Segway RMP User manual

Segway®Robotic Mobility Platform

User Guide

Segway Inc.

14 Technology Drive

Bedford, NH 03110

Segway is a registered trademark of Segway Inc.

®

Version 2.0 Segway RMP – User Guide

20277-00001 aa 2

Contents

Contents...................................................................................................................................... 2

How to use this guide ................................................................................................................ 3

Introduction ................................................................................................................................ 6

Segway Robotic Mobility Platform Models.............................................................................. 7

Balancing RMP Models ............................................................................................................7

Statically Stable RMP Models .................................................................................................. 8

Operator Supplied Equipment .................................................................................................. 9

RMP Specifications ................................................................................................................ 10

Assembly .................................................................................................................................. 12

RMP100 and RMP200............................................................................................................ 12

RMP50.................................................................................................................................... 14

RMP400.................................................................................................................................. 15

Theory of Operation: Balancing Dynamics ........................................................................... 16

Interaction With The Environment .......................................................................................... 16

Fore/Aft Motion ....................................................................................................................... 19

Turning ................................................................................................................................... 23

Configuration and Operation .................................................................................................. 24

Emergency-stop (E-stop) Function......................................................................................... 24

Safety Shutdown Function ..................................................................................................... 25

Basic Operation ...................................................................................................................... 26

Error Conditions...................................................................................................................... 30

Tire Pressure .......................................................................................................................... 31

RMP Configuration Parameters ............................................................................................. 32

Battery Packs ........................................................................................................................... 35

Safety Guidelines ................................................................................................................... 36

Charging ................................................................................................................................. 38

General Battery Information ................................................................................................... 41

Service Operations .................................................................................................................. 43

Contact and legal information ................................................................................................ 45

Report All Incidents ................................................................................................................ 45

How to Reach Us.................................................................................................................... 45

California Warning .................................................................................................................. 45

Segway Inc Patent and Licensing Information ....................................................................... 45

Glossary.................................................................................................................................... 46

Version 2.0 Segway RMP – User Guide

20277-00001 aa 3

How to use this guide

This guide is provided with Segway Robotic Mobility Platforms (RMP) to aid

users in understanding and integrating the Segway RMP into their application.

• Read this entire guide before turning on the RMP. Users of the RMP100

and RMP200 should pay particular attention to “Theory of Operation:

Balancing Dynamics”.

• Study and understand the section describing the Emergency Stop (E-stop)

and Safety Shutdown functions.

• Browse the “Segway Robotic Mobility Platform Interface Guide” to

understand the control and command architecture of the RMP.

• Install the appropriate USB Driver software before connecting the RMP to

a PC via USB.

Version 2.0 Segway RMP – User Guide

20277-00001 aa 4

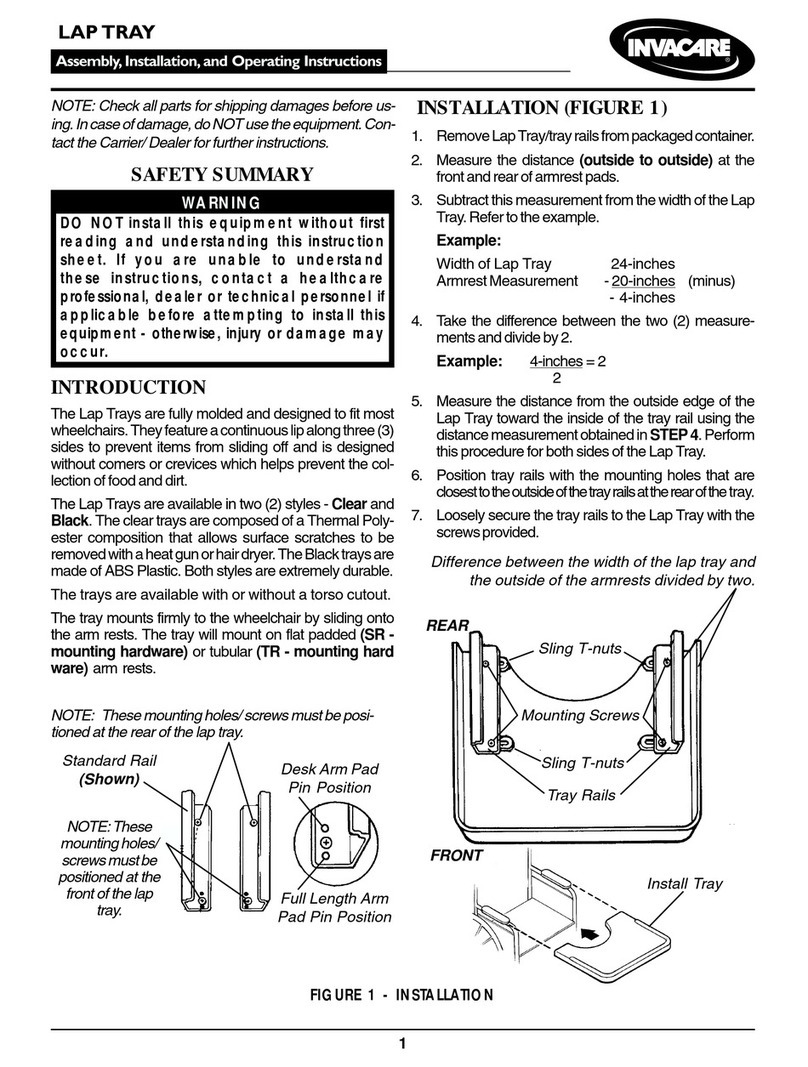

The Segway RMP is a powerful machine – its motors can

produce over 2 hp under certain transient conditions. Read and

fully understand the material in this guide before attempting to

use the RMP.

Do not sit, stand, or ride on the RMP

Do not drive the RMP at people or animals

Only enable the balance controller when the

platform is free to tilt [-20,20] degrees.

Do not lift the RMP off the ground when it is

balancing – the control system will spin the wheels

in an attempt to stay balanced.

20° 20°

!WARNING

Risk of Death or Serious Injury

Version 2.0 Segway RMP – User Guide

20277-00001 aa 5

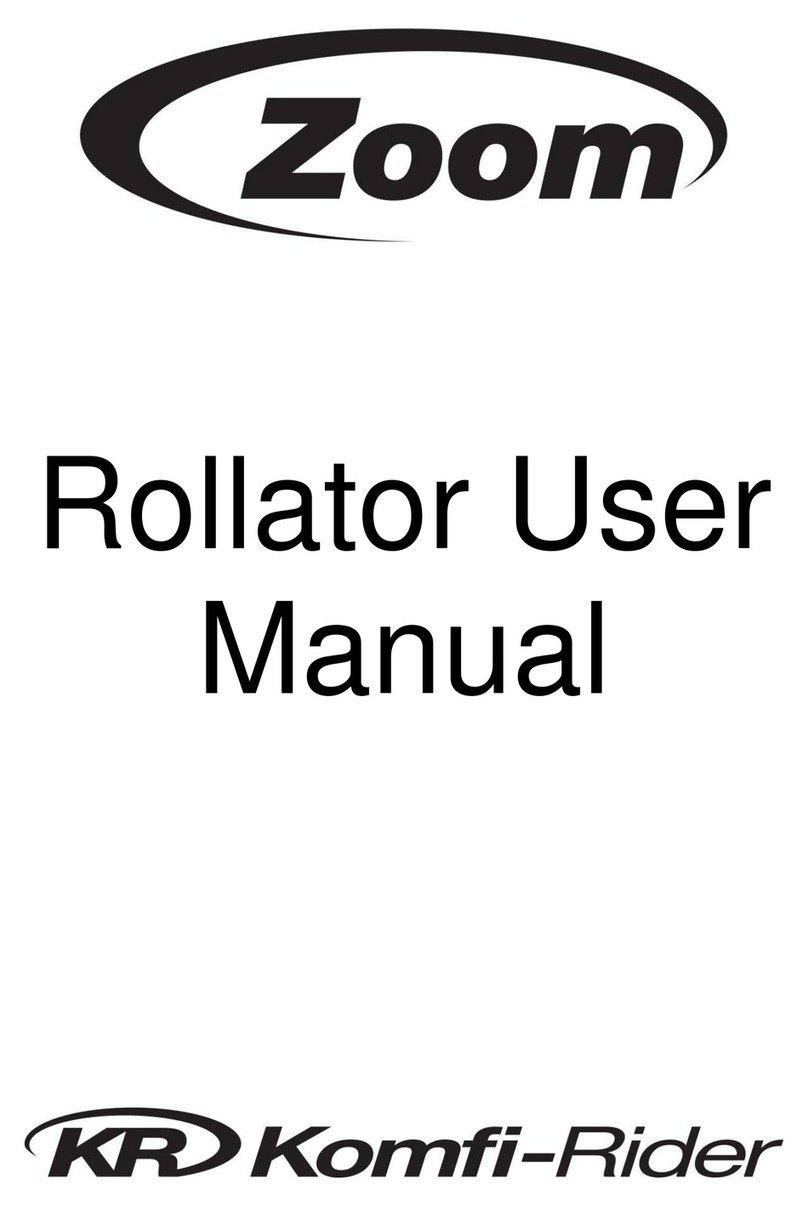

Do not lift the RMP by the wheels – your hands

may get pinched if the frame rotates

Avoid slippery surfaces, loose materials, or any

other surface that does not provide good traction.

Avoid obstacles and any terrain feature that could

interfere with wheel movement.

Disabling the balance controller will cause the

RMP to fall over – A falling RMP could strike

persons or objects nearby.

Pulling the E-Stop Lanyard will cause the RMP to

fall over – A falling RMP could strike persons or

objects nearby.

Do not enter balance mode without the frame

attached.

Alert people in the vicinity when RMP operation is

commencing.

!

!

Version 2.0 Segway RMP – User Guide

20277-00001 aa 6

Introduction

Segway Inc. provides these instructions for users of the Segway™ Robotic Mobility Platform

(RMP). These instructions and the Segway RMP are designed for use by research scientists and

engineers who are experienced with tele-operated and autonomous robots and their safe use.

Persons who lack that experience should not attempt to use the Segway RMP.

The Segway RMP is based on the design of the Segway Human Transporter (HT). The RMP is a

transportation platform designed for integration into a system that has a “control processor.” The

control, or host processor must create velocity and steering commands and output these in the

correct message format to the RMP. The control processor may communicate with the RMP

using either CAN bus or USB. The document “Segway Robotic Mobility Platform Interface Guide”

is essential to understanding communication between the control processor and the RMP. The

control processor may be a laptop receiving joystick commands from a stationary PC, a small

microcontroller (e.g. a Microchip PIC processor), or some other device that can send velocity and

steering commands to the RMP via USB or CAN bus.

The system designer is responsible for implementing appropriate safety

systems to prevent damage and/or injury. The system designer must

understand the operation of the RMP and anticipate hazards that may

result from loss of control or interaction with the environment. The Segway

RMP provides both a control command and an emergency stop switch that

can stop its forward movement in an emergency.

Use of the Segway RMP involves risk. If an RMP tire loses traction or runs into an obstacle, the

Segway RMP can fall over. If the RMP experiences an internal malfunction, the RMP may fall

over. If possible, the Segway RMP will perform a “Safety Shutdown” and automatically come to a

stop in the event of fully discharged battery packs or certain failures in the balancing system.

(After 10 seconds of audible warning, the RMP will shutdown - if the RMP is in “Balance Mode”, it

will fall over.) The Segway RMP does not dynamically balance laterally, so cornering at too great

a speed or traversing a slope can cause the Segway RMP to tip over sideways. The Segway

RMP is equipped with an E-stop tether. Pulling the tether will disable all motor power. In each of

these cases, the Segway RMP could cause injury to nearby person(s) or damage to property

situated on or near the Segway RMP. Careful use of the Segway RMP reduces, but does not

eliminate this risk. This risk may be further reduced by using the Segway RMP in “Tractor Mode”

and attaching additional ground contacting supports (e.g. casters) as described in the Tractor

Mode section of these instructions.

The Segway RMP should not be used to transport any person. Persons should not sit, stand, or

in any way attempt to ride on the Segway RMP.

Read and understand these instructions thoroughly before attempting to use the Segway RMP.

Retain this document for future reference.

Version 2.0 Segway RMP – User Guide

20277-00001 aa 7

Segway Robotic Mobility Platform Models

This guide is intended to help you setup and properly use the Segway RMP. There are five RMP

models, three balancing models (RMP100, RMP200 and RMP200ATV) and two non-balancing

models (RMP50 and RMP400).

Balancing RMP Models

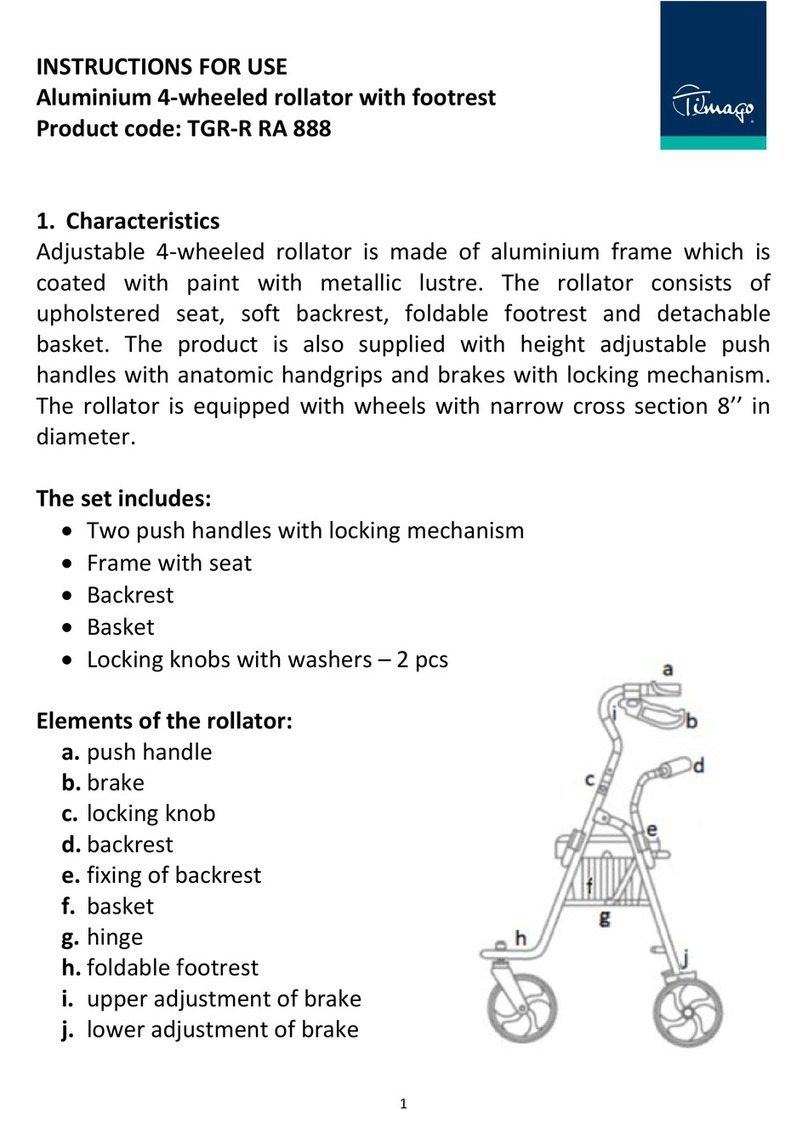

RMP 200 RMP 100

RMP 100: based on the p series Segway Human Transporter (HT).

RMP 200: based on the i Series Segway HT.

RMP 200ATV: based on the Offroad Series Segway XT.

Operation of these three models is nearly identical except for payload and terrain capabilities.

The RMP 100 has been tuned to handle lighter payloads and is more suitable for flat surfaces.

The RMP 200 has larger wheels and stronger motors to handle more challenging terrain and

larger payloads. The RMP200ATV is configured lithium batteries and all-terrain tires to enable

the highest level of terrain and payload capability.

Balancing RMP models have two operating modes: “Tractor Mode” and “Balance Mode”.

Tractor Mode provides statically stable operation, with a larger footprint and lower payload

height. The limits of stability are defined by the distribution of the contact points and the height of

the center of gravity.

Balance Mode provides dynamically stable operation with a smaller footprint and higher payload

height. This has the benefit of allowing for a much higher center of gravity while still maintaining

a small footprint.

Version 2.0 Segway RMP – User Guide

20277-00001 aa 8

Statically Stable RMP Models

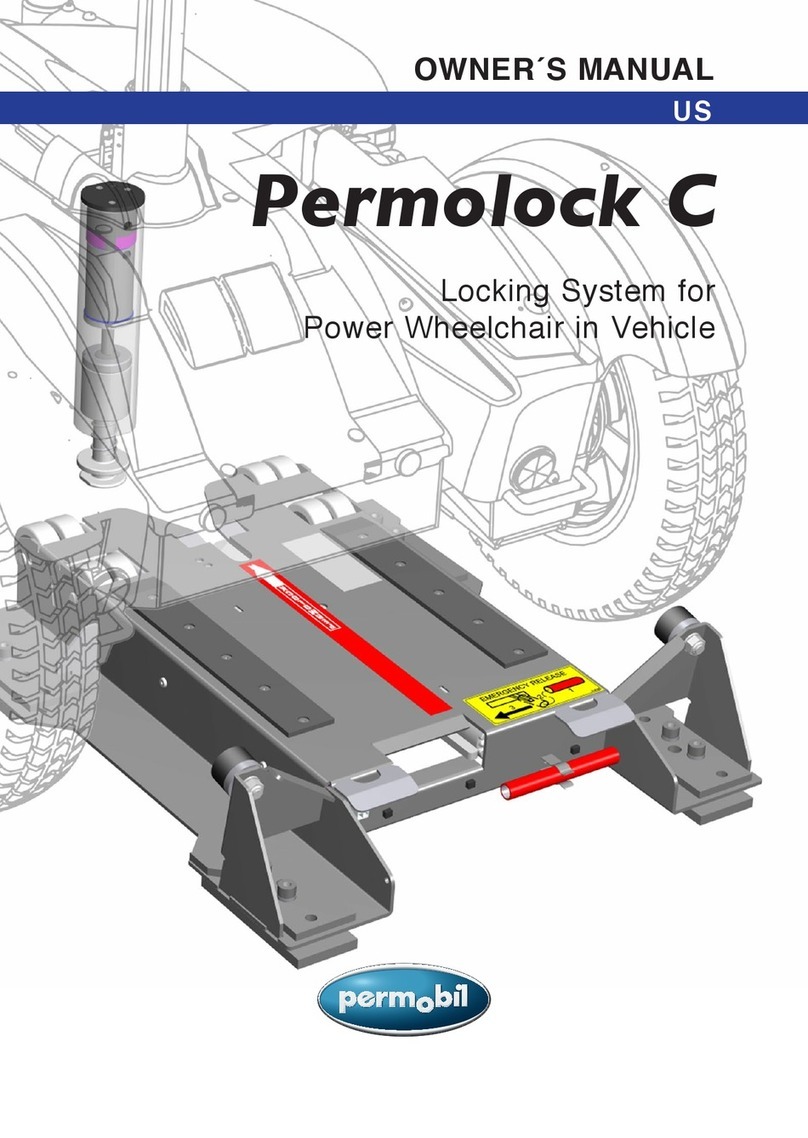

RMP 400 RMP 50

RMP 400: based on the Segway XT.

RMP 50: based on the p series Segway HT.

The RMP400 and RMP50 have only one operating mode: “Tractor Mode”

Tractor Mode provides statically stable operation, with a larger footprint and lower payload

height. The limits of stability are defined by the distribution of the contact points and the height of

the center of gravity.

Version 2.0 Segway RMP – User Guide

20277-00001 aa 9

Operator Supplied Equipment

The velocity and turn rate of the RMP are controlled via USB or Controller Area Network (CAN)

bus commands. These may be generated using a dedicated microcontroller, a PC system or

other computer based system to initiate commands. The user must provide a computer system

and write an application to communicate with the RMP.

The “Segway Robotic Mobility Platform Interface Guide” provides detailed information about the

communications interface. The information contained in the interface guide will be necessary to

control the RMP with a device other than the demonstration system.

Version 2.0 Segway RMP – User Guide

20277-00001 aa 10

RMP Specifications

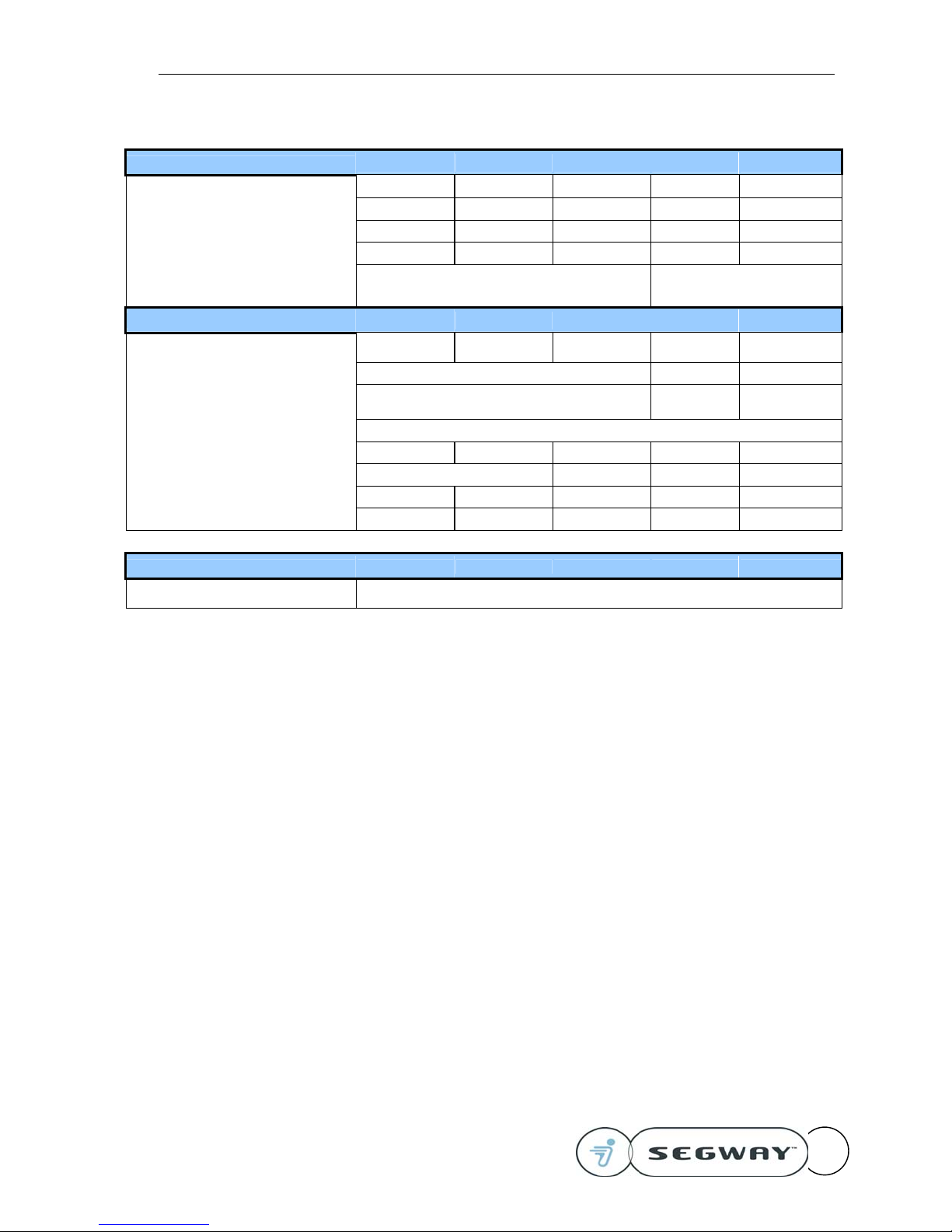

Command Interface All Models

Communications Link USB external, CAN available via internal connector

Control Industrial pushbutton interface for power and mode select

Data Update Rate 100 Hz

RMP firmware Programmed at assembly

Demo software Windows 2000 executable and source code provided

Performance RMP200 RMP200 ATV RMP100 RMP50 RMP400

Top Speed 10 mph (16 kph) 10 mph (16 kph) 6 mph (10 kph) 4 mph (6 kph) 18 mph (29 kph)

Payload 100 lbs (45 kg) 150 lbs (67 kg) 100 lbs (45 kg) 50 lbs (45 kg) 200 lbs (90 kg)

Turning Radius Zero Zero

(load dependent)

Turning Envelope 30 in (76 cm) 34 in (86 cm) 24 in (61 cm) 25 in (64 cm) 50 in (127 cm)

Maximum Climbing and Descending

Capability (traction limited) 10 degrees 5 degrees 0 degrees 45 degrees

Controller modes Dynamically stabilized and statically stable controller

modes Statically stable control mode ONLY

Batteries RMP200 RMP200 ATV RMP100 RMP50 RMP400

Battery Chemistry NiMH Li NiMH NiMH Li

Acceptable line current for charger: 90 to 260 Volts; 50 to 60 Hz

Charge Rate (72 Volt nominal) 600 milliamps per battery

Battery Life (Full Charge / Discharge Cycles) 300 to 500

Operating Temperature Range (NiMH) 32°F to 122°F (0°C to 50°C)

Operating Temperature Range (Li) 14°F to 122°F (-10°C to 50°C)

Charging Temperature Range (NiMH) 41°F to 77°F (5°C to 25°C)

Charging Temperature Range (Li) 14°F to 122°F (-10°C to 50°C)

Battery Weight (total) 19 lbs (8.6 kg) 23 lbs (10.3 kg) 15 lbs (6.8 kg) 7.5 lbs (3.4 kg) 46 lbs (20.6 kg)

Range and Energy RMP200 RMP200 ATV RMP100 RMP50 RMP400

Range under Optimal Test conditions 15 mi (24 km) 15 mi (24 km) 12 mi (19km) 6 mi (10 km) 15 mi (24 km)

Range under Good conditions 12 mi (19km) 12 mi (19km) 8 mi (13 km) 4 mi (6 km) 12 mi (19km)

Range under Severe conditions 8 mi (13 km) 8 mi (13 km) 4 mi (6 km) 2 mi (3 km) 6 mi (10 km)

Run time, stationary 8 hours

Recharge Time (from empty) ~6 hours ~8 hours ~4 hours ~4 hours ~8 hours

Environmental Capabilities All Models

Storage & Transport Temperature (no

damage to machine, <1 month) -20°C to +50°C (-4°F to +122°F)

Storage Temperature (for normal charging

and operation) +15°C to +35°C (+59°F to +95°F)

Humidity Range 0 to 95% RH (Storage); 5% to 95% RH (Operational)

Altitude Range (storage) Sea Level to 40,000 ft. (12,000 m)

Altitude Range (operation) Sea Level to 12,000 ft (3,700 m)

Version 2.0 Segway RMP – User Guide

20277-00001 aa 11

Dimensions RMP200 RMP200 ATV RMP100 RMP50 RMP400

Overall width 25 in (63 cm) 31 in (79 cm) 21.8 in (56 cm) 21.8 in (56 cm) 31 in (79 cm)

Overall height 29.5 in (75 cm) 30.5 in (78 cm) 27 in (69 cm) 27 in (69 cm) 21 in (53 cm)

Overall length 19 in (48 cm) 21 in (53 cm) 16 in (41 cm) 16 in (41 cm) 43.5 in (111 cm)

Weight 140 lb (64 kg) 160 lb (73 kg) 125 lb (57 kg) 60 lb (27 kg) 220 lb (100 kg)

Equipment mounting Multiple mounting bosses on top plate and side

support

Propulsion System

Motor Torque Constant @ motor shaft 0.071 Nm/amp 0.071 Nm/amp 0.054 Nm/amp 0.054 Nm/amp 0.071 Nm/amp

Motor Drive Peak Current, per wheel 70 amp 35 amp 70 amp

Motor Drive Continuous Current, per

wheel 24 amp 12 amp 24 amp

Gearbox Ratio 24:1

Battery Pack Capacity (total) 380 watt-hours 800 watt-hours 290 watt-hours 145 watt-hours 1600 watt-hours

Battery Pack Voltage (nominal) 72 volts 56 volts 56 volts 72 volts

Tire Diameter 19 in (48 cm) 21 in (53 cm) 16 in (41 cm) 16 in (41 cm) 21 in (53cm)

Wheel Track Width 21 in (53 cm) 24.5 in (62 cm) 18 in (46 cm) 18 in (46 cm) 24.5 in (62 cm)

Limited Warranty All Models

All parts & components 90 days

Version 2.0 Segway RMP – User Guide

20277-00001 aa 12

Assembly

All Segway Robotic Mobility Platform models may be assembled with basic hand tools. Using a

quality torque wrench is the best way to avoid stripped or broken fasteners, stripped threads, and

fasteners that vibrate loose. All fasteners should be checked periodically for tightness. The RMP

powerbase must be securely supported to prevent tipping before you begin assembling the RMP

frame.

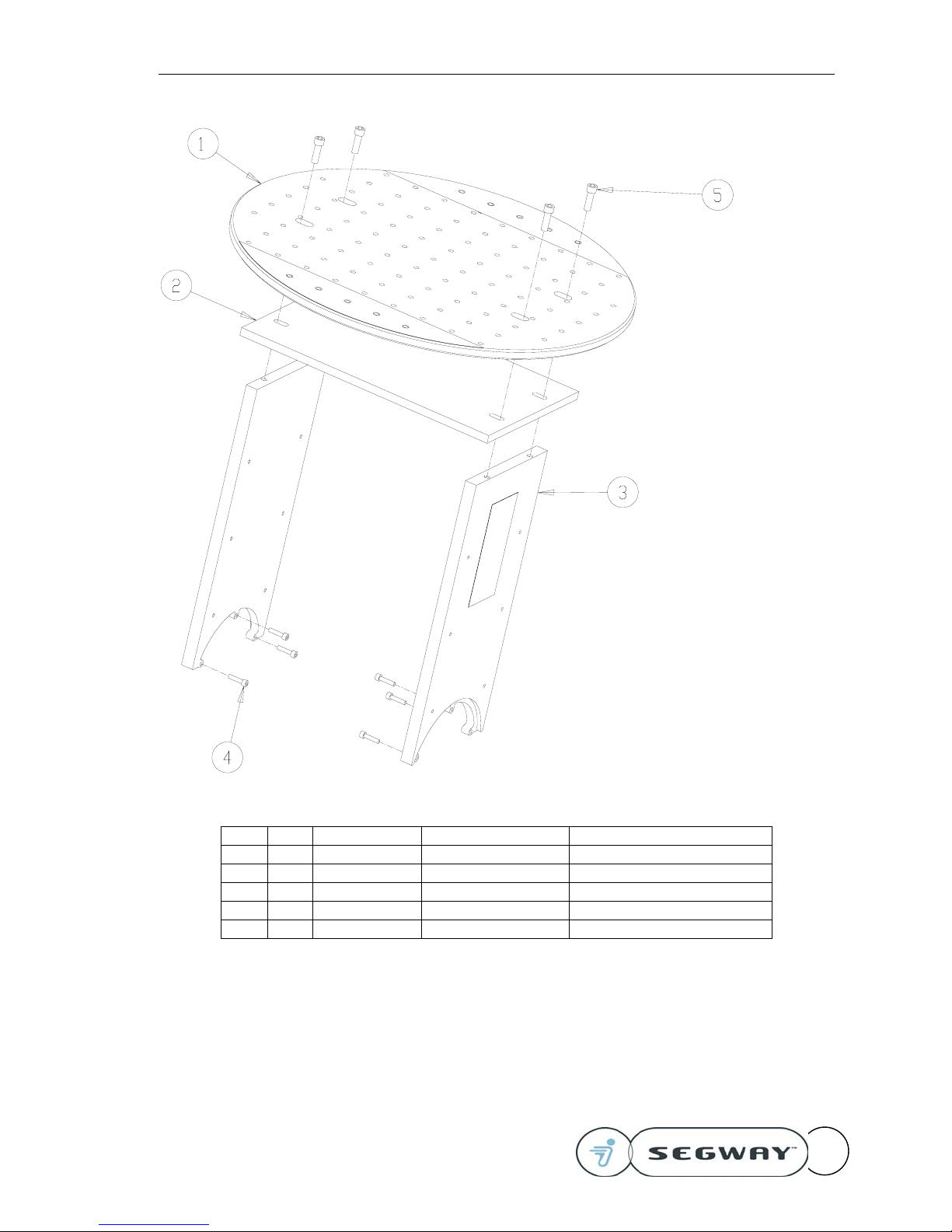

RMP100 and RMP200

The RMP Top Plate weighs approximately 30 lbs (13.6 kg) and the RMP Ballast Plate weighs 25

lbs (11.3 kg). Use an assistant if necessary to maneuver these plates to avoid dropping them or

pinching fingers. Exploded drawings of the various RMP frames are contained at the end of this

section.

Minimum Tools needed for assembly:

• 5mm Hex wrench

• 8mm Hex wrench

Recommended tools for easiest assembly:

• Torque wrench, 3/8 drive

• 5mm Hex bit socket, 3/8 drive

• 8mm Hex bit socket, 3/8 drive

Refer to the exploded view drawing below and begin by assembling the Vertical Plates (3) to the

inside of the gearboxes. Use M6 screws (4) to fasten the Vertical Plates to the gearboxes. Do no

tighten fully at this time.

If using the Ballast Plate, set it on the top of the Vertical Plates.

Place the Top Plate (1) on top and align the holes with the Vertical Plates. Use the appropriate

length 3/8-16 screws (5) to fasten the Top Plate to the Vertical Plates. If the holes do not line up

exactly, loosen the M6 screws (4) and move the Vertical Plates.

Snug down the 3/8-16 base plate screws then snug down the M6 screws. Next, torque the Top

Plate screws to 54 N-m (40 ft-lbs) and the M6 screws to 18 N-m (13.5 ft-lbs).

Version 2.0 Segway RMP – User Guide

20277-00001 aa 13

Item Qty. Part Number Description Comments

1 1 17941-00001 RMP Top Plate

2 1 17507-00001 RMP Ballast Plate

3 2 17506-00001 RMP Vertical Plate

4 6 17512-00001 M6x1x25 SHCS Tighten to 18 N-m (13.ft-lb)

5 4 17510-00001 3/8-16x1.25 SHCS Tighten to 54 N-m (40 ft-lb)

Version 2.0 Segway RMP – User Guide

20277-00001 aa 14

RMP50

The RMP50 is shipped fully assembled and ready for use. An exploded view of the RMP50

frame is supplied should disassembly be required.

Version 2.0 Segway RMP – User Guide

20277-00001 aa 15

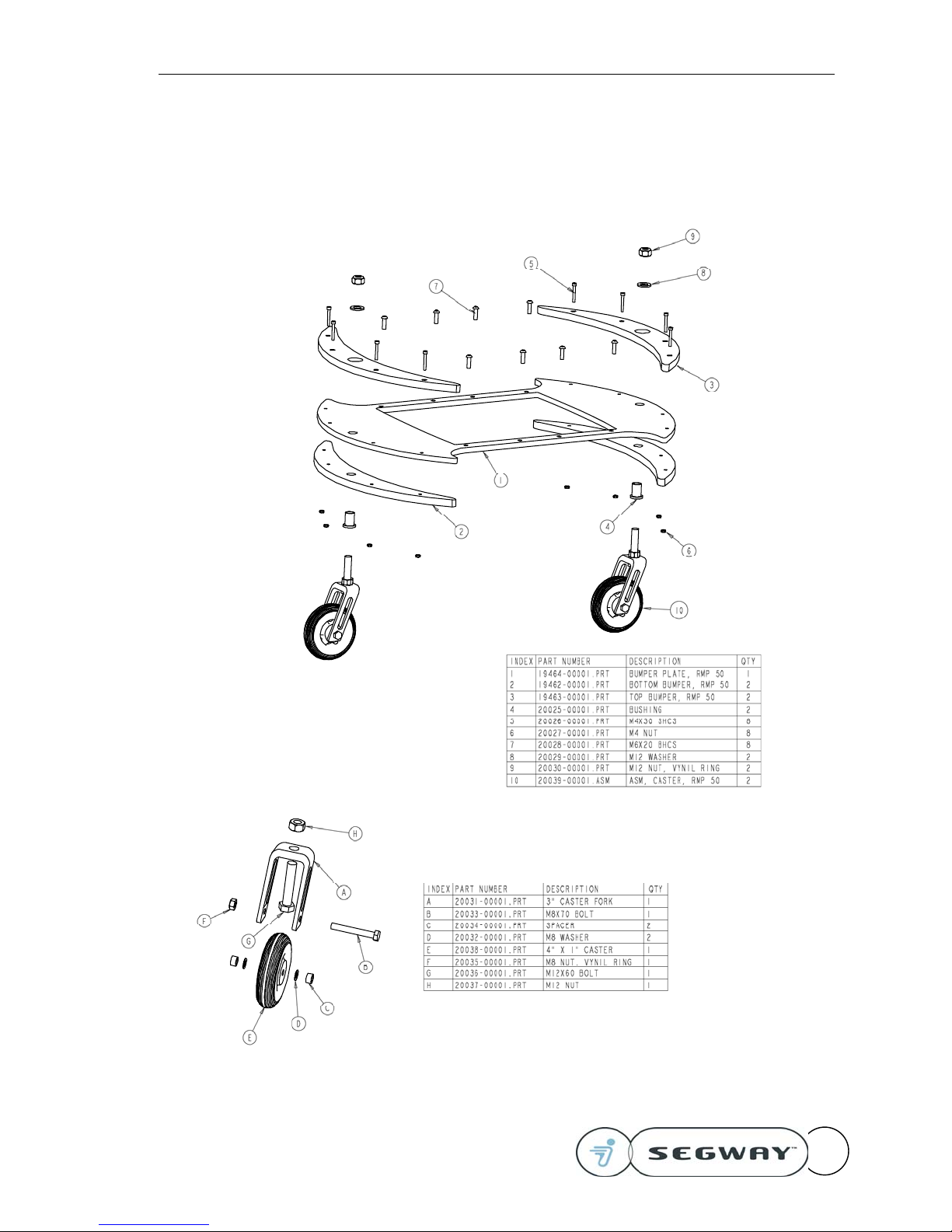

RMP400

The RMP400 is shipped fully assembled and ready for use. An exploded view of the RMP400

frame is supplied should disassembly be required.

Version 2.0 Segway RMP – User Guide

20277-00001 aa 16

!

Theory of Operation: Balancing Dynamics

Read and understand this section before starting and

operating the RMP. This information is critical to

understanding RMP operation.

The Segway Robotic Mobility Platform is a dynamically stabilized machine and has some unique

characteristics when compared to other robotic platforms. It may take some time to learn to use

these dynamics to advantage. Read and understand this entire manual before using the Segway

RMP.

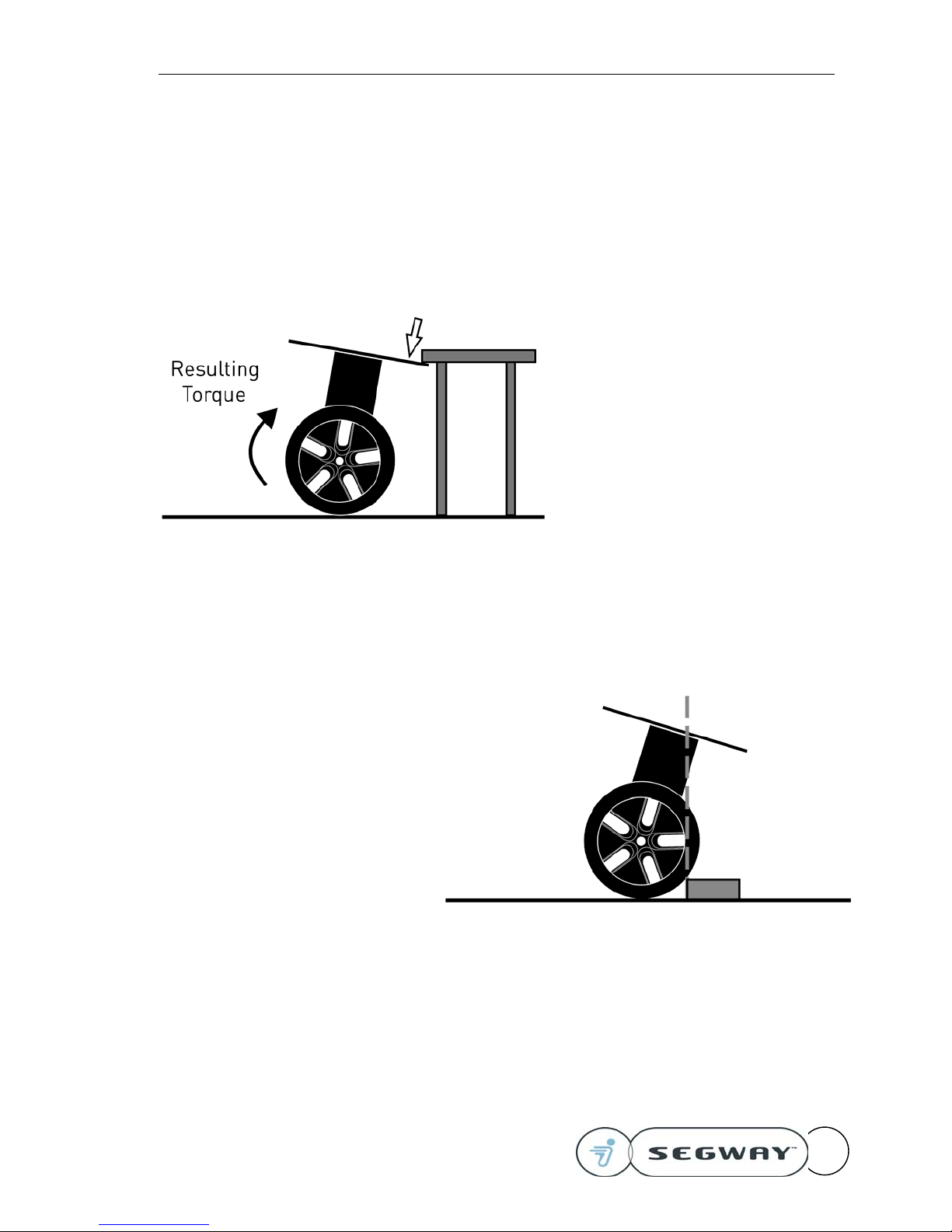

Interaction With The Environment

When the RMP makes contact with other objects in the environment, the results can be counter-

intuitive at first.

If the RMP is displaced from its desired position, it will lean against the displacement force,

creating a new equilibrium position. The harder it is pushed, the more it will lean.

Version 2.0 Segway RMP – User Guide

20277-00001 aa 17

Consider the situation depicted at

the right. The resulting torque

will try to drive the machine to the

right in order to reach a level

orientation. If the wheels and

frame are free to rotate,

equilibrium will be achieved.

Pushing down on the right edge of

the RMP will cause the machine

to move to the right.

The case shown to the right is very

different from a dynamic standpoint, but

the controller cannot differentiate

between this configuration and the one

above. In this case, the RMP will

accelerate faster and faster to the right

trying to bring the machine to level

equilibrium. It will quickly trip the position

error limit of 12 feet and switch to tractor

mode.

This case also results in rapid

acceleration to the right until the RMP

can level itself.

If the RMP is driven so that it

gets one edge caught under a

Version 2.0 Segway RMP – User Guide

20277-00001 aa 18

surface (e.g. a counter or table),

the resulting torque is also to

the right. In this case, for the

RMP to drive to the left on its

own, the edge under the table

must raise up to tilt to the left.

This will lift up on the table.

To get the RMP unstuck, an

external force must be applied to

push the RMP’s right edge down,

forcing the wheels to the left. If a

simultaneous command to drive

the RMP back is also applied, the

force required will diminish.

Alternatively, use the E-Stop to

disable the motors.

When the RMP needs to roll over an

obstacle, the CG of the system must

tilt forward over the contact point.

When the tire makes contact with

the obstacle, it stops rolling and the

frame tilts forward. Once the CG is

over the contact point with the

obstacle, the RMP will roll over the

obstacle (provided the obstacle is

small and sufficient traction exists).

Because torque is required to hold

this tilted position, there is a

tendency to overshoot the obstacle.

Approaching obstacles with a small

initial velocity typically helps in

traversing obstacles.

Version 2.0 Segway RMP – User Guide

20277-00001 aa 19

Fore/Aft Motion

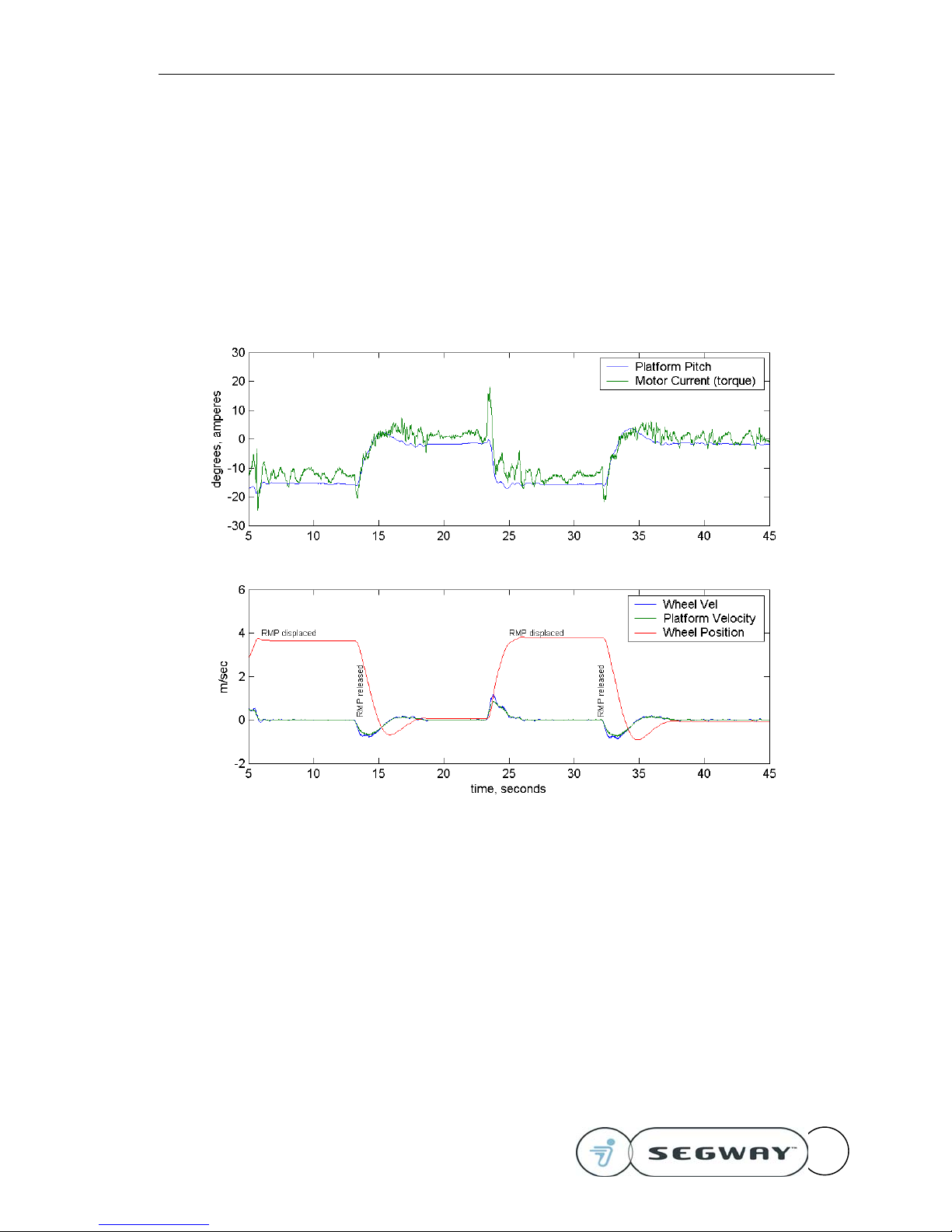

The following graphs show what happens when the RMP is displaced from a resting position.

Pay attention to the following behaviors.

• The torque applied by the wheels is non-zero when the RMP is displaced from equilibrium – it

is trying to return to its start location

• It will overshoot the desired pitch and position a little before coming to rest

• The wheels travel faster (and farther) than the top plate during this oscillation

• The response will vary slightly depending on the payload and the controller gain schedule

used.

This figure shows the response of the RMP when it is displaced and released

from an equilibrium position. The velocity command is zero throughout.

Version 2.0 Segway RMP – User Guide

20277-00001 aa 20

Velocity Commands

The next series of graphs show how the RMP accelerates in response to a desired velocity

command. Note the following features in the data:

• The wheels move back slightly at the start of a forward acceleration, creating a delay

• The wheel speed overshoots the desired speed in order to stop accelerating and maintain

constant speed

• The tilt angle of the RMP is a direct function of the acceleration limit – lower acceleration

rates produce less tilt.

This figure shows the response of the RMP to a step input in the velocity

command. The commanded speed is 4 mph or 1.77 m/sec. The Acceleration

scale factor was set to 50% of maximum (8 counts)

Table of contents