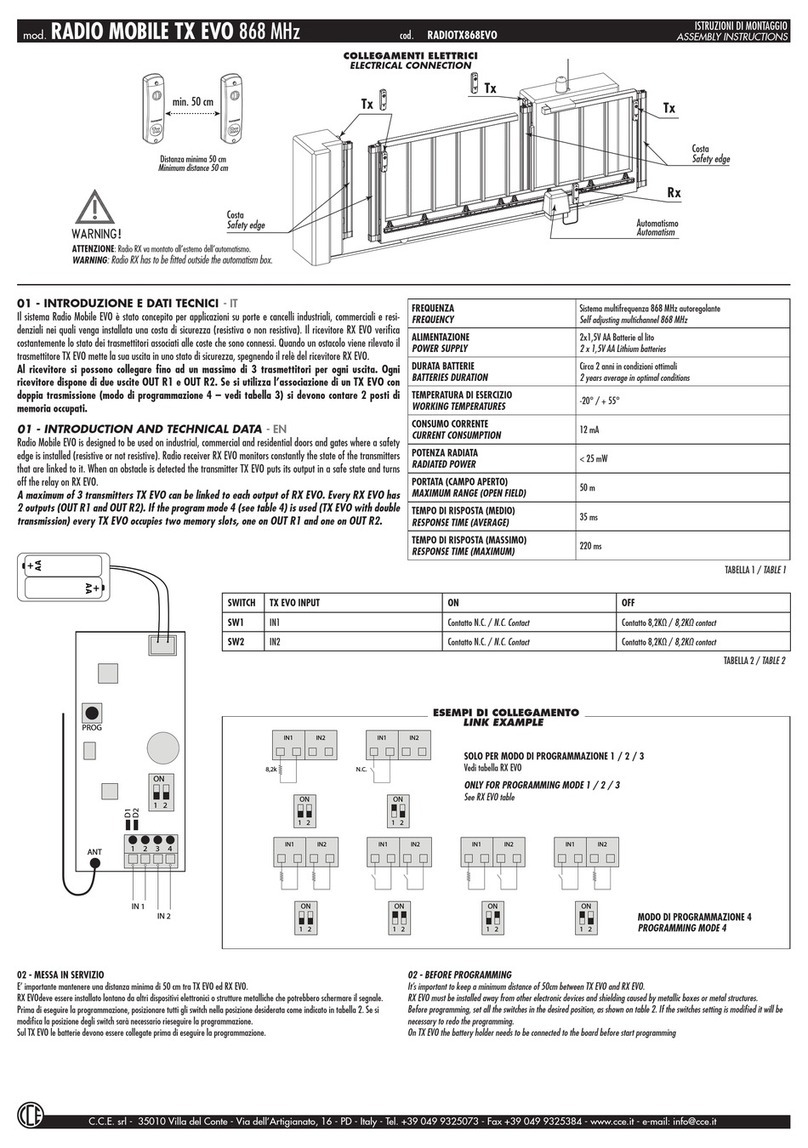

C.C.E.

C.C.E. RADIO MOBILE TX EVO Assembly instructions

La Toulousaine

La Toulousaine Intellidrive 400 Installation & programming manual

GFA

GFA ELEKTROMAT SE 6.80 FU-25,40 installation instructions

GTO

GTO E-Z GATE installation manual

Dea

Dea GULLIVER operating instructions

SOMFY

SOMFY MONOGRAM Motorised Roller/Roman quick start guide

Pro-Line System

Pro-Line System CS300 operating instructions

Chamberlain

Chamberlain MEGA SLIDE-X owner's manual