Table of Contents

Section 1: Introduction............................................................................................................ 1

Manual Overview......................................................................................................................................1

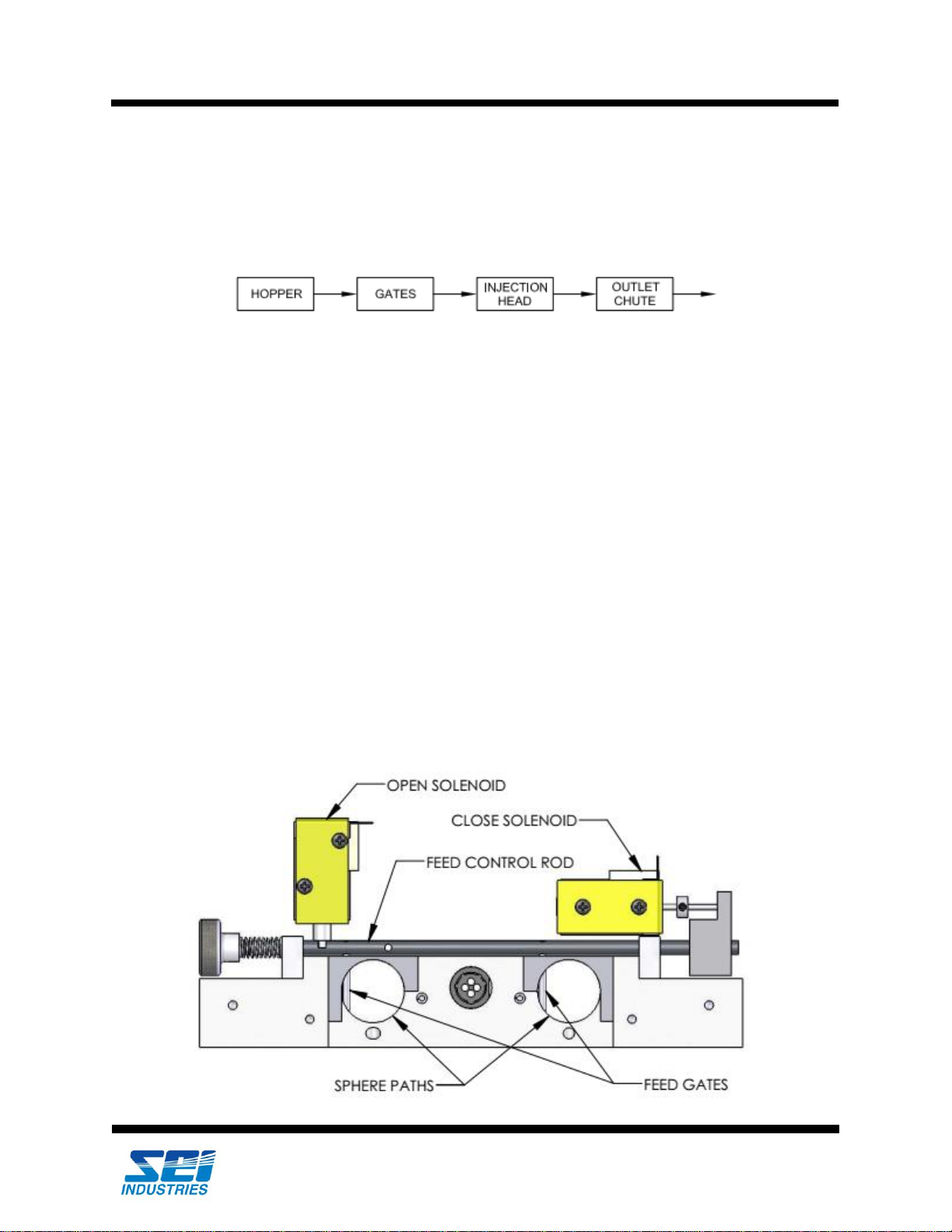

Section 2: Sphere Handling System....................................................................................... 3

Description................................................................................................................................................3

Sphere System Components .....................................................................................................................7

Sphere System Troubleshooting .............................................................................................................16

Section 3: Glycol System .......................................................................................................21

Description..............................................................................................................................................21

Glycol System Components....................................................................................................................22

Glycol System Troubleshooting..............................................................................................................25

Section 4: Water System ........................................................................................................31

Description..............................................................................................................................................31

Water System Components.....................................................................................................................32

Water System Troubleshooting...............................................................................................................35

Section 5: Control System......................................................................................................37

Control System Operation.......................................................................................................................37

Control System Components ..................................................................................................................45

Control System Troubleshooting............................................................................................................50

Section 6: Repairs for All Systems........................................................................................75

Hopper Repairs .......................................................................................................................................75

Feed Gate Repairs...................................................................................................................................80

Injection Head Repairs............................................................................................................................88

Glycol System Repairs............................................................................................................................92

Water System Repairs.............................................................................................................................97

Control System Repairs ........................................................................................................................103

Section 7: Supplier Cross Reference ..................................................................................111

Supplier Chart.......................................................................................................................................111

Alternate Supplier Contacts..................................................................................................................114

Section 8: Warranty ..............................................................................................................115

Appendix: Safety Data Sheet ...............................................................................................117