Securiton ASD 532 Guide

Securiton AG Alpenstrasse 20 3052 Zollikofen Switzerland T 140 425 en

ASD 532

Aspirating Smoke Detector

Maintenance

as of firmware version 01.00.08

Imprint

ASD 532, Maintenance, T 140 425 en 3 / 21

Imprint

Notice

This documentation, T

140 425, is valid only for the product described in technical description T 140 421, Sec.

1.

The document contains the maintenance instructions for the

ASD 532 aspirating smoke detector. Technical de-

scription T

140 421 is a component of the maintenance instructions.

In this document, T

140 425, only the points necessary for maintenance of the ASD 532 are described. The gen-

eral specifications of the

ASD 532 aspirating smoke detector can be found in technical description T 140 421.

© Securiton AG, Alpenstrasse 20, 3052 Zollikofen, Switzerland

Document T 140 4251is available in the following languages: German T 140 425 de

English T 140 425 en

French T 140 425 fr

Italian T 140 425 it

Spanish T 140 425 es

Portuguese T 140 425 pt

Swedish T 140 425 sv

Current edition: First edition 15.10.2015 Bmi/ksa

Notice

Validity for production version and firmware version

The following documentation is applicable only to the

ASD 532 aspirating smoke detector with the following pro-

duction version and firmware version:

Production version Firmware version

from 151015 from 01.00.08

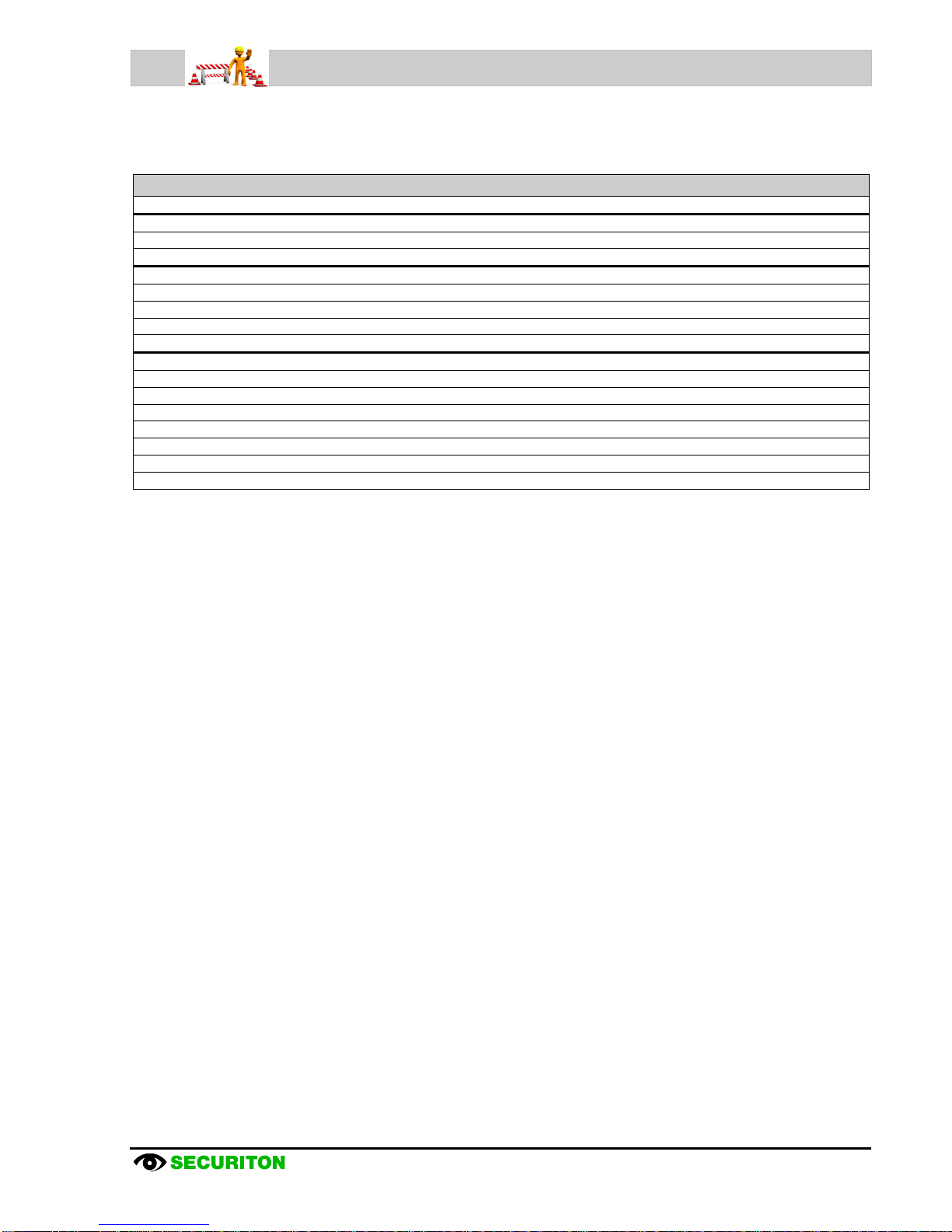

Other documents

Data sheet ASD 532

T 140 422

de / en / fr / it / es / pt / sv

Material for the sampling pipe

T 131 194

Multilingual (ED / FI)

Commissioning protocol

T 140 423

Multilingual (EDFI)

Data sheets

XLM 35

T 140 088

de / en / fr / it / es / pt / sv

RIM 36

T 140 364

de / en / fr / it / es / pt / sv

SIM 35

T 140 011

de / en / fr / it / es / pt / sv

SMM 535

T 140 010

de / en / fr / it / es / pt / sv

Aspirating Fan Unit AFU 32 mounting instructions

T 140 426

Multilingual (EDFI)

1Reference document: T 140 421

Safety information

4 / 21 ASD 532, Maintenance, T 140 425 en

Safety information

Provided the product is deployed by trained and qualified persons in accordance with this documentation T 140 425 and the

danger, safety and general information notices in this technical description are observed, there is no danger to persons or

property under normal conditions and when used properly.

National and state-specific laws, regulations and directives must be observed and adhered to in all cases.

Below are the designations, descriptions and symbols of danger, safety and general information notices as found in this docu-

ment.

Danger

If the Danger notice is not properly observed, the product and any other system parts may present a hazard for

persons and property, or the product and other system parts may be damaged to the extent that malfunctioning

results in danger to persons and pro

perty.

•

Description of which dangers may occur;

•

Measures and preventative actions;

•

How dangers can be averted;

•Any other safety-related information.

Warning

The product may be damaged if the warning information is not heeded.

•

Description of which damage can occur;

•

Measures and preventative actions;

•

How dangers can be averted;

•Any other safety-related information.

Notice

The product may malfunction if this notice is not observed.

•

Description of the notice and which malfunctions can be expected;

•

Measures and preventative actions;

•Any other safety-related information.

Environmental protection / recycling

Neither the product nor its components present a hazard to the environment provided they are handled properly.

•

Description of which parts have environmental protection issues;

•

Description of how devices and their parts have to be disposed of in an environmentally-friendly way;

•Description of the recycling possibilities.

Batteries

It is not permitted to dispose of batteries in the domestic rubbish. As the end user you are legally obliged to return

used batteries. Used batteries can be returned to the seller or taken to a designated recycling centre (e.g. a

community collection point or dealer) at no cost. You may also send them back to the seller by post. The seller

will refund the postage when you return your old batteries.

Document history

ASD 532, Maintenance, T 140 425 en 5 / 21

Document history

First edition Date 15.10.2015

Contents

ASD 532, Maintenance, T 140 425 en 7 / 21

Contents

_________________________________________________________________________________________

1General 9

1.1 Purpose 9

1.2 Abbreviations, symbols and terms 9

1.3 Opening and closing the detector housing 11

1.4 Removing and mounting the smoke sensors 12

_________________________________________________________________________________________

2Maintenance and service 13

2.1 General 13

2.2 Cleaning 13

2.3 Maintenance checks and function checks 14

2.4 Replacing units 16

2.4.1 Replacing the smoke sensor 16

2.4.2 Replacing the aspirating fan unit 16

2.4.3 Replacing the airflow sensor 17

2.4.4 Replacing the AMB 32 Main Board 17

2.5 Disposal 18

2.5.1 Materials used 18

_________________________________________________________________________________________

3Article numbers and spare parts 19

3.1 Detector housings and accessories 19

3.2 Sampling pipe and accessories 19

_________________________________________________________________________________________

4Technical data 20

_________________________________________________________________________________________

5List of figures 21

General

ASD 532, Maintenance, T 140 425 en 9 / 21

1 General

1.1 Purpose

The ASD 532 aspirating smoke detector has the task of continuously taking air samples via a sampling pipe tube network from

a monitored area and feeding the samples to a smoke sensor. Thanks to this detection method and the product’s excellent

properties under severe ambient conditions, the ASD 532 aspirating smoke detector is used wherever problems are to be ex-

pected owing to poorly accessible monitored areas or latent disturbance variables during operation such that optimal protec-

tion can no longer be guaranteed with conventional point detectors.

The SSD 532 smoke sensor is used in the ASD 532. It is available in the three following versions and sensitivity ranges:

•SSD 532-1 Alarm sensitivity range 0.5%/m to 10%/m

•SSD 532-2 Alarm sensitivity range 0.1 %/m to 10%/m

•SSD 532-3 Alarm sensitivity range 0.02%/m to 10%/m.

The ASD 532 aspirating smoke detector has two slots for additional modules. The following modules can be fitted:

•XLM 35 eXtended Line Module

•RIM 36 Relay Interface Module with 5 relays;

•SIM 35 Serial Interface Module.

1.2 Abbreviations, symbols and terms

The following abbreviations, symbols and terms are used in the Technical Description T 140 425. The abbreviations for tube

material and accessories are listed in a separate document: T 131 194.

ABS

=

Acrylonitrile-butadiene styrene (plastic)

AFS 32

=

Air Flow Sensor

AFU 32

=

Aspirating Fan Unit

AMB 32

=

ASD main board

ASD

=

Aspirating Smoke Detector

ASD PipeFlow

=

Calculation software for the sampling pipe, “ASD PipeFlow” as of Version 2.3

DIN

=

Deutsche Industrie Norm (German industry standard)

EMC

=

Electromagnetic compatibility

EN 54

=

European standards for fire alarm systems (Germany = DIN, Switzerland = SN, Austria = Ö-Norm)

FACP

=

Fire alarm control panel

FW

=

Firmware

GND

=

Supply ground (minus (-) pole)

General

10 / 21 ASD 532, Maintenance, T 140 425 en

Continuation:

HW

=

Hardware

IEC

=

International Electrotechnical Commission

Initial reset

=

First start-up on commissioning

IPS 35

=

Insect Protection Screen

LS

=

Airflow

LS-Ü

=

Airflow monitoring

Manufacturer

=

Securiton

OC

=

Open collector output

OEM

=

Original Equipment Manufacturer (reseller)

PA

=

Polyamide (plastic)

PC

=

Personal computer

PC

=

Polycarbonate (plastic)

PE

=

Polyethylene (plastic)

PVC

=

Polyvinyl chloride (plastic)

RIM 36

=

Relay interface module

RoHS

=

Restriction of Certain Hazardous Substances (eco-friendly manufacturing processes)

SIM 35

=

Serial Interface Board

SMM 535

=

Serial Master Module

SSD 532

=

Smoke sensor

SW

=

Software

UMS 35

=

Universal Module Support

VDC

=

Direct current voltage

VKF

=

Vereinigung Kantonaler Feuerversicherungen (Cantonal Fire Insurance Union, Switzerland)

XLM 35

=

eXtended Line Module

General

ASD 532, Maintenance, T 140 425 en 11 / 21

1.3 Opening and closing the detector housing

Warning about opening and closing

•

To open the detector box, use a flat-blade screwdriver no. 5 (8 mm). Smaller flat-

blade screwdrivers may

damage the material of the rotary snap locks.

•

To actuate the rotary snap locks, press them firmly

with the screwdriver towards the housing base and then

turn through 90°. The position of the lock slit shows the current status (see Fig. 1):

⇒approx. 45° angled toward detector housing corner = closed;

⇒approx. 45° angled toward detector housing edge = open.

In either position the rotary snap locks must snap into place.

Fig. 1Open, closing and securing the detector housing

The detector housing has to be opened for commissioning the ASD 532 (see T 140 421, Sec. 5.4.1).

Fig. 2Detector housing opened for commissioning

Opening / closing

A

A

AA

X/Y = 2± mm

U = 5± mm

X

UY

Locking

1. 2.

press turn

open

closed

open

closed

open

closed

open

Ethernet interface,

connection for PC

Display and

control elements

for device settings

Insulation strips

l batteryithium

HW Reset button

General

12 / 21 ASD 532, Maintenance, T 140 425 en

1.4 Removing and mounting the smoke sensors

Check the installation position when installing the smoke sensor. The connector plug of the smoke sensor must be face away

from the slots of the additional modules. The anti-twist rib on the smoke sensor case prevents an incorrect installation position.

The smoke sensor is secured inside the ASD housing using the two lock clamps. Connect the ribbon cable supplied with the

smoke sensor to the smoke sensor (large ribbon cable connector) and to the AMB 32 main board (small ribbon cable connec-

tor).

Fig. 3Removing and mounting the smoke sensors

Insect

protection

screen

Smoke

sensor

chamber

Anti-twist rib

big flat

cable connector

Flat cable

Smoke sensor

Lock clamps

Connection

for smoke

sensor

AMB 32

Maintenance and service

ASD 532, Maintenance, T 140 425 en 13 / 21

2 Maintenance and service

2.1 General

Warning

Maintenance and service work on fire alarm systems are subject in part to country

-specific laws and directives.

Maintenance and service work may be performed only by persons trained and authorised by the manufacturer of

the

ASD 532.

Depending on application, the

ASD 532 must be serviced at least once a year by th

e manufacturer or by qualified

personnel authorised and trained to do so by the manufacturer. If required (e.g. significant dirt hazard), the se

r-

vice interval is reduced to guarantee functional reliability. If filter boxes and/or filter units are used, the

service life

of the filter inserts play a role in the service interval. Depending on the level of dust and dirty in the object, filter

service may vary greatly. The optimum filter service life is to be determined on site on a case by case basis.

The operator is obligated to conclude a service agreement with the manufacturer or with an installer authorised by the manu-

facturer if the operator does not have the required service personnel trained by the manufacturer.

The statutory national directives (DIN VDE 0833-1, Cantonal Fire Insurance Union) governing maintenance must be observed.

Servicing, maintenance or inspection work on the ASD 532 may be necessary after an event (fire, fault).

If a detector housing has to be replaced due to a defect, the new ASD 532 is to undergo the same procedure as a first-time

commissioning (initial reset required). All the customer-specific configurations have to be carried out once again on the re-

placed ASD 532.

For maintenance work and function checks, observe the relevant information set out in Sec. 2.3 below.

2.2 Cleaning

Clean the detector housing with a non-aggressive cleaning agent (e.g. soap suds or similar).

Normally only the sampling holes need to be cleaned on the sampling pipe tube network. In applications where dirt is a major

issue, it may be necessary to clean inside the sampling pipe (blow out with compressed air or nitrogen). Only non-aggressive

cleaning agents may be used when cleaning the sampling pipe (e.g. soap and water or similar).

Warning

Aggressive cleaning agents (such as solvents, pure petrol or

other alcohol-

based agents) must not be used for

cleaning.

Maintenance and service

14 / 21 ASD 532, Maintenance, T 140 425 en

2.3 Maintenance checks and function checks

Notice

To avoid triggering fire incident controls, remote alerting and extinguishing areas when carrying out maintenance

work, it is

essential to block or switch off those systems beforehand.

For maintenance and function checks, carry out the following points:

1.

Block or switch off fire incident control and remote alerting on superordinate FACPs.

2.

Check that the supply voltage on the FACP is set in compliance with maintenance instructions for the control panel.

3.

Check that the sampling pipe inlet is correctly seated.

4.

Check the air outlet for any dirt or dirt and clean if necessary.

5.

If the

ASD 532 is used for equipment monitoring and plug-

in transitions from rigid to flexible pipe sections are in place,

check that the transitions are correctly seated (no leakage).

6.

Open the cover of the detector housing. Carry out the following measurements:

•Measure the operating voltage on terminal 1 (+), 2 (-) target value = 17.6 to 27.6 VDC.

•

Readout sampling pipe airflow value in switch setting Vand compare with commissioning protocol. If there is a d

e-

viation of more than half the set sensitivity (see examples and ), check the sampling pipe as follows:

- An increase in the value (more than 100%) tends to indicate pipe breakage

check the sampling pipe for

leaks (junctions, fittings, etc.)

- A decrease in the value (less than 100%) tends to indicate a pipe blockage c

heck the sampling pipe for pipe

blockage, clean as described under Item 9 or Item 10.

Set LS-Ü

sensitivity = ±20% (default); half of that = ±10%. The sampling pipe should therefore be checked if the

value is below 90% or above 110%.

Set LS-Ü sensitivity = ±50% (non-compliant with EN 54-

20), half of that = ±25%. The sampling pipe should therefore

be checked if the value is below 75% or above 125%.

7.

Switch off the ASD (pull terminal block 1/2 and if necessary 3/4 on the AMB

32). After disconnecting the ribbon cable

from the smoke sensor, carefully remove the sensor from the ASD.

8.

Use a soft, dry paintbrush to clean the inside of the smoke sensor chamber and the insect protection screen. Oil

-

free

compressed air or nitrogen can also be used for cleaning.

Warning

Do not use compressed air either to blow out or open the smoke sensor. Improper handling can affect the

response characteristics. Only the manufacturer is authorised to clean

dirty

smoke sensors. The smoke

sensors are monitored for dust and dirt; their states are displayed on the control unit. If required the smoke

sensor must be replaced.

After cleaning the smoke sensor chambers, re-insert the smoke sensor into the ASD.

Maintenance and service

ASD 532, Maintenance, T 140 425 en 15 / 21

Continuation:

9.

If it is necessary to clean the sampling pipe as indicated under

Item 6

, carry out the following measures (possibly also

according to Item 10):

•

Clean all sampling holes in the entire sampling pipe tube network. Tobacco pipe cleaners can be used for this pu

r-

pose.

•

If the sampling holes are not accessible, the entire sampling pipe tube network can be blown o

ut from the detector

housing using oil-

free compressed air or nitrogen. This is done via the manual ball valve or from the loosened

screw-junction piece (pipe connection) of the last accessory part in the direction of the sampling pipe network.

Warning

Blowing out from inside the smoke sensor chamber (through the fan) can damage the fan and is therefore

not permitted.

•

Open the accessory parts (water retaining box, filter-

box/filter unit, detector boxes) where fitted, and clean with a

soft dry paintbrush. Oil-

free compressed air or nitrogen can also be used for cleaning. Replace the filter cartridge in

the filter-box or filter unit. Close all the accessory parts again after cleaning.

•After cleaning the sampling pipe, re-connect it correctly to the ASD 532.

10.

In applications where dirt is a major issue, it may be necessary to clean the air

-

flow sensor. For this purpose (see

Sec.

2.4.3) take it out of the holder and clean with a soft, dry brush Caution

: Do not clean or touch the sensor

surface with your fingers.

Then re-insert the air-flow sensor as indicated in Sec. 2.4.3

make sure it is correctly

seated inside the holder.

11.

Switch the ASD back on again and wait until the fan has reached its optimal speed (at least 2 min).

12.

Check fault triggering, alarm

release and correct alarm transmission to the FACP. Log the completed tests in the co

m-

missioning protocol.

13.

Read out the air

-flow values Vonce again. If the values set out under Item 6

are still outside the tolerance range, the

airflow monitoring will have to be readjusted (initial reset as described in Sec. “Commissioning”, T 140 421).

Danger

A new initial reset is not usually necessary after cleaning work on the sampling holes (cleaning restores the

commissioning state). If an initial reset is necessary nonetheless after the work set out under

Item 13

, it

may

only

be carried out once it has been ensured that all possible measures for cleaning the sampling pipe

have been carried out (incl. a new filter cartridge).

If an initial reset is carried out with blocked sampling holes, there is the danger that insufficient air samples

or no air samples will be aspirated and hence the ASD 532 can no longer trigger an alarm.

14.

If maintenance or repair work was carried out on the

ASD 532

(including the sampling pipe) as a result of servicing

check, a new initial reset may be necessary.

15.

All measurements and tests carried out are to be entered and signed for in the commissioning protocol. The completed

commissioning protocol is to be stored with the ASD. If required, a copy can be made and stored in the system dossier.

16.

After completion of the servicing check, close the detector housing once again.

Maintenance and service

16 / 21 ASD 532, Maintenance, T 140 425 en

2.4 Replacing units

Warning

Defective units such as the AMB

32, smoke sensor, airflow sensor and fan may can only be replaced in the de-

energised state (with terminal block 1/2 and possibly 3/4 unplugged from the AMB 32).

2.4.1 Replacing the smoke sensor

The smoke sensor must be replaced if defective or if there is a dirt message.

To replace the smoke sensor proceed according to Sec. Fehler! Verweisquelle konnte nicht gefunden werden.. It is impor-

tant to ensure that the new smoke sensor has the same alarm sensitivity range as the old one (SSD 532-1, -2, -3).

2.4.2 Replacing the aspirating fan unit

To replace the AFU 32 aspirating fan unit, the AMB 32 main board must be removed. To do so, carefully unplug all the internal

cable connections (including fan connection). The plug-in terminals 1 to 21 do not necessarily have to be unplugged. After re-

moving the retainer screws on the AMB 32 using a Torx T10 screwdriver, the AMB 32 can be lifted up toward the cable in-

feeds and the retaining screws on the aspirating fan unit are then accessible. To dismantle the aspirating fan unit, remove the

two screws Ausing a Torx T15 screwdriver (see Fig. 4).

To mount the new fan, proceed in the reverse sequence. Important: Before screwing on the replacement fan, the supplied

spacers must be inserted into their fastening holes.

The connection cable must be placed in B.

Warning

After replacing the aspirating fan unit, it is imperative to carry out a new initial reset (see Sec.

“Commissioning

”,

T 140 421).

Fig. 4Removing the aspirating fan unit

A

B

B

Maintenance and service

ASD 532, Maintenance, T 140 425 en 17 / 21

2.4.3 Replacing the airflow sensor

Warning

When removing and mounting the airflow sensor, make sure that the sensor element is not damaged (i.e. does

not break). Do not pull on the connection wires.

After replacing an airflow sensor (new sensor), it is imperative to carry out a new initial reset.

Remove connector Aof the airflow sensor on the AMB 32. To remove an airflow sensor, gently press lock tab Btowards the

connector plug. The airflow sensor can then be carefully pulled out of its holder by gripping tab Cwith thumb and index finger

Attention: do not pull on the connection wires of the airflow sensor. To install the new airflow sensor proceed in the

reverse sequence. It is important to note the installation position (anti-twist safeguard) of the airflow sensor and that it is cor-

rectly seated in its holder. To do so, press the airflow sensor on grip tab Ctowards the housing base until the lock tab snaps

over the airflow sensor Attention: do not press on the connection wires of the airflow sensor.

Fig. 5Removing the airflow sensors

2.4.4 Replacing the AMB 32 Main Board

To replace the AMB 32 Main Board, unplug all the plug-in terminals with installation wires. Likewise, all internal cable connec-

tions (ribbon cable connectors) must also carefully be unplugged. Once the 5 fastening screws of the AMB 32 have been re-

moved using a Torx T10 screwdriver, the AMB 32 can be replaced. To install the new AMB 32, proceed in the reverse se-

quence.

Warning

When connecting the new AMB

32, take note of the correct assignment of the terminals and ribbon cable connec-

tors.

After replacing the AMB

32 it is imperative to carry out a new initial reset. Likewise, all customer-specific configu-

rations and pro

ject-specific settings from the “ASD PipeFlow”

configuration software must be carried out once

again. To do so, proceed according to Sec. “Commissioning”, T 140 421.

A

B

C

Airflow sensor Lock tab

Connector

Maintenance and service

18 / 21 ASD 532, Maintenance, T 140 425 en

2.5 Disposal

The ASD 532 aspirating smoke detector and its packaging consist of recyclable material that can be disposed of as described

in Sec. 2.5.1.

2.5.1 Materials used

Environmental protection and recycling

All raw materials and other materials used in the

ASD 532

and all the technologies used in manufacturing are

ecologically and environmentally friendly in compliance with ISO 14000.

All was

te resulting from assembly (packaging and plastic parts) can be recycled and should be disposed of ac-

cordingly.

Devices, sampling pipes or parts thereof that are no longer used should be disposed of in an environmentally

-

friendly manner.

The manufacturer of the

ASD 532

is obliged to take back any devices and sampling pipes that are defective or no

longer used, for eco

-friendly disposal. For this purpose the manufacturer has implemented a monitored and a

p-

proved di

sposal system. This service is available worldwide at cost price.

Materials used in the ASD 532:

Detector housing

PC / ABS

Smoke sensor SSD 532

Lexan (PC)

Fan housing / fan wheel

PBTP / PBTP

Fan electric motor

PU / Cu / barium ferrite powder

Circuit boards, general

Epoxy resin hard paper

Soldering process

Environmentally-friendly manufacturing compliant with RoHS

Foil on control unit

PE

Sampling tubes

ABS / PA

Fittings

ABS / PA

Clips

PA

ABS adhesives

ABS / solvent MEK (methyl, ethyl, ketone)

Danger with PVC plastics

Because PVC plastics when burned produce toxic, corrosive and environmentally damaging combustion pro

d-

ucts, the use of PVC is not permitted in many applications. The relevant

construction regulations must be ob-

served.

Ecology:

PVC plastics cannot be manufactured and disposed of without environmental impact. The recycling of PVC is

possible only up to a limited degree. Please refer to the danger notice above.

Sampling tubes

PVC, see danger notice above

Fittings

PVC, see danger notice above

PVC adhesives

PVC / solvent tetrahydrofurane, cyclohexanone

Article numbers and spare parts

ASD 532, Maintenance, T 140 425 en 19 / 21

3 Article numbers and spare parts

3.1 Detector housings and accessories

Designation Article no.

Aspirating Smoke Detector ASD 532-1

11-2000003-01-XX

Smoke sensor SSD 532-1, 0.5%/m to 10%/m

11-2000004-01-XX

Smoke sensor SSD 532-2, 0.1%/m to 10%/m

11-2000004-02-XX

Smoke sensor SSD 532-3, 0.02%/m to 10%/m

11-2000004-03-XX

eXtended Line Module XLM 35 incl. mounting set

11-2200003-01-XX

RIM 36 Relay Interface Module incl. mounting set

11-2200005-01-XX

SIM 35 Serial Interface Module incl. mounting set

11-2200000-01-XX

SMM 535 Serial Master Module

11-2200001-01-XX

SD memory card (industrial version)

11-4000007-01-XX

Printed circuit board AMB 32 main board

11-2200013-01-XX

Aspirating Fan Unit AFU 32, complete

11-2200008-01-XX

Air Flow Sensor AFS 32

11-2200007-01-XX

Insect Protection Screen IPS 35 (set of 2)

11-2300012-01-XX

Lithium battery

11-4000002-01-XX

Cable screw union M20 (set of 10)

11-4000003-01-XX

Cable screw union M25 (set of 10)

11-4000004-01-XX

UMS 35 Universal Module Support

4301252.0101

3.2 Sampling pipe and accessories

The article numbers of all the available parts for the sampling pipe (tubes, fittings, etc.) are listed in a separate document

(T 131 194).

Technical data

20 / 21 ASD 532, Maintenance, T 140 425 en

4 Technical data

Type

ASD 532

Supply voltage range

14 to 30

VDC

Max. power consumption, measured in

typical

Fan speed level III and at

14 VDC

24 VDC

ASD 532-1

Quiescent/fault

approx. 170

approx. 100

mA

Alarm

approx. 200

approx. 115

mA

additionally with 1x RIM 36

approx. 30

approx. 15

mA

additionally with 2x RIM 36

approx. 60

approx. 30

mA

additionally with XLM 35

approx. 15

approx. 5

mA

additionally with SIM 35

approx. 15

approx. 5

mA

SMM 535 (not from ASD but rather from PC via USB connection)

max. 100

mA

Switch-on current peak (caused by EMC protection elements on the ASD supply input)

approx. 5

A

for max. 1

ms

Sampling pipe length

see T 140 421

Sampling pipe diam., typical (inner/outer)

Ø 20 / 25

mm

Max. number of sampling holes

see T 140 421

Sampling hole diameter

Ø 2 / 2.5 / 3 / 3.5 / 4 / 4.5 / 5 / 5.5 / 6 / 6.5 / 7

mm

Response range

EN 54-20, class A, B, C

Protection type compliant with IEC 529 / EN 60529 (1991)

54

IP

Ambient conditions compliant with IEC 721-3-3 / EN 60721-3-3 (1995)

3K5 / 3Z1

class

Extended ambient conditions:

•Detector housing temperature range

–20 – +60

°C

•Sampling pipe temperature range

–20 – +60

°C

•Max. permissible temperature fluctuation in detector housing and sampling pipe operation

20

°C

•Max. permissible storage temperature for detector housing (without condensation)

–30 – +70

°C

•Ambient pressure difference between detector housing and sampling pipe (sampling holes)

must be identical

•Humidity ambient condition for detector housing (transient without condensation)

95

% rel. h

•Humidity ambient condition (continuous)

70

% rel. h

Max. loading capacity, relay contact

50

VDC

1

A

30

W

Max. loading capacity per OC output (dielectric strength 30 VDC)

100

mA

Plug-in terminals

2.5

mm²

Cable entry for cable Ø

Ø 5 – 12 (M20) / Ø 9 – 18 (M25)

mm

Noise level min. (if fan speed level I)

24.5

dB (A)

max. (at fan speed level III)

39.5

dB (A)

Housing material

ABS blend, UL 94-V0

colour

grey 280 70 05 / anthracite violet 300 20 05

RAL

Approvals

EN 54-20

Dimensions ASD 532-1 (W x H x D, without/with packaging)

195 x 333 x 140 / 215 x 355 x 160

mm

SSD 532-x (W x H x D, with packaging)

128 x 130 x 175

mm

Weight ASD 532-1 (without/with packaging)

1,700/1,950

g

SSD 532-x (with packaging)

335

g

Notice

Power consumption at maximum permitted voltage drop in the electrical installation (decisive value for calcu-

lating the conductor cross-section).

May cause the protective circuit to trigger immediately in the case of power supplies with overload protective

circuits (primarily in devices with no emergency power supply and output current of < 1.5 A).

Lower or higher temperature ranges are also possible subject to consultation with the manufacturer. The

manufacturer must be consulted if the device is used in the condensation range.

Table of contents

Other Securiton Smoke Alarm manuals