Securitron MXD-62 User manual

Copyright, 2000, all rights reserved •Securitron Magnalock Corp., 550 Vista Blvd., Sparks NV 89434, USA

Tel: (775) 355-5625 •(800) MAGLOCK •Fax: (775) 355-5636 •Website: www.securitron.com

An ASSA ABLOY Group company

PN# 500-12800 Page 1

Rev. A.2, 6/00

SECURITRON MODEL MXD-32, MXD-62 DOOR MOVEMENT EXIT DELAY

INSTALLATION AND OPERATING INSTRUCTIONS

1. DESCRIPTION

The MXD consists of several components which, when combined with a Magnalock, will

produce an initiate signal for delayed exit as controlled by Securitron’s XDT logic timer when

a person pushes on the door and moves it a modest distance.

The specific components within the MXD “kit” are:

A mounting sub-plate which affixes the magnet body to the door frame or header.

A sealed proximity switch array which is also mounted on the sub-plate. This changes state

to provide the initiate signal.

A stamped, stainless steel housing which covers the magnet body and proximity switch array.

A sealed permanent magnet affixed to a bracket that mounts behind the strike plate. As this

unit moves away from the proximity array, the array switches.

A special sex bolt with internal spring that permits the door to move away from the strike

plate (the strike plate remains secured to the magnet body) so as to create the initiate signal

when a person pushes on the door opening it up to one inch.

Rev. A.2, 6/00 Page- 2

Use of the MXD permits delayed exit without the need to alter the existing door latch and

hardware. The relatively large door movement that it supports (up to one inch) eliminates the

potential problem of false triggering if the door is rattled or subjected to wind loads. It is also

highly tamper resistant in the event that someone would wish to defeat its safety function of

allowing people to exit.

2. PHYSICAL INSTALLATION

2.1 DETERMINING HORIZONTAL OR VERTICAL MOUNT AND APPLYING TEMPLATE

The MXD can be mounted horizontally under the frame header or vertically along the frame.

Once you have selected the orientation for your installation, apply the template to set your

hole drilling positions. To apply the template, close the door (be sure it latches) and note that

the template has a folding line on it. The magnet mounting “sub-plate” is on one side of the line

and the strike plate/permanent magnet bracket is on the other. Position the fold in the template

along the edge the door stop makes with the door surface so that the sub-plate portion of the

template extends on to the door stop and the strike/permanent magnet bracket portion extends

on to the door surface. If you have a swing through type aluminum frame glass door, there

is no door stop so you simply position the template fold line on the edge between the door

surface and frame stile. In planning your installation for this type of door, a special

consideration comes into play. First, before drilling any holes, you want to be sure that the

aluminum door rail is wide enough to support the sex bolt. The MXD sex bolt is 1” (25MM)

diameter which is much thicker than normal magnetic lock sex bolts. This type of door is made

with extrusion widths which vary widely but some are so narrow that you can only mount the

MXD sex bolt when you are using the model 32 lock. Some others will accept a model 62 lock

but only when you are using the offset strike.

To determine in advance whether your door and the Magnalock that you intend to use will

accept the MXD sex bolt, just hold the template so that you can visually see the center point of

where the sex bolt will go into the door rail. Assure yourself that a 1” diameter hole around this

point will not strike the glass or any support rods internally.

Note: if you have an aluminum frame glass door with a blade stop, see the next section as the

template is used differently. Otherwise, the template will work on horizontal or vertical mounts

and on left hand or right hand doors but be sure that the edge of the template is flush to the

corner of the door stop for best mounted appearance (the MXD housing will reach to the corner

of the door stop).

Tape the template into position and using a center punch, mark the hole locations on the door

and frame. The template will indicate the number and positions of the hole locations as well as

the hole diameters. This depends on which Magnalock type is being used. Note that if the door

stop is narrow, you may need to add a filler plate to create a wide enough mounting surface for

the sub-plate.

2.2 TEMPLATE USE ON AN ALUMINUM FRAME GLASS DOOR WITH BLADE STOP

A blade stop is so narrow (around 1/8”) that nothing can be mounted on it. Therefore, you

cannot place the folded edge of the template in the corner made by the stop and door surface

as you will not be mounting on the stop. You will be mounting the sub-plate adjacent to the

stop directly on the frame extrusion. To use the template in this exceptional situation, cut it with

a scissors along the fold line. To mark the strike plate/permanent magnet bracket holes, open

the door slightly and insert the template behind the blade stop until it just touches the door

frame. Then allow the door to fully close (this will capture the template). You can then

Rev. A.2, 6/00 Page- 3

accurately punch your mounting holes for the strike plate/permanent magnet bracket just as if

the blade stop was not present.

To mark the holes for the sub-plate, you will use the other half of the template. Normally, you

would position its fold line edge to rest against the door surface but the blade stop is in the way.

Simply measure the distance from the door surface to the surface of the blade stop and

“subtract” that distance from the template half by either cutting the template or re-folding it. The

distance is usually around 3/8” (9.5MM) but it will vary from door to door depending on the

thickness of the blade stop and the spatial point at which the door is closed.

An alternate method for mounting the sub-plate dispenses with the template half and uses the

sub-plate as its own template. To employ this method, close the door and measure back from

the surface of the door past the blade stop 5/8” (16MM) for a model 32 Lock or 9/16” (14MM)

for a model 62 Lock. The best way to do this is to make two measurements and mark two

points each of which is the correct distance away from the surface of the door. Then a line can

be drawn between the two points. The sub-plate may be used as a straight edge for drawing

this line.

Align the front edge of the sub-plate to this line and you have achieved the correct backset.

To set the lateral position of the sub-plate, move it away from the frame corner about 1/8”

(3MM). This will allow the housing cover to fit over it and still produce an attractive mount that

appears to reach to the frame corner. Then mark and drill the mounting holes for the sub-plate.

2.3 IF THE DOOR IS THINNER OR THICKER THAN STANDARD

The MXD sex bolt is dimensioned to precisely fit a 1 3/4” (44.5 MM) thick door which is a

common size. If the door is a different thickness, contact the factory. Securitron can supply

washers for a thinner door, which go under the head and key in to the anti-rotation pins while

including new anti-rotation pins. For a thicker door, the bolt may be partially unscrewed to

expand it for use with up to a 2” thick (51MM) door. If you do this, be sure to install Threadlock

on the threads (Threadlock is furnished in a capsule with the MXD). When the bolt is

“expanded” to suit a thicker door however, its ability to allow to door to move for delay initiation

is proportionately reduced. The factory, however, can supply spacers to adapt the bolt to thicker

doors while retaining full door movement distance.

2.4 MOUNTING THE PERMANENT MAGNET BRACKET, MXD SEX BOLT AND STRIKE

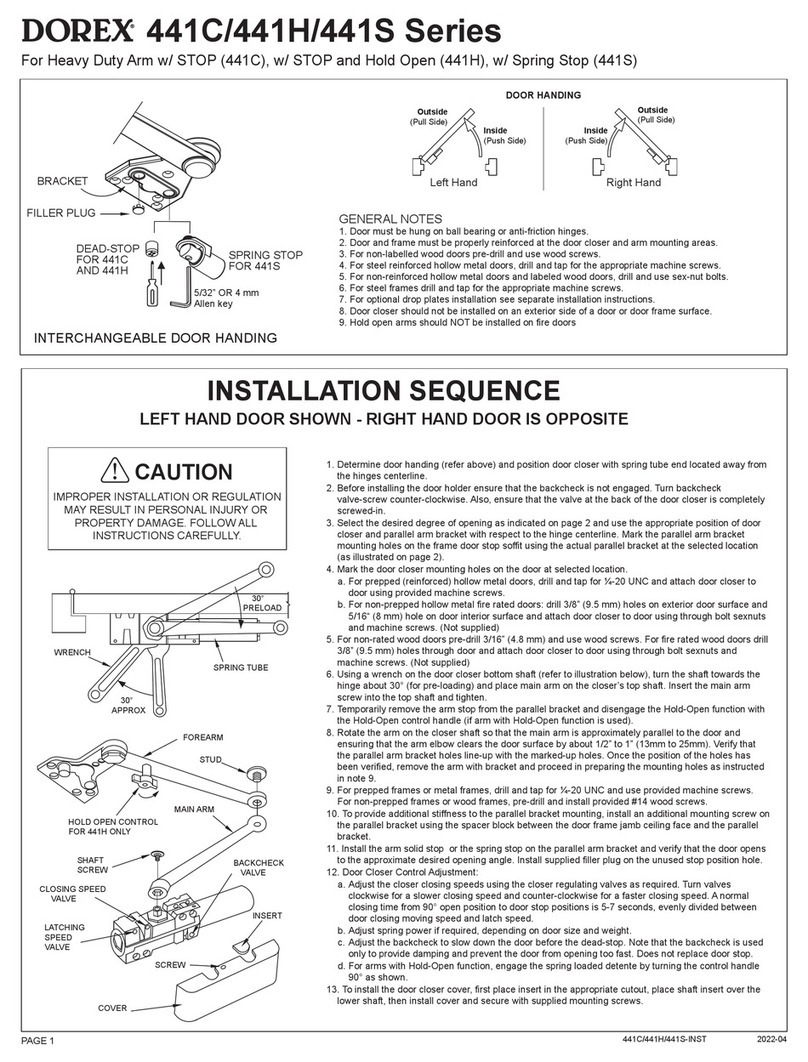

Note the assembly drawing in Figure 1. The first step after all the holes are drilled from the

template is to install the permanent magnet bracket. The model 62 version comes with four

self tapping screws to hold the bracket to the door and the model 32 version comes with two.

Note that this bracket is not handed. It can be flipped to place the permanent magnet

(concealed in an aluminum block) either to the right or the left to line up with the proximity switch

array on the sub-plate. The proximity switch array can also be transferred to either side of

the sub-plate (the holes are drilled for either position). The reason for this flexibility is to

maximize wiring options. In the case of a concrete filled header, for example, the cable can

not usually be pulled up into the header. A flex conduit fitting can be attached to either end of

the cover and the proximity switch array and permanent magnet pack would then be positioned

on the opposite side of the fitting.

Your next task is to mount the special MXD sex bolt. Be sure you have checked the previous

Section which covers a situation that deviates from standard sex bolt installation. Then, note

that the bolt includes two pins under the head which will go in two separately drilled holes for

anti-rotation. The pins act as their own template. Unscrew the threaded base plate of the bolt

and insert the bolt into the 1” hole which you should have previously drilled. Tapping the bolt

head will cause the pins to mark the door. Remove the bolt and drill 3/16” (5MM) diameter

Rev. A.2, 6/00 Page- 4

holes for these anti-rotation pins. Then, reinstall the sex bolt head, install some Threadlock

from the capsule on the sex bolt base plate threads and screw in the base plate

Next, install the roll pin bushings into the holes previously prepared for them and install the long

(2”) roll pins into the strike plate. Do not use the shorter roll pins delivered with the

Magnalock. Then, place the flathead strike mounting screw through its plastic bushing and

through the strike plate. On the other side of the plate, push three rubber washers and one

steel washer onto the strike mounting screw as shown in Figure 1. To screw this complete

assembly into the MXD sexbolt, you have to follow a special procedure to prevent the female

threaded shaft in the MXD sexbolt from spinning. First, apply Threadlock onto the strike

mounting screw threads and then Insert the screw into the MXD sexbolt and turn it a couple of

times to catch a few threads. Then pull on the strike plate so that the spring loaded female

threaded shaft in the sexbolt comes out. Hold it out against its spring pressure by rotating the

strike a bit so that the roll pins no longer go into their bushings but hit the permanent magnet

bracket. This will allow you to get a vise grip onto the female threaded shaft in the MXD sexbolt.

Turn the strike mounting screw a couple of more turns and then re-rotate the strike so that its

roll pins again insert into their bushings. Then finish tightening the strike mounting screw but

don’t over-tighten so that the rubber washers become compressed.

FIG. 1: STRIKE PLATE MOUNTING ASSEMBLY

SEXBOLT

MXD

STRIKE

FLATHEAD

SCREW

ROLL PINS

3 X RUBBER

WASHERS

DOOR

WHITE PLASTIC

BUSHING

WHITE PLASTIC

BUSHINGS

PERMANENT MAGNET

PERMANENT MAGNET

BRACKET NOTE: MXD-62 IS SHOWN. MXD 32

FOLLOWS THE SAME CONCEPT BUT

IS PHYSICALLY SMALLER.

STEEL

FLAT

WASHER

BASE

PLATE

APPLY

THREAD-LOCK

APPLY

THREAD-LOCK

2.5 MOUNTING THE SUB-PLATE

Using the template, you should have previously marked and drilled mounting holes for the sub-

plate. You have been supplied with an array of fasteners and because doors and stops will

vary, the selection of fasteners will vary from installation to installation. Note the following

points, however: Machine screws into blind nuts are much stronger than sheet metal screws so

they should be used for primary mounting with the sheet metal screws in a “helping” role.

Review the section on magnet mounting in your Magnalock manual to see how to mount and

collapse the blind nuts. Also, note that the hole preparation on the sub-plate allows for the use

of flat head or socket cap screws without the need for any washers.

Rev. A.2, 6/00 Page- 5

2.6 MOUNTING THE MAGNET BODY AND COVER

As you prepare to mount the magnet body, note that the cable runs along the milled slot and

then exits into the space between the sub-plate and cover. Drill a wireway hole to pull the cable

into the frame anywhere on or near the sub-plate slot. Then mount the magnet body utilizing

the 1 3/4” (model 32) or 2 1/2” (model 62) socket cap machine screws supplied with the housing

together with the washers. Don’t use the machine screws supplied with the Magnalocks as

they are too long. Do use the gold washers (furnished with the Magnalock hardware pack)

under the heads of the socket cap screws which mount the magnet body.

Next, test the installation. Make sure that the strike plate comfortably contacts the magnet

face as the door closes. If it does not, the outward projection of the strike plate should be

adjusted by adding or subtracting rubber washers. Next, verify that the door smoothly opens

and recloses the roughly one inch of movement that is permitted by the spring loaded sex

bolt. If the sex bolt appears to “drag”, the door and frame/header may be out of square as can

be the case with older buildings. This situation can be alleviated by slightly loosening the

magnet mounting screws which gives the magnet some ability to “tip” back into a square

condition. Alternately, shims may be placed under the appropriate edge of the sub-plate to

square up the installation.

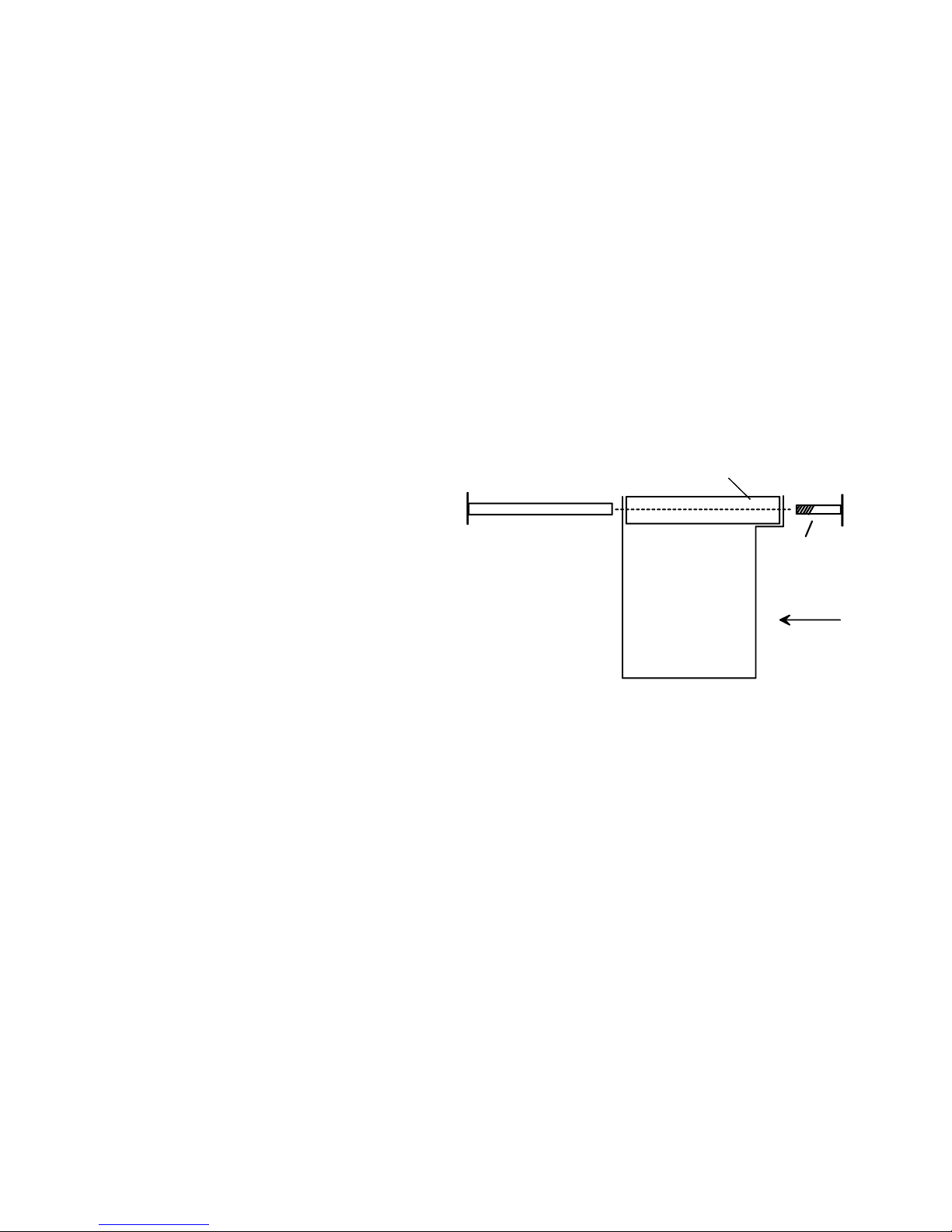

Finally, the cover mounts utilizing the binder

posts and matching screws. Do not mount

the cover yet as you will want to check

adjustment of the proximity switch array.

Mounting the cover is the final step when

everything else is complete. When you do

mount the cover, the long binder post

inserts into the cover and goes through the

corresponding hole in the sub-plate. See

the drawing to the right. The matching

screw secures it. Note that the screw

affixes the binder post from the side of the

cover that includes the opening for the

Magnalock face. This is so the blank head of the post faces away from the door. This reduces

the risk of tampering and looks better. If you have an aluminum frame glass door with a

blade stop, you will have to drill through holes through the blade stop (or remove a small

section) to pass the binder posts though for final cover mounting.

3. WIRING THE MXD

The sole purpose of the MXD is to send an initiate signal to Securitron’s model XDT delayed

exit logic timer. The signal is furnished from the two flying leads attached to the proximity switch

array on the sub-plate. These two wires are closed when the door is in the normal closed

position and they open when the door is pushed open approximately one inch which takes up

the slack in the assembly provided by the MXD sex bolt. The leads should be pulled up into the

same hole you make in the sub-plate with the Magnalock cable. They connect to terminals “+”

and “IN” on the XDT circuit board (see EXD instructions).

4. ADJUSTING THE DOOR MOVEMENT STROKE

When you have finished wiring of the complete door installation, put the door through its delayed

exit sequence several times by slowly opening the door to initiate delay. The factory set position

SUB-PLATE

COVER

BINDER POST SCREW

OPENING

FOR MAGNET

Rev. A.2, 6/00 Page- 6

of the proximity switch array should allow considerable door movement prior to the delay

starting. The benefit of this large movement (approximately 1”) is the avoidance of false

initiation through (for example) the door being rattled from the outside or moved by the wind.

The movement stroke can be reduced by loosening the screws that hold the proximity switch

array to the sub-plate and sliding the array farther from the door. Securitron recommends that

this be done only in special situations. Examples would be if the door will not physically move

far enough to reliably initiate delay without reducing the stroke because the door is thicker than

1 3/4” and you have not added a spacer to the MXD sex bolt (see Section 2.3.1) or if you

deliberately want to mechanically limit the amount of door movement because of high security

concerns for that door (you wish to avoid the possible insertion of a crowbar).

5. REDUNDANT OPERATION AND TAMPER PROOFING

The proximity switch array contains three proximity switches for the following reasons. Two are

wired such that if either switch de-energizes as the permanent magnet is separated from the

switch array, the delay initiate signal will be given. This provides redundant reliability of safe

egress operation as single component failure will not stop the MXD from allowing egress.

The third proximity protects against a certain type of tampering. It is wired such that if another

permanent magnet is brought near to it, it will initiate the delay. It is positioned so that it never

gets close enough to the permanent magnet pack on the door to trigger. A building guard

however may wish to defeat the function of the MXD in letting people go out, either because he

imagines that he is doing a useful thing by increasing security (at the expense of life safety) or

because he wishes to avoid having to respond to door alarms. If the guard comes to

understand that a permanent magnet is mounted behind the strike and that separation of this

magnet pack from the lock housing initiates the delay signal, he may try to defeat this function

by placing an external magnet around the housing. This will generally result in the delay

initiating from the third “tamper” proximity unit. The MXD therefore includes a strong defense

against tampering with its safety function. This function should nevertheless be periodically

tested by building management as maintenance of life safety should be the paramount

concern.

Rev. A.2, 6/00 Page- 7

MAGNACARE LIMITED LIFETIME WARRANTY

SECURITRON MAGNALOCK CORPORATION warrants that it will replace at customer’s request, at any time for

any reason, products manufactured and branded by SECURITRON.

SECURITRON will use its best efforts to ship a replacement product by next day air freight at no cost to the

customer within 24 hours of SECURITRON’s receipt of the product from customer. If the customer has an account

with SECURITRON or a valid credit card, the customer may order an advance replacement product, whereby

SECURITRON will charge the customer’s account for the price of the product plus next day air freight, and will

credit back to the customer the full amount of the charge, including outbound freight, upon SECURITRON’s receipt

of the original product from the customer.

SECURITRON’s sole and exclusive liability, and customer’s sole remedy, is limited to the replacement of the

SECURITRON product when delivered to SECURITRON’s facility (freight and insurance charges prepaid by

customer). The replacement, at SECURITRON’s sole option, may be the identical item or a newer unit which

serves as a functional replacement. In the event that the product type has become obsolete in SECURITRON’s

product line, this MAGNACARE warranty will not apply. This MAGNACARE warranty also does not apply to

custom, built to order, or non-catalog items, items made by others (such as batteries), returns for payment,

distributor stock reductions, returns seeking replacement with anything other than the identical product, or products

installed outside of the United States or Canada. This MAGNACARE warranty also does not apply to removal or

installation costs.

SECURITRON will not be liable to the purchaser, the customer or anyone else for incidental or consequential

damages arising from any defect in, or malfunction of, its products. SECURITRON does not assume any

responsibility for damage or injury to person or property due to improper care, storage, handling, abuse, misuse, or

an act of God.

EXCEPT AS STATED ABOVE, SECURITRON MAKES NO WARRANTIES, EITHER EXPRESS OR IMPLIED, AS

TO ANY MATTER WHATSOEVER, INCLUDING WITHOUT LIMITATION THE CONDITION OF ITS PRODUCTS,

THEIR MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE.

SECURITRON MAGNALOCK CORP., 550 Vista Blvd., Sparks NV 89434 USA

Tel: (775) 355-5625 l(800) MAGLOCK lFax: Mkt. (775) 355-5636, Fax: Admin. (775) 355-5633

An ASSA ABLOY Group company

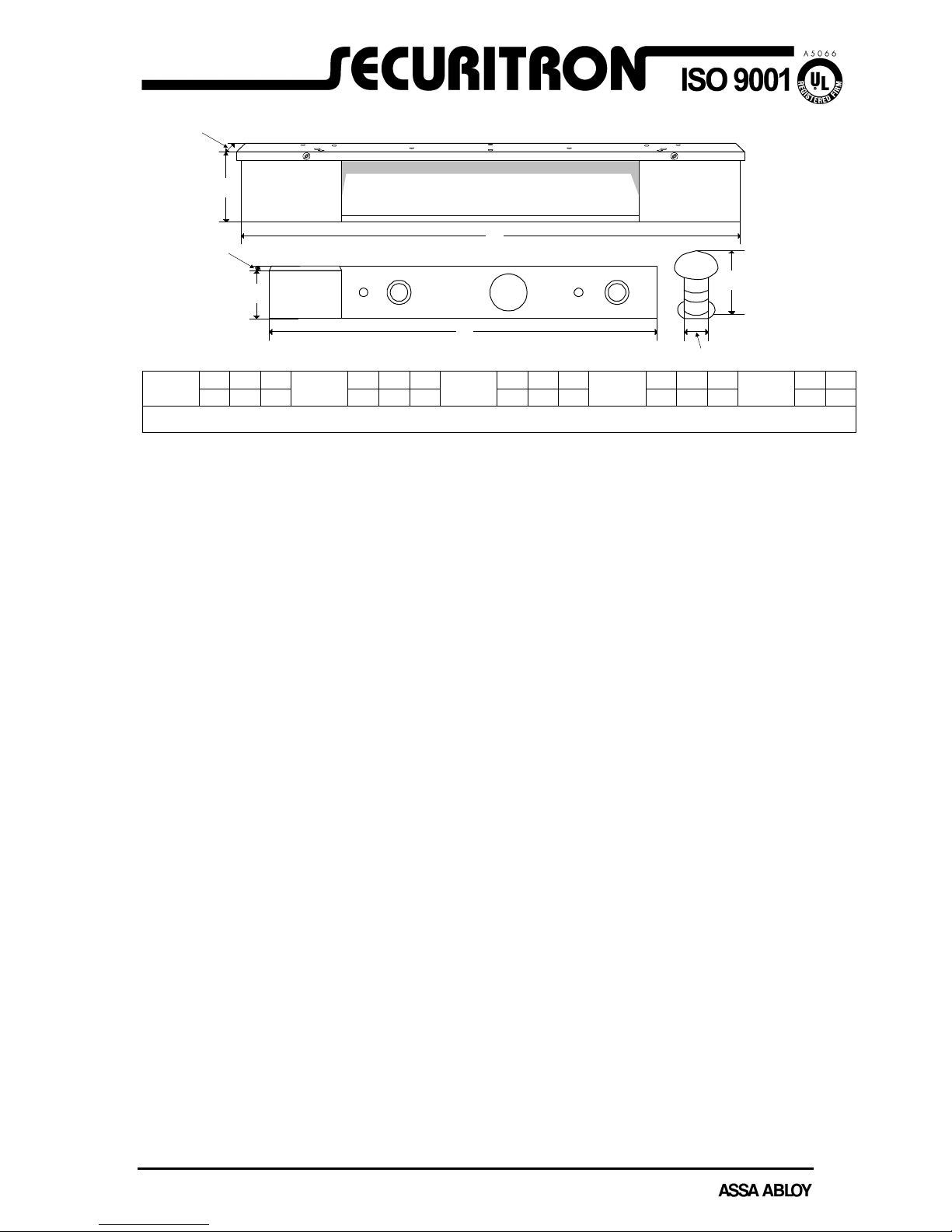

A

13

B

2.5

C

2.1

MODEL

MXD-32

HOUSING

NOTE: ALL DIMENSIONS IN INCHES. FASTENERS NOT SHOWN

A

B

CA

B

C

B

A

A

9.375

B

1.625

C

.875

MODEL

MXD-32

BACK PLATE

A

13

B

3.5

C

2.6

MODEL

MXD-62

HOUSING

A

9.375

B

1.625

C

.875

MODEL

MXD-62

BACK PLATE

A

1

B

3

MODEL

MXD-32/62

SEX BOLT

DOOR MOVEMENT HARDWARE MXD-32/62:

The Door Movement Hardware shall be produced by an ISO 9001 certified manufacturer. The door

movement hardware shall be of a modular nature and not an integral part of the magnetic lock. It shall

consist of an aluminum sub-plate for lock mounting, an adjustable magnetic switch for system initiation, a

spring loaded plunger sex bolt (to allow for door movement), a strike armature sub-plate with permanent

magnetic actuator and a stainless steel assembly cover for aesthetics and increased security. The door

movement hardware shall be tolerant to door play and shall be adjustable to allow a full 3/8” to a full 1” of

door movement to accomplish delay system initiation.

Securitron model MXD-32/62 door movement hardware.

MXDspc.doc

Rev. 5/99

This manual suits for next models

1

Table of contents

Popular Door Opening System manuals by other brands

Norton

Norton 8000 Series installation instructions

hawa

hawa HAWA-Motronic 60 Installation and commissioning instructions

Langer & Laumann

Langer & Laumann QKS6 user manual

CornellCookson

CornellCookson FS-150EP Series Installation instructions and operation manual

AGS

AGS Opera Bit user guide

Uaccess

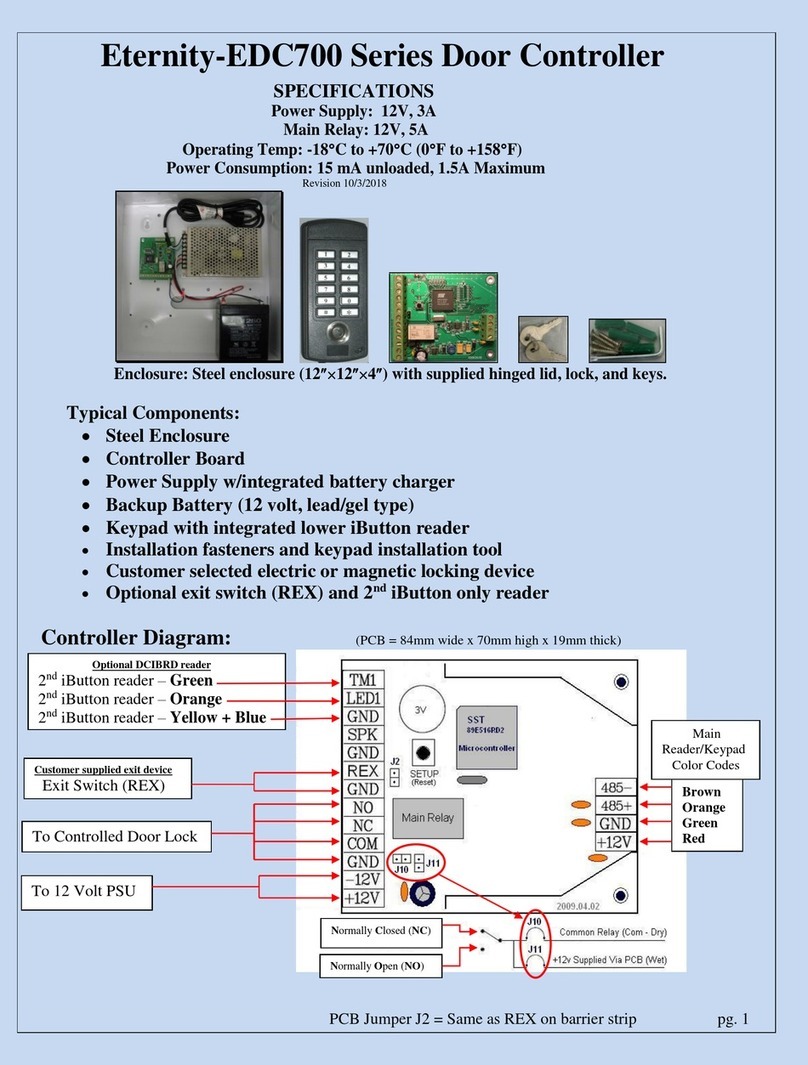

Uaccess Eternity EDC700 Series Installation

drive mobil

drive mobil Doormatic Operating instructions and safety guide

Automatic Technology

Automatic Technology DOMINATOR EasyRoller instruction manual

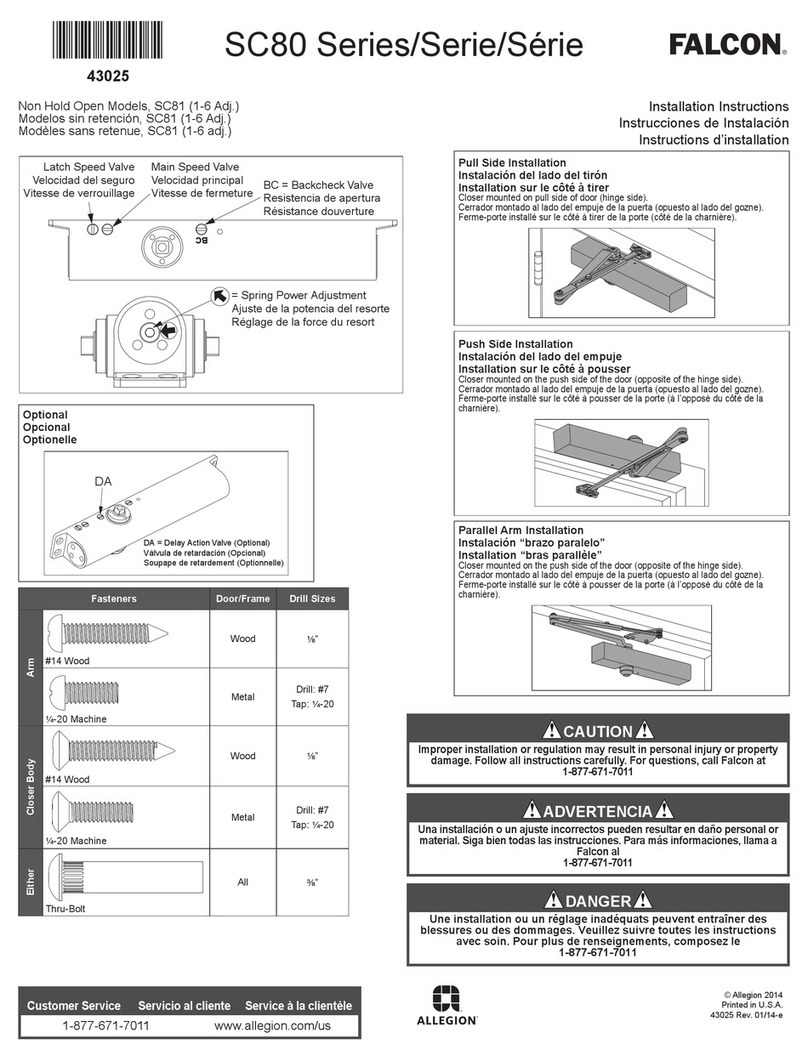

Falcon

Falcon SC81 installation instructions

Command access

Command access MLRK1 Series instructions

EZ-ACCESS

EZ-ACCESS CONCIERGE Series installation manual

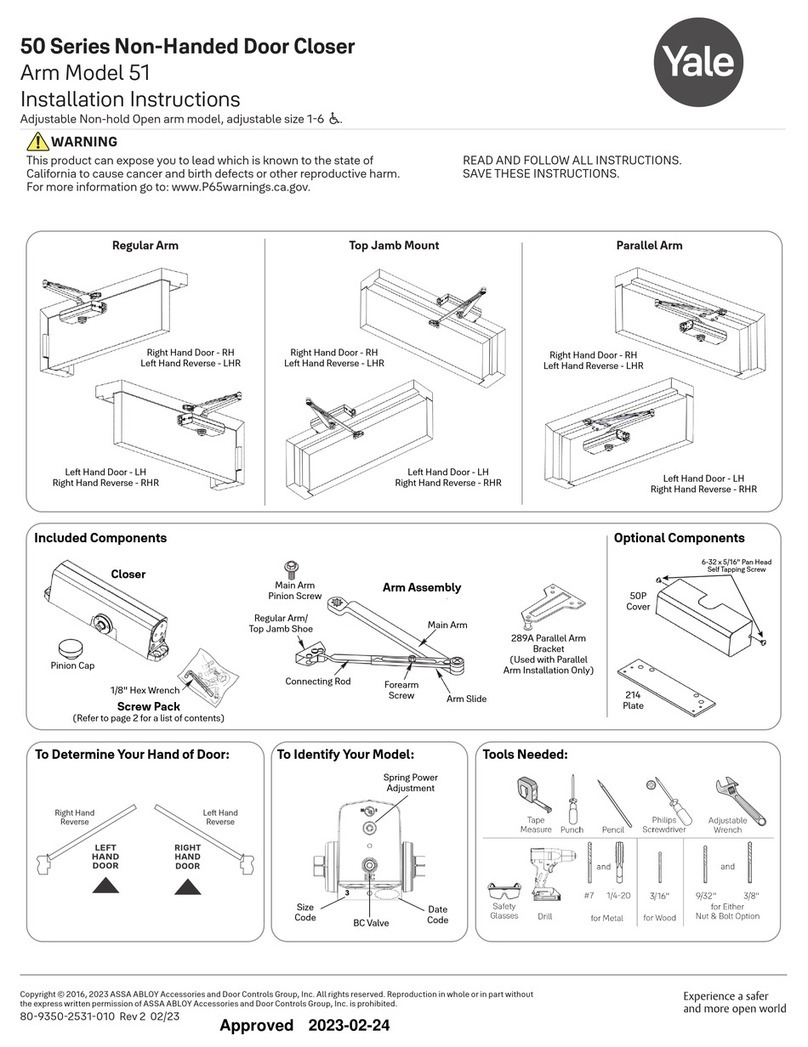

Yale

Yale 50 Series installation instructions