2

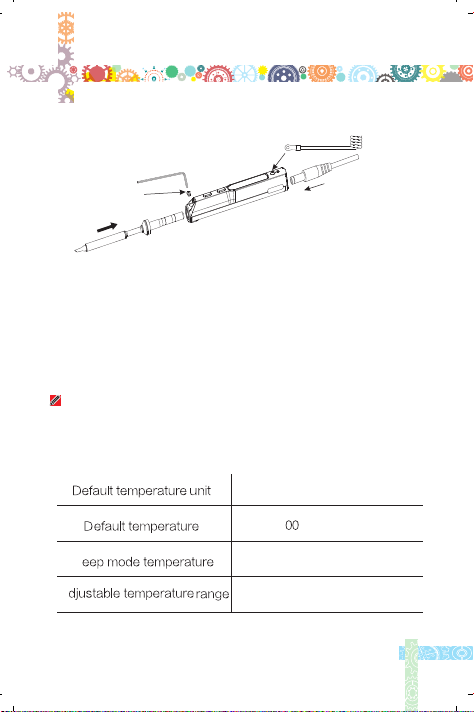

1.3 Warnings

Turn the power off when not in use, or left unattended.

When the power is ON, the tip temperature will rise between

100℃~400℃ (212℉~752℉)

Please do not wet the tool or operate it when your hands are wet

1.4 Cautions

Please avoid any severe shocks, for the control part is created

with precision electronic components.

The temperature of control knob will reach 50~60℃ after 40-

minute continuous use over 350℃.

A small chain of smoke may come out due to the high temperature

when use for the first time.

Do not attempt to repair the Mini Soldering Iron, or the warranty

will be invalidated.

1.5 Liability Statement

The user ought to undertake the responsibilities if any special,

indirect, consequential, incidental or secondary damages and

liabilities are caused out of any reason.

C

M

Y

CM

MY

CY

CMY

K

tiny电烙铁 使用说明.pdf 5 2015/12/7 10:06:56