See Water Oil Smart User manual

Oil Smart® Simplex Panel

Installation Manual

Oil Smart® Simplex System:

The Oil Smart® OSSIM-30 System incorporates pump

controls and alarm sensors that differentiate between

oil and water, allowing companies to responsibly

discharge the water without the risk of pumping oil.

Installation of the Simplex Panel keeps companies

in compliance with Elevator Code ASME A17.1 and

State/Federal regulations while reducing the risk of

adverse publicity, nes and expensive cleanup costs.

OSSIM-30

Single Phase 120/208/240V 60Hz.

(0-16.0 Pump Full Load Amps)

Features:

• Oil Smart® and Liquid Smart® Controls with 20’

cords and mounting hardware

• NEMA 4X Panel Enclosure: Heavy Duty

Polycarbonate, 10″x8″x4″, Clear Front

• CSA International Certied No. 229294

• UL Listed for the United States and Canada

• High Liquid Alarm with Test and Silence Features,

Red Beacon Alarm Light, White Light for Water

Present, Yellow Light for Oil Present

• Alarm Horn that Sounds at 85 Decibels at 10 Feet

• Complete Panel Remote Monitoring Dry Contacts:

Oil, Water, High Liquid

• HOA Switch and Green Light for Pump Run

Panel and Component Installation:

1. Caution: To maintain the NEMA 4X rating, make

all wiring connections with seal tight cable grips or

conduit connections (supplied by end user).

2. Determine mounting location for control panel. Mount

panel using mounting feet supplied.

3. The control panel should not be mounted in an

area that is subject to submersion.

4. It is recommended to use separate 120VAC sources

for the pump and alarm circuits.

5. Run pump cable, Liquid Smart® cable, and Oil

Smart® cable through conduit. Make eld connections

as shown on wiring diagram.

6. Run power line conductor through conduit. Wire to

terminals per enclosed schematic. Branch circuit

protection to be provided by end-user.

7. Mount Oil Smart Pump Control and Liquid Smart

Sensor with provided mounting hardware to pump

discharge pipe. The off sensor of the Oil Smart Switch

shall be positioned at least 3” above the impeller

of the pump. The Liquid Smart Sensor shall be

positioned at the appropriate high liquid level point.

Start up:

1. When power is applied, the green power light located

on the white front swing panel shall light.

2. The Pump HOA Switch shall be placed to the A (auto)

position to ensure the system will pump. The pump

can be tested or turned on manually if the HOA switch

is in the H (Hand-Manual) position.

To test the alarm circuit, push the test button on the front

panel, the audible alarm shall sound and the red beacon

will light.

Service:

Caution: Before checking electrical connections within

the control or attempting to replace any components,

turn off all branch circuits supplying power to the main

control panel.

Protecting the Environment since 1995.

www.seewaterinc.com

or www.oilsmart.org

951.487.8073 • 888.733.9283

Email: info@seewaterinc.com

121 North Dillon Avenue • San Jacinto, CA 92583

P.O. Box 1269 • San Jacinto, CA 92581

lacirtcelElanoitaNehthtiwecnadroccaniebtsumsnoitallatsnillA.1

Code, and any other applicable state and local electrical

requirements.

1. The switch and pump are not rated for explosive environments.

This product is intended for hydraulic oils only.

IM 701, Rev. 0515

Oil Smart® Simplex Panel

Installation Manual

WATER

WATER

OIL

LAYER

WATER

OIL

LAYER

Normal Condition (Water Only)

When water comes in contact with

the short (on) sensor, the pump will

turn on. The pump will remain on

until water clears the long (off) sen-

sor.

Oil Present Condition

If oil comes in contact with the (on)

sensor, the pump will not turn on.

Water (Oil Present Condition)

If the water level rises enough to

contact the (on) sensor under the oil

layer, the pump will turn on and re-

main on until the (off) sensor clears

of water.

Oil Smart® Switch Operation:

Testing:

Liquid Smart® Alarm Testing

Oil Test: Submerge both sensors in oil and the

amber oil indicator on the front panel will light.

Water Test: Submerge both sensors in water and

the white water indicator on the front panel will

light.

Both tests will turn on the red beacon alarm light

and sound the alarm buzzer.

Oil Smart® Pump Switch Testing

Place your thumb on the short sensor of the Oil

Smart® Pump Switch and the pump will turn

on. While touching the short “on” sensor, touch

the long “off” sensor with your ngers. Remove

your thumb from the on sensor and begin to

move your ngers down the off sensor. Remove

your ngers from off sensor and the pump will

turn off. Optional: Fill up sump area with water,

when water reaches the on sensor, the pump will

turn on and remain on until water clears the off

sensor.

Typical Installation for Oil Smart® Pump Switch

and Alarm System

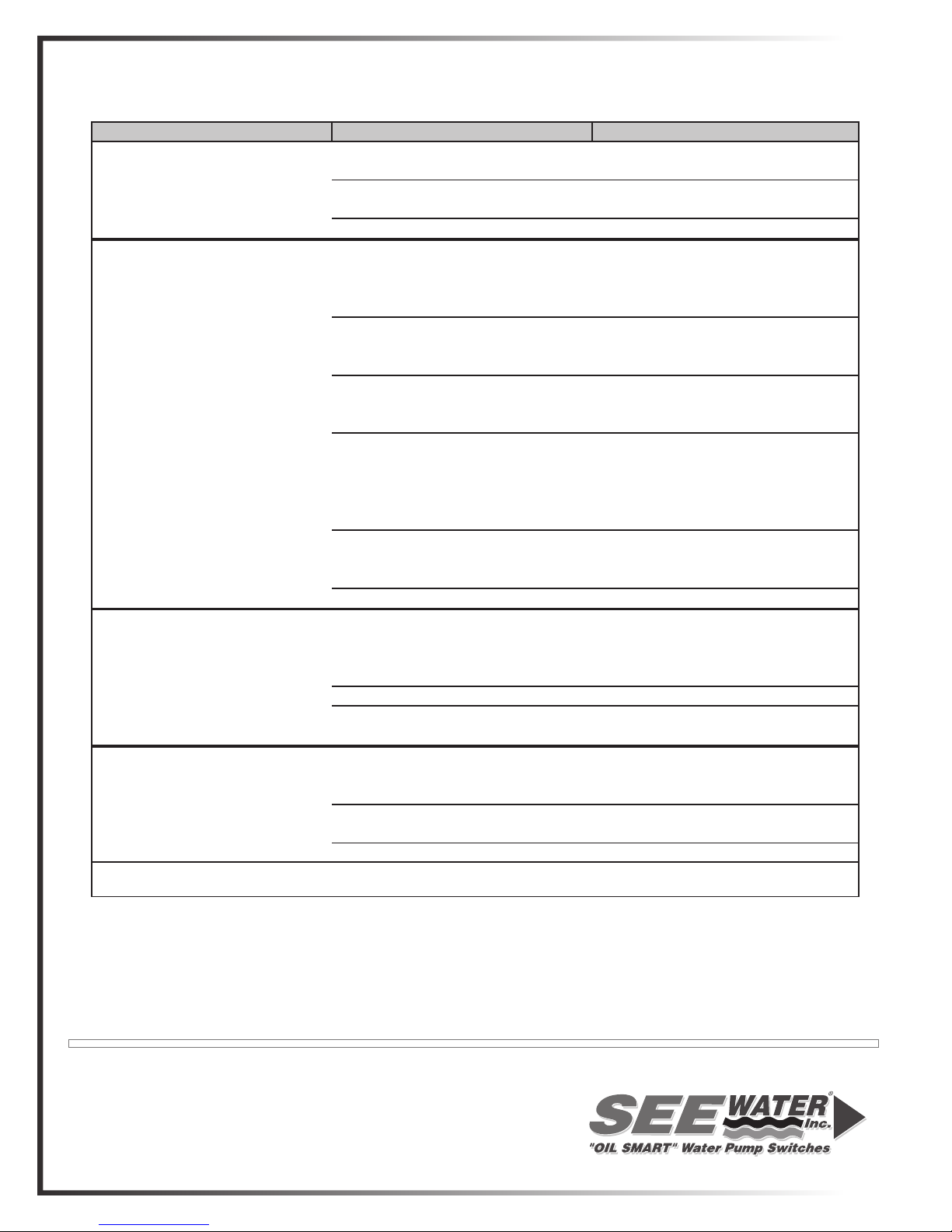

Problem Possible Cause Solution

Pump Control does not activate Incorrect Polarity Make sure phase and neutral are

the pump. Pump does not run. not reversed.

Loose connection in control panel. Confirm all connections are tight

or electrical system. and secure.

Defective Control Replace Control

Pump Control is not operating Problem with electrical system Check electrical circuits for

properly; not consistant or common neutrals;

staying on. may cause switch to not function

correctly.

Improper Field Wiring Do not run DC conductors

through same conduit as AC

conductors.

Control is not clean of conductive White plastic case must be kept clean.

material. Clean with houehold rubbing

alcohol and rag.

Improper Mounting of Components Keep control (1" to 2") clear of

any metallic material. Mount to pvc

pipe or if mounting to metal pipe, make

sure to mount with See Water

quick mount PVC bracket.

Float switch attached to pump Float switch must be removed,

secured in manual operation, or

replaced with correct pump.

Defective Control and/or Pump(s) Replace Control and/or Pump(s)

Alarm will not activate Power supply failure Confirm separate 120V power to

circuit board. Can be jumpered

from incoming power on pump

terminal if 120v is available.

Defective Alarm Sensor Replace Alarm Sensor

Loose connection in control panel. Confirm all connections are tight

or electrical system. and secure.

Pump will not turn on or pump is Incorrect match on control panel Confirm correct pump voltage and

not functioning properly. and pump. wires matched to correct control

panel

Loose connection in control panel. Confirm all connections are tight

or electrical system. and secure.

Defective Pump(s) Replace Pump(s)

Oil Smart Control Panel Troubleshooting Guide

Any technical questions on this product should be directed to See Water, Inc at 888-733-9283.

Protecting the Environment since 1995.

www.seewaterinc.com or www.oilsmart.org

951.487.8073 • 888.733.9283 • Email: [email protected]

121 North Dillon Street • San Jacinto, CA 92583

P.O. Box 1269 • San Jacinto, CA 92581

This manual suits for next models

1

Popular Control System manuals by other brands

Aqua Control

Aqua Control DOS CL 2 Deluxe WIFI Salz manual

flakt woods

flakt woods eq Controls Assembly and installation

WatchDog

WatchDog 3452H product manual

A/DA

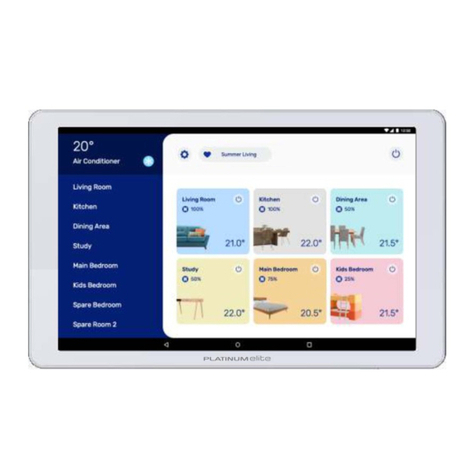

A/DA Platinum Elite installation manual

Fly Sky

Fly Sky Paladin PL18 user manual

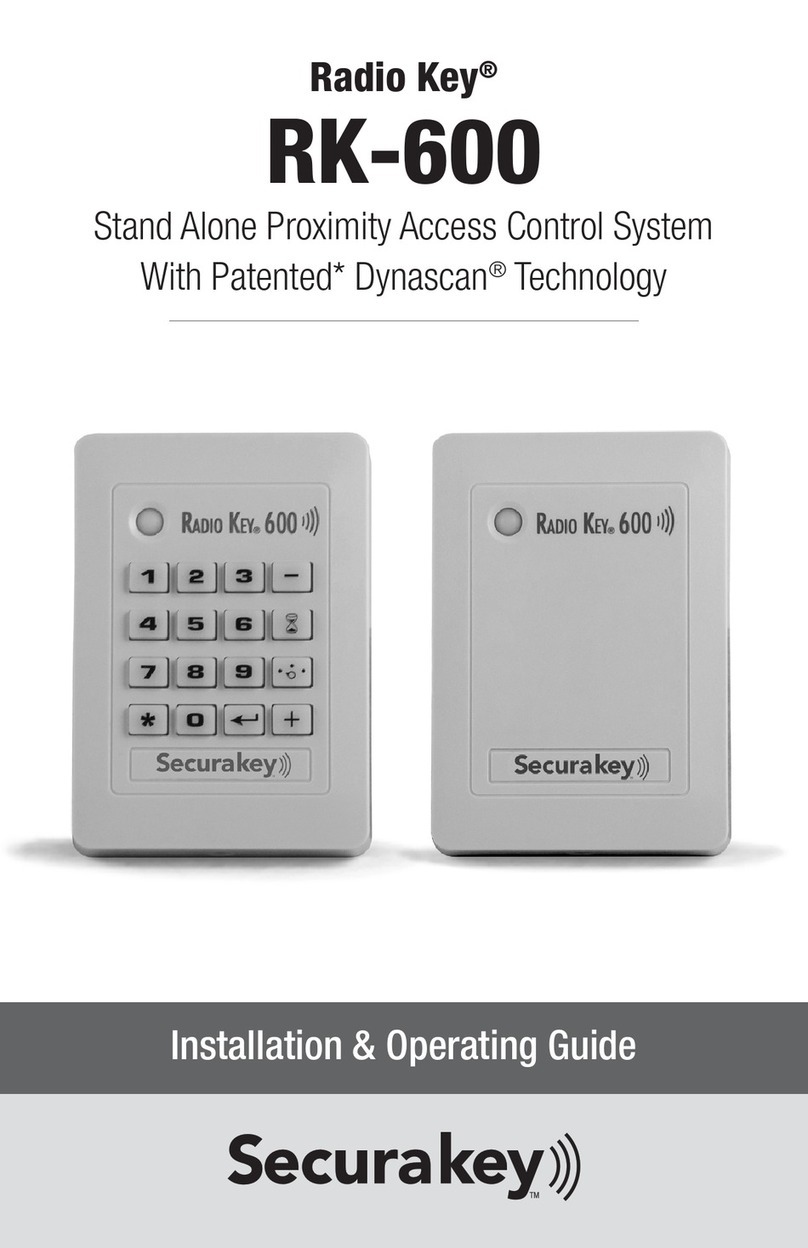

Securakey

Securakey Radio Key RK-600 Installation & operating guide