See Water Ultrasonic Pro UPRO-3003 User manual

Ultrasonic Pro™ Level Sensor

Installation and Operation Manual

UPRO-3003

Features:

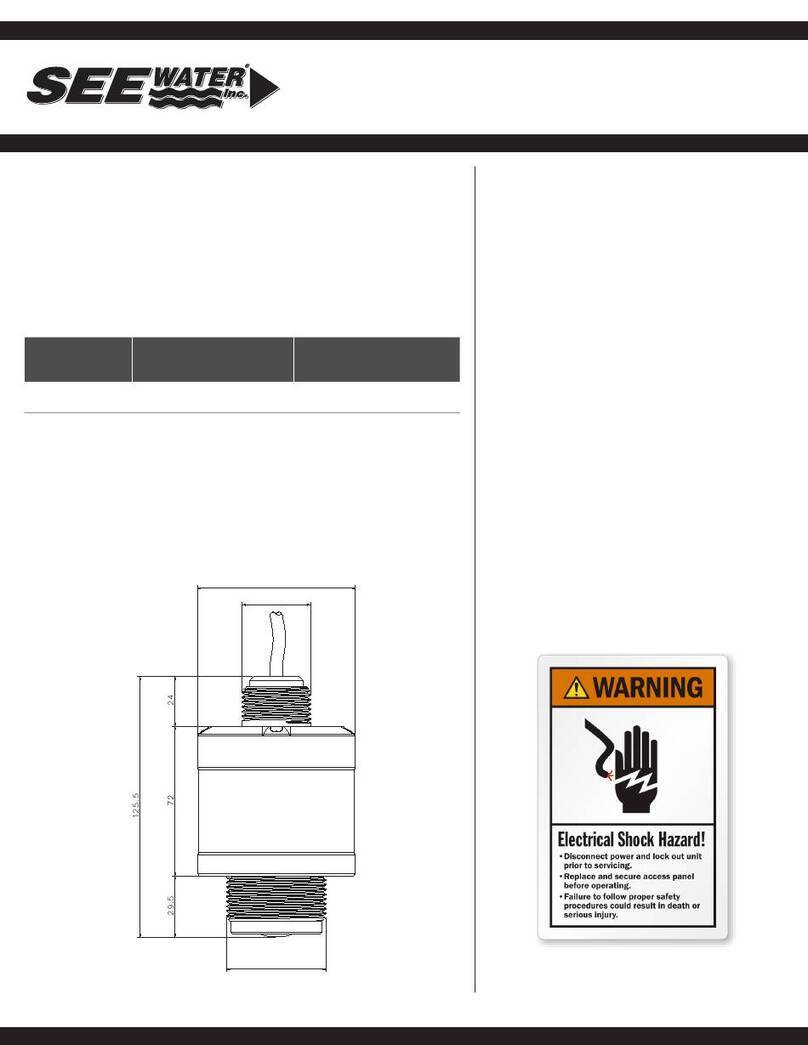

Dimensions:

• Supports M49*1.5mm threaded into type installation and coil clamping type

installation

• Many output options: Customizable with a 4-20mA three-wire system, 1-5v,

RS485 and more

• Less than 9°C design, resolution 3mm, less than 200ms response time

• Sealed so that it can be safely used for liquid level measurement in a wide

variety of applications, including with high-temperature toxic, volatile,

ammable, and strongly corrosive liquids

• Housing consists of NLEPF synthetic material, IP66 waterproof, anti-skid,

anti-corrosion, anti-explosion structure

• Anti-jamming high quality terminal blocks for long-term stability and reliability

• Two-year limited warranty

Electrical Properties:

Mechanical Properties:

Operating Condition:

• Power Requirement: DC24V/300mA

• Output Signal:

• Analog Signal: 4~20mA; 1~5V; Load>300Ω;

1~10V

• Digital Signal: RS485/RS232

• Scanning Frequency: 20.0KHz ~ 43.0KHz

• Electrical Connection: Wire pigtail

• Consumption: <1.5W

• Accuracy: 0.5%FS (at blind-fold drive away, 25°C)

• Material: ABS/Nylon

• Explosion Proof: Exiall BT4Gb

• Protection Class: IP65 (default); IP67, IP68

(customized)

• Operating Temperature: -20°C ~ 60°C

(-4°F ~ 140°F)

104

Ø71

M68X2

M20X1.5

Ø75

WARNING: A voltage potential between the ground wire of the unit and the

ground of other equipment can lead to electrolytic corrosion. Always ensure the

grounding system provides an equipotential between the transmitter and the

earthing ground connection. Avoid using the power system protective ground since

this will often have a signicant potential difference to the transmitter ground.

Also, note that dissimilar metals in the ground system may cause electrolysis

corrosion of the transmitter or other components in the ground system.

During installation, connect a voltmeter or ammeter between the shield ground

wire and the grounding connection. If there is a measurable voltage or current

electrolytic corrosion may be a serious possibility. If there is a potential

difference then some isolation system will be required. Improper grounding

may lead to damage or poor function.

Page 1-2 IM 5335 REV. 12/23

Model Range: ft (m) Cable Length: ft (m)

UPRO-3003 15ft (5m) 50ft (15m)

www.seewaterinc.com

951.487.8073 • 888.733.9283 • [email protected]

22220 Opportunity Way, Suite 101 • Riverside, CA 92518

Ultrasonic Pro™ Distance/Level Sensor

See Water’s Ultrasonic Pro™ Level Sensor combines an ultrasonic sensor,

temperature sensor, ultrasonic servo circuit, and transmission circuit; It also uses

SMD components and ASIC. The shell is made of quality NLEPF synthetic material

with solid texture and good acoustic characteristics. The body is waterproof and

can be used in a wide variety of applications. The Ultrasonic Pro™ Level Sensor is

also easy to install and simple to maintain.

Ultrasonic Pro™ Level Sensor

Installation and Operation Manual

UPRO-3003

The measure reference surface is the bottom line of the sensor. The highest solid

level cannot enter the blind area.The level measurement should avoid the feeling

hole; aim toward the smoother level surface. It is better to use a sun/rain shade

when mounting in an application that is exposed to weather elements. When

mounting, sensor should be kept a distance from the wall surface because of the

beam angle of the ultrasonic wave. When measuring the object level, the feeding

hole should be avoided to prevent interference with the ultrasound echo.

Using the bracket as a template, place a level across the

top and hold it in the desired location. Mark the four 3/16”

holes. Use a drill bit suitable for the intended substrate

and screw diameter and drill out the four holes (A 10-32

x 1 1/2” stainless steel screw is recommended). The

mounting holes can be bored to 1/4” to accept a larger

screw (A minimum of 1” penetration into the substrate

is recommended).The tolerances of the drill bit used

should meet the requirements of ANSI Standard B212.15.

Position the bracket, insert the screw through the

mounting hole of the bracket and tighten the screw until it

is fully embedded.

12°

3 [76]

17

16 [37]

4X Ø 3

16

[Ø5]

53

16 [131]

91

4 [235]

TOP VIEW

Slide the cord of the sensor through the slot in the

mounting bracket and use the included nut to secure

the sensor to the mount.

Page 2-2 IM 5335 REV. 12/23

Inowing medium: Do not mount the sensor in or above the lling stream. Make

sure to detect the medium surface, not the inowing liquid.

It is possible to achieve both horizontal and vertical mounting orientations by

rotating the sensor holder to the appropriate angle. The sensor holder can also

be adjusted to compensate for out of plumb conditions allowing the sensor to be

perpendicular to the medium.

www.seewaterinc.com

951.487.8073 • 888.733.9283 • [email protected]

22220 Opportunity Way, Suite 101 • Riverside, CA 92518

Installation:

Mounting Bracket:

Ultrasonic Sensor:

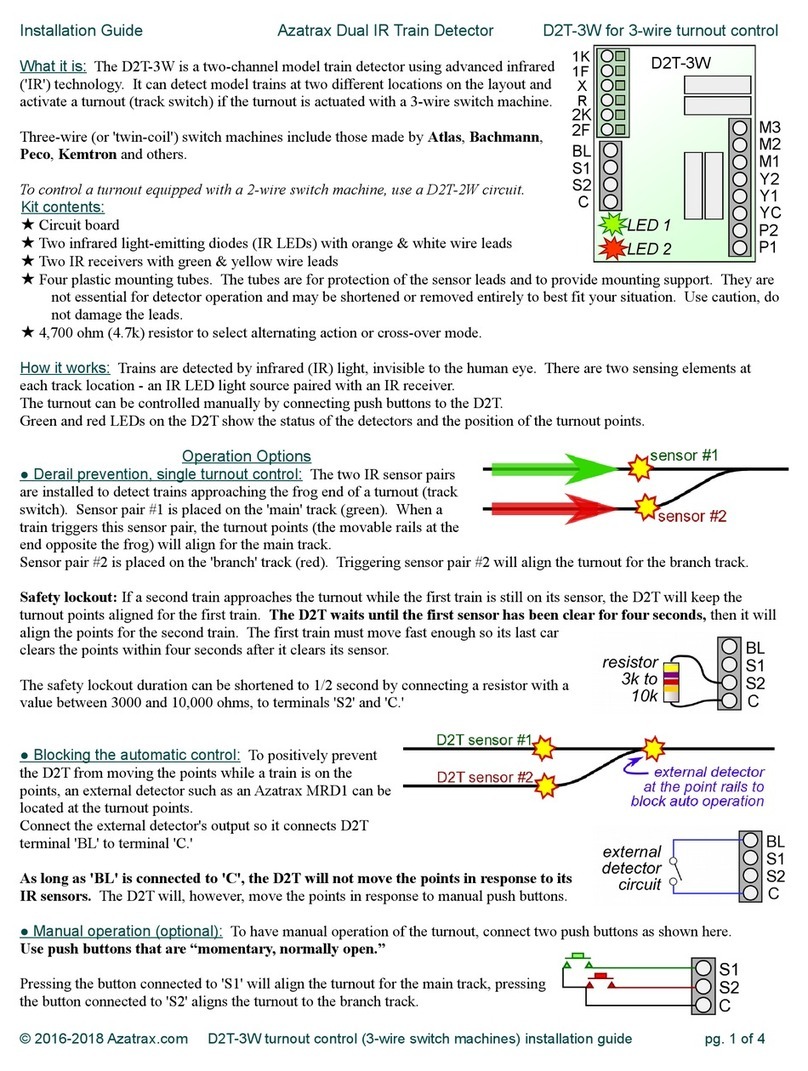

1. Wiring diagram of current (voltage) output connect with secondary unit.

2. Wiring diagram of serial output connecting with PC

External power / instrument / 485-232 / PC

Wiring Connection:

Instrument Secondary Instrument

Red

Yellow

Black

Supply + DC24V / 100mA Voltage Output

Input

GND

Output Supply -

DC Regulated

Voltage

Standard

Serial Port

Supply +

A

B

Output A

Output B

Supply -

Warranty:

See Water, Inc. warrants that products of its

manufacture are free from defects in material and

workmanship for a period of 2 years from the date of

purchase. This date shall be determined by the date on

the invoice and the serial number on the product.

Replacement of the product is at the discretion of See

Water, Inc. This warranty is valid when the product

is installed in compliance with the manufacturer’s

installation instructions. The manufacturer’s obligation

under this warranty shall be limited to the repair or

replacement of any parts found by the manufacturer

to be defective.

Green

Blue

Other See Water Security Sensor manuals

Popular Security Sensor manuals by other brands

Siemens

Siemens FDOOT271-O Mounting

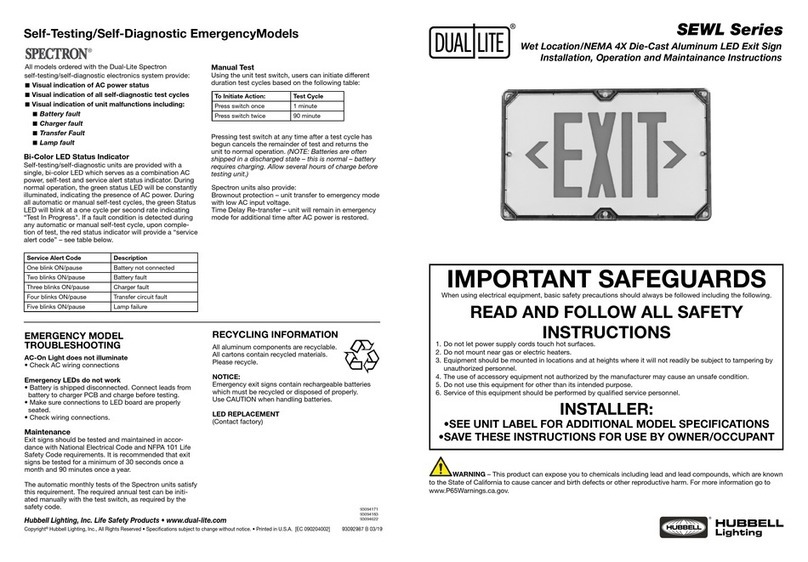

DualLite

DualLite SEWL Series Installation, Operation and Maintainance Instructions

Siemens

Siemens Cerberus DOTE1152 Technical description

PCB Piezotronics

PCB Piezotronics 320C03 Installation and operating manual

Ono Sokki

Ono Sokki VP-201 instruction manual

HP

HP 5973 Hardware installation manual