Seco EASYSHRINK 15 User manual

1

60ZFM08INUGB (07)

EASYSHRINK®15

OPERATING INSTRUCTIONS

SHRINKFIT DEVICES

2

Dear Customer,

We thank you for having purchased an Easyshrink®15 shrinking device.

This inductionshrinking device will offer you a lot of advantages:

- automatic* or programming heating cycles

- optimised cycles to shrink-grip and shrink-release tools

- localized and homogeneous heating of the clamping area

- minimal energy consumption

fast cooling of the tool and the toolholder

- clamping of carbide, HSS and steel toolshanks

These operating instructions will give you all necessary information to use this devicein the best way.

Should you need further clarifications, our sales-team stays at your full disposal.

Your Partner,

Seco Tools AB.

*Designed for Seco‘s toolholders, to be validated for other brands.

Provisions of warranty

If your product proves to be defective, although it has been used properly (in accordance with this written Operating

instructions manual), during a period of 24 months from the date of invoicing, this product will be repaired or replaced (at

Seco’s option), freeof charge.

This warranty covers the material defects. Any defect that occurs due to mishandling that is not mentioned in this Operating

instructions manual, or due to an improper maintenance, etc. is not covered. Seco’s sole liability is limited to repairing or

replacing the product. Any liability for indirect or consequential loss or damage of any kind incurred or suffered by the

customer due to a defect of the product is excluded.

3

TABLE OF CONTENT

DELIVERY CONTENT .............................................................................................................................................4

1. INTRODUCTION ............................................................................................................................................5

1.1. SHRINKING PRINCIPLE .............................................................................................................................5

1.2. SHRINKING WITH INDUCTION ....................................................................................................................5

2. RECEPTION OF YOUR DEVICE ...................................................................................................................6

2.1. TAKING DELIVERY....................................................................................................................................6

2.2. ACCESSORIES,SPARE PARTS AND OPTIONS .............................................................................................6

2.2.1. Universal sliding support...................................................................................................................6

2.2.2. Support ring......................................................................................................................................6

2.2.3. Air cooling cone ................................................................................................................................6

2.2.4. Heat focusing stopper.......................................................................................................................6

2.2.5. Depth comparator.............................................................................................................................6

2.2.6. Depth rulers for Shrinkfit depth setting..............................................................................................7

2.2.7. Protecting gloves..............................................................................................................................7

2.2.8. Complementary cooling devices.......................................................................................................7

2.3. DIMENSIONS (WHEN MOUNTED) ...............................................................................................................7

2.4. LOCALISATION OF THE DEVICE .................................................................................................................8

2.5. MOUNTING..............................................................................................................................................8

2.6. POWER SUPPLY ....................................................................................................................................10

3. EASYSHRINK®15 DEVICE: GENERAL DESCRIPTION.............................................................................11

3.1. OVERVIEW............................................................................................................................................11

3.2. KEYPAD AND DISPLAY PRESENTATION ....................................................................................................12

4. USING THE DEVICE....................................................................................................................................13

4.1. PUTTING THE DEVICE UNDER TENSION ...................................................................................................13

4.2.TURNING ON THE DEVICE.......................................................................................................................13

4.3. SHRINKING PROCEDURE ........................................................................................................................13

4.3.1. Description of the different heating modes .....................................................................................13

4.3.2. Selection of the heating mode ........................................................................................................14

4.3.3. Using programmable modes PRG1 and PRG2 ..............................................................................14

4.3.4. Preparation before shrinking cycle..................................................................................................16

4.3.5. Minimal and maximal shrinkfit assembly’s height ...........................................................................16

4.3.6. Shrinking depths to be respected ...................................................................................................17

4.4. SHRINKING A TOOL INTO A TOOLHOLDER ................................................................................................17

4.5. SHRINK RELEASE PROCEDURE ...............................................................................................................18

4.6. SHRINKING OF TOOLS WITH LARGER FRONT THAN SHANK ........................................................................19

4.6.1. Clearance between tool head and toolholder front face..................................................................19

4.6.2. Shrinking procedure for tools with larger front than shank..............................................................19

4.6.3. Shrink-releasing procedure for tools with larger front than shank...................................................20

5. COOLING.....................................................................................................................................................21

5.1.1. Piloting the cooling fans..................................................................................................................21

5.1.2. Cooling time modification................................................................................................................21

6. SAFETY PRECAUTIONS.............................................................................................................................22

7. RECOMMENDATIONS FOR USE AND MAINTENANCE ...........................................................................22

8. SAFETY FUNCTIONS OF THE EASYSHRINK®15.....................................................................................22

9. APPENDICES ..............................................................................................................................................22

9.1. TECHNICAL FEATURES...........................................................................................................................22

9.2. ELECTRICAL SKETCH .............................................................................................................................23

9.3. CE COMPLIANCE CERTIFICATE ...............................................................................................................24

4

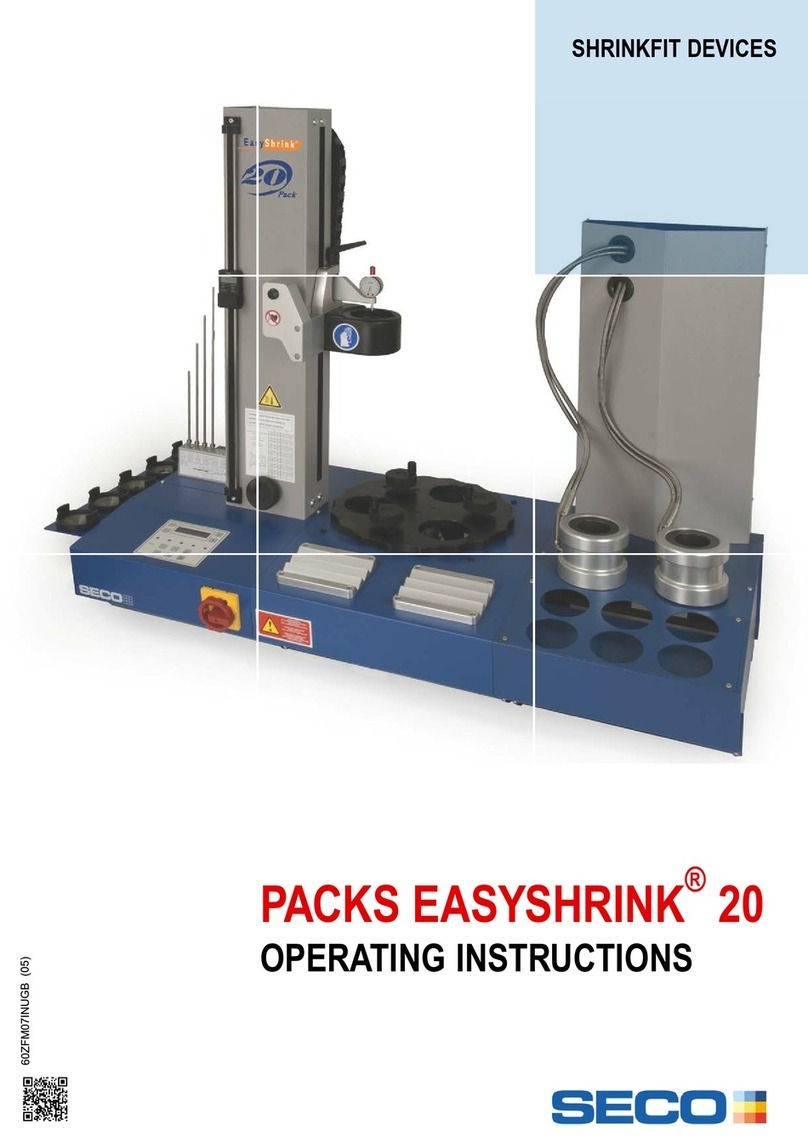

DELIVERY CONTENT

Heating column

(1 piece)

Main plate

(1 piece)

User instructions

(1 piece)

Set of 2 fixing screws and 1

cable tie

(1 piece)

Standard heat

focusing stopper

(complete set of 5 pieces)

Universal sliding

support

(1 piece)

Support ring

(1 piece)

Heat protective gloves

(1 pair)

Cooling cone

(1 piece)

5

1. INTRODUCTION

1.1. Shrinking principle

The Shrinkfit holder’s inside diameter is designed to be slightly smaller thanthe shank diameter of thecutting tool (step 0).

Using an heating system, the toolholder’s inside bore of the Shrinkfit holder is heated and expands. The tool shank can then be

slipped easily into it (step 1).

As the holder cools down, theresulting thermal contraction exerts a tremendous, uniform pressure around the entire surface of the

tool shank (step 2).

1.2. Shrinking with induction

Induction heating allows clamping tools in a few seconds. The coil offers high performance as the

energy is sprayed very rapidly and remains concentrated onthe clamping area. Therefore, there is

less energy remaining in the holder and the cooling time is decreased.

As a result, HSS tools can be shrinked and unshrinked with same thermal expansion coefficients

as the steel used for the holders.

d

1(holder)

d

1(tool)

d

1(holder)

d

1(holder)

d

1(tool)

Step 0

d1(holder) < d1(tool)

Step 1: heating

d1(holder) > d1(tool)

Step 2

d1(holder) = d1(tool)

(with constraints)

Step 2

d1(holder) = d1(tool)

(with constraints)

Step 2: cooling

d1(holder) = d1(tool)

(with constraints)

d

1(tool)

6

2. RECEPTION OF YOUR DEVICE

2.1. Taking delivery

The device you have received has been controlled andtested in ourplant according to ISO9001 specifications.

If the equipment has been stored or transported under unacceptable conditions, the equipment may be permanently damaged. In

this case the manufacturer willexclude all warranty claims andobligations.

2.2. Accessories, spare parts and options

This paragraph shows the most common accessories for this device. Please refer to the latest Machining Navigator ‘Tooling

Systems’ or latest Update for further information.

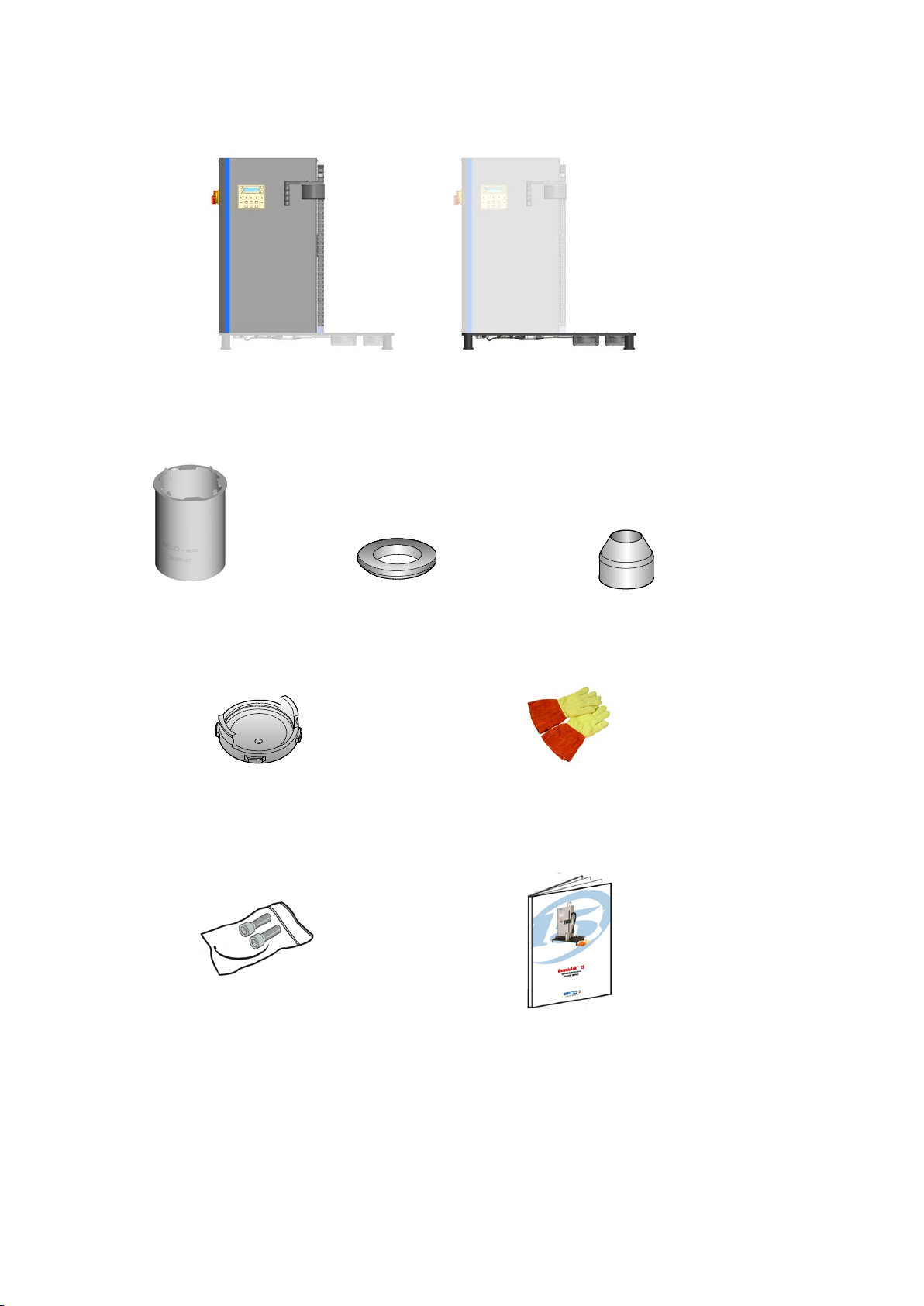

2.2.1. Universal sliding support

Designed for easy and safe displacement of the toolhoder from the shrinking slot to the cooling slots of the device.

Part N° ZFAR08T

2.2.2. Support ring

Once set on the universal sliding support, the support ring allows a direct holder positioning. Available for all types

of toolholders (SA30 to SA50,HSK25 to HSK100, Seco-Capto C3 to C8). Part N° ZFAR07xx

2.2.3. Air cooling cone

Once set on the universal sliding support, the air cooling cone focuses the air stream against the holder front end for

cooling. Part N° ZFAR03C

2.2.4. Heat focusing stopper

For positioning of the inductor housing.

Part N° Standard stoppers: ZFAT08Cxx

Part N° Split heat focusing stoppers: ZFCE252x

Part N° Locking ring for split heat focusing stoppers: ZFCM08IN000

2.2.5. Depth comparator

User friendly measuring accessory to set the position of the stop end screw (for DIN type holders), for

reliable Shrinkfit depth. The distance between the stop endscrew’s front and the holder’s front face is directly

readable on the comparator.

Part N° Z847031

Split

stopper

Standard

stopper

7

2.2.6. Depth rulers for Shrinkfit depth setting

A depth ruler is an economic alternative to the depth comparator, enabling easy setting of the stop rods

on Packs Easyshrink®20 according to a required Shrinkfit depth. The distance between stop rod’s front

and holder’s face is directly readable on the ruler.

Depth ruler size 1 (∅2,5 mm) for Shrinkfit holders dia. 3 to 5 mm, depth capacity 10 to 35 mm:

Part No. ZFCM07IN282.

Depth ruler size 2 (∅5 mm) for Shrinkfi t holders dia. 6 to 32 mm, depth capacity 20 to 75 mm:

Part No.ZFCM07IN254.

2.2.7. Protecting gloves

Direct skin contact with hot toolholders will cause severe injuries. The use of appropriate protecting gloves is

mandatory to warranty the security of youroperators. Conform to norm EN407 and EN388. Part N° ZFAG01

2.2.8. Complementary cooling devices

Complementary water cooling devices are available for faster cooling of the toolholders. Please refer to the Machining Navigator

‘Tooling Systems’.

2.3. Dimensions (when mounted)

840

880

400

50KG

8

Centering

pins

2.4. Localisation of the device

The Easyshrink®device is a table device, to be localized in a dry and clean working place, on a stable and rigid surface.

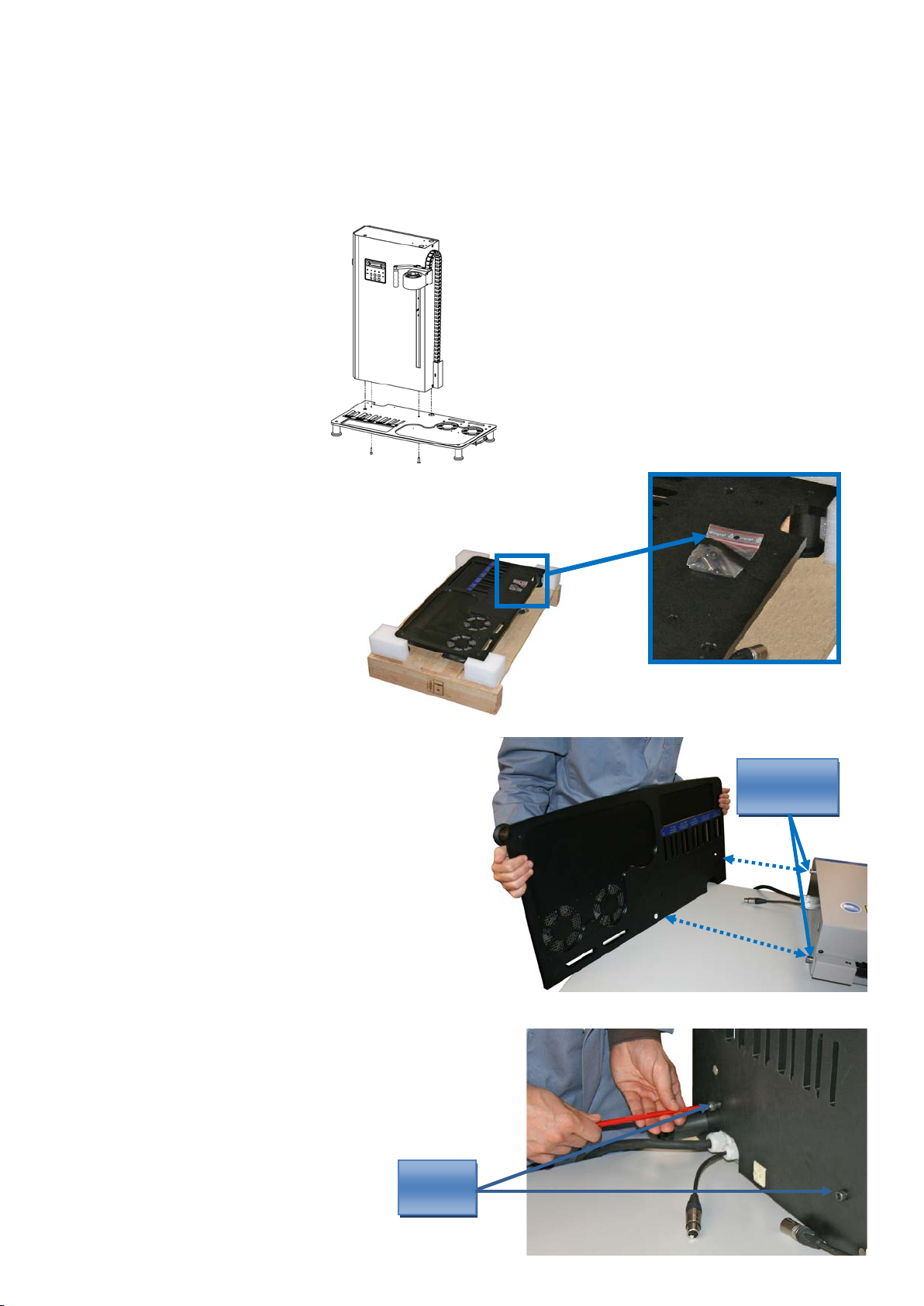

2.5. Mounting

A bag with two fixing screws and one cable tie is delivered on the main plate of the device.

Make sure you save theseparts that are required tomount the device.

1) Lay the column on a table.

2) Present the main plate against the column and fit the centering

pins in the slots of the main plate.

3) Fix the column on the main plate, using the two fixing screws.

Fixing

screws

9

4) Plug the fans’ powersupply wire in.

5) Use the provided cable tie to fix the fans’ power supply wire on

the main plate.

6) The main plate’s feet (on the back, left corner) can be set in

height to warranty the stability of the device.

‘clic’

10

2.6. Power supply

The Easyshrink®device is meant to be supplied with power according to these

specifications:

AC 3x400V + PE/ 16A/ 50-60 Hz.

A 3,5 meter cable is supplied.

Please install the appropriate male and female plugs to connect the device to your electrical network and make sure the proper

tension is delivered between each pin.

Note: A transformer for USA or Canadian voltages is available

as an optional accessory. Please contact your Seco

representative.

Name of

the pin

Designation

of the pin

Colour of the

wire

L1 Phase L1 brown

L2 Phase L2 black or grey

L3 Phase L3 black

PE Ground green & yellow

Tension in V

230

230

230

400

400

400

L1 → L2

L1 → L3

L2 → L3

Measure between the

pins

PE → L1

PE → L2

PE → L3

11

3. EASYSHRINK®15 DEVICE: GENERAL DESCRIPTION

3.1. Overview

Main swith

Inductor housing

Cooling stations

Storage rack for tools

Keypad and

display

Main plate

Storage rack for

support rings

Universal sliding

support

Storage rack for heat

focusing main plates

12

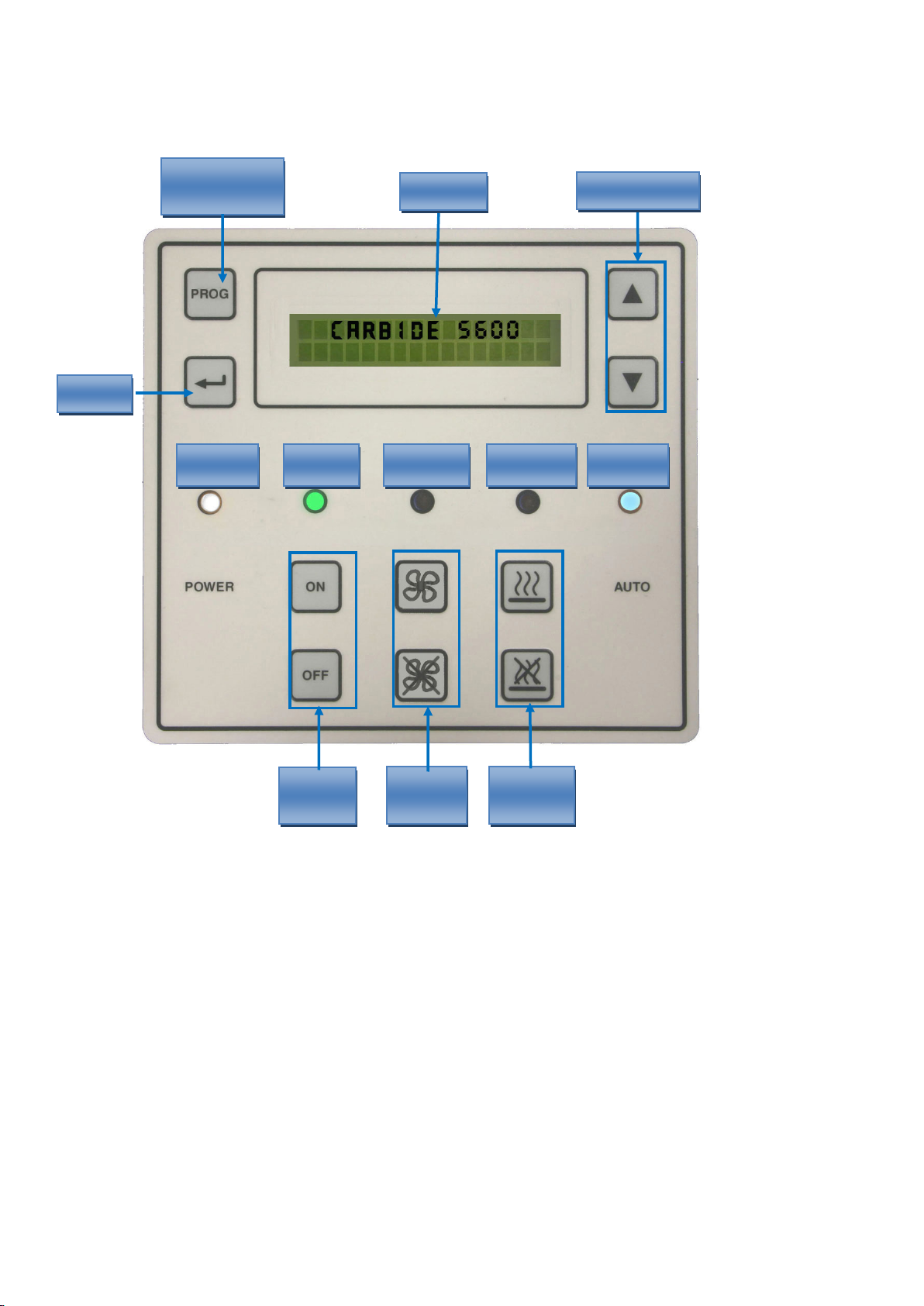

Programming

button

Heating

cycle

Fans

On/Off

Device

On/Off

Enter

Main switch

on/off

Device

on/off

Cooling fans

on/off

Heating cycle

on/off

‘auto’ mode

on/off

Display

3.2. Keypad and display presentation

Scrolling keys

13

4. USING THE DEVICE

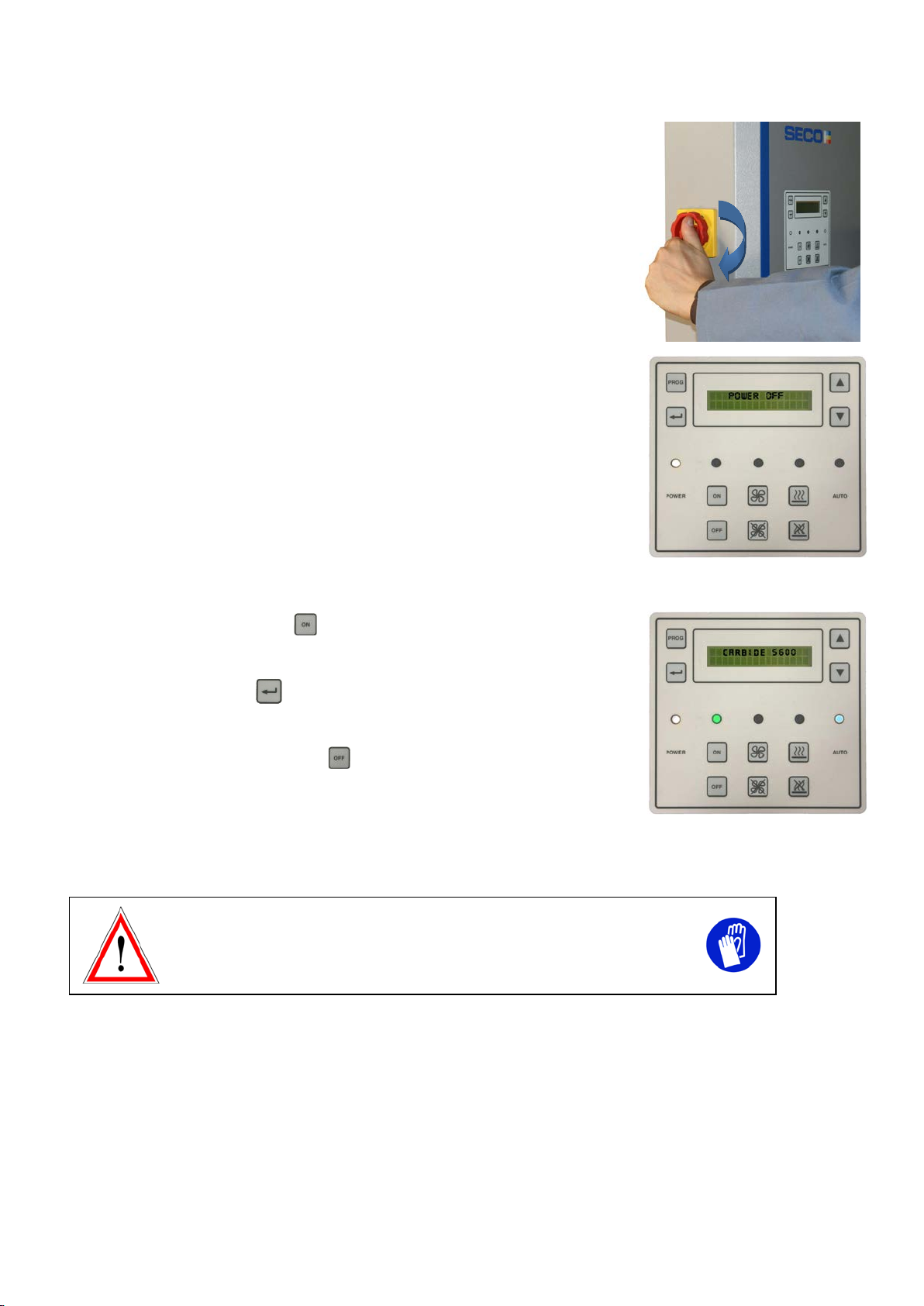

4.1. Putting the device under tension

Switch on the main interrupter of the device.

On the keypad, the white LED will go on.

Display shows: POWER OFF.

4.2. Turning on the device

Switch on the module by pressing key .

Select the required mode on the control panel according to the Shrinkfit holder front end

type (see § 4.3.) and press key

Device is ready for a shrink grip or release heatingcycle.

Switch off the control panel by pressing key .

4.3. Shrinking procedure

Wearing supplied protective gloves is imperative while handling the device

and Shrinkfit holders/tools.

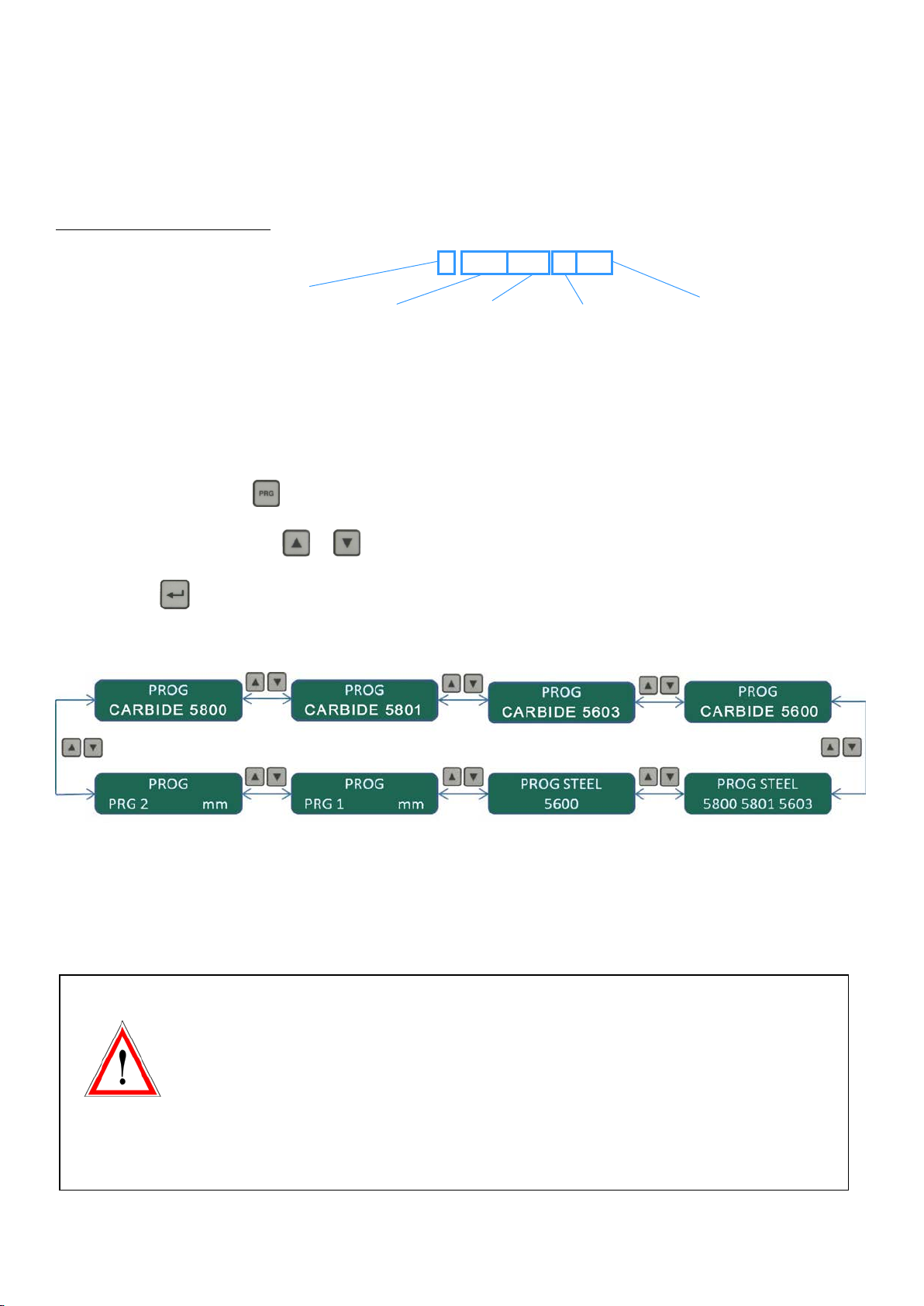

4.3.1. Description of the different heating modes

AUTOMATIC MODES: User selects the required automatic mode on the control panel, no need to select the diameter.

CARBIDE 5800: optimised shrink grip &release of carbide and heavy metal tools in type 5800 holders

CARBIDE 5801: optimised shrink grip &release of carbide and heavy metal tools in type 5801 holders

CARBIDE 5603: optimised shrink grip &release of carbide and heavy metal tools in type 5603/5803 holders

CARBIDE 5600: optimised shrink grip &release of carbide and heavy metal tools in type 5600 holders

STEEL 5600: shrink grip & release of HSS and steel tools in type 5600 holders

STEEL 5800-5801-5603: shrink grip & release of HSSand steel tools in type 5800, 5801,5603/5803holders.

14

PROGRAMMABLE MODES:User programms the suitable cycle, inone of the 50 files of modes PRG1 and PRG2, using the

control panel.

Mode PRG1: possibility to programm up to 25 customised heating cycles

Mode PRG2: possibility to programm up to 25 customisedheating cycles

Seco Shrinkfit holders Code key

E 9304 5603 10 120

4.3.2. Selection of the heating mode

• Selection of the required mode:

On the control panel, press key

Select the required mode using key or (see picture below)

Then press key to confirm your selection

Device is ready fora shrink grip or release heating cycle.

4.3.3. Using programmable modes PRG1 and PRG2

•Heating time modification

In order to prevent misuse of these modes, the modification of the heating times is secured and

an access code is required.

By security measure, heating times of PRG 1 and PRG 2 are preset to 0 second.

The access code and the procedure to modify the heating times are given on request and after

complete information about the risks.

Any change of the preset time must be made carefully, toolholder overheating makes it unusable.

In case of modification without our agreement, Seco Tools AB. cannot be held as responsible for

any damage.

Front end type

Tool fitting Ø size

E= Monobloc holder

Gauge length

Back end taper type

15

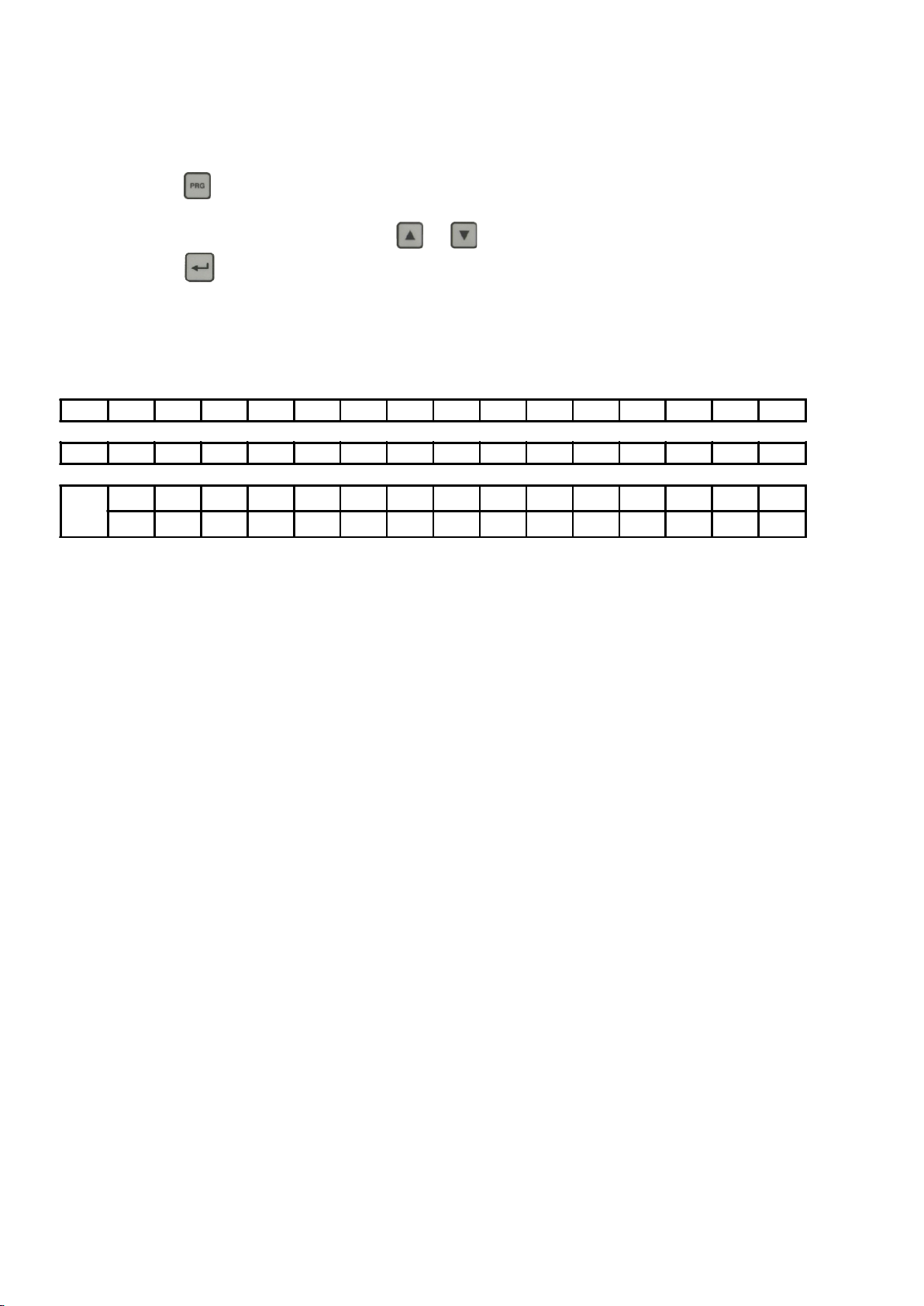

• Selection of the unit mm, inch, or mm and inch with mode PRG 1 or PRG 2:

On the control panel, select mode PRG 1 or PRG 2 (see § above)

Press two times key

Choose between mm, inch, or mm and inch using key or

Press two times key to confirm and come back to working mode.

•Diameter scrolling according to the selected unit.

Note: Diameters X1, X2, X1’’and X2’’ are used for special diameter of tools, they can be programmed for specific applications.

Scrolling in mm

Ø(mm) Ø 3 Ø 4 Ø 5 Ø 6 Ø 8 Ø 10 Ø 12 Ø 14 Ø 16 Ø 18 Ø 20 Ø 25 Ø 32 Ø X 1 Ø X 2

Scrolling in inch

Ø (inch) Ø 1/4" Ø 3/8" Ø 1/2" Ø 5/8" Ø 3/4" Ø 7/8" Ø 1" Ø 1"1/4 Ø X 1" Ø X 2"

Scrolling in mm and inch

Ø

(mm +

inch)

Ø 3 Ø 4 Ø 5 Ø 6 Ø 1/4" Ø 8 Ø 3/8" Ø 10 Ø 12 Ø 1/2" Ø 14 Ø 16 Ø 5/8" Ø 18 Ø 3/4"

Ø 20 Ø 7/8" Ø 25 Ø 1" Ø 32 Ø 1"1/4 Ø X 1 Ø X 2 Ø X 1" Ø X 2"

16

4.3.4. Preparation before shrinking cycle

1) Position theuniversal sliding support on the heating station.

2) Install on it the support ring that corresponds to the Shrinkfit toolholder’s taper.

Please refer to the latest Machining Navigator ‘Tooling Systems’ or to the

Machining Navigator ‘Update’ to select the appropriate support ring.

3) Choose the adapted heat focusing stopper that corresponds to the tool shank

diameter.

Note: 5 heat focusing stoppers are supplied with each device, capacities: Ø 3-6,

Ø 8-14, Ø 16-18, Ø 20-25, Ø 32 mm.

4) Install it into the location diameter in the inductor housing. Turn it around to

lock it on the inductor housing.

4.3.5. Minimal and maximal shrinkfit assembly’s height

Minimum height between

inductor and flange location

160 mm

Maximum height between

inductor and main plate

620 mm

Maximum ‘A length’ of the

assembly ‘holder+tool’

460 mm

Universal

sliding

support

Support ring

620

460

160

17

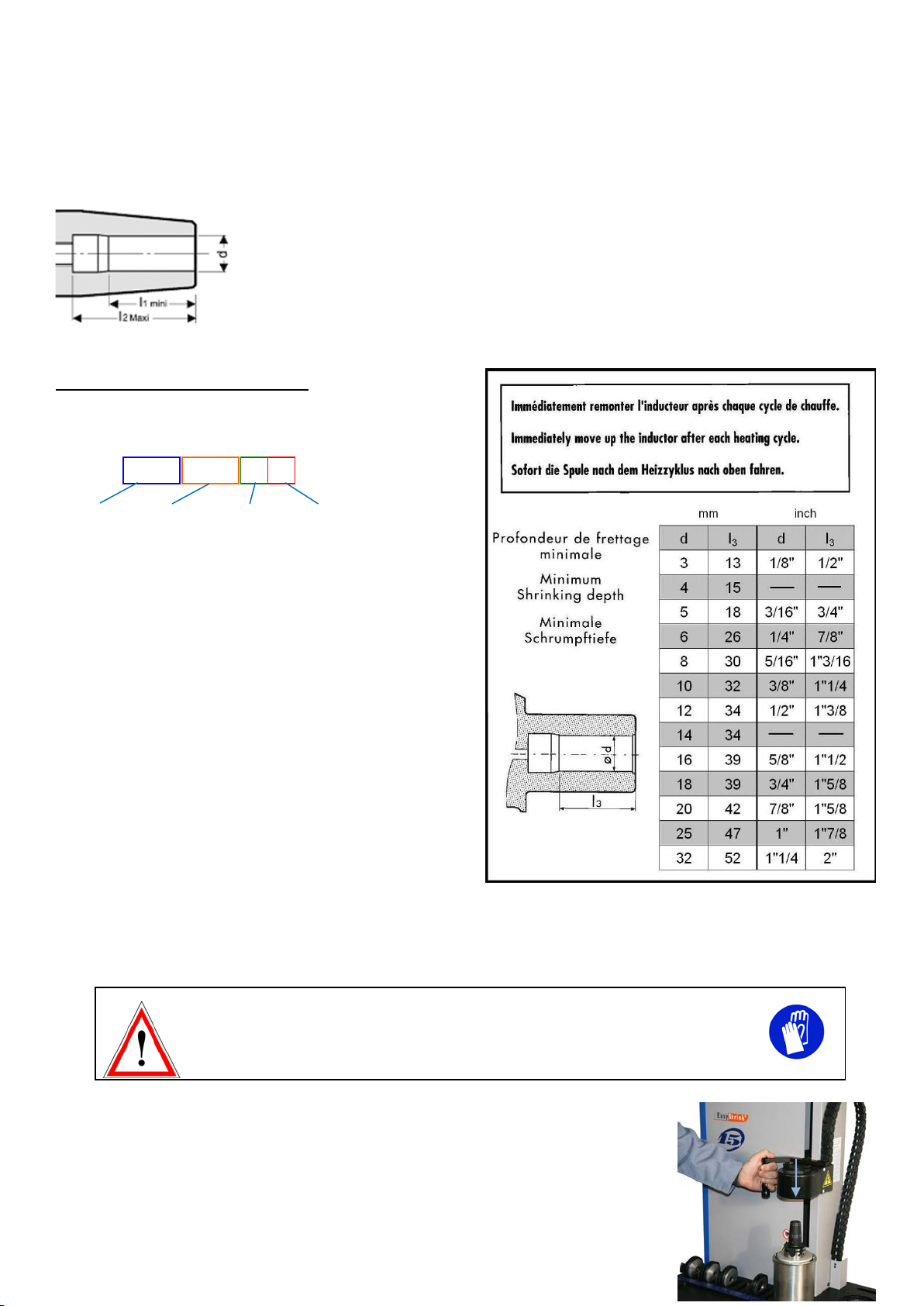

4.3.6. Shrinking depths to be respected

In order to guarantee torque transmission and to increase service life of the tool, recommended

values for shrinking depth must be respected.

Find the minimum shrinking depth from the chart below (also on the device).

Example for a Seco toolholder type 5603

The diameter d and the jauge length are indicated on the

toolholder:

The shrinking depth (depending on the position of the stop end

screw) must be set minimum to l3.

In this case, the chart indicates l3=39 mm.

4.4. Shrinking a tool into a toolholder

Wearing supplied protective gloves is imperative while handling the device and

Shrinkfit holders/tools.

Note: recommended cylindrical tool shank tolerance is h5 or h6 (maximum h5 for Ø 3 to 5 mm,

maximum h6 forØ 6 to 32 mm).

1) Move the inductor housing downwards, until the heat focusingstopper entersin contactwith the

top of the toolholder.

E9343 5603 1670

Front end

type

Tool

diameter

Jauge length

Back end

taper type

18

2) Select the appropriate heating mode (see § 4.3.2 for details).

3) Start the heating cycle by pressing key . Display is flashing during the heating cycle.

The heating stops automatically at the end of the preset time or by pressing the key . The

cooling fans are automatically triggered during15 minutes (see § 5.).

4) Fit manually the tool in the bore. The tool will be skrink-fitted within 3 to 5seconds

.

Note: on completion of the heating cycle, it is imperative to immediately remove the inductor

housing from the tool in order to avoid heat spreading into the inductor housing (risk of

deterioration).

On completion of the heating cycle and in order to prevent overheating of toolholders, the

device stays in standby mode, avoiding any handling during 30 seconds. Display will scroll

until end of the standby time.

Note : standby mode cannot be interrupted.

4.5. Shrink release procedure

Wearing supplied protective gloves is imperative while handling the device and

Shrinkfit holders/tools.

Preparation for shrink-release is the same as for shrink-fit. Introduction of the tool is replaced

by its ejection.

19

4.6. Shrinking of tools with larger front than shank

Wearing supplied protective gloves is imperative while handling the device and

Shrinkfit holders/tools.

4.6.1. Clearance between tool head and toolholder front face

Note: For tools with larger front end than shank, split heat focusing stoppers covering tool shank

diameter Ø 3-32 are available as accessories, capacities : Ø 3-6, Ø 8-14, Ø 16-18, Ø 20-25, Ø 32

mm.

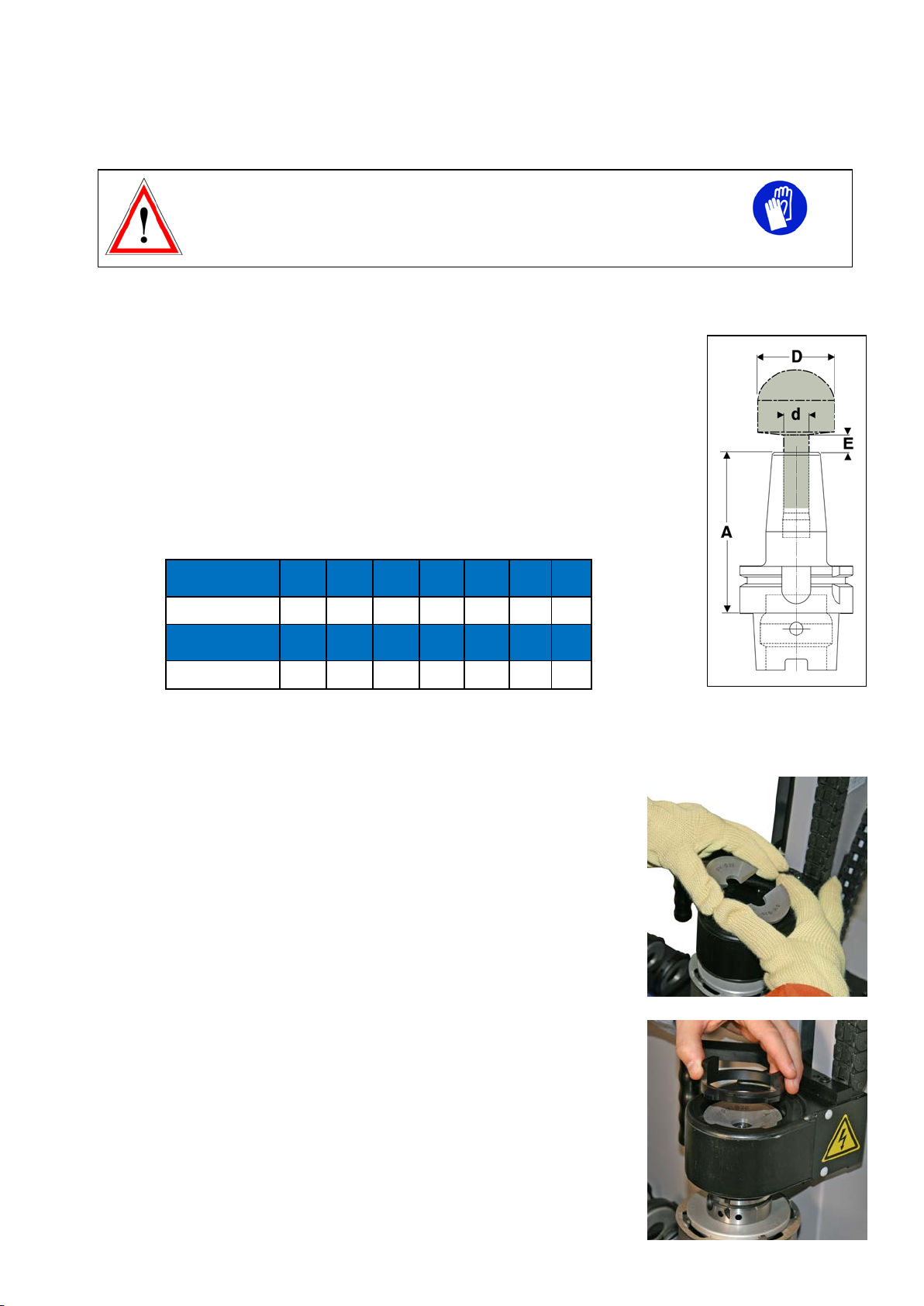

To successfully shrink/release special tools,it is necessary to observe the following conditions:

-Maximal diameter of the cutter Dis 3 x d

-Ø Dmaximum = Ø63 mm (maximum bore Ø ofinductionunit).

-Adimension = 70 mm minimum (due to the inductor housing dimension).

-Edimension changes dependingon tool shank diameter d: see chart below.

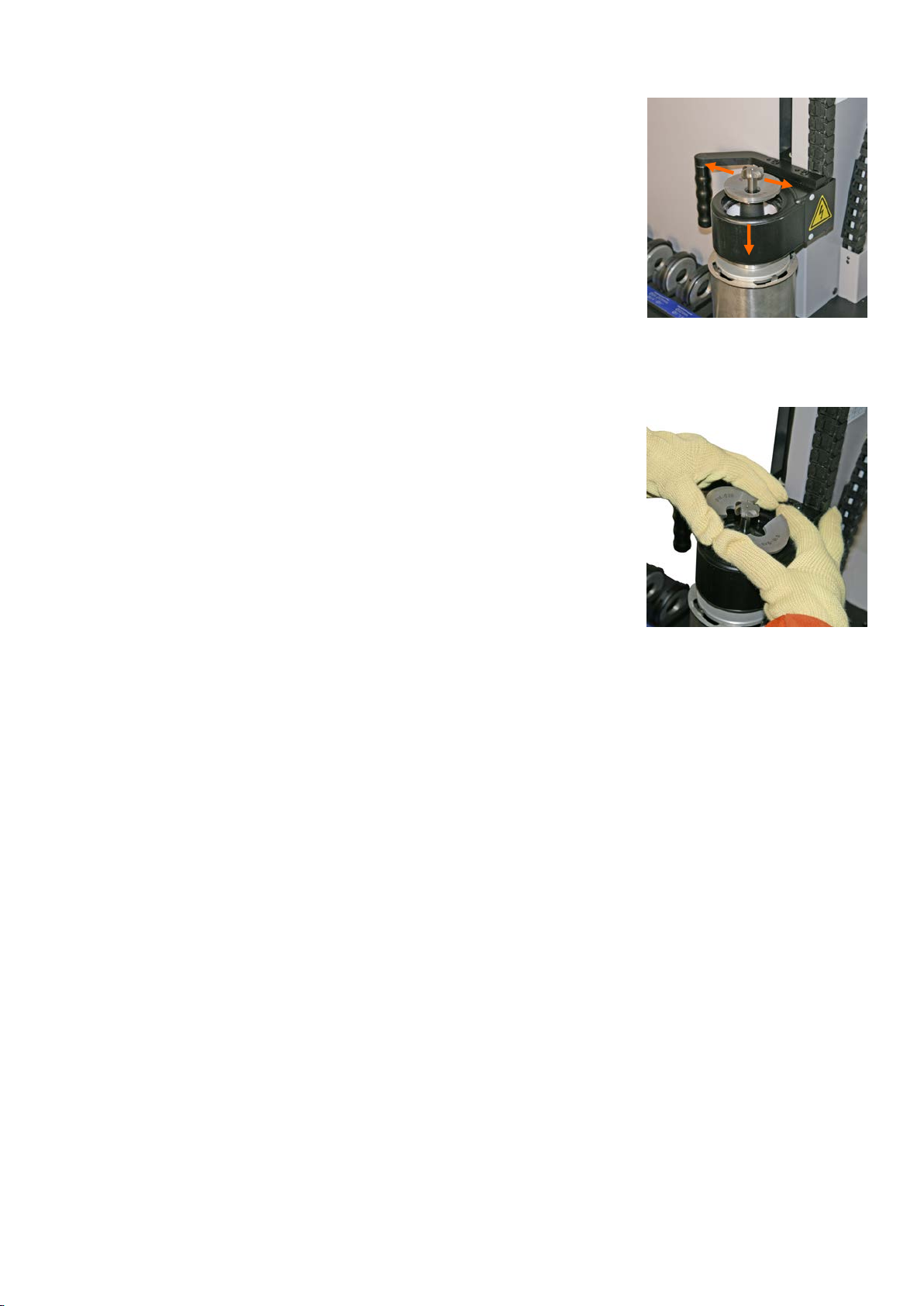

4.6.2. Shrinking procedure for tools with larger front than shank

Assemble the two split heat focusing stoppers that correspond to the tool shank Ø and install

them into the location diameter in the inductor housing.

Fit the lock ring in place to retain the split heat focusing stopper in the inductor housing.

Start the heating cycle as for a standard tool (see § 4.3.4.).

Tool shank d Ø

(mm)

3456810 12

Dimension E (mm)

66,5 77,5 78,5 9,5

Tool shank d Ø

(mm)

14 16 18 20 25 32

Dimension E (mm)

11 8,5 9776,5

20

After shrinking, remove the lock ring and move the inductor housing downwards, exposing

the split heat focusing stopper. Remove the split heat focusing stoppers (caution: they may

be hot).

Move the inductorhousing upwards to allow the toolholder to be removed.

Note: Overall height of the inductor housing limits « A » dimension to 70 minimum. Any less

than this and it will not be possible to lower the inductor housing sufficiently to gain access to

the split heat focusing stopper assembly.

4.6.3. Shrink-releasing procedure for tools with larger front than shank

1) Move the inductor housing below the front face of the toolholder and fit the appropriate

split heat focusing stopper assembly around the shank of the cutting tool.

2) Move the inductor housing upwards so that the split heat focusing stoppers seat in the

inductor housing location diameter.

3) Fit the locking ring.

4) Start the heating cycle as for a standard tool (see § 4.3.4.).

5) On completion of the heating cycle move the inductor housing upwards in order to extract

the tool from the toolholder.

After the end of the heating cycle, move the universal sliding support along with the hot toolholder on a cooling slot and cover it

with an air cooling cone or use a complementary cooling device.

2

1

Table of contents

Other Seco Industrial Equipment manuals