Seiko 4R35B Quick start guide

Other Seiko Watch manuals

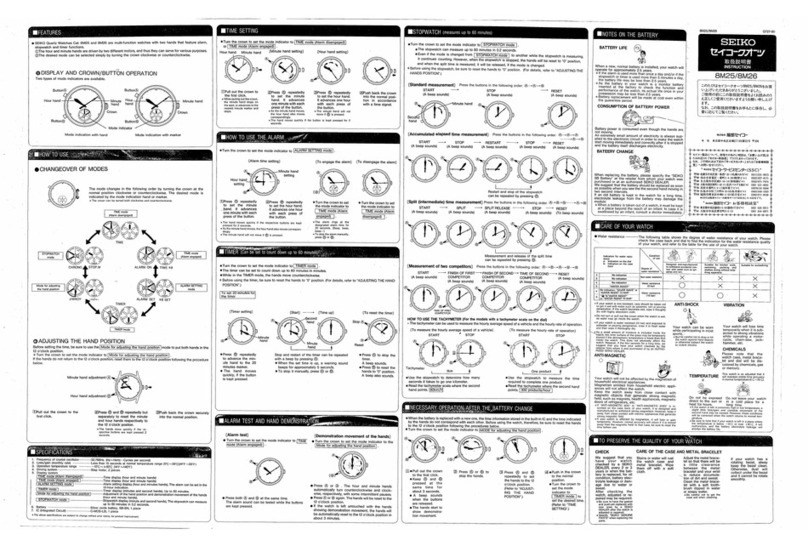

Seiko

Seiko Prospex SNR035 User manual

Seiko

Seiko 6A32 Installer manual

Seiko

Seiko Map Meter Instruction and safety manual

Seiko

Seiko 4205B Quick start guide

Seiko

Seiko 8M25 User manual

Seiko

Seiko S064 User manual

Seiko

Seiko S101A Quick start guide

Seiko

Seiko Cal. 7T12 User manual

Seiko

Seiko 6M25 User manual

Seiko

Seiko Spectrum SVRD001 G510 User manual

Seiko

Seiko 5R86 User manual

Seiko

Seiko Conceptual SUR377P User manual

Seiko

Seiko Presage SPB397J User manual

Seiko

Seiko SPC244P1 User manual

Seiko

Seiko Astron 7X52 Installation guide

Seiko

Seiko ANALOGUE QUARTZ SOLAR V145 User manual

Seiko

Seiko 4F32 User manual

Seiko

Seiko Presage SSA439J User manual

Seiko

Seiko KINETIC 9T82 User manual

Seiko

Seiko 1B25 User manual