SEFRAM SFX+V2 User manual

SEQUENCER WITH

DIFFERENTIAL PRESSURE

SWITCH

Technical notice

FI 72.0567.0221E

Page 2 / 45

SUMMARY :

DESCRIPTION :

The SFX+V2 is an adjustable device for the control and

automatization of declogging equipment, whose declogging is done

by compressed air injections.

It can manage filters organized in several cells (= compartments)

and with several compressed air reservoirs.

Depending on the configuration, declogging is carried out in

ONLINE or OFFLINE mode.

The SFX+V2 manages various controls, such as electric

consumption of SV, position of cell insulation, compressed air

consumption on tanks, dust emissions ...

The SFX+V2 has a historical record of faults and events.

The SFX+V2 incorporates the functional program corresponding

to the configuration of the filter. Adjustment of some parameters can

be done easily on site thanks to the user interface.

The user interface is a multi-lingual 7 "colors touchscreen. Access

is protected at several levels by passwords.

The SFX+V2 has a native RS485 Modbus communication in

order to communicate with the outside (ex: supervision).

It can be adapted to multiple fieldbuses thanks to a gateway also

integrated in the SFX+V2 cabinet.

The SFX+V2, depending of the filter configuration, is composed

of a master box/cabinet and several slave boxes. A configuration in

form of a bus allows, especially, to reduce the wiring compared to a

conventional configuration. In fact, the slave boxes can be placed

near the declogging solenoid valves while collecting the information

necessary for proper declogging (compressed air pressures, cell

position) and by controlling the cell and tank isolation.

For each SFX+V2, an electrical diagram is associated. Refer to it

for connections and dimensions.

Depending on the filter configuration, some parts of this manual

are not used.

Page

- DESCRIPTION

2

- CHARACTERISTICS

Master box/cabinet

Slaves boxes

4

4

5

- CENTRAL UNIT BOARD

6

- SLAVE BOARD

Coding

Protections

7

7

8

- USER INTERFACE

General

Cycle

About

security

HMI

Languages

Parameters

Sequencer / filter configuration

Online shooting sequence

Operating time

Counters

Dust emission

Compressed air

Customer communication

Manual mode

Historical

Faults

Events

Current faults

10

10

11

12

13

14

15

16

17

22

24

26

27

28

29

30

31

32

34

36

OPERATION

Putting in service

Online

Offline

37

37

38

39

- FAULT CHECK

Electrical faults

Mini pressure faults

re-inflation tank faults

SV non-opening faults

Dust emission faults

Link faults

Cell opening / closing faults

Other faults

40

40

40

41

41

42

43

43

43

- PRECAUTIONS

44

- WARRANTY

44

- CERTIFICATE

44

- GENERAL INSTRUCTIONS OF

SAFETY, ASSEMBLY,

COMMISSIONNING AND

MAINTENANCE

45

- ANNEX

SEQUENCER WITH

DIFFERENTIAL PRESSURE

SWITCH

Technical notice

FI 72.0567.0221E

Page 3 / 45

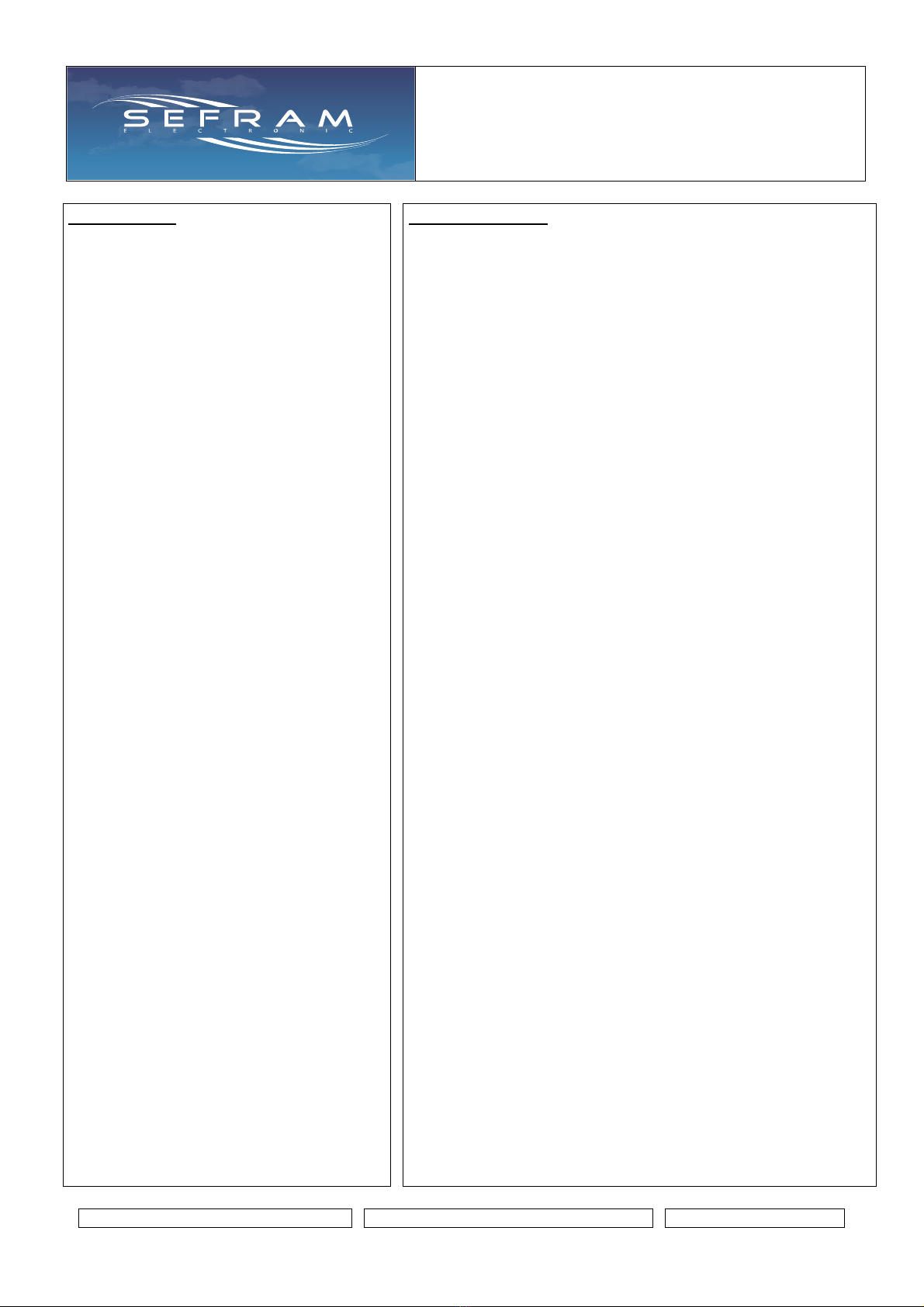

Overview:

Maximum configuration :

Number of cells: 32

Number of SV per cell: 64 - with a maximum total of 512 SV on the complete filter.

Number of slave boxes: 32

Number of tanks: 32

Number of dust emission probe: 16

Number of digital inputs: 12 (extension possibility)

Number of relay outputs: 6 (extension possibility)

MASTER box/cabinet:

- 7 "touch color HMI

- digital inputs management

- RELAY output management

- analog input / output 4 / 20mA

- integrated dP pressure switch

CUSTOMER communication:

MODBUS RTU protocol - native RS485

On demand :

PROFIBUS, MODBUS TCP / IP,

PROFINET, others ...

PLC /DCS

superviseur

SLAVE boxes: (up to 32)

- Management of up to 18 EV outputs per box

- Integrated Air/Compressed pressure switch

- Cell / tank isolation management

- Cell position control

Dust emission check

- Management of up to 16 dust emission

probes

SEQUENCER WITH

DIFFERENTIAL PRESSURE

SWITCH

Technical notice

FI 72.0567.0221E

Page 4 / 45

CHARACTERISTICS:

Master box/cabinet :

- Supply voltage

230VAC 50/60Hz

Other : on request

- Consumption

According to configuration

- General protection

By circuit breaker

- Characteristics of digital inputs:

Voltage: 24VDC supplied by the device

Charge current +/- 1mA

- Relay contact characteristics:

dry contact. max: 125VAC / 0.3A - 30VDC / 1A

(to be protected by the user)

- Operating temperature:

-20°C to 55°C

- Storage temperature:

-20° to 70° C

- Box / cabinet

RAL7035 painted steel dimensions depending on configuration

PC RAL7035 on request - IP55

DP pressure load loss measure (on request):

- Scale

0-500daPa

- maxi pressure ( P+ > P- )

400 mbar

- precision

class 2 on the maximum sensor scale (100 mbar)

→ from 0 to 60 ° C this class takes into account linearity,

hysteresis, the effects of temperature and repeatability

- DP order response time

1 second

- High / low alarm response time

5 seconds

4-20mA analog output (on request):

- Description

Transfer of the pressure load loss measure (DP)

- Type

Integrated power supply, non-isolated

Maximum load <500 Ohms

- Calibration value

4 mA = 0 daPa / 20mA = 500 daPa

4-20mA analog input (on request):

- Description

4-20mA signal receiver

- Type

Passive

- Calibration value

Configuration at the HMI

Touch screen :

- Size / Technology

7 inch / TFT LCD / Resistive touchscreen / buzzer

- Resolution / Colors

800 x 480 / 65536 colors

- USB

USB Slave Vers 2.0

- Date / time calendar

Battery lithium 3V Type CR2032

- protection index

IP65 / NEMA 4

Communication with outside (ex: to supervision):

- protocol

MODBUS - RTU / RS485 (2 wires) - not isolated

Note: Gateway available for other type of network.

- ID number

From 1 to 147

- speed

2400, 4800, 9600, 19200, 38400, 57600 or 115200 bauds

- Type

8N1, 8N2, 8E1 or 8O1

- Max distance

Up to 1200m

- Cable to use

Shielded twisted pair cable; STP type

SEQUENCER WITH

DIFFERENTIAL PRESSURE

SWITCH

Technical notice

FI 72.0567.0221E

Page 5 / 45

Slaves boxes :

- Supply voltage :

Several versions

Solenoid valves voltage DC

Version supply AC : 100 to 240V 50-60 Hz

Version supply DC : 24Vdc

Solenoid valves voltage AC

115V/230V 10% 50-60 Hz

24V/48V 10% 50-60 Hz

- Consumption max :

Solenoid valves voltage DC

Version supply AC : 1A

Version supply: 2.5A

Solenoid valves voltage AC

5VA + SV consumption

- Number of solenoid valve outputs

18 max

- Electrical connection / cable outlet

3 versions: Individual- multi - Integrated pilots

- Protections :

Solenoid valves voltage AC : see table 1 page 8

Solenoid valves voltage DC : see table 2 page 9

- Solenoid valve voltage:

According to version:

24VDC integrated / Pmax 25W or 40W

24V / 48V / 115V / 230VAC 50-60Hz / Pmax 25VA or 45A

Others on request

- Characteristics of digital inputs:

Voltage: 24VDC supplied by the device

Charge current +/- 1mA

- Relay contact characteristics:

dry contact. max: 125VAC / 0.3A - 30VDC / 1A

(to be protected by the user)

- Operating temperature:

-20° to 60°C

Integrated pilot version: 0°C to 60°C

- Storage temperature:

-20° to 70° C

- Case :

Material ABS - IP65

Material PC - IP65 on request

Compressed air pressure measure:

- Scale

0 –6 Bars

Display accuracy: 0.1Bar

- max pressure

17 Bars

- Precision

1.5% on the maximum sensor scale (10Bars)

→ from 0 to 50 ° C this precision takes into account linearity,

hysteresis, the effects of temperature and repetitiveness

- Humidity

0 to 95% RH –not condensed

- Output 4-20mA

On request

Integrated power supply, non-isolated - Max load <500 ohms

Note : Read the electrical diagram supplied with the sequencer in order to be aware its configuration and specific

characteristics.

SEQUENCER WITH

DIFFERENTIAL PRESSURE

SWITCH

Technical notice

FI 72.0567.0221E

Page 6 / 45

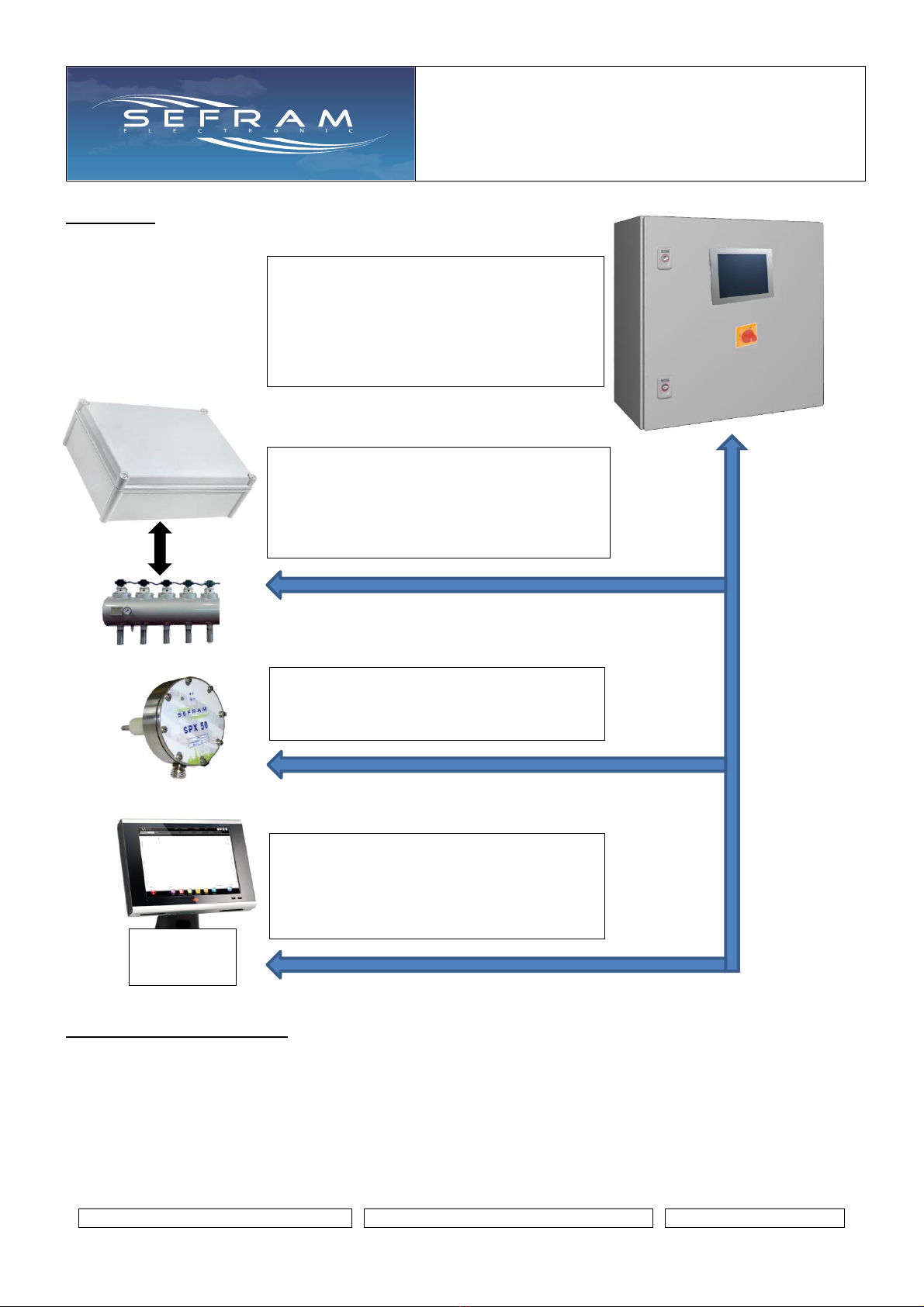

CENTRAL UNIT BOARD :

This board is located in the master box/cabinet. It is the heart of the SFX+V2 system.

It contains all the filter configuration as well as its settings.

It constantly communicates with the slave boxes and the HMI screen.

It processes the exchanges coming from the Modbus RTU client communication.

Depending on the configuration, it can be equipped with a pressure sensor for measuring the load loss pressure,

4-20mA analog input and output, several digital inputs and relay outputs.

Note: a kit exists to backup or restore the SFX+V2 settings to or from a disk file. This kit, consisting of a USB cord

and PC software, connects to this card. See the associated documentation (FI72.05666)

Red led:

Permanently on, signal of the

presence of the 24VDC

power supply

Blue LED: flashes regularly (1s) if the central unit is working

Yellow LED: representative of exchanges with the HMI screen

Green LED: representative of exchanges with Modbus client communication (or

exchange with gateway in the case of Profibus communication,

TCP / IP, Profinet ...)

Red LED: representative of exchanges with the slave boxes

SEQUENCER WITH

DIFFERENTIAL PRESSURE

SWITCH

Technical notice

FI 72.0567.0221E

Page 7 / 45

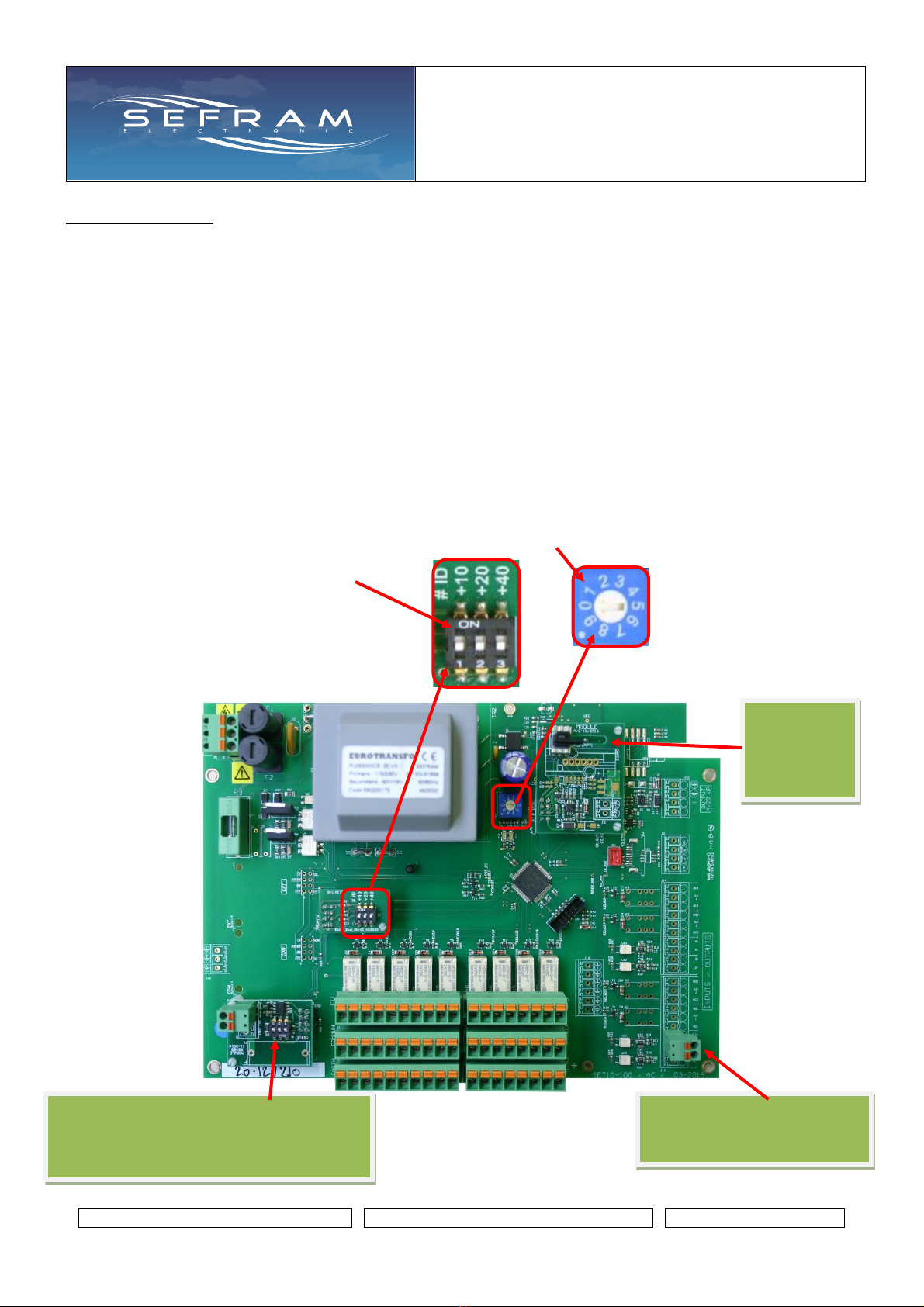

SLAVE BOARD :

This board is located in the slave box.

Depending on the configuration, it can be equipped with a pressure sensor for measuring the compressed air in a

tank with the possibility of a 4-20mA output for measure transfer.

It can be equipped with digital inputs and outputs to control the isolation of a tank or the isolation of a cell with

position control.

It manages the activation of a maximum of 18 SV while controlling the electrical and compressed air consumption.

A digital input (for dry contact) is provided on this board in order to make locally, on the concerned slave, a

sequential activation of its SV outputs: at each pulse, a shot is made followed by a pause time. If the input remains

closed (= 1), then the shots follow. Be carreful: these forced locally activation are made independently of the

controls and automation which are managed by the master box/cabinet.

Several slave boxes are used in an SFX+V2.

Each box is identified on the bus by a unique number.

This identifier determines the role of the box in the configuration of the filter (→see associated electrical diagram of

the SFX+V2). To set this number, the card has a rotary switch and microswitches in order to perform the coding:

the number is formed by the position of the rotary switch (0 à 9)

and by adding 10 if SW1 put ON

20 if SW2 put ON

40 if SW3 put ON

Note: the number can therefore

vary from 1 to 79.

Digital input: forcing activation

of SV output.

Be carreful: see above

Board

compressed

air

sensor

Slave box bus communication board

if the last box on the bus, put the central

switch to "ON"

SEQUENCER WITH

DIFFERENTIAL PRESSURE

SWITCH

Technical notice

FI 72.0567.0221E

Page 8 / 45

There are two leds (yellow and red) on the slave board:

Note: possibility of having a local user interface: contact us.

Protections on slave board :

Table 1 : Voltage solenoid valves AC

Supply voltage

230VAC

115VAC

48VAC

24VAC

Solenoids valves voltage

230VAC

48VAC

48VAC

24VAC

24VAC

24VAC

115VAC

48VAC

24VAC

fuse F1 caliber

General protection

F1A

F1A

F1.6A

F1.6A

fuse F2 caliber

General protection

F1A

F1A

F1.6A

F1.6A

fuse F3 caliber

SV protection

F1A

F1A

F1A

F1A

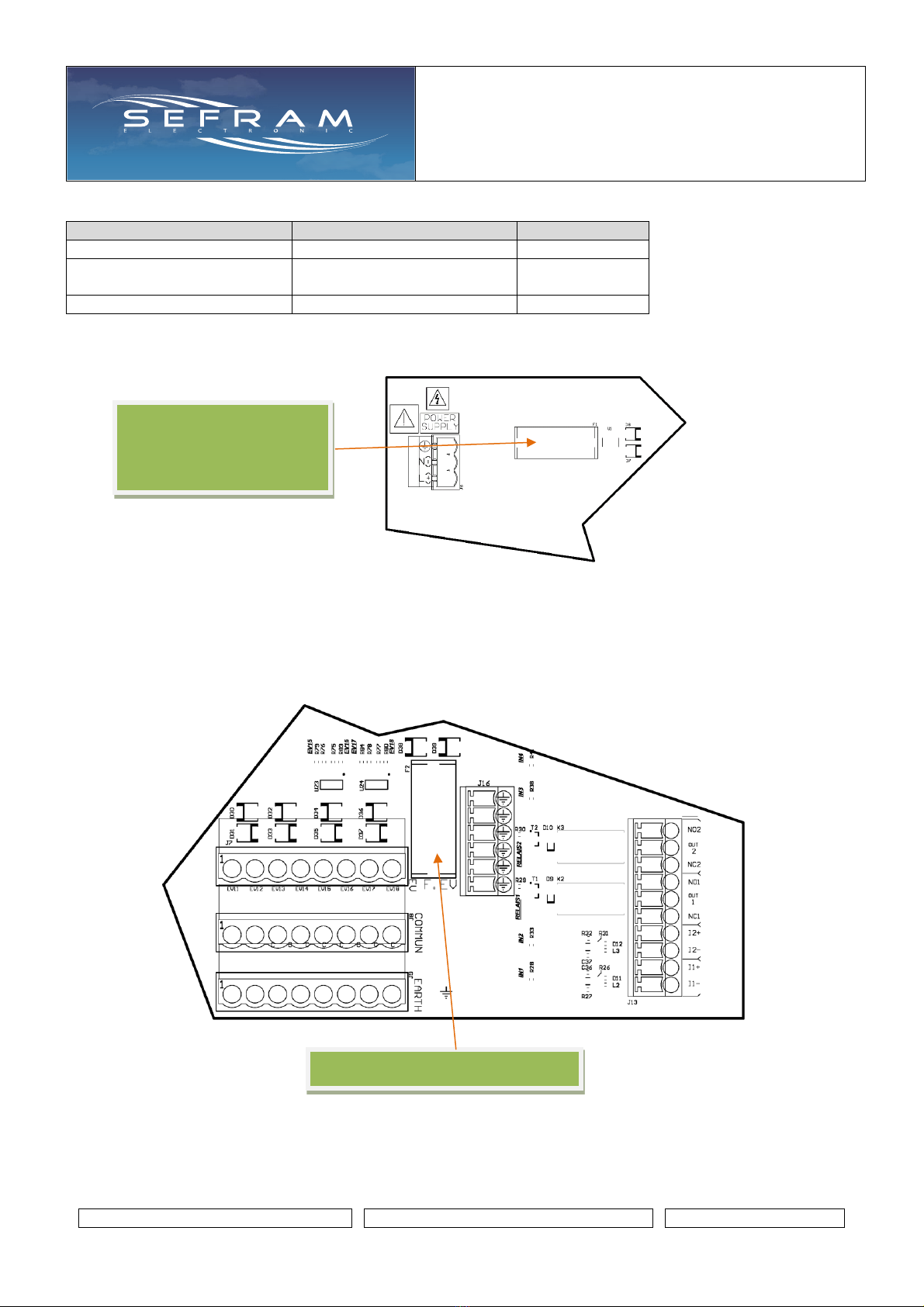

The protection fuses are accessible after dismounting the front panel of the box. The fuses are located at the top left

of the board:

Fuses F1 and F2 :

Device general protection

5x20mm

Caliber: see table 1

Fuse F3 :

SV outputs protection

5x20mm

Caliber: see table 1

If communication on slave bus detected:

Yellow led: representative of receptions (RX)

Red led: representative of transmissions (TX)

If no communication detected on slave bus:

Yellow led: off

Red led: flashes regularly

SEQUENCER WITH

DIFFERENTIAL PRESSURE

SWITCH

Technical notice

FI 72.0567.0221E

Page 9 / 45

Table 2 : Voltage solenoid valves DC

Supply voltage

100 –240VAC

24VDC

Solenoids valves voltage

24VDC

24VDC

General protection

Self-protected power supply

against overcurrents

F2.5A

SV protection

F1.6A

F1.6A

In the 24V DC power supply version only, the general protection fuse is accessible after removing the front panel of

the box. The fuse is located at the top left of the board:

The SV output protection fuse is accessible after removing the front panel of the cabinet. It is located at the bottom

right of the map:

Fuse: SV output protection

Fuse:

General protection

24VDC power supply

version only

SEQUENCER WITH

DIFFERENTIAL PRESSURE

SWITCH

Technical notice

FI 72.0567.0221E

Page 10 / 45

USER INTERFACE :

General :

1. Name of the page

2. Current date and time

3. Current security level

The possible actions by the HMI are associated with the security level in which the system is

See page Security for more information

: link to CYCLE page

: link to previous page

: link to next page

3

2

1

SEQUENCER WITH

DIFFERENTIAL PRESSURE

SWITCH

Technical notice

FI 72.0567.0221E

Page 11 / 45

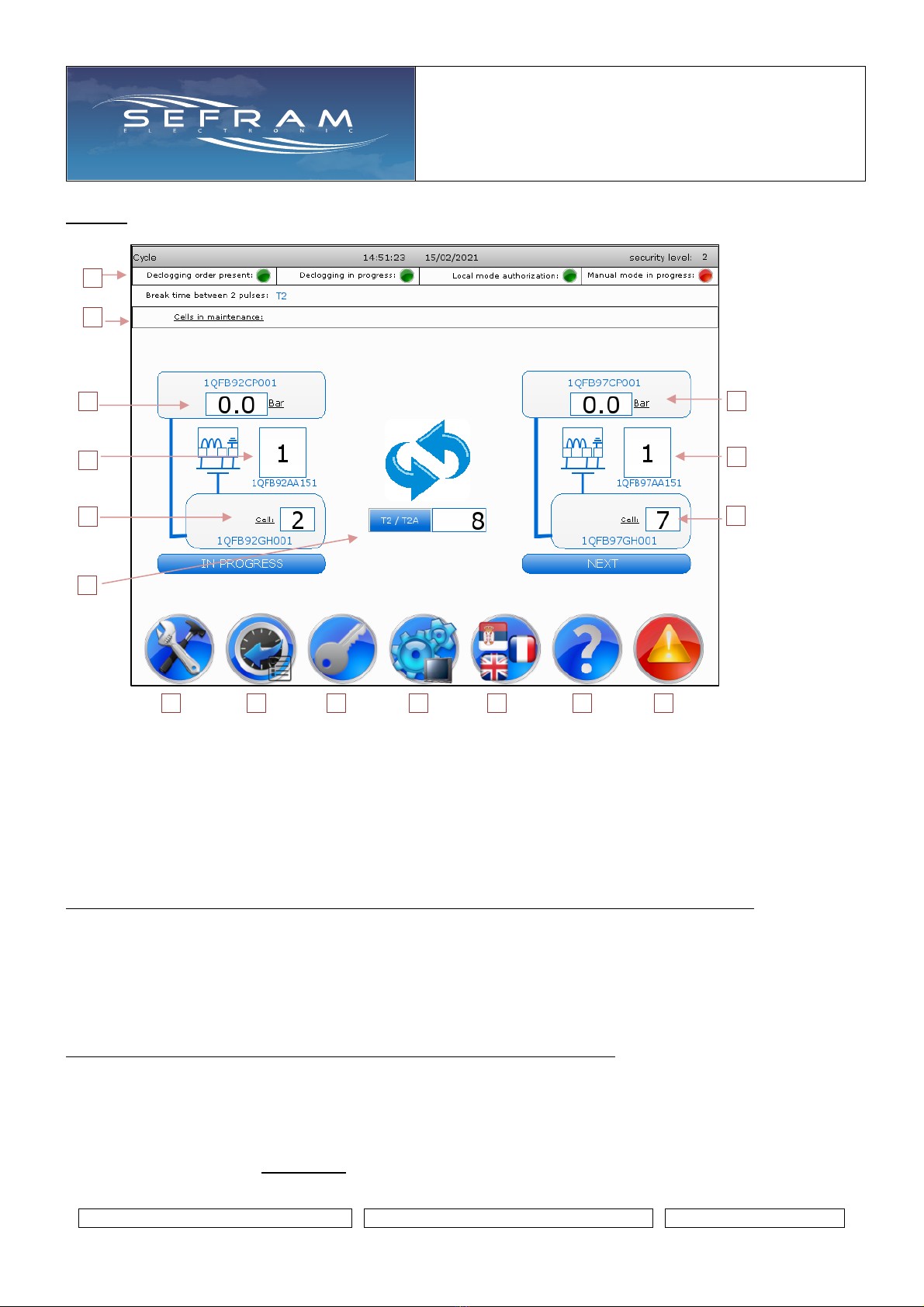

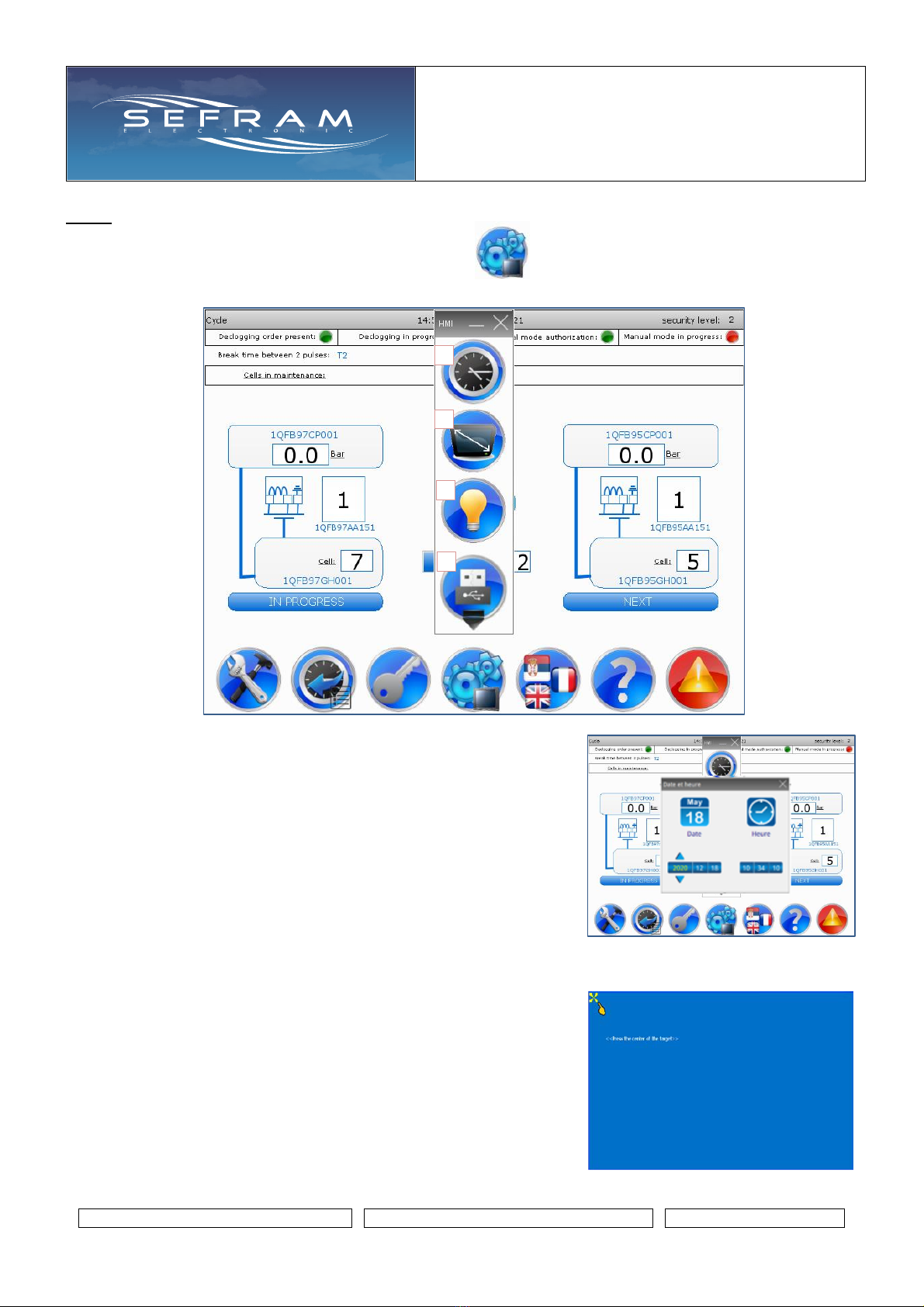

Cycle :

1. Visual on the run orders present / operation in progress

Information transmitted by the DCS via a COM or by manual override via the HMI

These operating orders come from the COM DCS according to the MODBUS exchange table specific to

the configuration

RED : inactive

GREEN = active

2. Display of the number of cells in maintenance. A cell in maintenance cannot be declogged.

All the declogging solenoid valves associated with a cell in maintenance will not be activated (no pulse).

Points 3, 4 and 5 indicate information on the solenoid valve being activated or the last one activated.

Note: nothing is visible if declogging has not yet started (in the case of power on)

3. Measure of the pressure (compressed air) of the associated tank. Display of the name given to the tank.

4. Number of the solenoid valve of the associated cell. Display of the name given to the solenoid valve.

5. Number of the associated cell. Display of the name given to the cell.

6. Current declogging cycle time / Time countdown

Points 7, 8 and 9 indicate information on the next solenoid valve to be activated.

Note: nothing is visible if no steps in the sequence are available.

7. Measure of the pressure (compressed air) of the associated tank. Display of the name given to the tank.

8. Number of the solenoid valve of the associated cell. Display of the name given to the solenoid valve.

9. Number of the associated cell. Display of the name given to the cell.

10. Link to the pages of Parameters

1

2

3

4

5

7

8

9

10

11

12

13

14

15

16

6

SEQUENCER WITH

DIFFERENTIAL PRESSURE

SWITCH

Technical notice

FI 72.0567.0221E

Page 12 / 45

11. Link to the pages of Historical : faults and events

12. Link to the page Security

13. Link to the page HMI parameters

14. Link to the page Langue

15. Link to the page A propos de

16. Link to the page Current faults. Appears only if at least 1 current fault is present

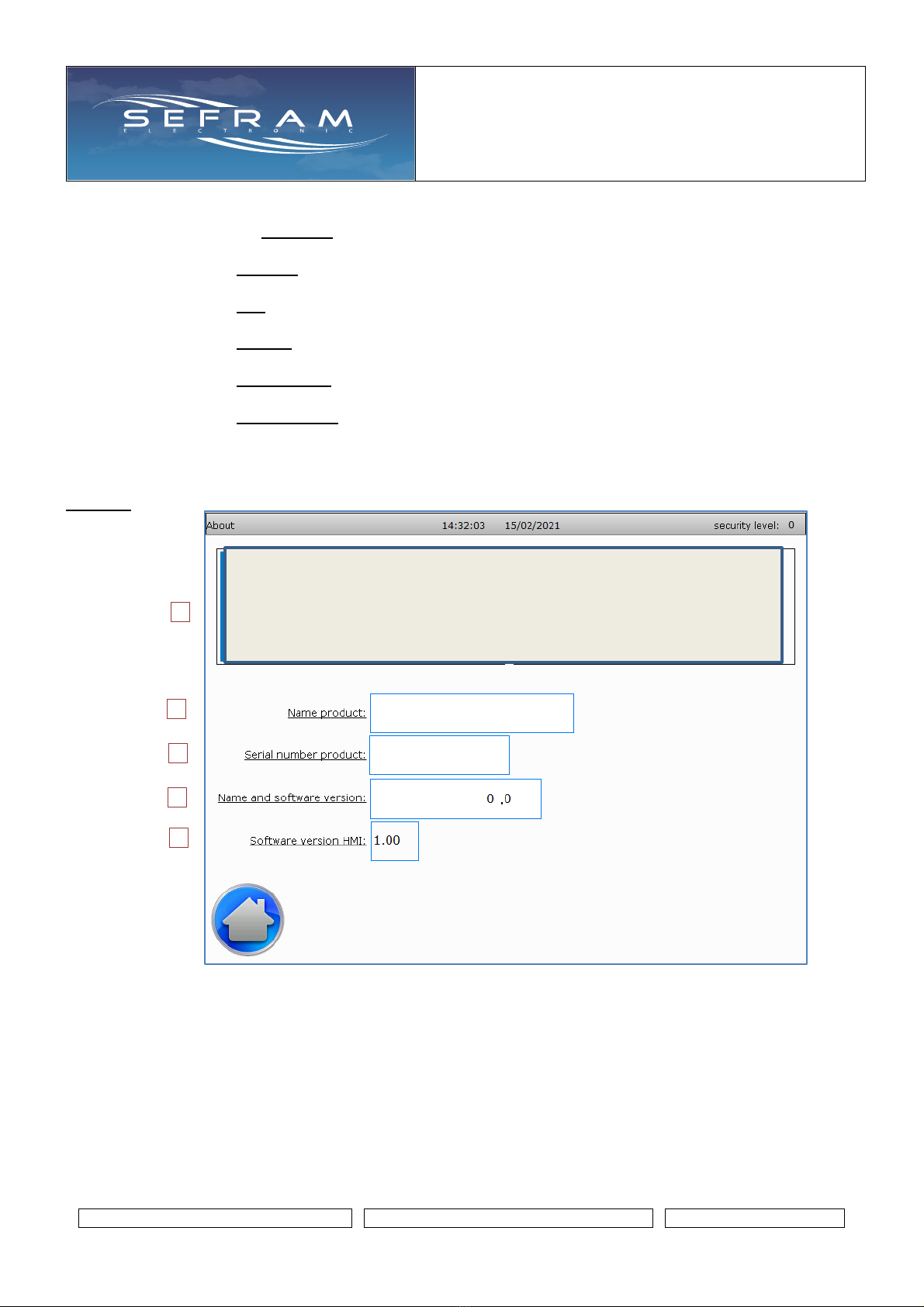

About :

1. Contact details of the manufacturer

2. Product name.

configurable at Manufacturer level

3. Product serial number

4. Name and software version of the central unit board integrated in the master cabinet

5. Software version of the HMI

1

2

3

4

5

SEQUENCER WITH

DIFFERENTIAL PRESSURE

SWITCH

Technical notice

FI 72.0567.0221E

Page 13 / 45

Security :

The possible actions by the HMI are associated with the security level in which the system is.

Each level of security is password protected.

security

Default

password

Navigation

Visualization

Reset faults

Historical

clear

Modifications

and saving of

operating

parameters

Changes to the

sequencer

configuration

Import of

saved

parameters

0 : operator

0

x

x

1 : maintenance

1

x

x

x

x

2 : manufacturer

2

x

x

x

x

x

x

1. Enter the password. Keyboard display by pressing the icon

2. Initialization of the security level to 0 by pressing the icon

3. Current security level

4. Changing the password for the current security level

and those lower

Press the icon to access the modification table

•Press the password you want to change

•Enter the new password using the keyboard

•Confirm with the ENT key

5. Export / Save the parameters set into memory by pressing the icon

Used to make a backup of the SFX+V2 parameters in a reserved memory on the central unit card.

Access in manufacturer level.

6. Import of parameters saved in memory by pressing the icon

Allows you to return to the SFX+V2 parameters that were present during the backup.

Access at maintenance level.

1

2

3

4

5

6

SEQUENCER WITH

DIFFERENTIAL PRESSURE

SWITCH

Technical notice

FI 72.0567.0221E

Page 14 / 45

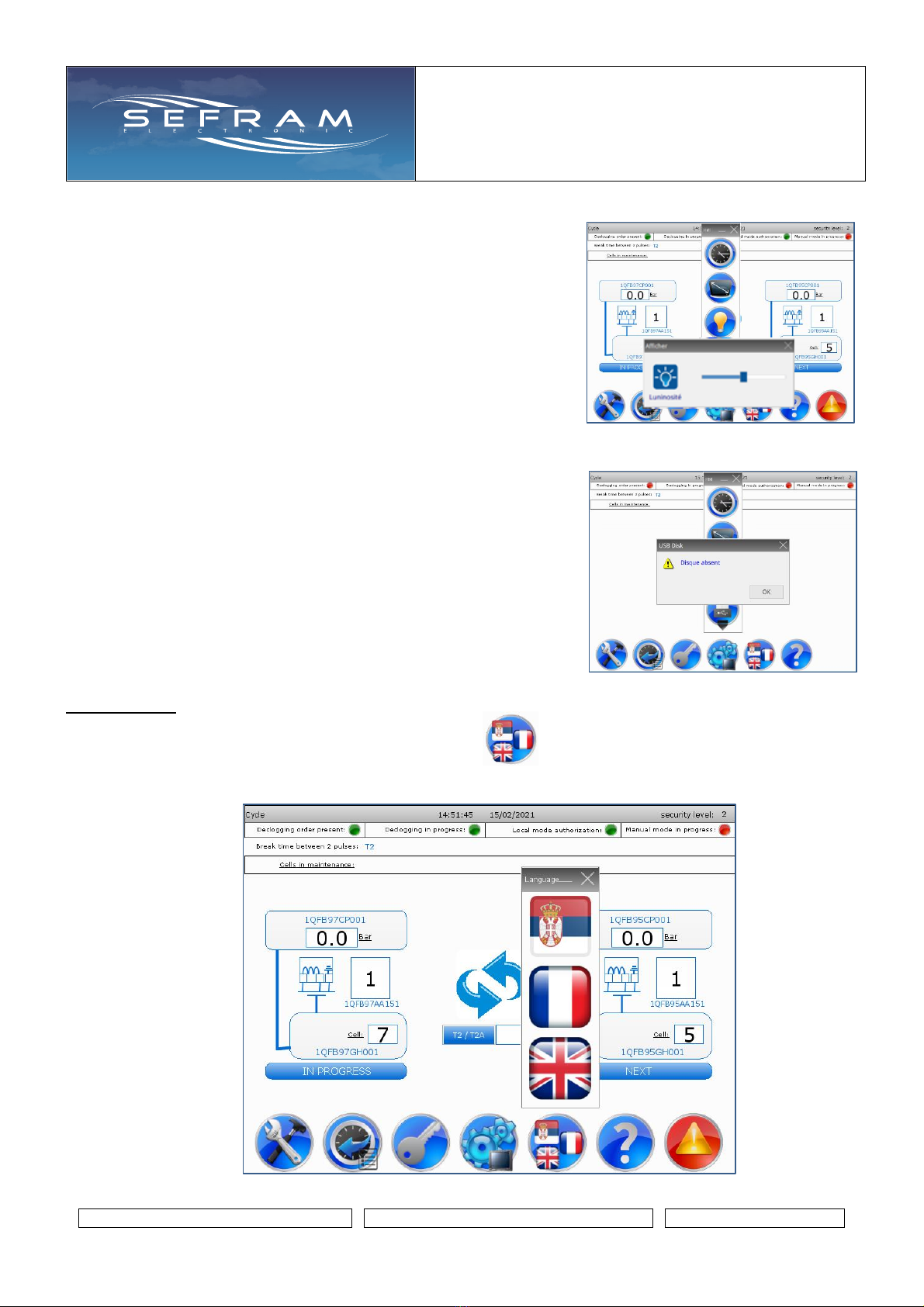

HMI :

Access to the HMI settings is made by pressing the icon

1. Access to the date and time setting by pressing the icon

2. Access to the recalibration of the HMI touch screen by pressing the icon

•Press the cross that appears on the screen

Many times

1

2

3

4

SEQUENCER WITH

DIFFERENTIAL PRESSURE

SWITCH

Technical notice

FI 72.0567.0221E

Page 15 / 45

3. Access to the HMI brightness adjustment by pressing the icon

4. Safe removal of the USB key by pressing the icon

Languages :

Access to the language setting is made by pressing the icon

3 languages are available: Serbian, English and French

Press the icon representing the desired language

SEQUENCER WITH

DIFFERENTIAL PRESSURE

SWITCH

Technical notice

FI 72.0567.0221E

Page 16 / 45

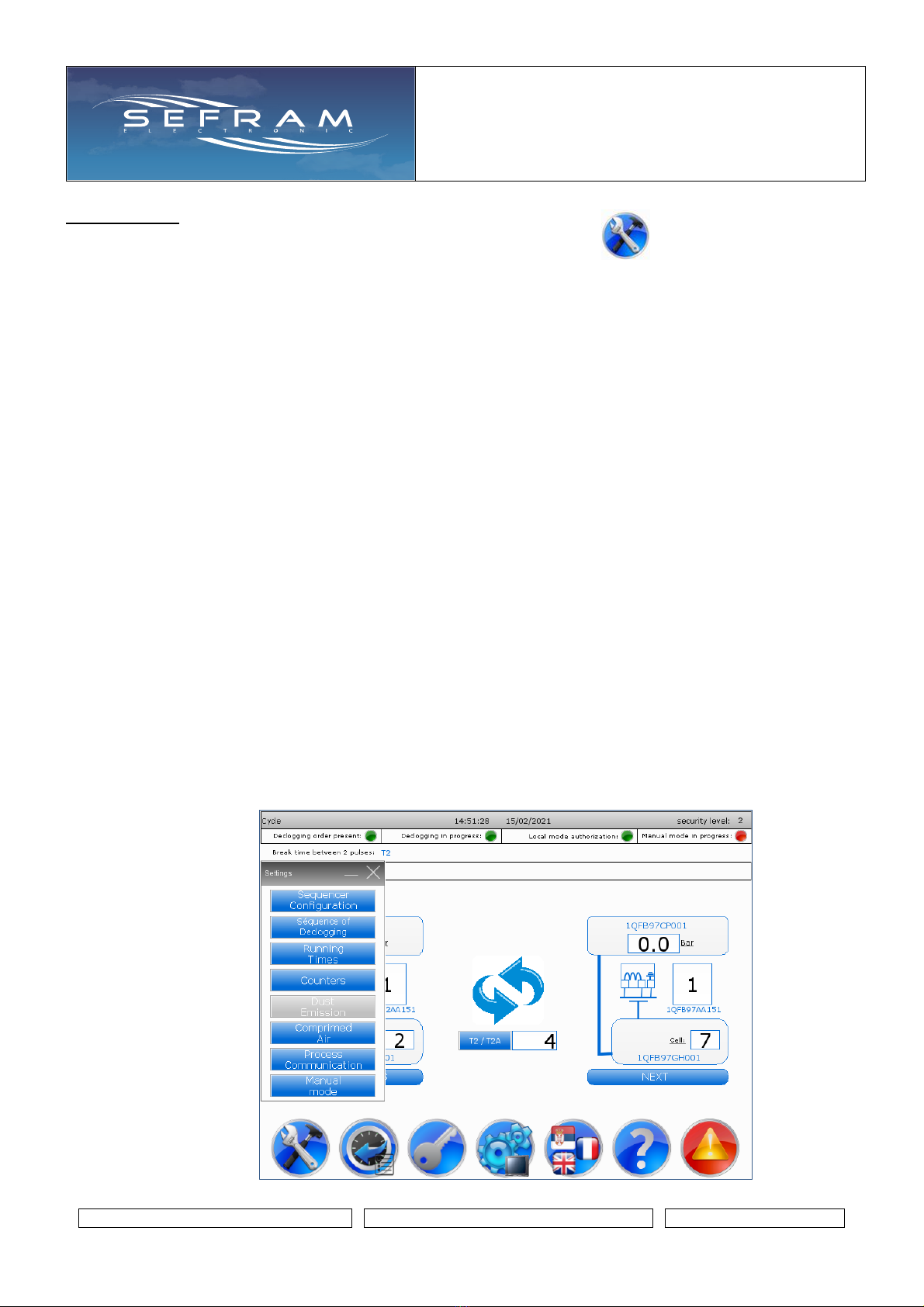

Parameters :

Access to the various sequencer parameters is made by pressing the icon

The parameters are classified according to their function:

•Filter configuration

Display of the number of cells, tanks, number of solenoid valves, etc. which compose the filter

Designation of the declogging cells, tanks and solenoid valves

•Séquence de shots

Configuration of the declogging order for an ONLINE type declogging cycle

•Operating Time

Configuration of operating times, control, etc.

•Counters

Display of various operating counters

•Dust emissions

Settings related to the dust emission incident function - check of pierced sleeves

Accessible if the dust emission function has been integrated into the filter configuration

•Compressed air

Settings related to pressure controls in compressed air tanks

•Customer communication

Settings related to customer communication. Exchange between the sequencer and the operator's

DCS

•Manual mode

Access to the forced operation request of certain functions

Access in level "1: Maintenance"

SEQUENCER WITH

DIFFERENTIAL PRESSURE

SWITCH

Technical notice

FI 72.0567.0221E

Page 17 / 45

Sequencer / filter configuration (1/4):

Display of general parameters on the filter configuration

1. Type of declogging: ONLINE or OFFLINE

2. Number of cells constituting the filter

3. Number of declogging solenoid valves per cell

4. Number of slave boxes required to manage the declogging sequence

5. Number of compressed air tanks constituting the filter

6. Total number of declogging solenoid valves constituting the filter

7. With or without dust emission check option

This option consists in checking that there is no appearance of dust emission downstream of the

filter.

8. If the dust emission check option is integrated, display of the number of probes fitted on the filter.

Parameters 1 to 8 cannot be modified, they are defined during the project.

9. Setting the type of stop of the cleaning cycle

When the SFX+V2 loses the run orders, the cleaning cycle has 2 stop modes:

•Stop "on cycle": the SFX+V2 stops the declogging cycle as soon as the run order is lost.

The cycle will resume where it was stopped when the run order is present again.

•Stop "end of the cycle": the SFX+V2 finishes the current cycle and stops.

Access in maintenance level

10. Depends the configuration, forcing the run order from the HMI

Access at manufacturer level

11. Depends the configuration, forcing the local mode authorisation from the HMI

Access at manufacturer level

1

2

3

4

5

6

7

8

10

11

9

SEQUENCER WITH

DIFFERENTIAL PRESSURE

SWITCH

Technical notice

FI 72.0567.0221E

Page 18 / 45

Sequencer / filter configuration (2/4) :

From this page, it is possible to name each of the tanks constituting the filter.

These names then appear in the CYCLE page, page where it is possible to view the progress of the

declogging cycle.

Naming only possible at manufacturer level.

Operations to do:

•Click in zone “1” the tank you want to name

•Display of the tank selected in zone "2"

•Click in zone 3 so that the

alphanumeric keypad appears

•Enter the desired name on the keypad

•Confirm with the ENT key

•Update of the name of the tank selected in

zone 1

1

2

3

SEQUENCER WITH

DIFFERENTIAL PRESSURE

SWITCH

Technical notice

FI 72.0567.0221E

Page 19 / 45

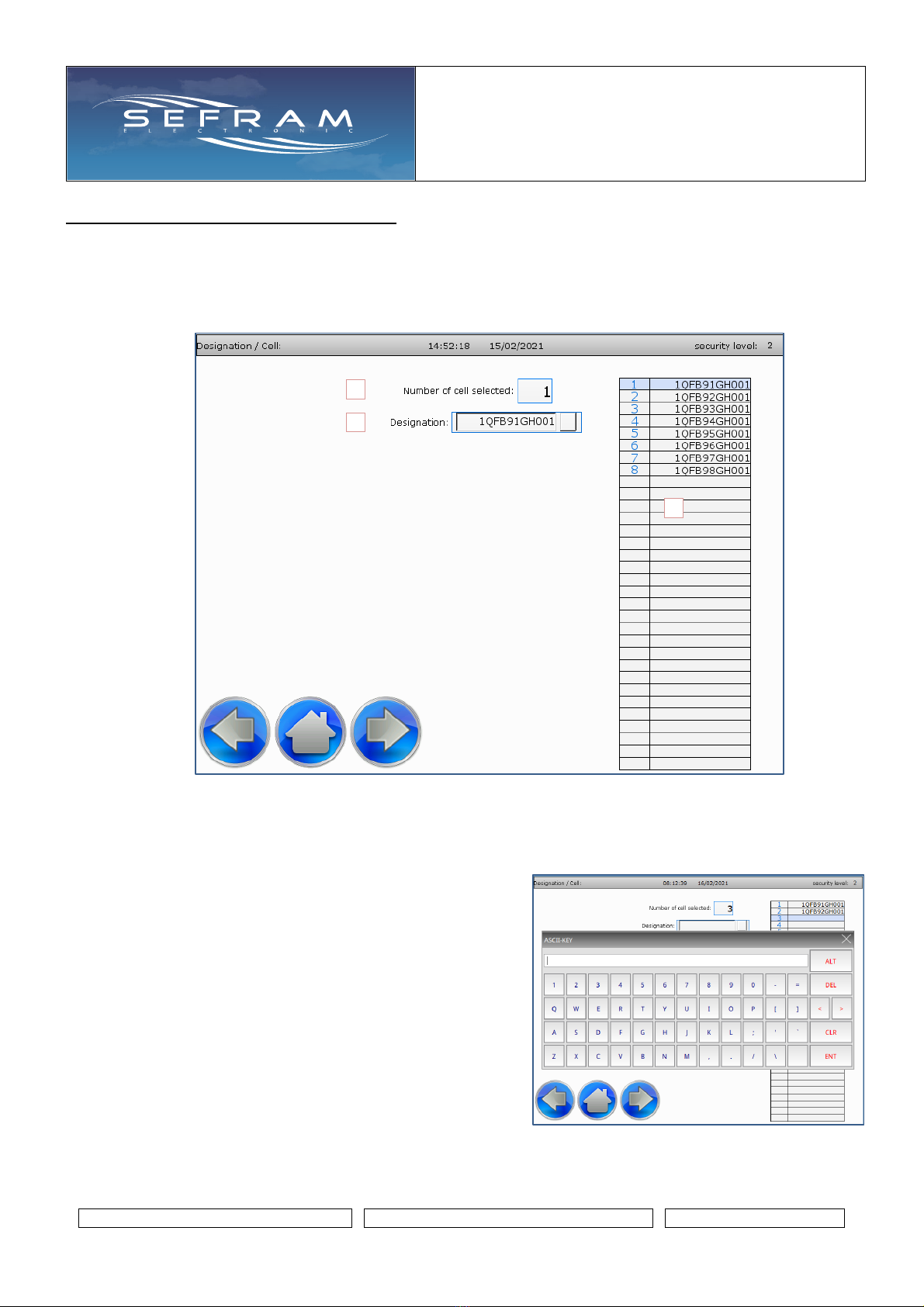

Sequencer / filter configuration (3/4) :

From this page, it is possible to name each of the cell constituting the filter.

These names then appear in the CYCLE page, page where it is possible to view the progress of the

declogging cycle.

Naming only possible at manufacturer level.

Operations to do:

•Click in zone “1” the cell you want to name

•Display of the cell selected in zone "2"

•Click in zone 3 so that

the alphanumeric keypad appears

•Enter the desired name on the keypad

•Confirm with the ENT key

•Update of the name of the cell selected in

zone 1

1

2

3

SEQUENCER WITH

DIFFERENTIAL PRESSURE

SWITCH

Technical notice

FI 72.0567.0221E

Page 20 / 45

Sequencer / filter configuration (4/4) :

From this page, it is possible to name the solenoid valves constituting the filter.

For this part, it is considered that the name of a solenoid valve consists of:

•A prefix identical to all solenoid valves of the same cell

•Followed by a solenoid valve number. Number incremented by 1 for the next one

It is therefore just necessary to record the name of the 1st solenoid valves of each cell.

The following solenoid valves are renamed automatically.

For all other names, it will be necessary to provide it during the project study.

These names then appear in the CYCLE page, page where it is possible to view the progress of the

declogging cycle.

Naming only possible at manufacturer level.

1

2

3

4

5

Table of contents

Other SEFRAM Recording Equipment manuals

Popular Recording Equipment manuals by other brands

Druck

Druck RTD-INTERFACE Quick Start and Safety Manual

Double Intelligence Technology

Double Intelligence Technology SIENNA Multimedia Interface installation guide

Aiwa

Aiwa XC-RW500 Service manual

Tubbutec

Tubbutec SH-1oh1 user manual

Tascam

Tascam DR-680 owner's manual

oticon

oticon Genie 2 Instructions for use