Seiko 6N76A Quick start guide

Other Seiko Watch manuals

Seiko

Seiko W620 User manual

Seiko

Seiko GRAND SEIKO User manual

Seiko

Seiko V14J User manual

Seiko

Seiko G300 User manual

Seiko

Seiko 8R46 User manual

Seiko

Seiko Prospex 7K32 User manual

Seiko

Seiko 8T67 User manual

Seiko

Seiko Conceptual SUR380P User manual

Seiko

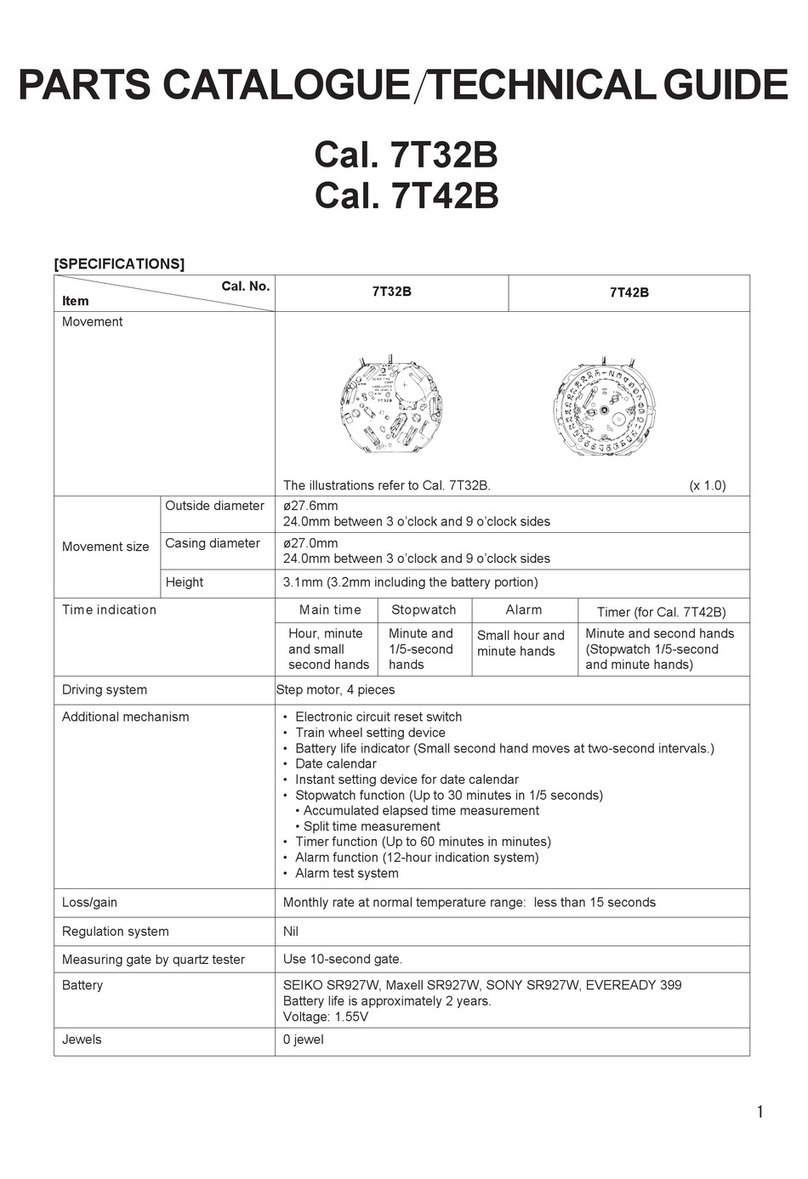

Seiko 7T32B Quick start guide

Seiko

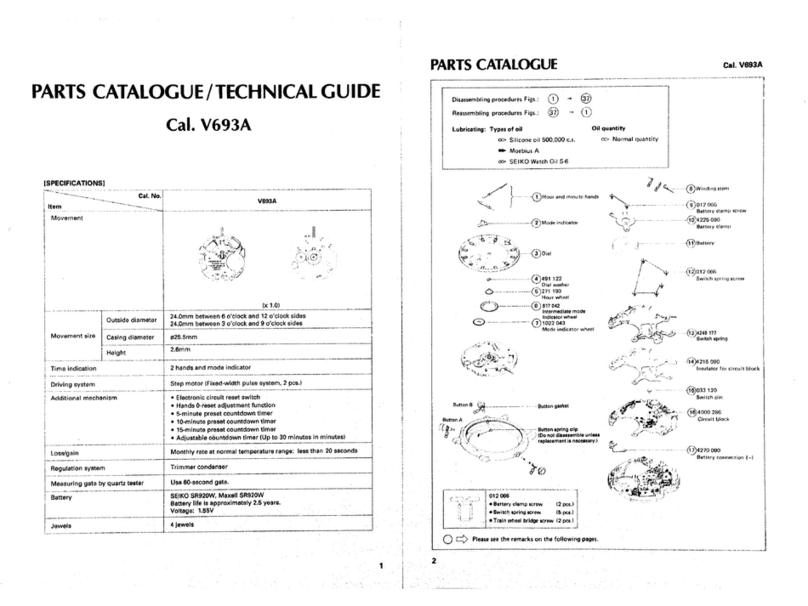

Seiko V693A Installer manual

Seiko

Seiko ASTRON User manual

Seiko

Seiko SKY671P1 User manual

Seiko

Seiko G757(GZC) User manual

Seiko

Seiko 6A32 User manual

Seiko

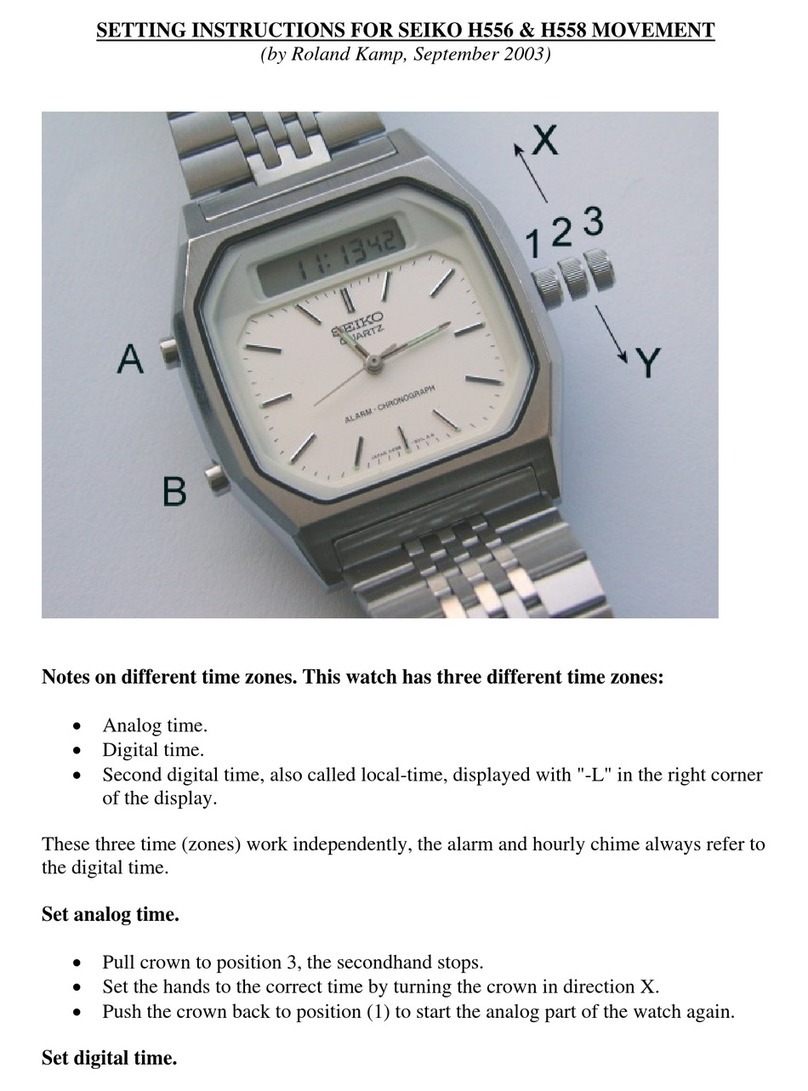

Seiko H558 User manual

Seiko

Seiko SRG019P2 User manual

Seiko

Seiko 8F35 User manual

Seiko

Seiko VELATURA 7T62 User manual

Seiko

Seiko S101A Quick start guide

Seiko

Seiko Conceptual SSB421P User manual