6138A ChronOgraPh Mechanisllfl

Explanationson this page

arefor the nuclcus

of 6138A.

Sufficiently checkand adjust the assernbled

movetnent.

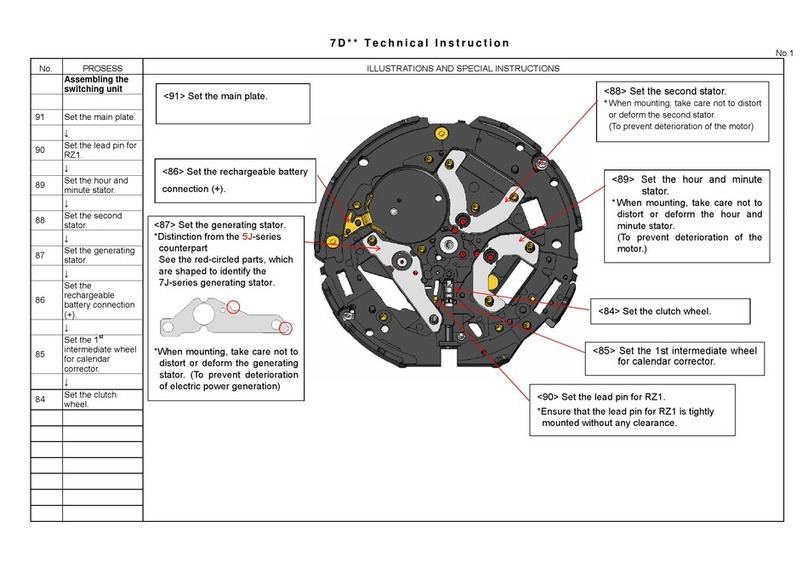

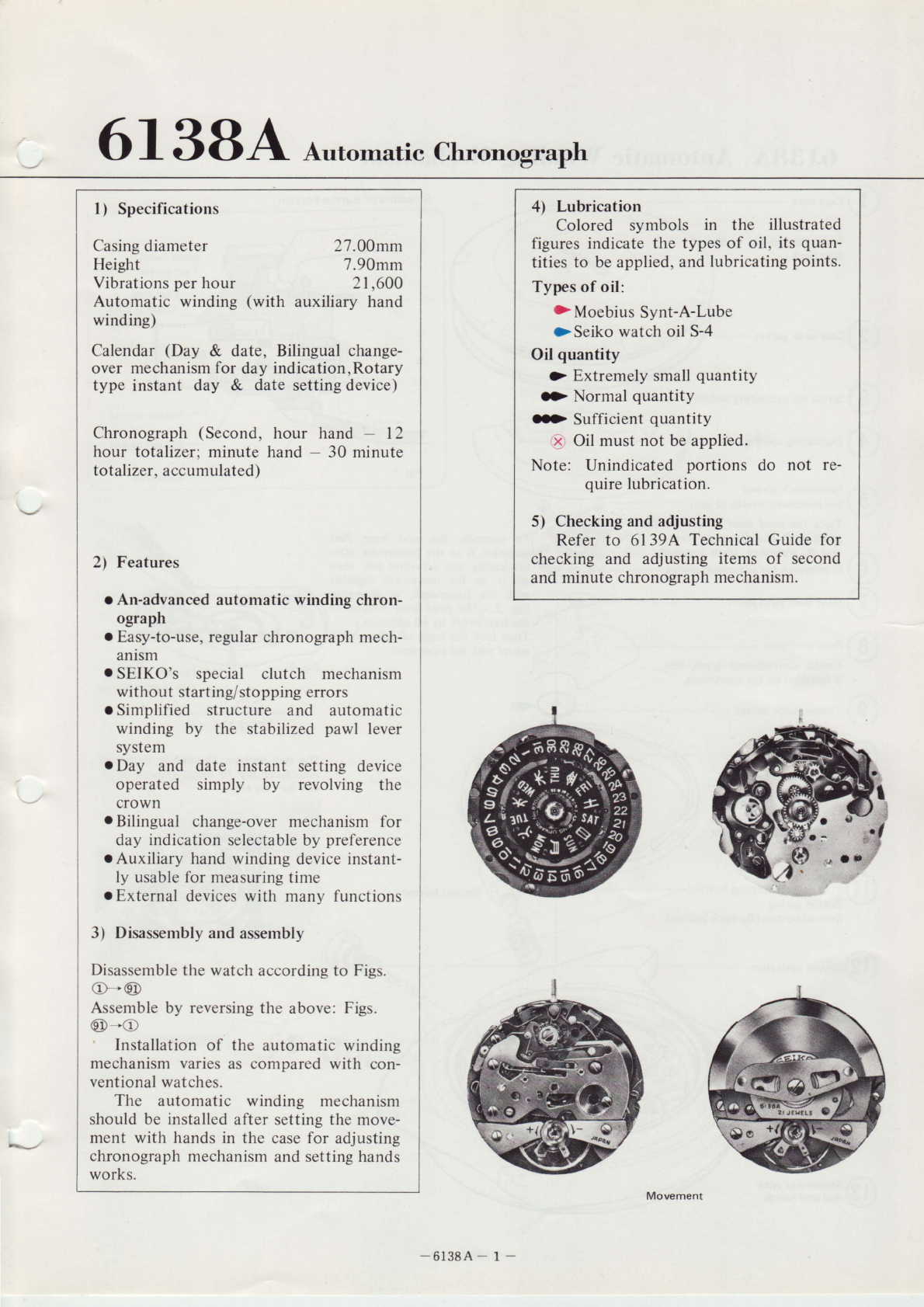

I.Items to be checked before assemblingthe iewelled

pallet fork and staff, after setting the chronograph

bridge.

l) Confirm that free running force is transmitted

unaffectedly. Even though no roll back motion

exists, as long as it functions smoothly there is no

problem. And at the same time check the perform-

ance of starting and stopping actions of the hour

recording wheel by turning over the movement.

2) Check for meshing condition of the first and

secondcoupling /euers

(Refer to 5139A-8).

3) Check clearance between the second coupling lever

and the intermediate hour recording wheel stop

lever pin and their actions.

When stopping, clearance must exist between the

second coupling lever and the intermediate hour

recording wheel stop lever pin; when starting, the

second coupling lever must push and move the

intermediate hour recording wheel stop lever pin.

む

{lntermediate

minute recordin9

wheel}

1. Mesh the intermeditte minute recording

wheel and the minute recording wheel.

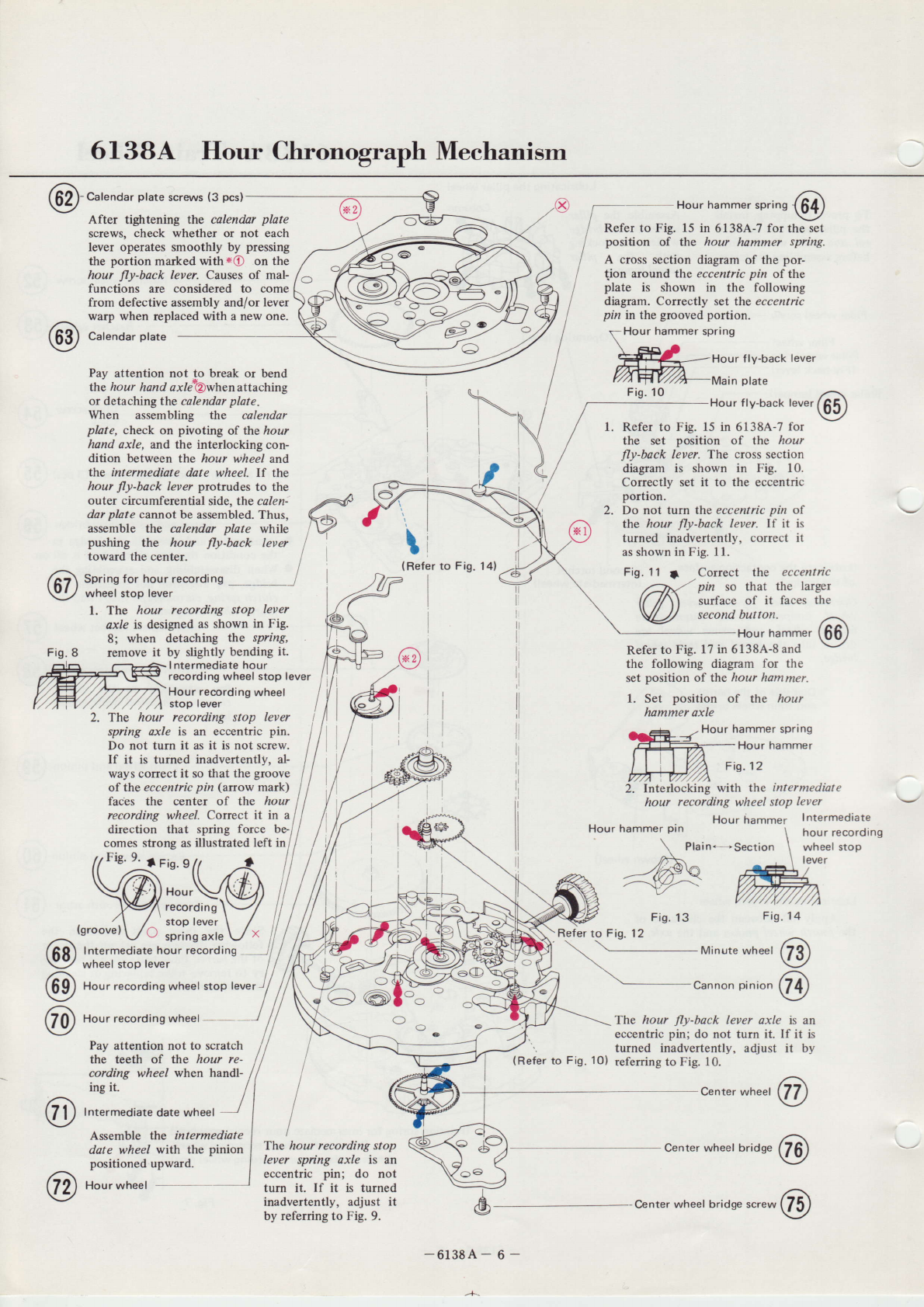

Refer to Fig. l0 for assembling this

spring

(6138A-7)

Refer to Fな

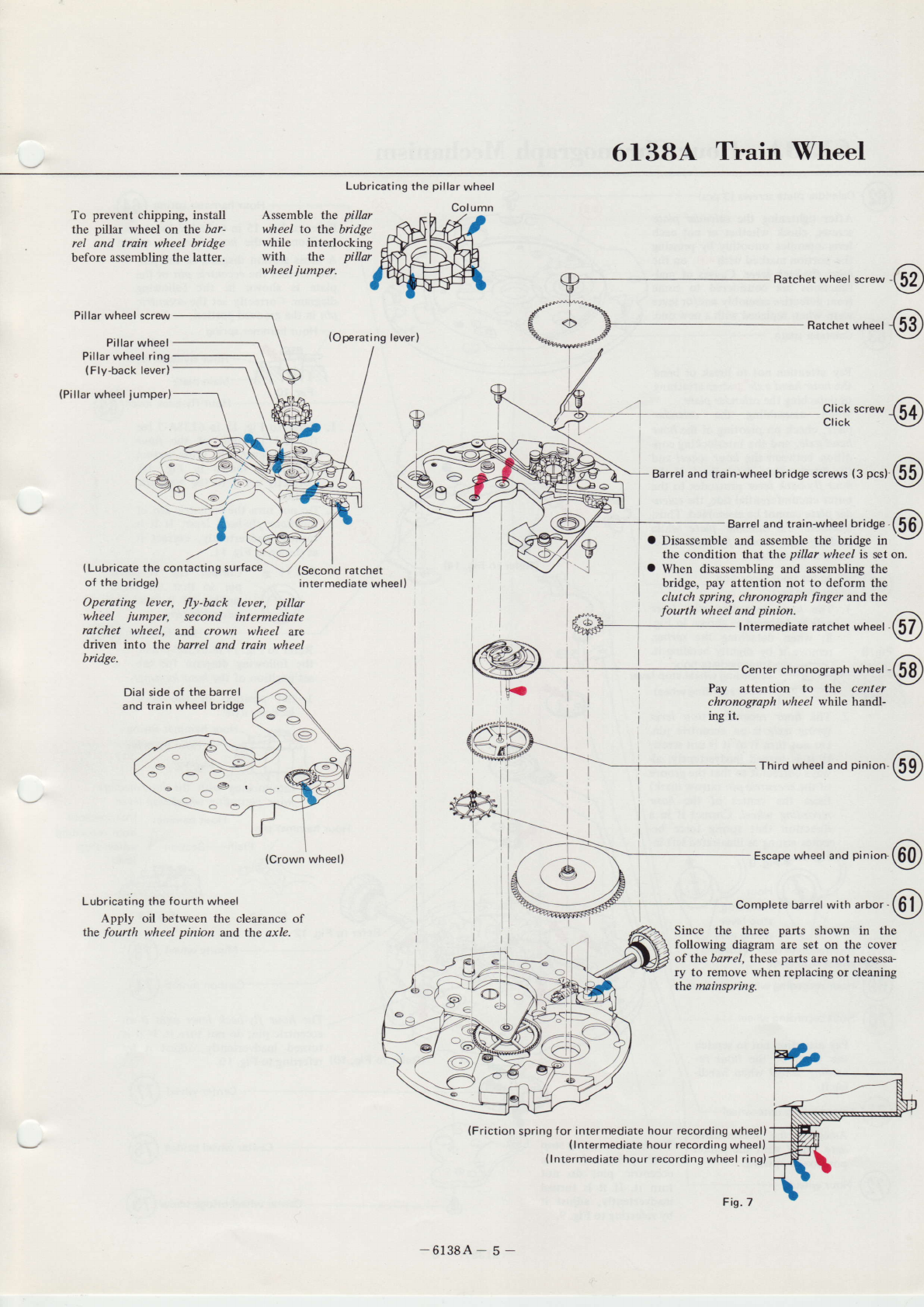

.7 foF aSSembling this

spring(6139A‑5)

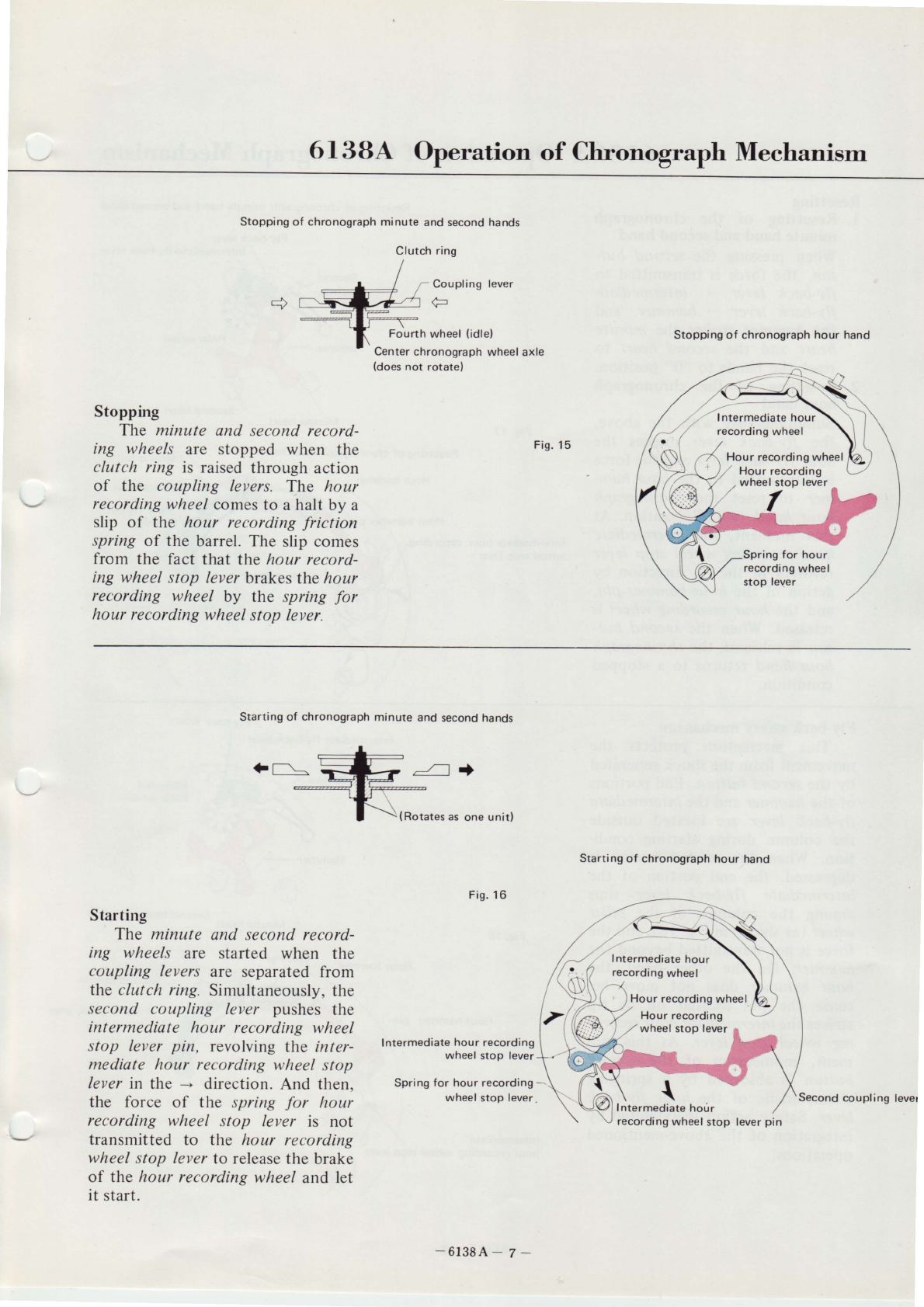

Stop Start

嗅 χ

二

斐

ζ

iI:‖

∬:l11:"r

缶

recordi ng

wheel stop lever

Fis.4

Should they malfunction, adjust

them by tuming the secondcoupl-

ing lever axle eccentricpin. In this

case,

perform this adjustment

while

observing

the delicateclearance

be-

tween thesecondcoupling

leverand

the clutchlever.

2. Itemsto bechecked

after

assemblingthebalance

l) Checkfor strength

andheight

of the minute recording

iumper (Refer to 6139A-8).

2) Check for meshing position

of the chronograph finger

(Refer

to 6139A.-9).

3) Check for contacting condi-

tion of the hammer and

hearts

(Refer to 61394-10).

Balancecock screws

(2 pcsl

Balance

cock

Balancecomplete with stud

Palletcock screws

(2 pcs)

Palletcock

Jewelled

pallet

fork and staff

\ - Firstcouplingleverscrew

\-- First

couplinglever

Holdlnぃ¨w for co¨eVers①

①①

\

\\

①①①①①①

`

│、

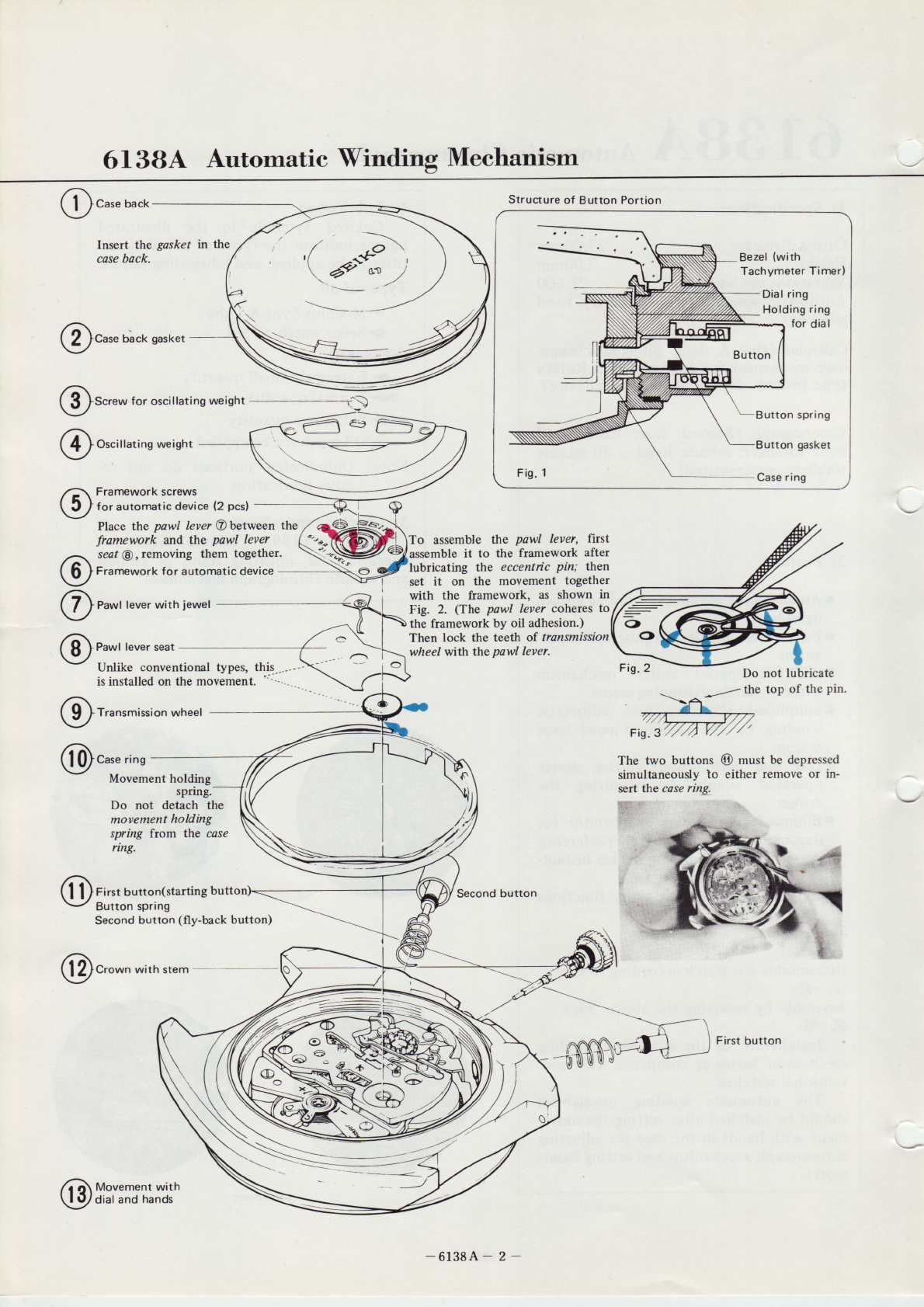

Trainwheel

(process

of forcetransmission)

Transmissionof forcewhenchronogtaphmechanismisstarted.

Transmissionofforce whenchrenographmechanismisstopped.

Whentheminute andsecondchronographs

arestarted,theforceistransmitted

to both chronograph

and

train wheelby theactionofthe clutch,andwhenthe

chronographs

are stopped,the force is transmitted only to the train wheel.

Whenthe hour chronographis started,

theforceistransmittedfrcm thebarrel

+ friction sping for intermediatehour recordingwheel+intermediate hour

recording wheel - hour recording wheel. When the hour chronographis Hour

stopped,force transmission

to thehour recordingwheelis stoppedby aslipof

thefriction springfor intermediate hour recording wheel.

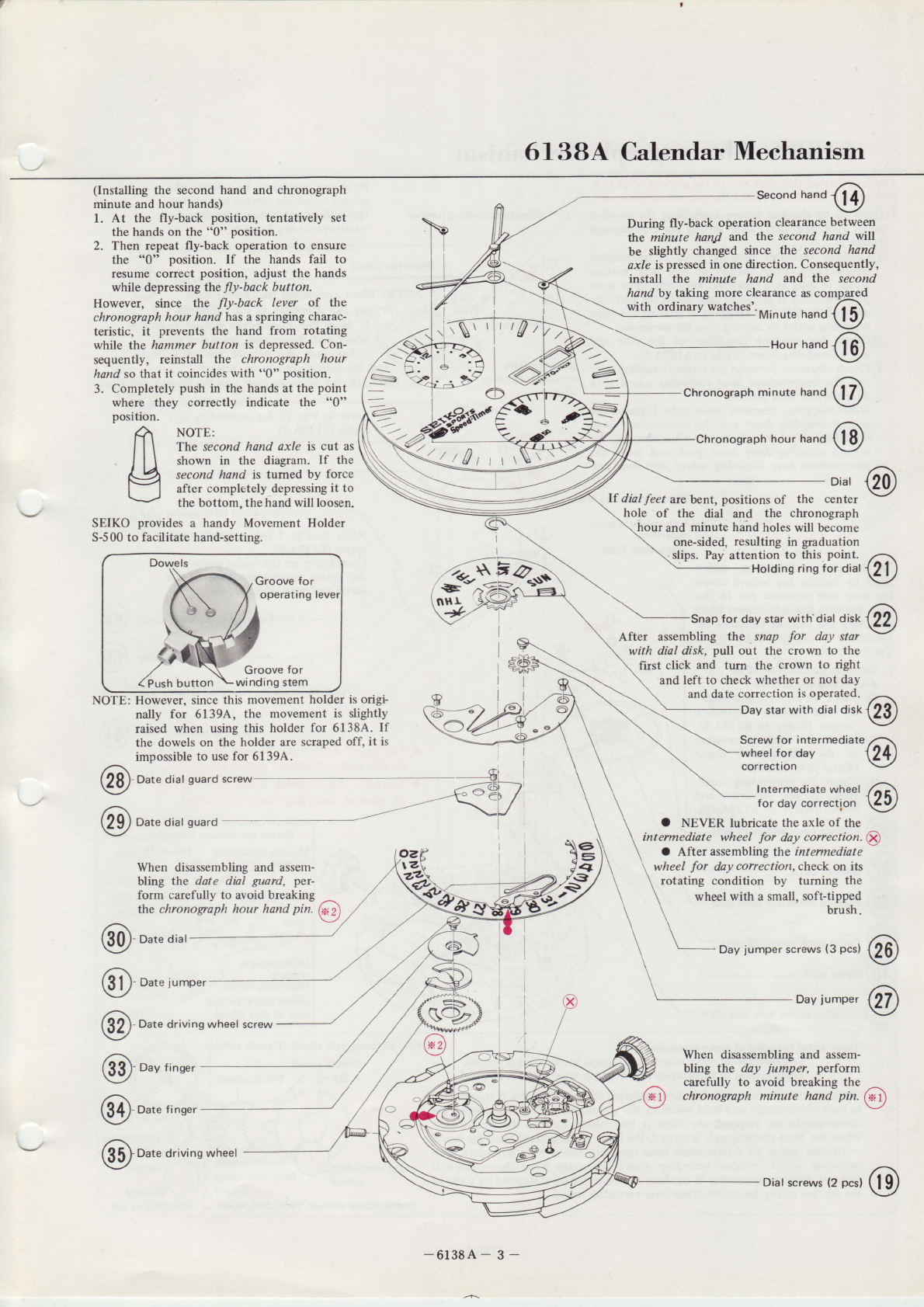

It is not necessiuy to remove the

minute recording jumper and,

screws.

g Minute recordingjumper Move them only when adjusting the

\ minute recording iumper.

\ Chronograph bridge screws

(3 pcsl

(Hammer

click) Chronographbridge

NOTE: When assembling the chronogroph

bridge, pay attention to the following.

@④

9

∠『

謂:驚

九賜鰐

耀

Ъ

胤ノ

昭

″力θα

忠躙

静無

①

Hammer ④

―

―

一

―Mttte rec∝

d…J④

―∞

¨mgleverttmgO

Completelysetthe centerportion of

the spring around the tube of the

- barreland train wheelbridge.

\__ A

Second coupting tever (5 l,

O 1hc pinof tlte st'tz-rlld tottltlittg /t'l r/ ir ttttttlrlriv

do rrot rotate it e\ccp1 dtrring rditrstrrtcttt.

e Asserrtblr- lh( (t)uplitlX 1t'tr'r'r iri r \trftitig ri'ntlilt,,r

to prcvert danraging Lltc lrttrrllt vlttli

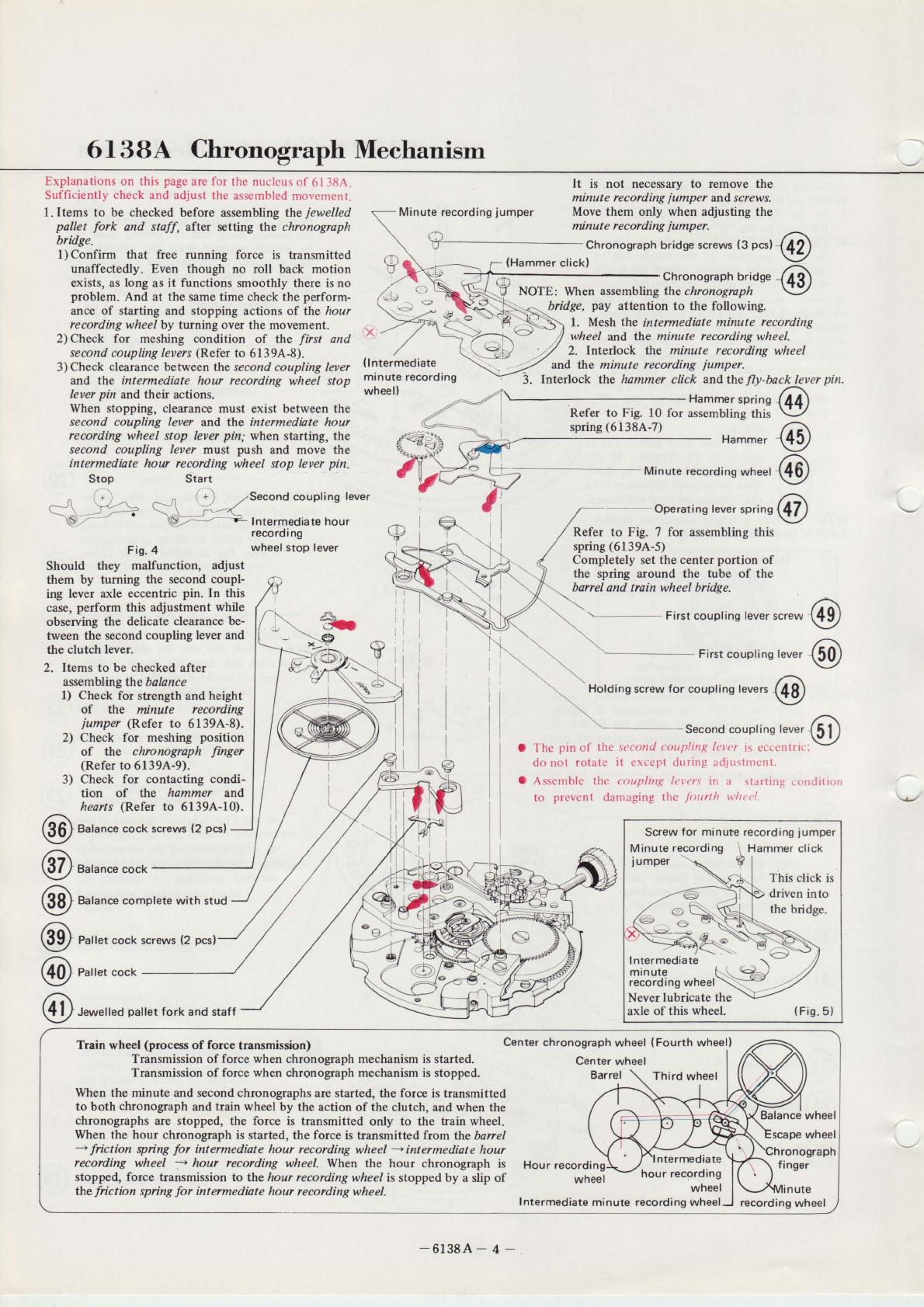

Centerchronograph

wheel {Fourth wheel)

Center

wheel

Barrel Third wheel

scapewheel

hour recording

wheel

finger

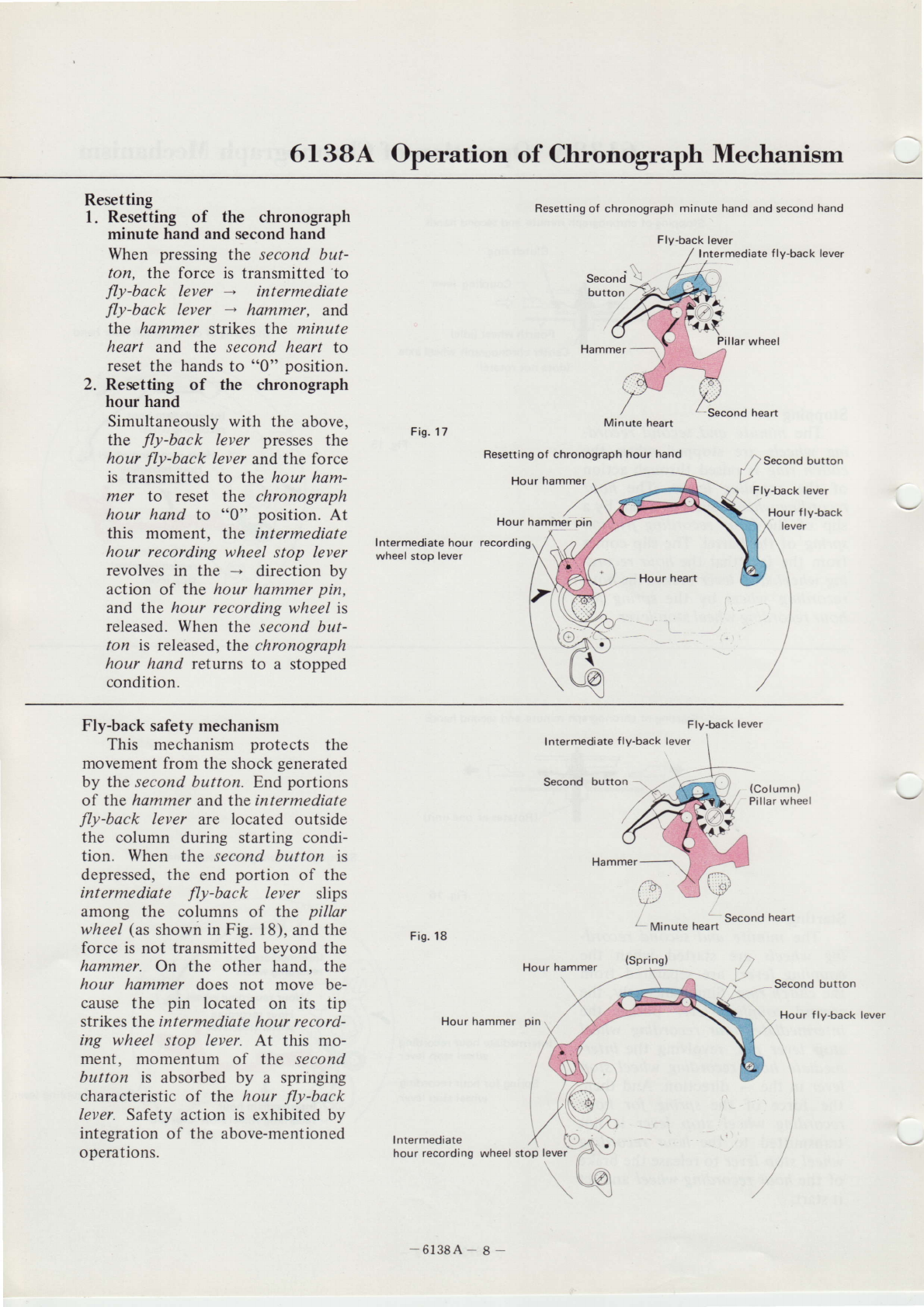

3. Interlock the hammer click andthefly-back leverpin.

Screw

for minuterecording

jumper

Wttrマ

hg

ξTamm∝

引ょ

This click is

dr

en into

1郵

罵

Tiedヾ

L

Neverlubricatethe v

axle

of thiswheel. (Fig.

5)

‑6138A‑4‑

Intermediate

minute recordingwheel recordingwheel