Seen IRIS 860 Sensor User manual

© Copyright 2021 Seen Safety Limited. IRIS 860 Installation Guide. Version 2.3 1

INSTALLATION GUIDE

SEEN IRIS 860 Sensor

SEEN IRIS 860 Cab Box

www.seensafety.com | we’ve Got Your Back

© Copyright 2021 Seen Safety Limited. IRIS 860 Installation Guide. Version 2.3 2

Contents

Before you start 3

System overview 3

Power requirements 4

Sensor mounting 5

Sensor wiring 6

Cab Box wiring 7

Cab Box Sensor Cable 9

Weather shield 10

Set-up examples 11

Internal self check function 13

Sensor maintenance 13

Trouble-shooting 14

Connecting an accessory 16

Changing the sensor settings 18

Software settings 20

Warranty 21

Specifications 22

Important warning

SEEN IRIS 860 sensors can provide collision warning

assistance to the operator but do not replace the need for

proper operator training and best practice safe operating

procedure. While IRIS 860 sensors can alert the machine

operator to a potential collision, the operator is always

fully responsible for the safe operation of the equipment.

IRIS 860 sensors do not comply with the regulatory

standards required for devices which are intended to

directly control vehicle or machine safety functions. Using

the sensor accessory port to control a vehicle or machine

function is entirely your own risk. Detection can never be

guaranteed.

IRIS 860 sensors are a CLASS I LASER PRODUCT.

Disassembly or modification of this device may result in

hazardous radiation exposure and will void the warranty.

This installation and set-up guide has been prepared with

all due care and attention, however, Seen Safety Limited

cannot be held responsible for any errors or omissions in

this guide or any consequences thereof.

Seen Safety Limited

Unit 4, 69 Kaiwharawhara Road

Wellington 6035,

New Zealand

+64 4 381 4475

www.seensafety.com

support@seensafety.com

IRIS 860 sensors and Cab Boxes require a 12–24

volt power supply. Power supplies exceeding

24 volts require a DC/DC voltage converter.

© Copyright 2021 Seen Safety Limited. IRIS 860 Installation Guide. Version 2.3 3

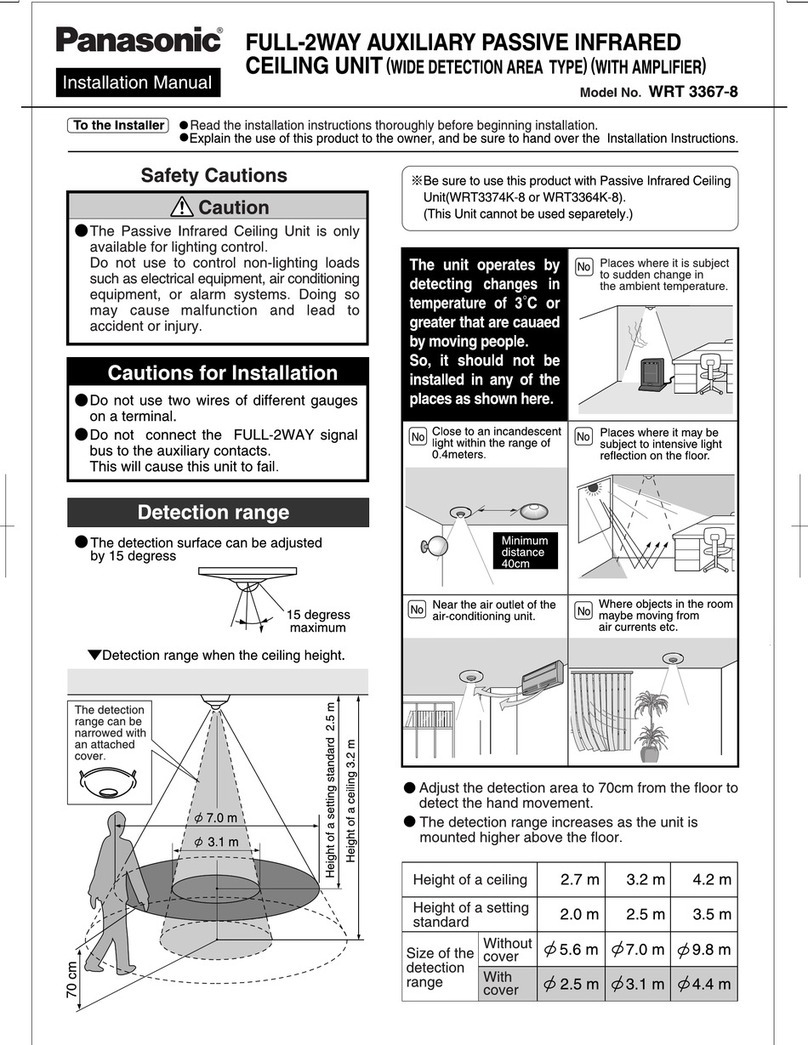

System overview

SEEN IRIS 860 sensors are intended for use on heavy mobile

equipment like forklifts and wheel loaders. The sensor uses

non-visible infrared laser light to detect the presence of

retroreflective material such as the retroreflective tape found

on day/night high visibility safety clothing and markers.

Each sensor has a 60º horizontal by 45º vertical field of view

and can detect retroreflective material between 0.8 and 8.0

metres from the sensor face. Detection is indicated by a loud

continuous-tone audible alert.

Sensor settings –such as the detection distance– can be pre-

set using SEEN’s free IRIS 860 setup app.

=

Buzzer

M6 mount

M6 mount

Vent

Accessory

socket

Power

socket

Back

IRIS 860 sensor

60º

45º

Before you start

Read this guide in full before starting installation. Incorrect

installation may void the warranty. If you need help contact

your supplier or Seen Safety customer support by emailing

support@seensafety.com

IRIS 860 sensors and Cab Boxes require a 12–24

volt power supply. Power supplies exceeding

24 volts require a DC/DC voltage converter.

Laser

transmit

Front Side

LED

© Copyright 2021 Seen Safety Limited. IRIS 860 Installation Guide. Version 2.3 4

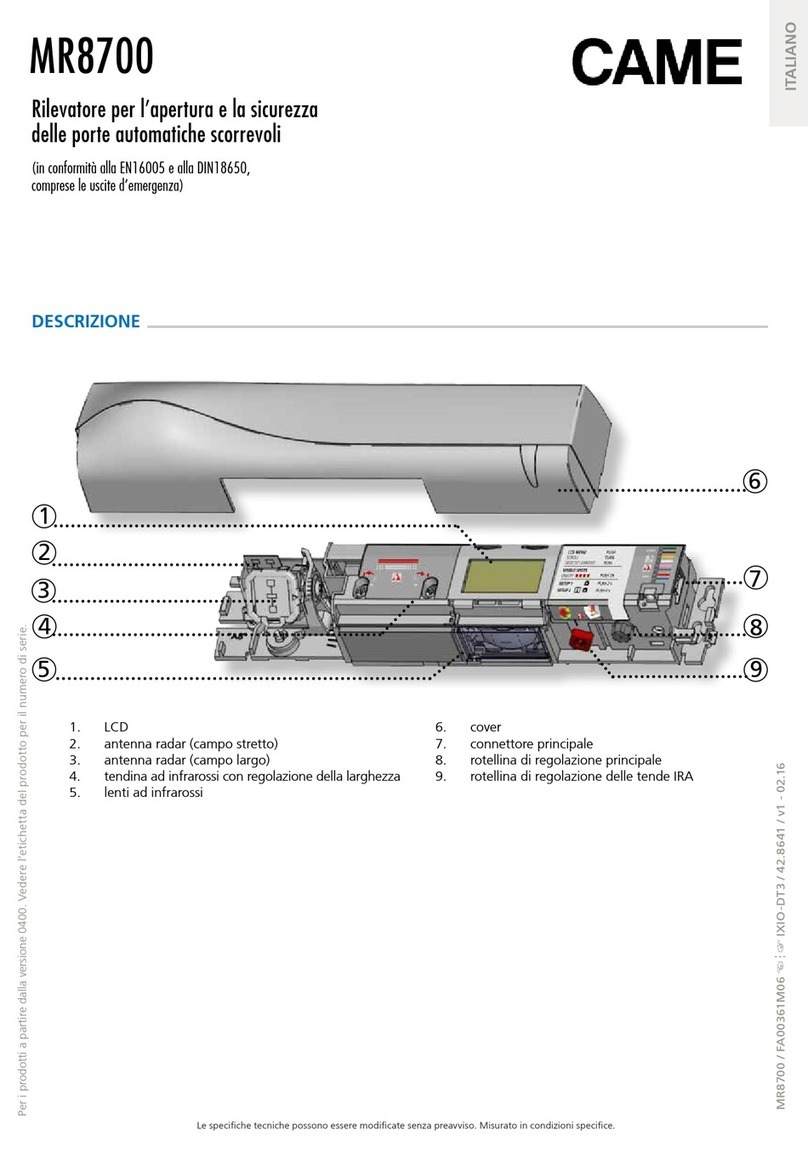

Power requirements

IRIS 860 sensors and Cab Boxes require a 12–24

volt power supply. Power supplies exceeding 24

volts require a DC/DC voltage converter.

If voltage reduction is required

Use a non-isolated DC/DC converter

• Non-isolated type

• Input rated to the machine power supply

• Output 12 or 24 volts at 2 amps*

• Rated as suitable for use on automotive equipment.

*Use a 5 amp converter if using a Cab Box with multiple

sensors plus accessories.

An isolated DC/DC converter can be used but

it must be bridged

Isolated converters must be bridged as shown In the

diagram opposite. Bridging is required because the

direction signal input is isolated from the IRIS 860

sensor ground (-V in) meaning the direction signal is

not grounded.

If the direction signal does not share the same ground

reference as the sensor/Cab Box, the sensor will

not receive the direction signal and will not alert as

expected (assuming the sensor is pre-set to only alert

while it is receiving a direction signal – the default

setting).

A connection across the DC/DC converter isolation

barrier (as shown by the dashed line) is required so

that both circuits share a common ground.

WARNING. If another accessory sharing the DC/

DC converter requires an isolation barrier for safety,

use a separate DC/DC converter for the IRIS 860

sensor.

Isolated DC/DC

converter with bridge

Ground (BLUE)

Non-isolated

DC/DC

converter

+

+

–

–

DC 12-24V out

36/48/60V in

Sensor / Cab Box

Power Cable

Direction signal

DC 3.5-100V (BLACK)

Battery electric machine with

high voltage power supply

Power DC 12-24V (BROWN)

Bridge

+

+

–

–

DC 12-24V out

36/48/60V in

Sensor / Cab Box

Power Cable

© Copyright 2021 Seen Safety Limited. IRIS 860 Installation Guide. Version 2.3 5

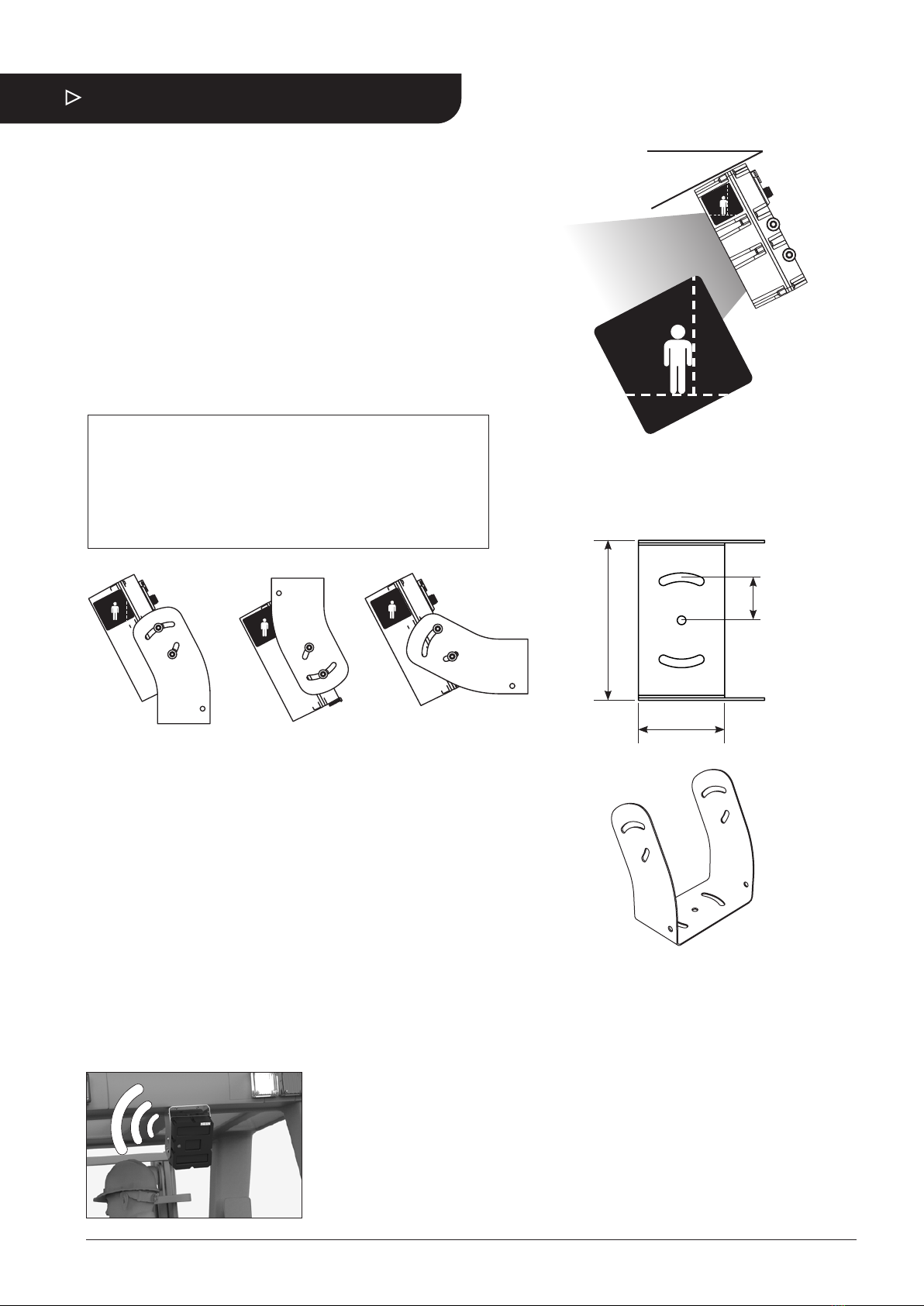

Sensor mounting

The supplied stainless steel mounting bracket can be used on

horizontal, vertical, or angled surfaces. The sensor should be

mounted approximately 2 metres / 6-7 feet above the ground.

1. Choose mounting option A, B, or C as shown below.

2. Noting the required bracket orientation relative to the

sensor, securely attach the bracket to a solid surface using

appropriate M6 fasteners and torque settings.

3. Mount the sensor in the bracket as shown in the diagram.

Finger-tighten the four M6 screws (supplied) to hold the

sensor in the bracket. Adjust the sensor to the correct angle

using the sticker as a guide. (Refer to page 10 if using a

Weather Shield.)

4. Tighten the four M6 mounting screws to a maximum of 10Nm.

Note. An additional custom mounting plate may be required to

mount the IRIS 860 bracket in the required location.

WARNING. Do not drill into any roll-over or falling-object

protection structure (ROPS / FOPS) as this may compromise

the strength of the structure and void the machine warranty.

A. On top B. Underneath* C. Vertical**

27º

Correct angle

The sticker indicates

the correct angle

*Not compatible with a Weather Shield. Refer to page 10.

**The vertical mount option may not be suitable for installations

where multiple sensors are used because the sensor bracket

cannot be rotated to the required angle. Refer to page 12.

Alert volume

The 94dB alert may be uncomfortably loud if the sensor is

mounted close to the operator’s head. Options:

• Consider a Top Mount instead of an Underneath Mount.

• Set the sensor to Reduced Volume in the IRIS 860 setup app.

• Use SEEN’s snap-on volume reduction cap accessory.

35mm

130mm

70mm

© Copyright 2021 Seen Safety Limited. IRIS 860 Installation Guide. Version 2.3 6

Sensor wiring

IRIS 860 sensors and Cab Boxes require a 12–24

volt power supply. Power supplies exceeding

24 volts require a DC/DC voltage converter.

• If using a Cab Box skip to page 7.

• Use a voltage reducer if the supply voltage is greater than

24 volts. Refer to page 4.

• The direction signal input can be up to 100V.

• Follow the machine manufacturer instructions for

connecting a third-party accessory.

IRIS 860 sensor

Ground

Direction (centre)

Ignition power

Orientation slot

Sensor Power Cable (5 pin)

IRIS 860 sensor

Accessory socket

Power socket

Sensor Power

Cable

BROWN

Power (ignition)

DC 12-24V 0.7A

BLUE

Ground

BLACK

Direction signal

DC 3.5-100V 1mA

Correct functionality

• Power on > Green LED and single beep followed by red LED

flash (to indicate the sensor has booted) then steady green

LED.

• Detection > Red LED and continuous audible alert.

• Pre-alert (if set) > Flashing Red LED and beeping audible

alert.

Direction Dependent Alert

By default IRIS 860 sensors are pre-set so they can only alert if

they are receiving a direction signal (usually reverse) from the

machine. This direction dependent setting can be changed in

the IRIS 860 setup app.

© Copyright 2021 Seen Safety Limited. IRIS 860 Installation Guide. Version 2.3 7

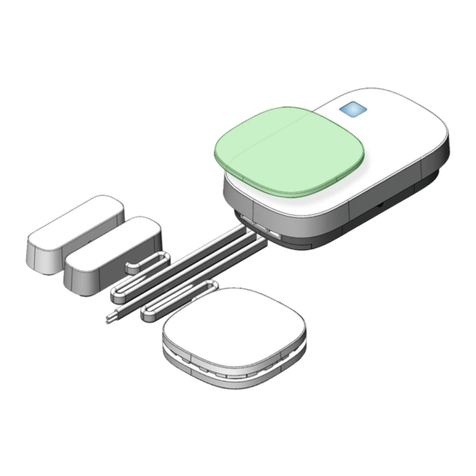

Cab Box

Sensor Cable

Cab Box

Power Cable

Cab Box

Cab Box wiring

A Cab Box is used on closed-cab machines to provide an audible

detection alert and LED indication to the operator inside the cab. Up

to four IRIS 860 sensors can be connected to each Cab Box.

A Cab Box Sensor Cable is used to connect each sensor to the Cab

Box. These cables are available in 5m, 10m, or 15m lengths.

IRIS 860 sensor

Cab Box Sensor Cable

Cab Box

© Copyright 2021 Seen Safety Limited. IRIS 860 Installation Guide. Version 2.3 8

Cab Box Power Cable

IRIS 860 sensors and Cab Boxes require a 12–24

volt power supply. Power supplies exceeding

24 volts require a DC/DC voltage converter.

Note. The 5-pin sensor power cable supplied with each

sensor is not required and should NOT be used.

• Use a voltage reducer if the supply voltage is greater than

24 volts. Refer to page 4.

• The direction signal input can be up to 100V.

• Follow the machine manufacturer instructions for

connecting a third-party accessory.

BROWN

Power (ignition)

DC 12-24V 4.0A

BLUE

Ground

BLACK

Direction signal

DC 3.5-100V 1.0mA

Direction

Ground Ignition power

Orientation slot

Cab Box Power Cable (4 pin)

Correct functionality

The LED and audible alert on the Cab Box mirrors the LED and

audible alert on the connected sensor.

• Power on > Green LED and single beep followed by red LED

flash (to indicate the sensor has booted) then steady green

LED.

• Detection > Red LED and continuous audible alert.

• Pre-alert (if set) > Flashing Red LED and beeping audible

alert.

Direction Dependent Alert

By default IRIS 860 sensors are pre-set so they can only alert

if they are receiving a direction signal (usually reverse) from

the machine via the Cab Box. This direction dependent setting

can be changed in the IRIS 860 setup app.

4 pin Cab Box Power socket

© Copyright 2021 Seen Safety Limited. IRIS 860 Installation Guide. Version 2.3 9

Cab Box Sensor Cable

Cab Box Sensor Cables are used to connect the sensor to the

Cab Box. They are available in 5, 10, and 15 metre lengths. One

end of the cable has a re-wireable plug which can be removed to

assist the threading of the cable through the machine chassis or

to shorten the cable. When re-attaching the plug check that the

wire colours match the diagram below. Use the screw-block as a

reference.

Note. The re-wireable plug should be connected to the Cab Box

to protect it from the elements. The moulded end should be

connected to the sensor.

5. Grey (Centre)

4. Black

Screw-block

3. Blue

2. White

1. Brown

Re-wireable plug Wire stripping guide

9mm

16mm

Grey wire (centre)

Other wires

8mm 9mm

Moulded end

(Attach to sensor)

Re-wireable plug

(Attach to Cab Box)

Cab Box Sensor Cable

1. Unscrew first

2. Unscrew second

Cable

© Copyright 2021 Seen Safety Limited. IRIS 860 Installation Guide. Version 2.3 10

Weather Shield

A Weather Shield (P/n SI-115) helps protect the sensor from

rain, heat and UV.

Note. It is not possible to attach a weather shield to a sensor

mounted in the ‘Underneath’ position.

Step 1

Before installing the weather shield,

gently tighten screw A on both sides

to hold the sensor in the bracket at

the correct angle.

Step 3

Insert screw B on both sides. Check

the alignment and evenly tighten the

four M6 mounting screws to maximum

10Nm.

Step 2

Place the weather shield over the

sensor and bracket so that the round

holes in the weather shield fit over

screw A on both sides.

Screw A

Screw B

Screw A

© Copyright 2021 Seen Safety Limited. IRIS 860 Installation Guide. Version 2.3 11

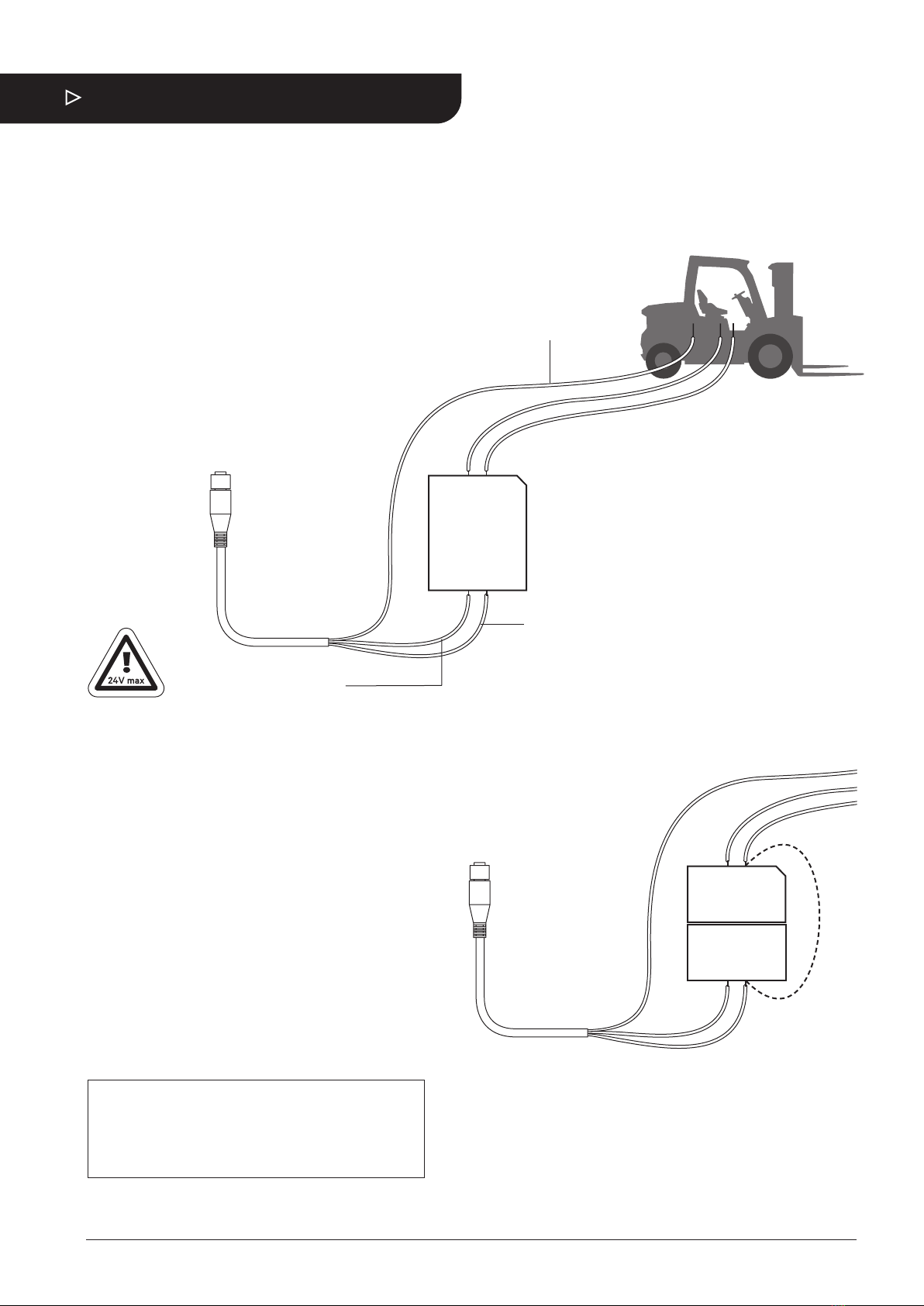

Set-up examples

Forklift

• 1 or 2 sensors on the top-rear of the machine

• 3m critical risk zone

• 1m pre-alert zone

• Sensor set so to only alert in reverse

Wheel-loader

• 1 or 2 sensors on the back of the machine

mounted above the radiator

• A cab box inside the cab with cables connected

back to each sensor

• 5m critical risk zone

• 1.5m pre-alert zone

• Sensor set to only alert in reverse

Critical risk zone = continuous audible alert

Pre-alert = beeping audible alert

A customised detection zone can help to minimise

non-critical detections

Note. The scenarios shown above are examples only. Your

specific requirements may dier.

© Copyright 2021 Seen Safety Limited. IRIS 860 Installation Guide. Version 2.3 12

Dual sensor side-by-side

When two sensors are mounted side-by-side the sensor brackets

should be spaced approximately 160mm / 6” apart and rotated

approximately 20º outwards. The combined field-of-view is

around 100-105º depending on the amount of overlap.

30-35º

30-35º

20º

~ 160mm / 6” apart

~ 1m / 3ft apart

20º

Dual sensor cross-over

Compared to the side-by-side mounting option, the cross-over

mounting option oers improved detection zone overlap close to

the machine, reduces the 0-0.8m no-detection zone, and increases

the overall field-of-view.

The sensor brackets should be spaced approximately 1m / 3ft

apart (about the width of a forklift cab / wheel loader engine) and

each bracket should be rotated approximately 30-35º inwards.

The combined field-of-view is around 120-130º depending on the

amount of overlap.

CHECK. In either option, when

angled correctly both sensors

should simultaneously detect a

person standing in the center of the

detection zone at the maximum and

minimum detection range.

© Copyright 2021 Seen Safety Limited. IRIS 860 Installation Guide. Version 2.3 13

Internal self check function

IRIS 860 sensors have an automatic internal self-checking

function. If a fault is detected the sensor (and cab box if

used) will flash and beep a pattern indicating the type of fault

detected.

Window contamination dust/dirt

Situation: The sensor operates in a dusty or dirty environment

Problem: The sensor windows are excessively contaminated.

Indication: Continuous beep and flash sequence long-short-

short, long-short-short etc. — - - — - - — - - — - -

Solution: Clean the sensor windows

Window contamination ice/condensation

Situation: The sensor operates in a cold store / freezer

environment.

Problem: Ice or condensation on the windows may be

triggering the window self check test.

Indication: Beep and flash sequence long-short-short, long-

short-short etc. (— - - — - - — - - — - - )

Possible solution: First check whether pedestrian workers can

be reliably detected with ice or condensation present on the

windows. If detection is reliable, then the window self check

function may be turned o using SEEN’s setup app. Use this

setting with caution because the window self-check function

will be disabled. Contact SEEN customer support for more

information.

Sensor internal fault

Any error sequence that is NOT long-short-short, long-short-

short indicates an internal fault. Unplug the sensor and contact

your reseller or supplier to arrange repair or replacement.

IRIS 860 sensors have no user-serviceable parts.

Sensor maintenance

IRIS 860 sensors have no user-serviceable parts.

Other than keeping the windows and buzzer free of dust and

dirt, no scheduled maintenance is required.

Remove dust and dirt using clean water and a clean non-

abrasive cloth.

Do not use high pressure water jets to clean.

Do not use chemical cleaners including alcohol, benzene,

thinners, and degreasers.

© Copyright 2021 Seen Safety Limited. IRIS 860 Installation Guide. Version 2.3 14

Trouble-shooting

1. The sensor LED is green on but the sensor does not

alert

Possible cause 1: The sensor may be set to only alert when

it receives a direction (usually reverse) signal input, but the

direction signal has not been connected.

Solution: Ensure the direction input is correctly wired to the

machine’s direction signal.

Possible cause 2: The retroreflective test target is too close

to the sensor.

Solution: Move further back. Detection starts 0.8m (3 ft)from

the sensor face.

2. A sensor set to be direction dependent, always alerts

Possible cause: The reverse signal input wire is twisted

together with the ignition power, meaning the sensor is always

receiving a direction signal input.

Solution: Ensure the power cable direction signal wire is

correctly wired to the machine’s direction signal.

3. The sensor and/or Cab Box are correctly wired but the

sensor/s do not behave in the expected way

Possible cause: Electrical earthing issue on the reverse signal.

Solution: Check that the ground reference on the direction

signal is the same as the ground reference on the sensor

power supply. Refer to page 16.

4. The Cab Box is correctly wired but the sensor/s do not

behave in the expected way

Possible cause: Wrong power cable.

Solution: Use the 4 PIN Cab Box power cable supplied

with the Cab Box. Do not use the 5 PIN sensor power cable

supplied with each sensor.

5. The sensor repeatedly beeps and flashes with the

sequence long-short-short, long-short-short

Cause: Blocked window.

Solution: Clean the windows and the self-check alert should

cease. If the sensor is operating in a cold-store freezer, ice on

the window maybe triggering the self checking function. Refer

to the Internal Self Check section on page 12.

6. The sensor is beeping and flashing and the sequence

is NOT long-short-short, long-short-short

Cause: Internal fault detected.

Solution: There are no user serviceable parts. Contact your

supplier for repair or replacement.

© Copyright 2021 Seen Safety Limited. IRIS 860 Installation Guide. Version 2.3 15

7. A sensor with a connected accessory will not power

up when plugged in with a USB config cable.

Cause: The USB port cannot supply suicient power.

Solution: Unplug the accessory from the sensor before

connecting the USB config cable.

8. At start-up the sensor gives a continuous tone alert

when the vehicle is in gear.

Cause: Test Mode may be enabled and has been

inadvertently activated. Refer to page 22.

9. Direction signal grounding issue

Applies to a sensor or Cab Box connected to a direction signal

input (e.g. reverse). If a DC/DC converter is used also refer to

page 4.

Note: In this example the direction signal is REVERSE.

Problem: The sensor / cab box is correctly powered and

connected to the reverse direction signal, but the sensor does

not alert, even when the reverse direction signal is active.

Possible cause: The reverse direction signal and sensor power

supply may not share a common ground.

To check the reverse direction signal ground:

• Unplug the sensor or Cab Box power cable

• Switch the vehicle ignition to ON (preferably without

starting the vehicle for safety)

• Attach a voltmeter across the ignition power pin (+) and

the ground pin (–) of the power cable. The voltage should

be between +10V and +29V. Refer to the plug diagrams

opposite.

• Next, attach the voltmeter across the reverse direction pin

and the ground pin (–). When the vehicle is NOT in reverse,

the voltage should measure between 0V and +1V. When the

vehicle IS in reverse it should measure between +3V and

+100V.

If the vehicle is in reverse and the voltage is not 3-100V

between the ground pin (–) and the reverse direction pin,

there may be a grounding issue.

Direction

Signal

Cab Box Power Cable

Ignition power (+)

Orientation slot

Ground (–)

Direction (centre)

Sensor Power Cable

Ignition power

Orientation slot

Ground

© Copyright 2021 Seen Safety Limited. IRIS 860 Installation Guide. Version 2.3 16

–

+

Connecting an accessory

The 8-pin M12 accessory socket outputs an electrical signal

while the IRIS 860 is detecting. The signal output behaviour

can be controlled in the IRIS 860 setup app. By default the

detection signal is only live during a detection in the Critical

Alert zone.

Accessory Cable

The IRIS 860 Accessory Cable (P/n SI-121) can be used to

connect a third-party accessory such as a camera, data-

logger, light etc.

IMPORTANT. Do not attach the Accessory Cable to a Cab

Box. The Accessory Cable is for the IRIS 860 sensor only.

Pin no. Wire colour Description

1 Brown 12V accessory power supply

2 White Ground / Earth

3 Blue Detection NPN

4 Black Detection 3.6V logic output

5Grey Do not connect

6 Pink Detection 12V logic output

Note. Refer to the accessory socket pin-out diagram on

page 23 for the complete specification.

Accessory use-case examples

External buzzer or light

On detection the NPN transistor switch closes putting 12V

across the connected accessory. The maximum supply current

is 500mA.

6

1

2

Alignment slot

3

4

5

12V power supply (BROWN)

IRIS 860 ground (WHITE)

Detection NPN (BLUE)

Detection 3V6 (BLACK)

Do not connect (GREY)

Detection 12V (PINK)

Accessory socket Accessory cable

Pin

1

2

3

4

5

6

7

8

NPN switch connects

to Ground during

detection

12V accessory

Ground

© Copyright 2021 Seen Safety Limited. IRIS 860 Installation Guide. Version 2.3 17

–

+

Camera with digital input

The IRIS 860 accessory power supply is used to power

the camera accessory (maximum supply current 500mA).

Detection 12V puts 12V on the camera trigger during detection.

This is a low power output and can only sink/source a few

milliamps of current. If required, add an external regulator to

limit the 12V detection logic output voltage (e.g. down to 5V or

3.3V) or use Detection 3V6 (black) for a 3.6V detection output.

External relay

On detection the NPN transistor switch closes putting 12V

across the relay. A flywheel diode is required across the relay

coil to protect the NPN transistor against the coil transient

when the detection event ends and the coil is switched o.

–

+

12V power supply (BROWN)

IRIS 860 ground (WHITE)

Detection NPN (BLUE)

Detection 3V6 (BLACK)

Do not connect (GREY)

Detection 12V (PINK)

12V power supply (BROWN)

IRIS 860 ground (WHITE)

Detection NPN (BLUE)

Detection 3V6 (BLACK)

Do not connect (GREY)

Detection 12V (PINK)

Accessory socket

Accessory socket

Accessory cable

Accessory cable

Pin

1

2

3

4

5

6

7

8

Pin

1

2

3

4

5

6

7

8

NPN switch connects

to Ground during

detection

Output high

during detection

Logic buer

12V relay

12V camera

Ground

Ground

Flywheel diode

12V power supply

12V trigger input

© Copyright 2021 Seen Safety Limited. IRIS 860 Installation Guide. Version 2.3 18

Changing the sensor settings

Requirements

• IRIS 860 sensor

• IRIS 860 USB Config Cable P/n SI-122

• SEEN’s free IRIS 860 setup app

• A Mac or Windows computer with a USB port, or an OTG

compatible Android smart phone or tablet

You may also need

• A USB OTG adapter*

• An IRIS 860 USB Config Cable to Sensor Cable Adapter

P/n SI-124

*AnOTGorOn The Goadapter(sometimes called anOTG

cable, orOTG connector) allows you to connect a full sized

USB-A cable to your phone or tablet through the Micro USB

or USB-C chargingport. These adapters are available from

technology retailers.

Device compatibility

• Not all smart phones and tablets are USB OTG compatible

• Non OTG compatible devices cannot support USB serial

communications and will not connect to the sensor

• Some OTG compatible smart phones and tablets will not

supply suicient power to the sensor

• Check your device can connect to an IRIS 860 sensor

BEFORE going on site.

Note. SEEN have tested and recommend the LENOVO Tab

M8 HD P/n TB-8505F tablet it to provide reliable connection.

(This tablet requires a USB OTG Micro USB adapter.)

Note. If the sensor has an accessory attached, remove the

accessory prior to attaching the USB config cable. The

accessory may draw more power than the USB plug can

supply and the sensor will not power on.

Software

Download IRIS 860 setup app at

www.seensafety.com/download

© Copyright 2021 Seen Safety Limited. IRIS 860 Installation Guide. Version 2.3 19

USB OTG

adapter

Cable Adapter

2

USB Config

Cable

USB Config

Cable

USB Config

Cable

USB connection

Direct to sensor

• Launch the SEEN IRIS 860 setup app

• Connect the IRIS 860 sensor to the computer or Android

mobile device using an IRIS 860 USB Config Cable (OTG

compatible smart phones or tablets will require a USB OTG

adapter)

• Wait a few seconds for the sensor to power up and boot

(indicated by red LED flash then steady green)

• The sensor LED will glow green when powered on

• Follow the on-screen instructions.

Cab Box

Power Cable

1

Cab Box

Sensor Cable

Cab Box

Sensor Cable

Via the Cab Box Sensor Cable

If direct access to the sensor is diicult the USB config cable

can be connected to a Cab Box Sensor Cable from inside the

cab.

• Requires an IRIS 860 Cable Adapter (P/n SI-124)

• Launch the SEEN IRIS 860 setup app

• Unplug the relevant Cab Box Sensor Cable from the Cab

Box and plug it into the Cable Adapter

• Attach the Cable Adapter to the USB Config Cable

• Plug the USB plug into the USB port on the computer or

Android mobile device. (For OTG compatible smart phone or

tablet a USB OTG adapter will be required)

• Wait a few seconds for the sensor to power up and boot

(indicated by red LED flash then steady green)

• Follow the on-screen instructions.

© Copyright 2021 Seen Safety Limited. IRIS 860 Installation Guide. Version 2.3 20

Software settings

Sensor settings can be changed using SEEN’s free IRIS 860

setup app.

Critical alert

A detection in the Critical alert zone is indicated by a

continuous audible alert tone from the sensor (and Cab Box if

used). The factory default setting is 4m / 12 ft.

Pre-alert

A detection in the Pre-alert zone is indicated by a beeping

audible alert tone. The factory default setting is 0m.

Note: The combined total of Critical alert distance plus Pre-

alert distance cannot exceed 8.0 metres.

Direction Dependent Alert

Requires connection to the vehicle direction signal (e.g.

forward or reverse). Options:

• Sensor can only alert when the direction signal is active

• Sensor can only alert when the direction signal is not active

• Sensor can always alert (direction signal is ignored)

Volume

Options: Normal / Reduced / OFF

When Reduced is selected the alert volume is decreased from

94dB at 1 metre to approximately 86dB at 1 metre. This setting

can be used in situations where the sensor is mounted close to

the operators head and the alert is uncomfortably loud.

OFF completely disables the audible alarm. Use with caution.

Test Mode

Options: ON / OFF

If Test Mode is set to ON in the sensor setup software, the

machine operator can toggle the sensor into a mode where

it temporarily ignores the Direction Dependent Alert setting.

This allows the operator to safely walk around the machine

to test the sensor is detecting without needing to put the

machine in a reverse or forward gear.

Procedure

Turn the ignition on (to power the sensor), wait 2 to 5 seconds,

then turn the ignition o. The next time the ignition is turned

on the sensor will be toggled to Test Mode, indicated by a

flashing green LED on the sensor (and Cab-Box if used).

Test Mode lasts 2 minutes. The green LED on the sensor (and

Cab Box if used) flashes to indicate Test Mode is active.

The operator can check the sensors are working by walking

into the detection zone wearing a reflective safety vest.

Detection is indicated by an audible alert tone and red LED.

Direction signal check

This test ensures the Direction Dependent Alert signal is

connected. While Test Mode is active, when the operator

engages the Direction Dependent Alert gear, the audible alert

should sound indicating that the direction signal is correctly

connected.

Other manuals for IRIS 860 Sensor

3

This manual suits for next models

2

Table of contents

Other Seen Accessories manuals